The science of food

OPPORTUNISM IN THE FOOD INDUSTRY—ENHANCING

» The science of food and beverage VOLUME 38 • ISSUE 1 • 2023

GLOBAL SOURCING PRACTICES

PUBLISHER & CEO Christopher J. Forbes cforbes@dvtail.com

MANAGING EDITOR Sean Tarry starry@dvtail.com

COPY EDITOR Mitchell Brown

CONTRIBUTORS

Juan Marcelo Gómez

John G. Keogh

Xiaonan Lu

Jana Manolakos

Jennifer Ronholm

SENIOR ACCOUNT Leesa Nacht EXECUTIVE lnacht@dvtail.com

ART DIRECTOR Sharon MacIntosh smacintosh@dvtail.com

SECRETARY/ Susan A. Browne TREASURER

MARKETING Stephanie Wilson MANAGER swilson@dvtail.com

PRODUCTION Crystal Himes MANAGER chimes@dvtail.com

CANADIAN FOOD BUSINESS ADVISORY COMMITTEE

Marcia English, Associate Professor, St. Francis Xavier University

Michael Nickerson, Saskatchewan Research Chair and Professor, University of Saskatchewan

Hosahalli Ramaswamy, Professor, McGill University

Amanda Wright, Association Professor, University of Guelph

Canadian Food and Business is published 4 times per year by Jesmar Communications Inc.,

205 Riviera Drive, Unit 1 Markham, Ontario L3R 5J6

905.886.5040 Fax: 905.886.6615

www.canadianfoodbusiness.com One year subscription:

Canada $35, US $35 and foreign $95. Single copies $9. Please add GST/HST where applicable. BioLab Business subscription and circulation enquiries: Garth Atkinson, biondj16@publicationpartners.com Fax: 905.509.0735

Subscriptions to business address only. On occasion, our list is made available to organizations whose products or services may be of interest to you. If you’d rather not receive information, write to us at the address above or call 905.509.3511.

The contents of this publication may not be reproduced either in part or in whole without the written consent of the publisher. GST Registration #R124380270.

PUBLICATIONS MAIL AGREEMENT NO. 40063567

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT.

205 RIVIERA DRIVE, UNIT 1 MARKHAM, ON L3R 5J6 email: biond@publicationpartners.com

BioLab Business, a sister publication of Canadian Food Business, is a proud member of BioteCanada and Life Sciences Ontario.

Publisher of BioLab Business Magazine

Printed in Canada

SCIENCE HELPING TO ENSURE SAFER FOODS

When it comes to protecting the health and wellbeing of a population, few considerations can be more important than ensuring the safety of the food that people are eating. As a result, those operating within the food industry, from manufacturers and processors to foodservice providers, are under constant scrutiny as it relates to their levels of cleanliness and the safety of their products.

With this in mind, within the Spring issue of Canadian Food Business magazine, we focus our attention on the science behind food safety and some of the innovations being developed in order to support the efforts of those operating within the industry.

It’s no secret that any misrepresentation of food that’s found out by consumers will likely result in quite a bit of negative public response and backlash. In spite of this, opportunism along the supply chain remains a prevalent concern for many. We take a look at ways in which misrepresentation can impact businesses and consumers, and the need for tighter global supply chain practices to eradicate the problem.

As part of the scope of food safety, the cleanliness of restaurants and quick serve establishments are also of critical importance. And, at the core of restaurant cleanliness and food safety is handwashing—a significantly uncontrolled practice within any establishment. We feature CleanBands and its Founder and CEO, Dave Iwonkow, who’s developed a smart wearable device supported by digital sensor technology meant to aid in the assurance of handwashing compliance.

And, what could be more important to meat processors and their customers than understanding exactly what’s in the product that they’re providing. As such, we highlight P&P Optica—a developer and provider of proven automated solutions for meat processing plant inspections—and the ways in which its Smart Imaging System is helping to more accurately identify foreign objects in meat while also understanding its chemical composition in-stream, aiding meat processors’ efforts to ensure consistent safety and quality for their customers.

In an age that’s being defined for many industries, at least in part, by general instability and uncertainty, food purveyors and their partners are putting forth an incredible amount of effort to ensure that the food Canadians eat is safe. And, given continued advancements in science and technology, the support that the industry needs to satisfy these assurances is becoming increasingly available, laying the foundation for greater food safety and quality in the country.

In 2022,

Science

For further information, contact sbrowne@dvtail.com

Sean Tarry EDITOR

Technology

Food Business magazine

the Canadian Institute of Food

&

(CIFST) and Canadian

launched a partnership to create a platform for leading experts, innovators and scientists to showcase the latest trends, knowledge and developments that are changing the face of Canada’s food industry today.

EDITOR'S NOTE CANADIAN FOOD BUSINESS VOLUME 38, ISSUE 1 • 2023 2

11 inside standard GUEST EDITORIAL 4 NEWS BITES 6 FOODWARE 17 MOMENTS IN TIME 19 feature FEATURES 8 OPPORTUNISM IN THE FOOD INDUSTRY— CAN WE LEARN FROM WALMART’S GLOBAL SOURCING PRACTICES? THE GREEN LIGHT Atlantic Canada-based company leveraging technology to help enhance food safety WHAT’S IN 14 YOUR MEAT? State-of-the-art automated solution helping meat processing plants more accurately inspect for safety and quality CANADIANFOODBUSINESS.COM 3

Next generation of food safety

By Jennifer Ronholm and Xiaonan Lu, Department of Food Science and Agricultural Chemistry, McGill University

Ashuman beings, we each require daily nourishment. However, food consumption has never—and can never —be completely risk-free. In Canada, Health Canada is responsible for establishing thresholds of acceptable risk that correlates to a desired level of consumer protection. Since scientific knowledge is constantly evolving and novel foods are continually introduced to the marketplace, existing thresholds must be regularly adjusted. The Canadian Food Inspection Agency is responsible for enforcing safety thresholds established by Health Canada. Together these institutions run programs to improve food safety, such as guiding industry in applying hazard and critical control point (HACCP) principals to prevent food borne illnesses and improving food traceability so that sources of infection can be determined quickly and accurately.

