LEAN

MAXIMIZING VALUE

LEAN CONSTRUCTION ENHANCING PRODUCTIVITY

Definition and Approach:

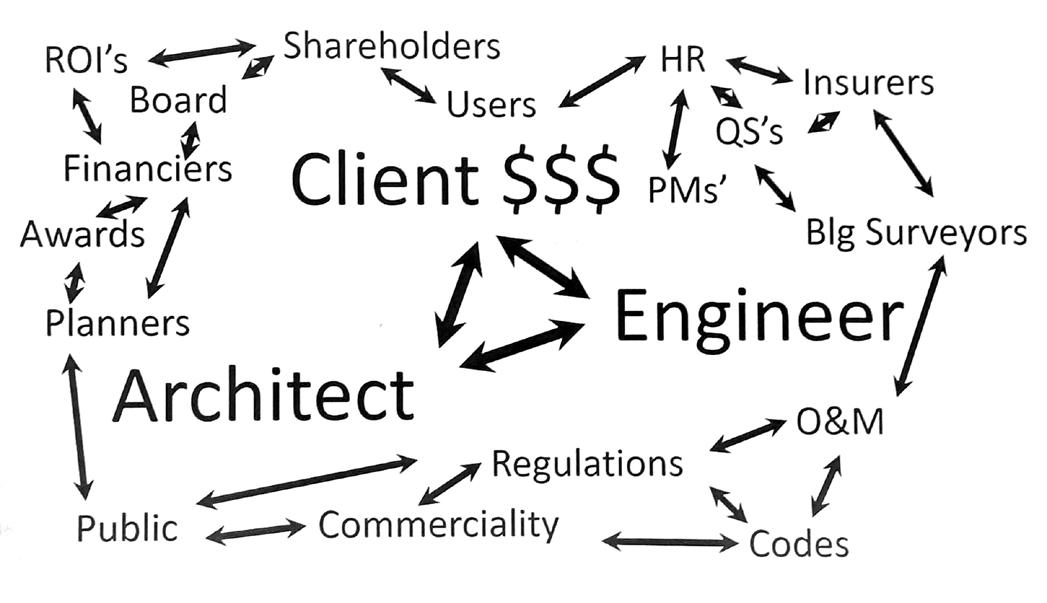

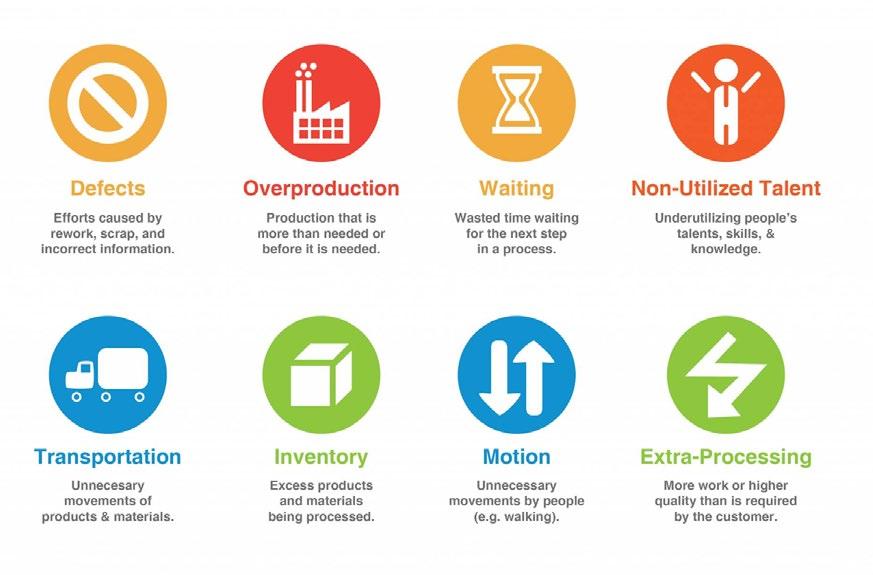

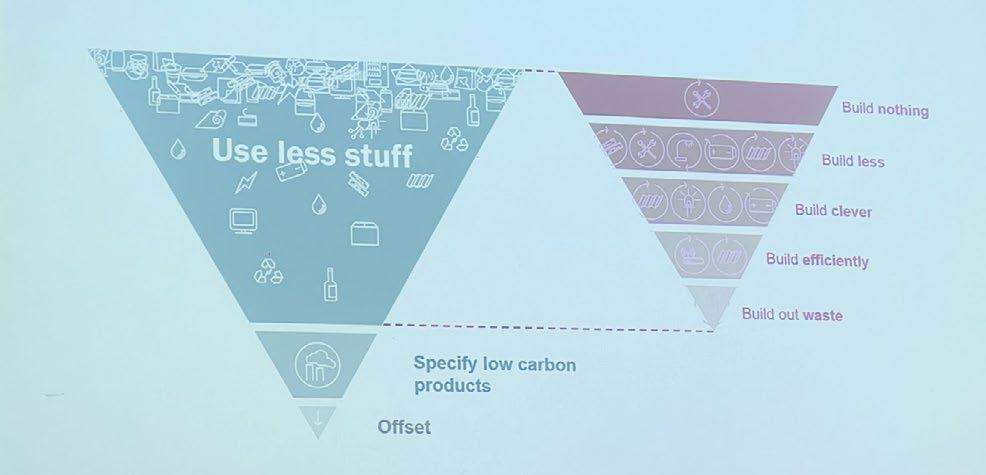

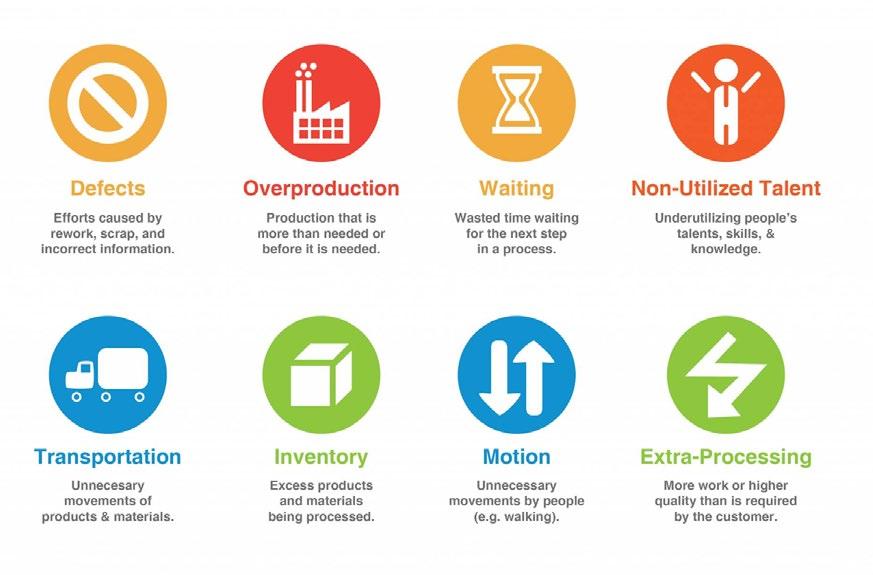

Lean Construction aims to design production systems to minimize waste of materials, time, and effort, maximizing value (Koskela et al., 2002).

The Lean Construction Institute (LCI) describes it as a production management-based approach useful for complex, uncertain, and fast-paced projects7

The Concept of Waste as Understood in Lean Construction

My understanding of waste in construction has been changed. It is not just about material waste. It goes beyond that!

Lean construction identifies waste as any activity not adding value to the customer. Significant inefficiencies include rework, low labor efficiency, and material waste. Adopting lean principles from manufacturing can improve overall productivity and performance.

Ease of

Ease of DFMA

Design for Manufacture and Assembly

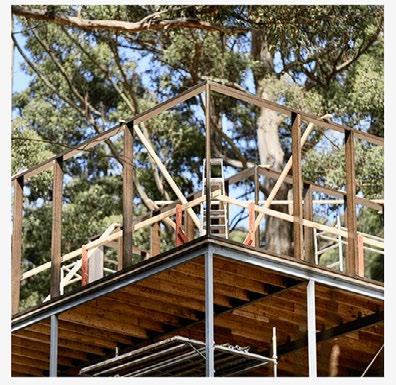

Off-site and automation On Site

Value Stream Mapping (VSM)

Activities

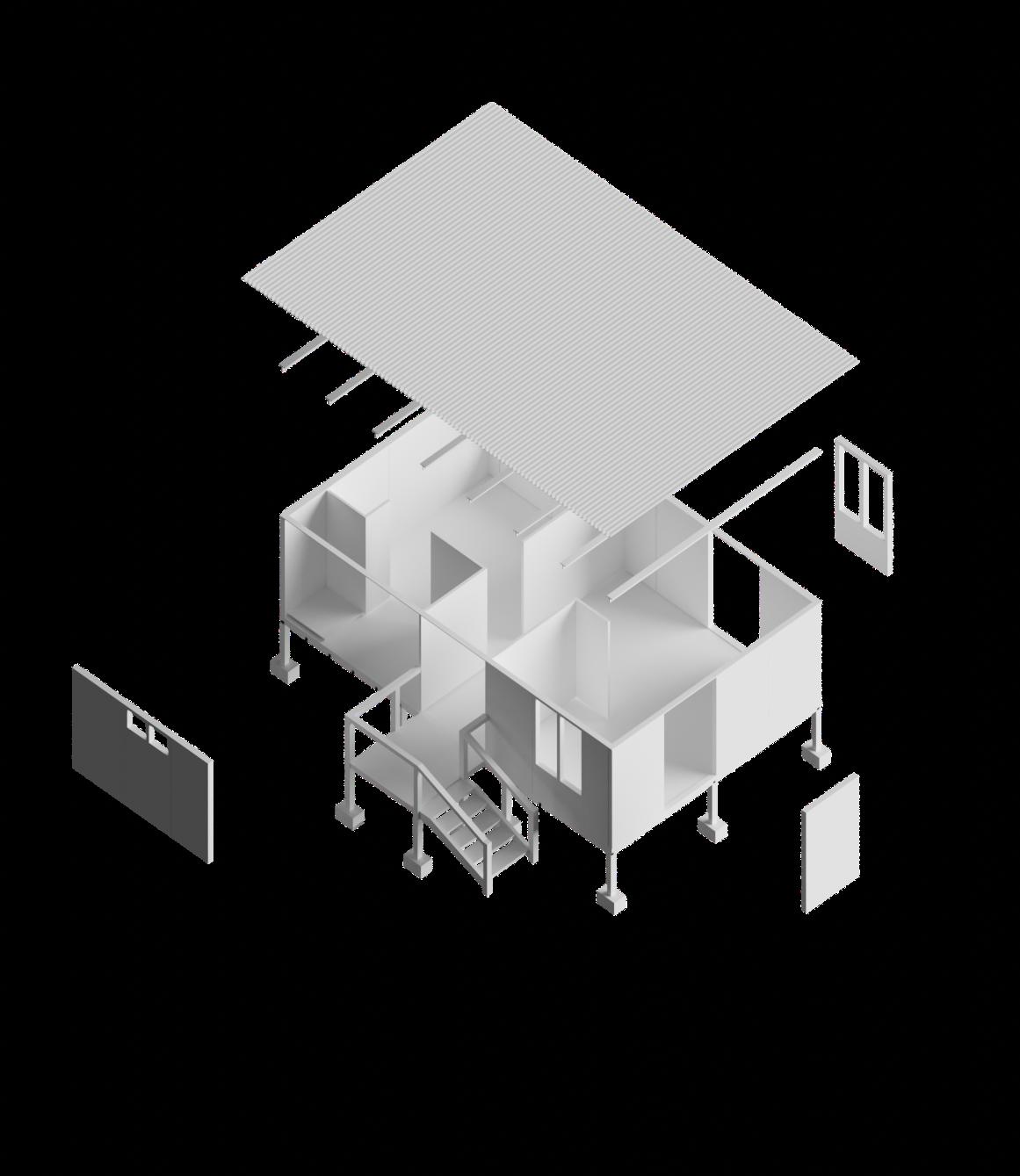

VOLUMETRIC CONSTRUCTION

Opportunities

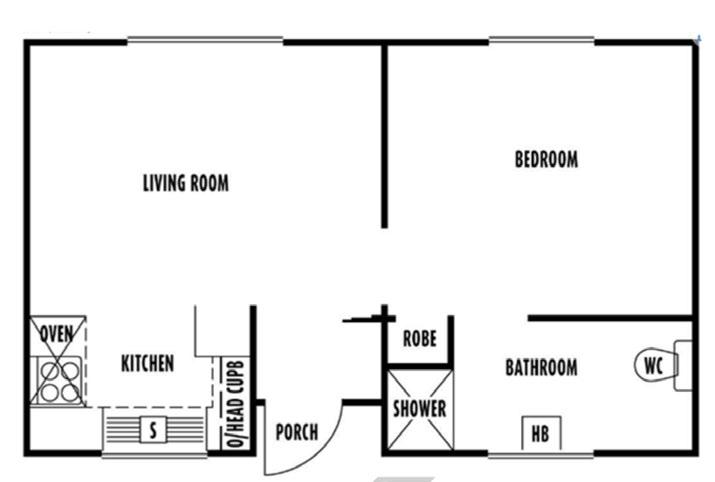

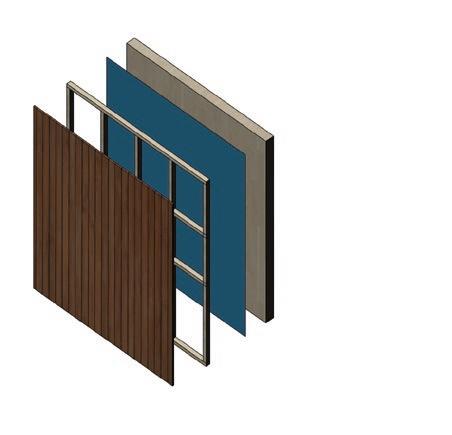

DfMA, part of the Design for Excellence (DfX) framework, includes Design for Manufacture, Assembly, Transportation, Sustainability, and more. It focuses on off-site manufacturing and automation.