New era of food safety—smart food safety

The new era of smarter food safety blueprint was developed by the US FDA a few years ago and it is centered around four core elements, namely tech-enabled traceability, smarter tools and approaches for prevention and outbreak response, new business models and retail modernization, and food safety culture. Working together, these elements will aid in creating a safer and more digital, traceable food system. This new generation of food safety embraces advanced technology, big data, digital tools, and automation that can facilitate

rapid, accurate, sensitive monitoring of the food supply chain in a user-friendly manner. The ideal smart food traceability system can track the location of any food, the ingredients it contains, and packaging at any location in the supply chain from producers to consumers. There will be a database about the product in the traceability system. If food recalls are required, a traceability system will aid in quickly identifying the source of contamination, enabling parties to take effective recall actions to protect consumers from the contaminated food.

Introduction of whole genome sequencing and next generation sequencing for food safety

In Canada, the decision to recall food items is science-based and made using three equally weighted streams of evidence: 1) Epidemiology, 2) Microbiology, and 3) Food Safety Investigation. Within the microbiology stream of evidence, the phylogenetic relatedness of all food and clinical isolates within the investigation must be established. This information is used to understand the likely food-hazard combination that is responsible for the outbreak. Whole genome sequencing, paired with bioinformatic analysis and interpretation, has now been established as the gold standard with which to establish the phylogenetic relationship between isolates. Starting from an isolated colony, a genomic sequence can be

4 GUEST EDITORIAL BIOLAB BUSINESS VOLUME 38, ISSUE 1 • 2023

produced in two to three days. Older technologies allowed phylogenetic relationships to be established based on tens of datapoints, at most, and this resulted in problems with both over- and under-discrimination. However, whole genome sequencing allows the comparison of thousands of core-gene sequences in a few hours—allowing a certainty in phylogeny that was never before possible.

Introduction of novel sensing techniques for food safety

Sensors have been massively developed for rapid diagnostics of food chemical and microbiological hazards. A specific sensor ideally includes a separation element and a detection element. The separation element allows recognition and separation of the target compounds/microbes from the complicated food sample matrices. Then, the detection element achieves sensitive and rapid detection via generating a signal as readout. Separation element is more critical than detection element as the interference from food sample matrices is highly challenging. Compared to the classical biomedical sample matrices (blood, urine, sputum, body fluids), food sample matrices are more complicated, especially solid foods such as meat and fresh produce. The effective separate elements for construction of a sensor include, but are not limited to, antibody, aptamer, and molecularly imprinted polymers.

IoT, cloud computing and artificial intelligence for food safety

With the advancement of the Internet-of-Things (IoT), more data on food can be transmitted and processed in real-time. IoT allows things and objectives to be connected anytime and anywhere. It is growing rapidly and will become popular in food safety. To effectively use these data, machine learning is highly demanded. On the other aspect, cloud computing enables users to perform complex computation without the expense of maintaining costly hardware and software. It helps store, share, manage, and analyze the data from food sensors and identifiers, which are accumulated along with the movement of food in the supply chains. Particularly, the fifth-generation (5G) network as a new generation technology has more bandwidth, enables real-time data transfer with

FSMA and HACCP for the food industry

HACCP has been widely accepted and applied by the Canadian food industry. It has been effectively functional in responding to various chemical and microbiological contaminants in the agri-food commodities. The Food Safety Modernization Act (FSMA) is still relatively new to Canadian food producers as it has been transforming the food safety system by shifting the focus from responding to foodborne illness (HACCP) to preventing it. FSMA is enacted in response to significant changes in the global agrifood system and in our understanding of foodborne illnesses and their consequences to our consumers. For example, we now realize that preventable foodborne illnesses are a critical public health issue and also a threat to the economics of the agri-food system.

Improving food safety

While consuming food will never be risk-free, modern safety management practices like HACCP, paired with new technologies like IoT, food traceability, and whole genome sequencing are being used to improve risk management and improve the safety of the food supply. It is important to remember that risk analysis and risk mitigation are science-based processes, any approach to managing the food supply chain will also involve other concepts such as culture, values, and consumer preferences. Technologies can be developed and deployed to improve food safety without having to limit food choices to manage safety.

BIOLABMAG.COM 5 GUEST EDITORIAL

low latency, and supplies gigabit connections without location restrictions.

Jennifer Ronholm and Xiaonan Lu

Maple Innovation Challenge winner announced

They can, at times, find themselves in a bit of a sticky situation, but the team of 14 jurors charged with judging the Maple Innovation Challenge recently named a winner.

After some tasty sampling, on Monday, February 6, the competition’s grand prize was awarded to Yuchen Bai and Arianna Sultani of Team ‘Novaland’ University of Guelph with their maple innovation of chickpea pancake mix.

A competition created for food science and culinary arts students across Canada; through a collaboration between QMSP, The Maple Treat Corporation and the Canadian Institute of Food Science and Technology, winners receive $1,500 cash courtesy of the Maple Treat Corporation and a one-hour consultation with a Canadian Food Innovation Network (CFIN) Regional Innovation Director.

For more information about the Maple Innovation Challenge, visit https:// mapleinnovationchallenge.ca/

Brand refresh for agriculture and agri-food products

The Government of Canada recently announced the launch of a Canada Brand refresh for agriculture and agri-food products in international markets.

Unveiled by The Honourable Marie-Claude Bibeau, Canada’s Minister of Agriculture and AgriFood, the refresh represents a modernization of the Canada Brand program, in addition to a new digital toolkit meant to help Canadian agriculture and agri-food businesses showcase their products in global markets.

Launched in 2006 by Agriculture and Agri-Food Canada, the Canada Brand refresh includes a new logo, modernized graphics and branded taglines, refreshed marketing messaging; a revitalized photo library; a revamped client portal system; and, a revamped marketing toolbox with video content, animated graphics, GIFs and digital stickers. It’s all part of what Bibeau considers a significant support for Canadian producers, placing them in good stead for the future.

“Canadian agriculture and agrifood products enjoy an excellent reputation internationally, and this updated brand will be a powerful tool for our Canadian agriculture and agrifood exporters in highly competitive markets. They are a powerful driver of our economy, and we will continue to help them unlock new markets and opportunities.”

NEWS BITES

CANADIAN FOOD BUSINESS VOLUME 38, ISSUE 1 • 2023 6

Team 'Novaland': Arriana Sultani and Yuchen Bai.

What that dog doin’?

The Rogers Centre, home of the Toronto Blue Jays, just received an upgrade for the upcoming baseball season in the way of a new porch called ‘hot dog headquarters’ courtesy of iconic Maple Leaf Foods Inc. brand Schneiders.

In conjunction with the launch of ‘hot dog headquarters’, which will be located

Preventing food fraud

The Government of Canada continues to intensify its commitment toward eliminating the sale of misrepresented

on the stadium’s 200 level, overlooking right field, Schneiders will also make its limited time footlong hot dogs available at stores across Canada.

The porch, which can accommodate up to 150 people, welcomes fans to visit and try the delicious hot dog menu selections only available for concession at

section 209.

“We’re excited to partner once again with the Toronto Blue Jays,” said Casey Richards, President and Chief Growth Officer, Maple Leaf Foods. “The Schneiders Porch is designed true to the brand’s authentic recipes, high craftsmanship standards, and irresistible taste.”

food in the country. And, it was recently revealed within the Canadian Food Inspection Agency’s (CFIA) Food Fraud Annual Report that the federal government successfully prevented 100,000 kg. of fraudulent food from being sold last year.

This year’s report includes results from the testing of 844 samples, identifying 6 categories of foods that are most commonly misrepresented. Testing showed an overall compliance rate of 92.7 per cent for fish, 77.5 per cent for honey, 99.1 per cent for meat, 86.9 per cent for olive oil, 64.3 per cent for other expensive oils, and 90.8 per cent for spices.

The Honourable Jean-Yves Duclos, Minister of Health, applauds the CFIA’s efforts in combatting food fraud, and in protecting Canadian businesses and their consumers.

“Our government takes food fraud seriously,” he says. “When food is misrepresented, it prevents consumers from making an informed choice, and can create an uneven, unfair market. This report highlights the excellent work being done to protect consumers and food businesses from this deceptive practice.”

Kid-approved breakfast and snack food

Nola Baking Co. recently announced the launch of its simple, healthy and delicious kid-approved breakfast and snack foods.

The launch, in partnership with Sesame Street, is aimed at making fueling kids with healthy foods fun and delicious, and includes Nola’s Powers Pancakes and Boost Bars, available in delicious flavours and fun Sesame Street packaging featuring iconic characters like Elmo, Cookie Monster and Big Bird.

Developed in collaboration with nutritionists and food scientists, Nola’s Power Pancakes and Boost Bars are packed full of nutrients to keep kids growing strong, while being gluten-free, vegan and free of refined sugars and artificial preservatives.

NEWS BITES

CANADIANFOODBUSINESS.COM 7

Hot dog headquarters at The Rogers Centre in Toronto

Opportunism in the food industry— can we learn from Walmart’s global sourcing practices?

By Juan Marcelo Gómez and John G. Keogh

By Juan Marcelo Gómez and John G. Keogh

FEATURE

CANADIAN FOOD BUSINESS VOLUME 38, ISSUE 1 • 2023 8

In a post-pandemic world, global food ecosystems exposed numerous supply chain risks that arise from the complexities in the governance of global sourcing. Many businesses have increased their global sourcing reach to satisfy diverse and growing consumer demands. Economic benefits may be more significant for companies that can fulfil demand based on good governance practices combined with supply chain due diligence and logistical agility. But there are both a food safety and reputational risk involved as supplier opportunism

is intricately linked to various types of frauds, deception, and ethical and moral lapses. Opportunism is defined as self-interest seeking with guile or pursuing self-interest benefits, such as shirking responsibility for food safety, cheating or withholding information from the buyer.

In Walmart’s 2020 annual report, many global sourcing issues are considered operational risks. Walmart notes, “We expect our suppliers to comply with applicable laws, including labour, safety, anti-corruption and environmental laws, and to otherwise meet our required supplier standards of conduct.”

Post-contractual (ex-post) issues relate primarily to hidden actions or behaviours of the supplier that lead to moral hazard. As opposed to (ex-ante) or pre-contractual issues, which relate to instances of hidden information or distorted information exchange that can lead to a situation called adverse selection. In the latter, the falsehoods are discovered ex-post. Many risks in global sourcing can be related directly to the unobservability of the actions and behaviours of suppliers. These risks are consistent with the operational risk statements mentioned in Walmart’s annual report. To reduce these risks, mechanisms that improve transparency and trust in global food ecosystems must be prioritized.

Adverse Selection

Supplier management and onboarding could be considered a relatively mature academic research and industry practice area. However, supply chain risk management lacks consensus in the literature. The risk of adverse selection is created when a potential new supplier purposefully hides or provides false information before signing the supplier contract. For example, a new overseas supplier may deliberately withhold information about their company operations from the buyer or purposefully share fraudulent, incomplete, or inaccurate information. This may include false claims of resource competence, including the firm’s technical knowhow, the provision of fake or lapsed certifications such as fake food safety laboratory test results, or false claims of organic, kosher or halal. New suppliers may have improperly implemented food safety management protocols which could result in frequent product safety recalls. They may have insufficient or outdated machinery and tooling, undeclared subcontracting, precarious financial situations, or a bad credit rating—these are just some of the potential problems.

Moral hazard

For businesses, post-contractual opportunism creates a moral hazard. When such ex-post opportunism occurs, the supplier’s and the buyer’s interests diverge for various reasons. This could include situations where the supplier feels mistreated and perceives a substantial power imbalance with the buyer. As a result, suppliers may act in their self-interest and knowingly deceive buyers by supplying low-quality products or unsafe ingredients, blending non-organic and organic products, and sourcing from unapproved upstream suppliers and or shirking their moral and ecological obligations such

FEATURE

CANADIANFOODBUSINESS.COM 9

as engaging in deforestation causing habitat loss, or engaging in forced labour or child labour. They may be involved in animal abuse or various forms of corruption or bribery of public officials to maximize their profits. Opportunism can be interpreted as food fraud or economically motivated adulteration when there is a deliberate misrepresentation, dilution or substitution of a food ingredient or product against the agreed expectations of another party.

The globalization of food chains has created a lucrative food fraud opportunity. While it is challenging to estimate the global burden of food fraud, the Canadian Food Inspection Agency (CFIA) website indicates that up to ten per cent of food traded could be subject to various types of fraud. In 2019, the CFIA blocked over twelve tonnes of adulterated honey from entering the Canadian market. Food fraud is alive and well, and Canadian taxpayers are investing over $5 million a year to enhance market surveillance activities.

We theorize that during the COVID-19 pandemic, many businesses in the food industry experienced supply interruptions and massive product and economic losses, while recent increases in inflation across global markets have provided fertile ground for opportunism. The fact that opportunistic behaviour in the food industry appears to be a lucrative business has increased the attention of organized crime regimes to use the food chain as a space to be explored and exploited. Collaboration between governments, enforcement agencies, businesses and researchers are essential as innocent consumers are increasingly exposed to human health and safety risks. This creates challenges for regulatory controls that, while they aim to achieve compliance and enforcement, are reactive at best. In a recent publication on food fraud in Canada by the Arrell Food Institute at the University of Guelph, it was noted: “A 2019 survey of Canadian food business operators highlighted that 56 per cent of respondents were confident they could address food fraud vulnerabilities, but only 33 per cent indicated their business was safe from food fraud.”