Challenges

• Fast Production • Off-Site • Controlled Setting • Transportation • Costly

Choosing by Advantage (CBA)

• Identify Alternatives

• Define Factors

• Define must have/want to have criteria for each other

• Describe the attributes of each alternative

• Decide the advantages of each alternatives

• Decide the importance of each advantage

• Evaluate Cost Data

Key Takeaways

:

Lean Construction and DfMA can greatly improve efficiency and value in construction projects by reducing waste and enhancing process flexibility and transparency.

With the help of Value Stream Mapping, both opportunities and challenges can be identified in Volumetric Construction System.

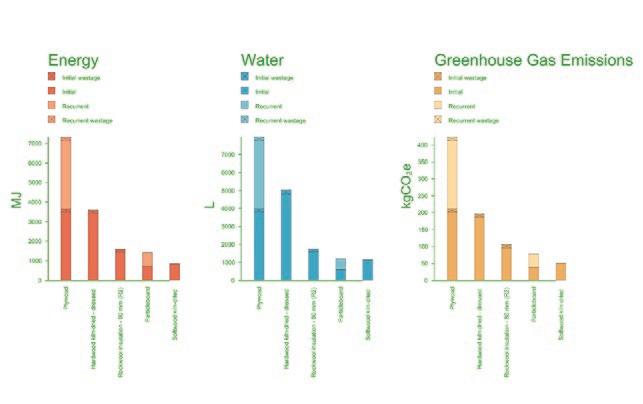

Also using CBA analysis technique the choice of materials further could be evaluated by identifying several factors such as embodied carbon emission, thermal performance, pricing and their availability.

Studio E-07 Backyard Futures: Movable Homes Studio Research Journal By Dristi Chakma | 1420680 21 20

PRESENTATION

CONSTRUCTION & DFMA (Gao Shang)

ELIMINATING WASTE

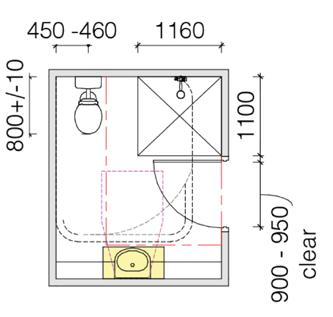

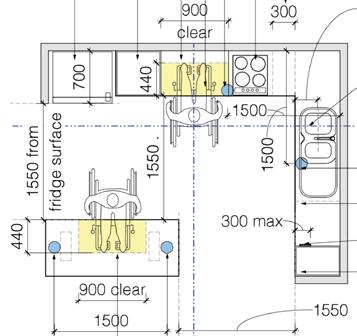

Prefabricated Bathroom is 30% expensive in Australia!

Synergising DfMA and Lean in Construction, Dr Gao Shang, Senior Lecturer, The University of Melbourne Director, Lean Construction ANZ (Vic Council) April 2024

7.

Studio E-07 Backyard Futures: Movable Homes Studio Research Journal By Dristi Chakma | 1420680 23 22