The time is ripe for business leaders to step up their efforts in gaining better insights into risks while improving governance practices across global food trade sourcing practices. The focus should be on supply chain due diligence, good governance and reducing the risk of supplier opportunism by implementing proactive supplier controls, which could include unannounced audits. Reducing the risks to the health and safety of consumers must be a priority alongside enhancing transparency and trust across all global sourcing processes.

Could we learn from Walmart’s global supply chain governance practices?

While problems in the global food chain are abundant, good examples of trade governance, such as those outlined by Walmart in its annual report, may assist other business leaders in modelling policies and controls that are adequate in practice and uphold higher trading standards for the benefit of consumers. In doing so, Walmart has continuously stepped up its efforts to address critical areas of vulnerability, which

have increased transparency across stakeholders, as we have previously argued.

Walmart has instituted a global policy which enables a system of controls managed by its anti-corruption compliance programme. The system aims to prohibit anti-regulatory business practices by adopting an in-source and integrated ethics and compliance organization, including anti-corruption, training and communication, licenses and permits, management of third-party risks, and data analytics.

Walmart’s ethics and compliance organization comprises a global to local market team that routinely conducts cross-disciplinary and geographical assessments across the business, including a community of subject matter experts to share best practices. Anti-Corruption compliance focuses on third-party providers by assessing unaddressed risks and aligning organizational process assets, while anti-corruption training is provided internally and externally to third-party providers available in many languages. In addition, third parties, or intermediaries, are required to adopt anti-corruption practices and undergo routine site and financial audits across international markets. From a monitoring perspective, Walmart has implemented a centralized system to comply with licenses and permits at global and local levels. This has increased risk reduction through the implementation of safeguards and improved workflow. Analytical systems use collected data at different transactional and functional levels while incorporating business intelligence approaches such as screening external public data to manage unassessed risks, including litigation and sanctions, proactively. The integration of ethics and compliance has enabled Walmart to create a process that is guided by transparency across the organization to proactively identify and mitigate risks while at the same time engage a learning organization through continuous improvement.

In conclusion, in its 2022 annual report, Walmart understands that there isn’t room for opportunism in its increasingly globalized business and that misrepresentation to its customers can have significant adverse and cascading effects on the brand, its reputation and ultimately, its financial performance.

About the Authors:

Juan Marcelo Gómez is a trusted advisor in the private and public sectors. He is an assistant professor at Toronto Metropolitan University for The Ted Rogers School of Management in Retail Management. He specializes in supply chain and procurement and risk and regulation of complex trade systems.

John G. Keogh is the Managing Principal at the supply chain advisory and research firm Shantalla Inc. He provides confidential advisory and research on supply chain technologies, industry standards, food ecosystems transparency and trust. John is a professor of practice at the McGill University Centre for the Convergence of Health and Economics (MCCHE) and sits on the board of directors at the Canadian Institute of Food Science and Technology (CIFST).

FEATURE CANADIAN FOOD BUSINESS VOLUME 38, ISSUE 1 • 2023 10

Giving safety the green light

Atlantic Canada-based company leveraging technology to help enhance food safety

By Sean Tarry

By Sean Tarry

FEATURE

Dave Iwankow, CEO of CleanBands, sporting the innovative foodservice technology.

CANADIANFOODBUSINESS.COM 11

Photo courtesy of Dave Iwankow

Alothas changed in and around the foodservice industry over the course of the past three years or so. Impacts of the COVID-19 global pandemic, which have disrupted and disturbed virtually every sector around the world, just about turned restaurant and hospitality operations on their heads. Public health restrictions and protocols significantly diminished opportunities for foodservice operators to continue servicing guests while severely shaking people’s collective confidence concerning entering establishments. However, as we now seem to be entering something of a post-pandemic era, opportunities have returned for restauranteurs to cater to their visitors. And, according to Dave Iwankow, CEO of CleanBands—a company that’s designed a revolutionary system that helps ensure hygienic excellence for foodservice staff—it also presents them with the chance to assure their guests of the cleanliness and safety of their visit.

unobtrusive for both the person wearing them as well as guests of an establishment. And, most importantly, supported by sensor technology that’s deployed at designated handwashing sinks, the bands will let everyone know when it’s time for the individual wearing them to clean their hands. If the face on the band is yellow, it means that 25 minutes have passed since the individual’s last handwashing, serving as a prompt to wash their hands soon. If the light turns red, it means that too much time has passed in between handwashes, and that the individual must stop everything that they’re doing and wash their hands. When handwashing, the band’s face will turn blue and remain so for at least 20 seconds of washing. And, when the face on the band is green, it means that the individual’s hands have been properly washed for the appropriate amount of time.

Quantified results

It’s a simple yet ingenious invention that could serve to differentiate the establishments using them from their competitors who don’t. And, as Iwankow points out, CleanBands can also ensure that one of the two pillars of food safety is met, allowing restaurateurs to monitor compliance among their staff, and guests to dine with the peace-of-mind that those serving them their food are following handwashing protocol.

“When it comes to food safety, handwashing is something that’s most often been taken a little bit for granted,” he says. “And that’s because it’s always been assumed as part of the basic standards of a restaurant or other foodservice establishment. Everyone expects that there aren’t any rats or bugs. That’s what we have health inspectors for. And the same could traditionally be said about handwashing—everyone just assumed it was happening. However, the reality of it is that handwashing is very poorly controlled, and it’s a concern among today’s consumer that’s been brought into the spotlight of late as their awareness around cleanliness and safety has been heightened since the onset of the pandemic. In light of this, I saw an opportunity to develop a way by which those working within the foodservice industry could prove to their guests that their food is being handled with the utmost of cleanliness.”

Ensuring handwashing

The opportunity that Iwankow refers to parlayed into the development of digital bands that foodservice staff wear on their wrists like a bracelet. They’re dynamically assigned to staff when they start their shifts, are worn by those individuals for the duration of their shift, and are returned to their charging stations after use, remaining at the restaurant. A minimal design and lightweight feel means that they’re

“The two most important aspects that help ensure food safety are temperature control and handwashing,” he explains. “If a restaurant owner can manage those two things, then the risk of foodborne outbreaks within their establishments decreases significantly. Temperature has historically been relatively easy to control—you stick a thermometer in and monitor the temperature reading. Today, there are systems that allow kitchens to put their temperatures online, allowing chain establishments to know exactly what temperature their soups are at all of their locations across the country. Until now, there’s been nothing equivalent when it comes to handwashing. With CleanBands, handwashing is quantified in order to alert managers that training is being followed and that their staff are doing what’s required to reduce risk for customers.”

Setting a standard

When it comes to customer safety and the things that foodservice establishments need to be doing to reduce risks, there can be a pretty hefty price to pay for those who shirk their responsibilities. In fact, in 2020, Chipotle Mexican Grill was ordered to pay US$25 million in order to resolve criminal charges levied against the American fast food giant over accusations of serving tainted food and general uncleanliness, much of which was related to a lack of handwashing discipline. In response, Chipotle’s corporate decision-makers developed a sheet that managers of the restaurant’s locations must sign at the end of each shift, confirming that all staff washed their hands according to the company’s protocol. Iwankow argues that it’s a measure that just isn’t enough.

FEATURE

“ Handwashing compliance while wearing CleanBands is visible and provable. And, our hope is that their use will broaden over time."

CANADIAN FOOD BUSINESS VOLUME 38, ISSUE 1 • 2023 12

“Introducing a control that’s simply a sign-in sheet where managers initial their confirmation of handwashing isn’t actually a control at all,” he asserts. “Handwashing compliance while wearing CleanBands is visible and provable. And, our hope is that their use will broaden over time. We’re focusing at the moment on the larger chains that have multiple locations, like Tim Hortons and A&W. We want to prove our concept and the efficacy of our bands at foodservice establishments that have a lot of counter traffic. And, as the use of CleanBands hopefully becomes widespread, with their efficacy recognized by the industry, we’d love to help set a standard for handwashing whereby foodservice locations can proudly post their handwashing compliance rating on their front doors.”

Capturing opportunities

The opportunity to roll this type of technology and control out within a number of other sectors is not lost on Iwankow who sees the possibilities. For now, however, CleanBands is only entering the field-testing stage and has been deployed

within a number of local Charlottetown, PEI establishments. But, when discussing the future of the company and the technology that can play such a critical role in the assurance of food safety within the foodservice industry, the CleanBands Founder and CEO has some aggressive plans and ambitious targets.

“We’ve had a lot of interest from a number of different restaurant brands both in Canada as well as the United States. Right now, we’re trying to get our bands into as many restaurant locations as possible within Charlottetown to allow us the chance to perfect our technology. And, by the middle of the year, we expect to be able to expand beyond the Atlantic region and start working on more of a national basis. Looking ahead to the next few years, we’re going to continue speaking with and introducing our technology to as many of the big brands as possible. The quick serve food industry in North America is represented by around 2,000 or so brands operating at least 100 locations. So, it’s going to be about capturing as many of those opportunities as possible in order to scale up use of our solution.”

FEATURE

CANADIANFOODBUSINESS.COM 13

CleanBands technology works to ensure the cleanliness of foodservice staff. Image courtesy of Dave Iwankow

What’s in your meat?

STATE-OF-THE-ART AUTOMATED SOLUTION HELPING MEAT PROCESSING PLANTS MORE ACCURATELY INSPECT FOR SAFETY AND QUALITY

By Sean Tarry

Forthose operating within the meat processing sector, there are few things more important than ensuring the safety and quality of the product that leaves their facilities on their way to store shelves. Perhaps the most critical aspect of providing this assurance for consumers is possessing the ability to identify foreign materials in the meat that’s being processed. However, it’s increasingly becoming just as important to be able to confirm the quality of the product as well. In fact, according to Heather Galt, VP, Customer Experience and Strategy at P&P Optica—a developer and provider of proven automated solutions for meat processing plant inspections—it’s the single biggest potential differentiator among competitors, and of utmost importance in the minds of consumers.

“Finding anything in a product as a consumer can be extremely off-putting,” she asserts. “And, when a company has to make the announcement of an unfortunate recall, there is often quite a bit of negative exposure, especially when it's caused by the presence of foreign materials. So, this is an area of paramount importance for meat processors, both from a detection and prevention perspective. It’s an ongoing priority for the industry whose operators are constantly looking for newer, more effective ways to keep foreign materials out of their stream of products with a focus on ensuring that clean product leaves their doors on their way to stores and eventually the consumers’ home.”

Smart Imaging System

It also happens to be an area of intense focus for P&P Optica and the technology-enabled equipment that it develops for use by those operating within the meat processing industry. The company’s patented Smart Imaging System, which combines hyperspectral imaging, artificial intelligence and machine learning, is able to identify the chemical composition of products in-stream while detecting the presence of low-density foreign materials as well. It’s a ground-breaking advancement within the realm of meat inspection that Galt says stands P&P Optica apart from others within the inspection solution space.

“Processors understand that foreign materials, especially those of low-density like plastics, are really hard to find within their product with existing solutions,” she explains. “X-rays are able to spot high-density materials, and metal detectors can detect metal. But there are a lot of other materials within processing plants that can go undetected, even with those solutions in place. Because we use chemistry we’re able to identify each and every piece of foreign material within a meat product, regardless of its composition.”

An incredibly powerful tool

Galt goes on to explain that by combining hyperspectral imaging, artificial intelligence and machine learning technologies to understand the chemical composition of meats, it

FEATURE

CANADIAN FOOD BUSINESS VOLUME 38, ISSUE 1 • 2023 14

FEATURE

CANADIANFOODBUSINESS.COM 15

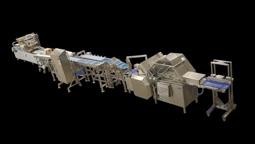

The PPO Waterfall Configuration, part of PPO’s Smart Imaging is designed for double-sided inspection, with multi-rejection mechanisms. Image courtesy of P&P Optica

also enables processors to control the quality of their product as well. For instance, P&P Optica’s technology is able to identify muscle myopathies like woody breast in chicken, while measuring a meat’s lean point, moisture, pH level and more. And, it’s all done in-stream, in real-time, without compromising the detection of foreign materials.

“Because our system is equipped to detect foreign materials and assess quality characteristics at the same time, collecting and processing an unparalleled amount of information concerning food chemistry, in real time, it makes it an incredibly powerful tool for processors.”