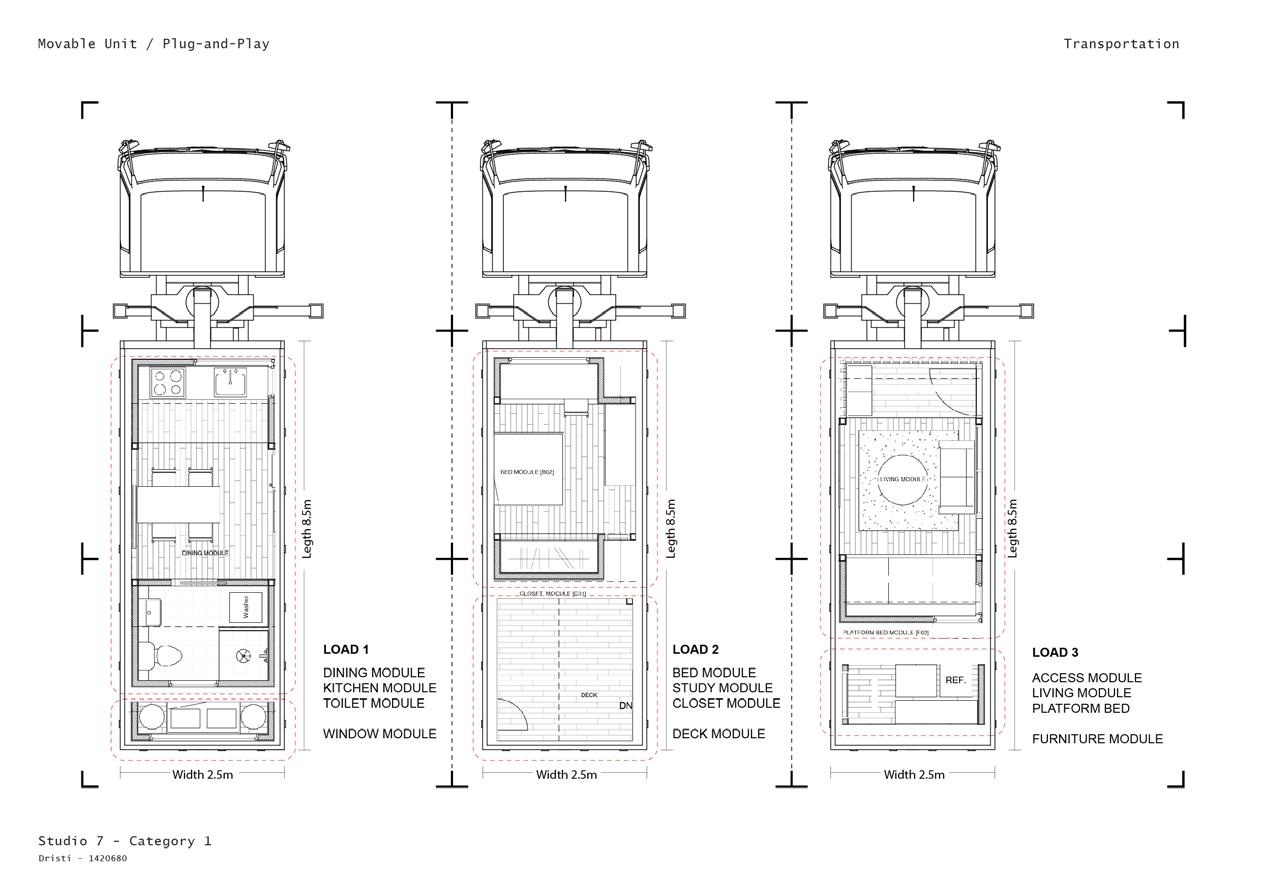

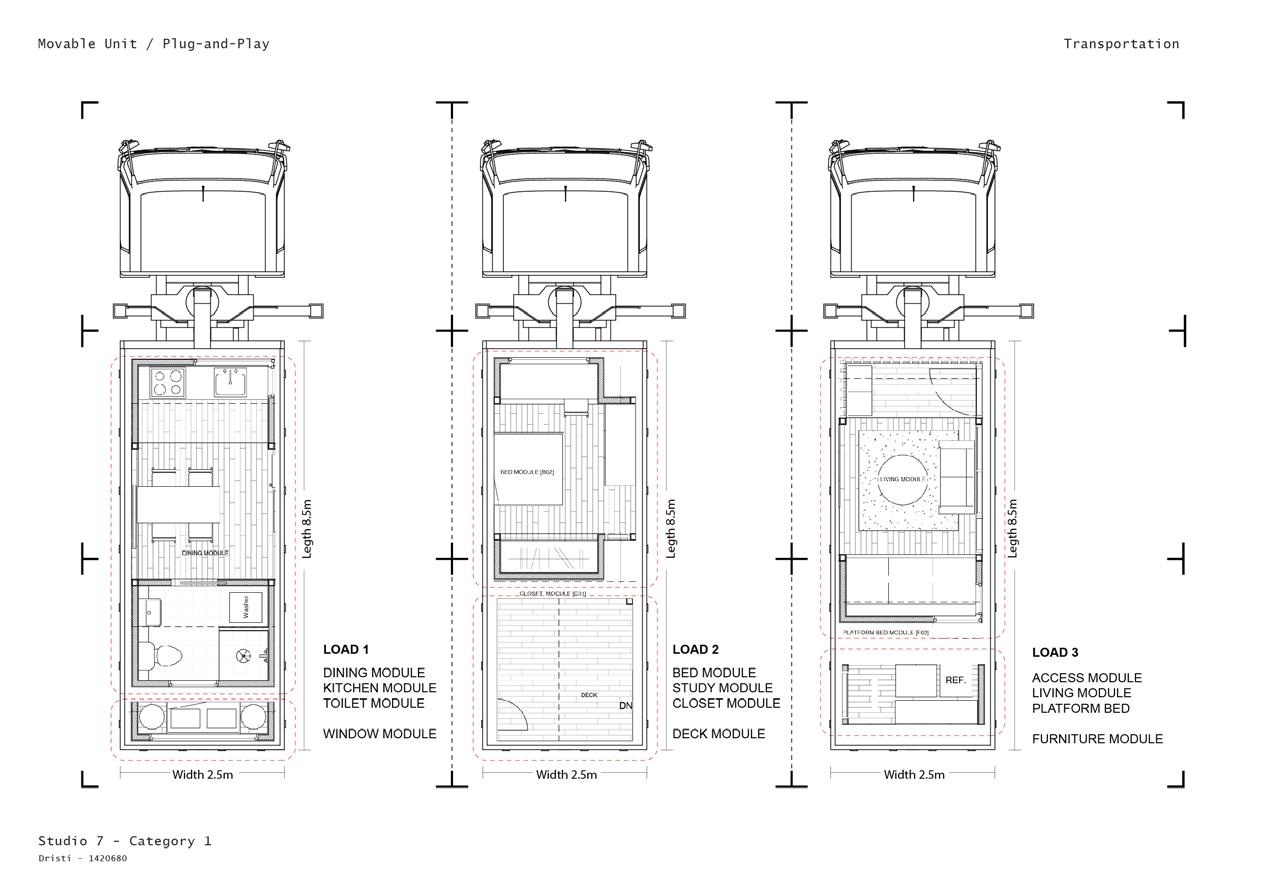

(Jas Johnston) PRESENTATION IMPLEMENTATION Building Components Module and Components Flexible Customizations Vartions with modular customization Digital Design Tools Components Selection Customized Design Movable Unit / Plug-and-Play Studio 7 - Category 1 Catalogue Main Module Bedroom Bathroom Kitchen SMALL MEDIUM LARGE $19,172 17,990 kgCO2-e 22,498 kgCO2-e 33,410kgCO2-e 20,560kgCO2-e 7,710 kgCO2-e 33,410kgCO2-e 17,168kgCO2-e 11,565kgCO2-e 30,840kgCO2-e 15,420kgCO2-e 8,610kgCO2-e $3,699 $18,218 9,642 kgCO2-e 25,712kgCO2-e 41,782kgCO2-e 14,463kgCO2-e 21,470kgCO2-e 41,782kgCO2-e 10,767kgCO2-e 19,284kgCO2-e 38,568kgCO2-e $7,198 $4,430 $1,661 $7,198 $2,492 $6,644 $1,855 $3,322 Timber Steel Andrea 1381020 Artem - 1052679 Dristi 1420680 Movable Unit / Plug-and-Play Studio 7 - Category 1 Sample House Small Medium Large Extra Large $29,332 65,150 kgCO2-e 81,475 kgCO2-e $21,705 $50,719 93,419 kgCO2-e 116,828 kgCO2-e $48,811 $73,767 116,550 kgCO2-e 161,825 kgCO2-e $70,905 $63,675 153,558 kgCO2-e 192,037 kgCO2-e $61,767 Timber Steel Andrea 1381020 Dristi 1420680

CANDOUR MODULAR CONSTRUCTION

Studio E-07 Backyard Futures: Movable Homes Studio Research Journal By Dristi Chakma | 1420680 25 24 PRESENTATION