Leveraging data

Beyond the actual inspection for foreign materials and analysis of chemistry composition of product, during which P&P Optica’s Smart Imaging System makes over 16 million decisions every minute, identifying issues in real time, pixel by pixel, it’s continuously learning and improving. Driven by machine learning, performance of the system is constantly optimizing for faster, more accurate results. And, incidents that are captured by the company’s system are stored and presented in PPO Insights—a dashboard where users of the solution can review and analyze particulars concerning their plant’s inspections. It’s all part of what Galt refers to as a “comprehensive suite” of inspection services made possible by P&P Optica’s advanced system.

“Certainly for meat processors, our system offers all of the capabilities they require in order to ensure that their name is consistently on a foreign-material-free, top quality product,” she says. “It also dramatically reduces the chance of a recall becoming

necessary, saving the credibility of companies and enhancing the perception of their brands in the minds of their consumers. In the end, satisfying the consumer and ensuring an excellent and safe product is the objective for those working within the meat processing industry. And, given the increased expectations of today’s consumer, those processors who can do this most consistently will differentiate themselves from their competitors who cannot.”

Digitizing and automating

Given the range of benefits that P&P Optica’s Smart Imaging System offers its users, it’s easy to understand the confidence with which Galt speaks of its capabilities and possibilities. And, looking ahead, she’s just as optimistic about the plans the company has to broaden its focus and the extent of the technology’s potential where food safety and quality is concerned, suggesting that the system will soon provide even greater use and benefits for the industry.

“One of the most important parts of our strategy moving forward is to take that chemical data that we get from the facilities that we’re working with and help them use it beyond the incident itself. If a piece of plastic is found on the line, the priority is to remove it. The next priority is to ensure that the same incident doesn’t happen again by learning how to better manage suppliers and processes, and by identifying patterns that suggest areas for improvement and figuring out ways those improvements can be made. It’s how processors can start to digitize their plants, use more automation and leverage the resulting data to continue making enhancements to their operations.”

M CM MY CMY AWB-Lab-BioBusiness-one-third-Feb2023-outline.pdf 1 2023-02-17 10:25:13 AM CANADIAN FOOD BUSINESS VOLUME 38, ISSUE 1 • 2023 16

A fresh peel

The Wyma Vege-Peeler peels a variety of vegetables that are auger-fed into a drum and sprayed with either fresh or recycled water. With custom-designed brushes that can be adjusted to control speed, peeling action is accurate and effective. Yielding losses as low as 5 per cent on certain vegetables, the Vege-Peeler improves the appearance of fresh vegetables, resulting in more premium packed produce and an increased presence on retailers’ shelves.

www.wymasolutions.com/

Compact and portable depositor

Featuring an ergonomic hand-held nozzle with food grade hose, small footprint and 4” swivel castors, sanitary, all-stainless-steel construction, and optional tray to keep your buckets off the floor, the Unifiller iSpot Depositor is userfriendly, compact, portable and versatile. In addition, cleaning it is quick and easy, making product changeover more efficient.

www.unifiller.com/

Starch yield maximizing rasper

Given that the yield of a rasper determines to a large extent the overall yield of an entire starch operation, the SiccaDania rasper has been designed to efficiently rupture cell walls, yielding the maximum amount of starch from the root. The product obtained after the rasper can be considered a mixture of pulp fibres, fruit juice and starch, making rasping a one-pass operation.

https://siccadania.com/

Precise pumping

Provisur Technologies’

Weiler AccuPump is a positive displacement, lobe style pump designed to quickly and precisely feed chub packaging and loafportioning machines. As its name implies, it is precisionengineered to provide accurate targeted weights by reducing product giveaway. Its gentle, lowtemperature positive pumping action preserves particle definition and protects product quality. Two models are available to suit capacity needs.

www.provisur.com/en/

Production amplifying pepperoni peeler

Ushering in a new era in pepperoni peeling, the Kohler Automatic Peeler separates meat sticks from their casings in the blink of an eye. Best suited for use with long sticks of pepperoni, salami, and sausage, a quick release system allows for continuous, non-stop peeling within an entirely hands-off process from start to finish.

www.kohlerindustries.com/

Custom-designed homogenizer

Custom-designed to each specific use-case, Anderson Dahlen SPX Gaulin Homogenizers can be used across a wide range of materials, with a spectrum of pressures up to 8,700 psi. These tailored homogenizers serve to meet safety and efficiency needs, whether working in biotech, food, dairy, chemical, pharma, cosmetics, or other industries.

https://andersondahlen.com/

FOOD WARE

CANADIANFOODBUSINESS.COM 17

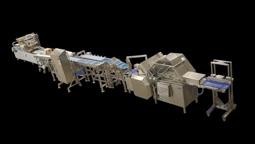

A clean take on conveyor systems

Tri Mach’s Ever-Kleen Sanitary Conveyor Systems are passive transfer conveyors that are easy to disassemble and clean, resulting in increased productivity and the highest levels of food safety. Conveyor systems are custom-designed and fabricated to suit exact specifications and are easily integrated with existing equipment to help improve operational efficiencies.

www.tri-mach.com/

Kneading help?

ROSS/AMK Kneader Extruders combine the efficiency of a double arm sigma blade mixer with the convenience of an extrusion screw for the mixing and discharging of heavy viscous materials exceeding 10 million cP. During the mixing cycle the blades rotate toward each other while the mixing constantly feeds new materials into the mixing blades. After the mixing/kneading cycle is complete, the screw directions are reversed to extrude the finished product from the mix zone out through a discharge die and on to further processing or packaging.

www.mixers.com/

What a grind

MPBS Industries’ TALSA W130-U2 Commercial Meat Grinder features stainless steel construction, removable stainless-steel head, feed screw, and ring, a feed screw extraction wrench, lubricated metallic gearbox, sealed base, thermally protected motor and safety switch under the tray, taking the grind out of meat grinding. https://mpbs.com/

Boom… roasted!