IMPLEMENTATION

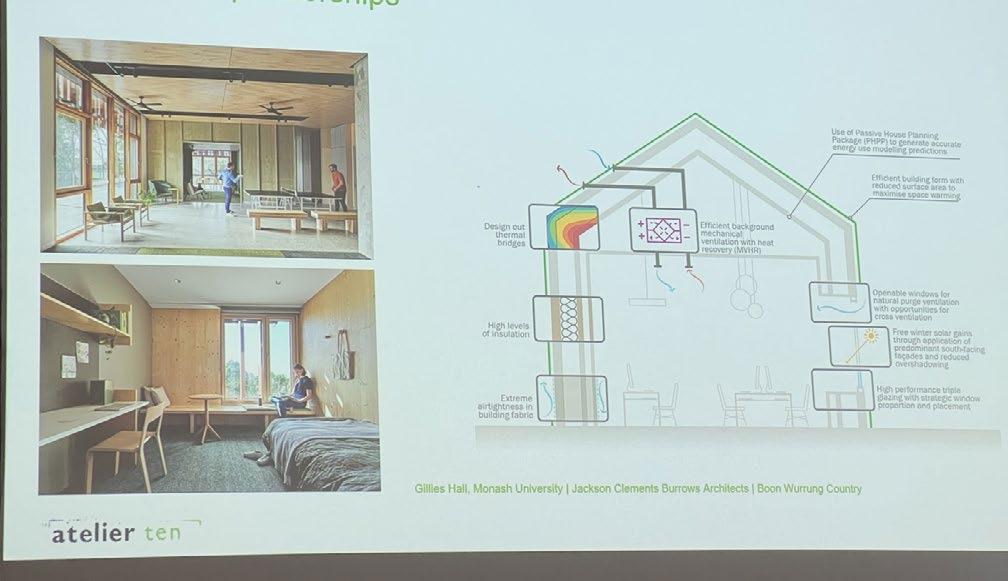

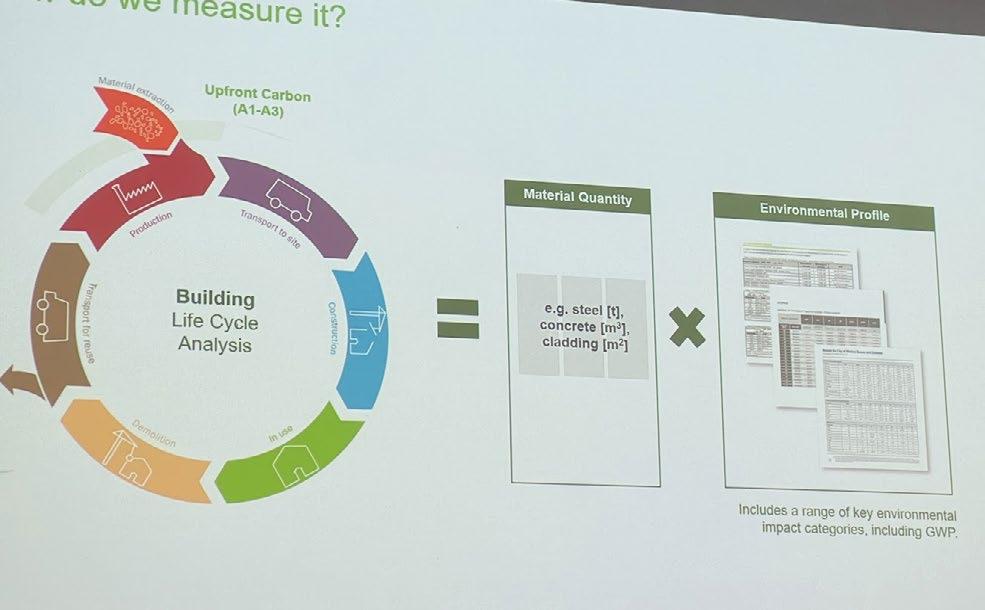

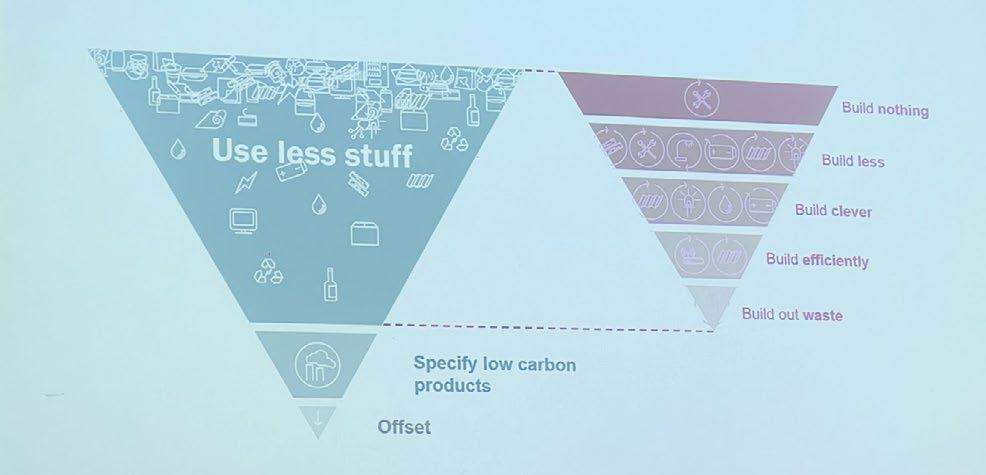

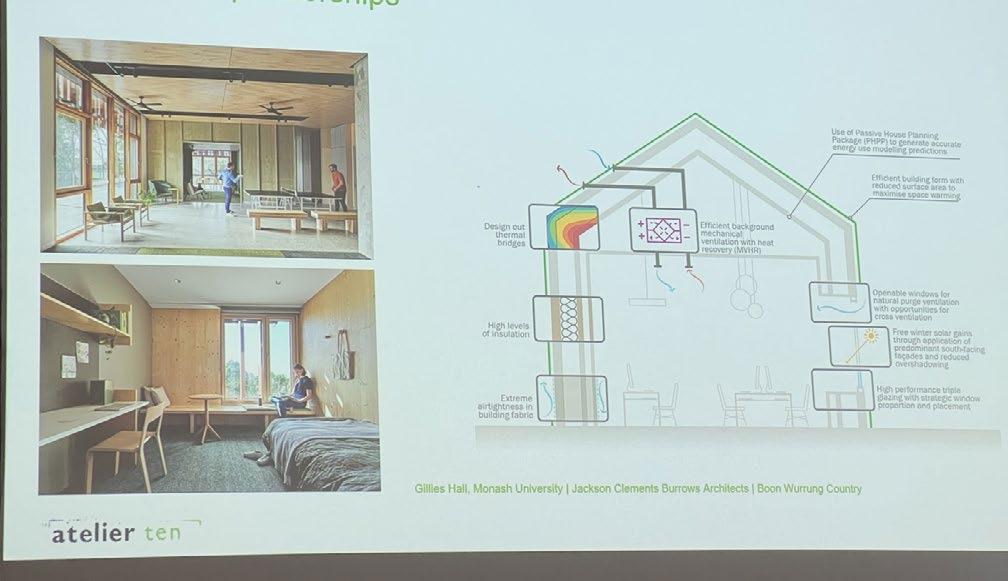

Environmentally Sensitive Design (Lucy Marsland)