Heat and Control’s Rotary Dryer Roaster is a high volume, energy-efficient continuous multi-zone convection system that provides optimal drying/ roasting in a gentle, and sanitary manner. First-in, first-out production and even heating with a smart, step-spiral, and flighted drum design achieves uniform drying and roasting. Ideal for use with nuts and dough-coated nuts, seeds, jerky, meat chips and protein-based snacks, pet treats, pellet snacks and pork rinds.

www.heatandcontrol.com/

Ag-West page 16

FCC page 21

FOOD WARE

LIST OF ADVERTISERS & WEBSITES

agwest.sk.ca

fcc.ca/food

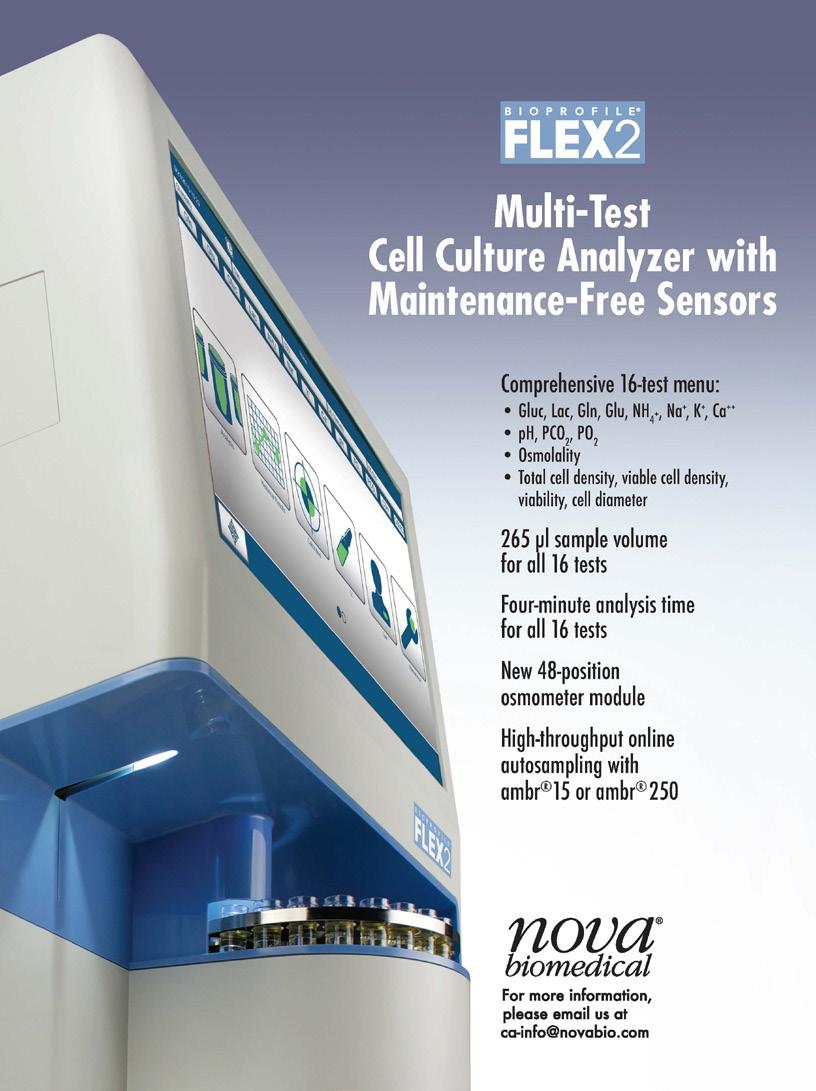

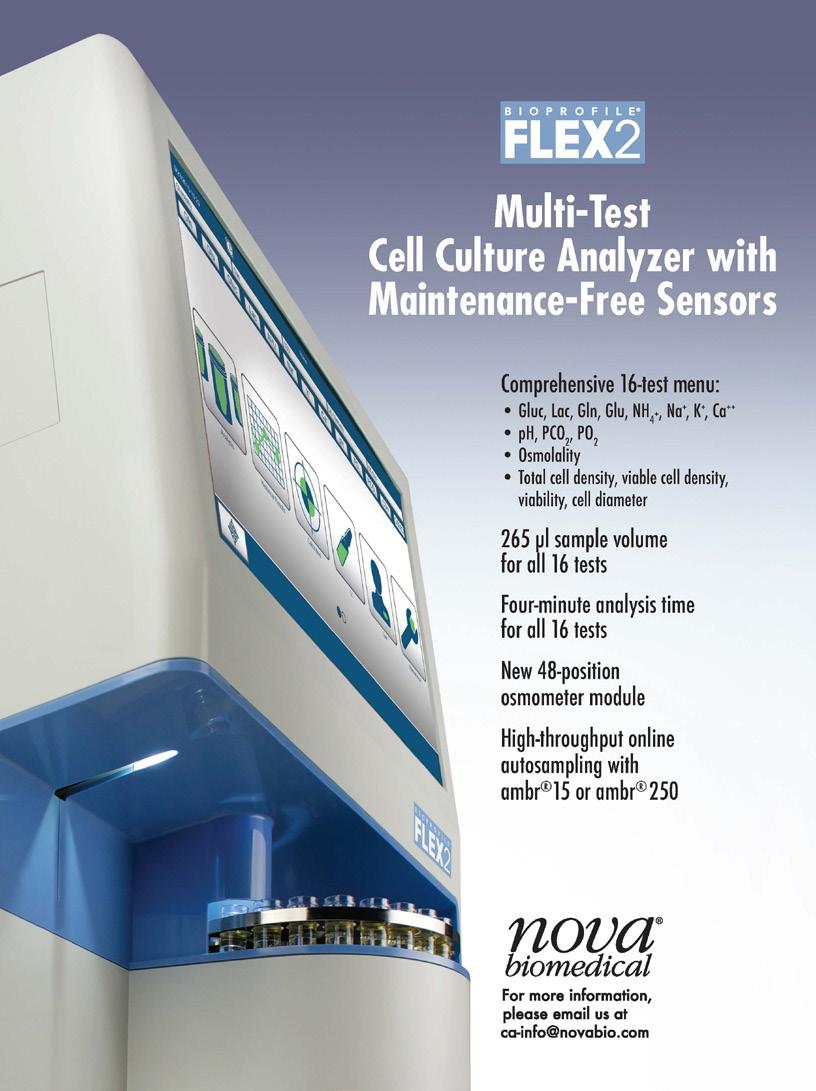

Biomedical page 22 ..........................................................................................................................................................................ca-info@novabio.com CANADIAN FOOD BUSINESS VOLUME 38, ISSUE 1 • 2023 18

Nova

The evolution of Canada’s Food Guide

Guiding the food selections of Canadians through the years and multiple iterations

By Sean Tarry

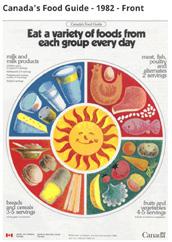

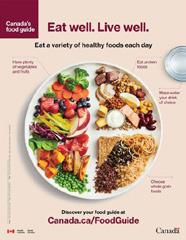

For more than 80 years, Canada’s Food Guide has been the authority with respect to guiding the food choices of Canadians from coast-to-coastto-coast. There have been a total of nine iterations of the Guide developed through the years, including the most recent edition which was released in 2019. And, it’s undergone a number of different name changes and makeovers. However, what’s remained the same is the publication’s purpose: to guide the food selections and promote the nutritional health of Canadians.

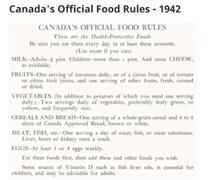

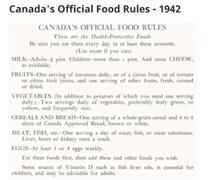

Introduction of the Guide

First introduced in 1942 as Canada’s Official Food Rules, it served as a means to guide Canadians across the country concerning proper nutrition during a wartime period when rations were not uncommon. Identifying six food groups (Milk; Fruit; Vegetables; Cereals and Breads; Meat, Fish, etc.; and Eggs) and the recommended daily servings, authors of the publication were forced to base its “rules” on 70 per cent of the dietary standard in light of limited access to certain foods. Just two years later in 1944, the publication was renamed Canada’s Food Rules which included an expansion of the Meat and Fish food group to include cheese and eggs, in addition to a recommendation to use iodized salt.

Early changes

Subtle but important changes were made to the Rules in 1949 based on feedback and insights provided by teachers across the country who had amassed a breadth of experience using the publication within their curriculums. For

instance, “at least” was added to the Milk group to accommodate the greater energy needs of some individuals. And, advice about fish oil was replaced with a recommendation for a Vitamin D supplement since dietary surveys of children had uncovered inadequate intakes of the vitamin.

Industry evolution

An updated version was not developed for another 12 years, when in 1961 it was again renamed, this time becoming Canada’s Food Guide. And, as a result of an evolution of methods related to food processing, storage, and transportation, the types of food that were available to Canadians throughout the year began to evolve as well. For instance, citrus fruit made its debut in the Guide as a result of a boom in the development of highways throughout the continent, allowing for the transport of new foods into the Canadian market.

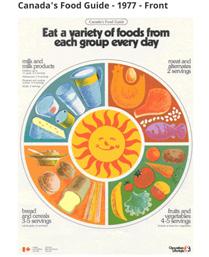

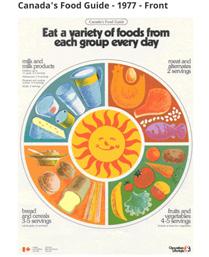

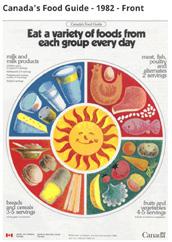

Impact of diet on cardiovascular health

More than a decade-and-a-half passed before the next iteration of the Guide was published in 1977. This version didn’t contain too many changes of significance. But it did pare the number of food groups down from five to four with the merging of fruits and vegetables into the same group. In 1982, however, following the submission of the landmark Report of the Committee on Diet and Cardiovascular Disease to Health Canada, a revision to the Guide was prompted in order to take into account the relationship between a healthy diet and the prevention of heart disease and other chronic diseases.

MOMENTS IN TIME BIOLABMAG.COM 19

Dietary philosophy shift

The 1992 updated edition, which was named Canada’s Food Guide to Healthy Eating, marked a new era in the Guide’s nutritional direction. It was accompanied by a shift in philosophy which embraced a total diet approach when choosing foods rather than the traditional foundation diet concept. The total diet approach brought with it wide ranges of serving suggestions from the four food groups to reflect the varying energy needs for different ages, body sizes, activity levels, genders and conditions such as pregnancy and nursing.

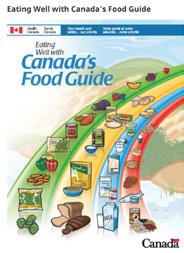

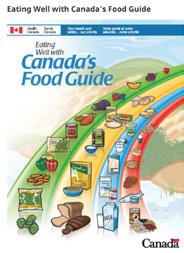

All-in-one tool

The penultimate updated edition of the publication released in 2007 saw another name change, this time titled Eating Well with Canada’s Food Guide. Designed as an all-in-one tool, this version of the Guide served to address some of the challenges that were identified in the previous iteration while building on its strengths, including its consistency

with current science. In addition, for the first time, the 2007 Guide was translated into 10 different languages in addition to English and French. A tailored Food Guide for First Nations, Inuit and Métis was translated into Cree, Ojibwe and Inuktitut. in addition to English and French. And, a significant online component was developed which included a range of resources and tools.

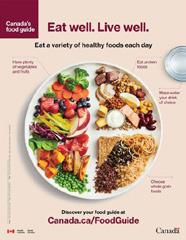

Today’s Guide

The current iteration of Canada’s Food Guide, released in January 2019, maintains the purpose that it’s been intended to serve all along, recommending that Canadians eat a variety of healthy foods every day, including an appropriate amount of vegetables, fruits, protein foods, and whole grains. It also suggests that people adopt water as their drink of choice in order to properly and effectively quench the body’s metabolic functions. In addition, the Guide makes the following recommendations concerning health behaviours and habits related to eating:

• Be mindful of eating habits

• Cook more often

• Enjoy food

• Eat meals with others

• Use food labels

• Be aware of food marketing

• Limit foods high in sodium, sugars or saturated fat

• Involve others in planning and preparing meals

• Notice when you are hungry and when you are full

• Serving size vs. proportion

Addressing the last point (serving size vs. proportion), the current Guide includes an updated approach concerning recommended servings. Rather than recommending specific servings of food from the four food groups, a proportional diet is suggested, which contains 50 per cent of an individuals daily calories coming from vegetables and fruits, 25 per cent from whole grain foods, and 25 per cent from protein foods.

Maintained purpose

Canada’s Food Guide continues to evolve, as it has done for more than eight decades now, adapting recommendations based on a number of different factors and variables. And, through its evolution and adaptations, it’s maintained the same overarching purpose focused on guiding Canadians’ food choices while promoting the nutritional health of everyone in the country.

MOMENTS IN TIME 20 BIOLAB BUSINESS VOLUME 38, ISSUE 1 • 2023

Behind Canadian food?

We’re behind you.

We’re FCC, the only lender 100% invested in Canadian food, serving diverse people, projects and passions with financing and knowledge.

Let’s talk about what’s next for your business.

FCC.CA/FOOD DREAM. GROW. THRIVE.

FCC.CA/FOOD DREAM. GROW. THRIVE.

By Juan Marcelo Gómez and John G. Keogh

By Juan Marcelo Gómez and John G. Keogh

By Sean Tarry

By Sean Tarry