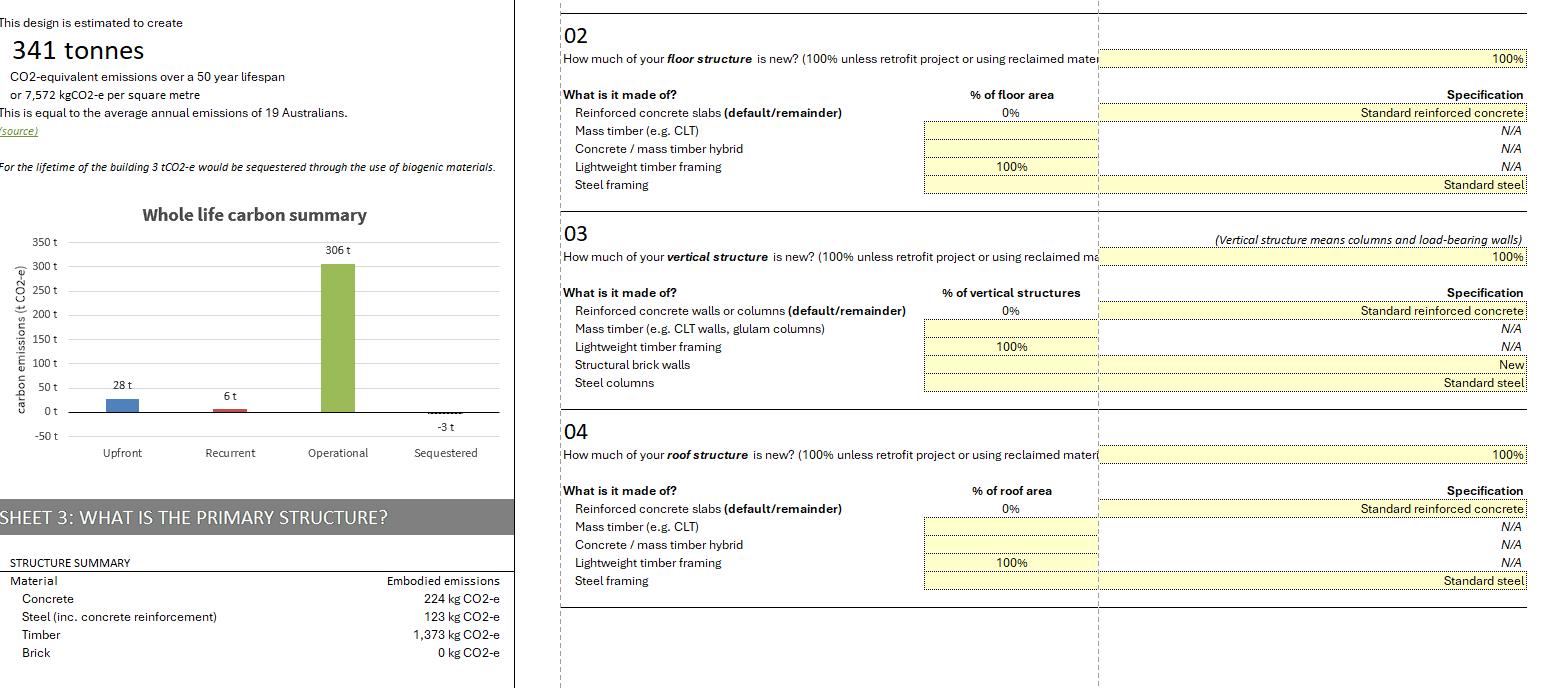

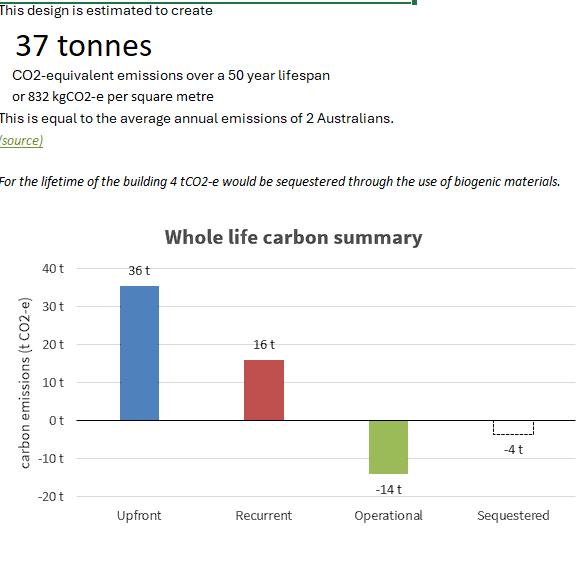

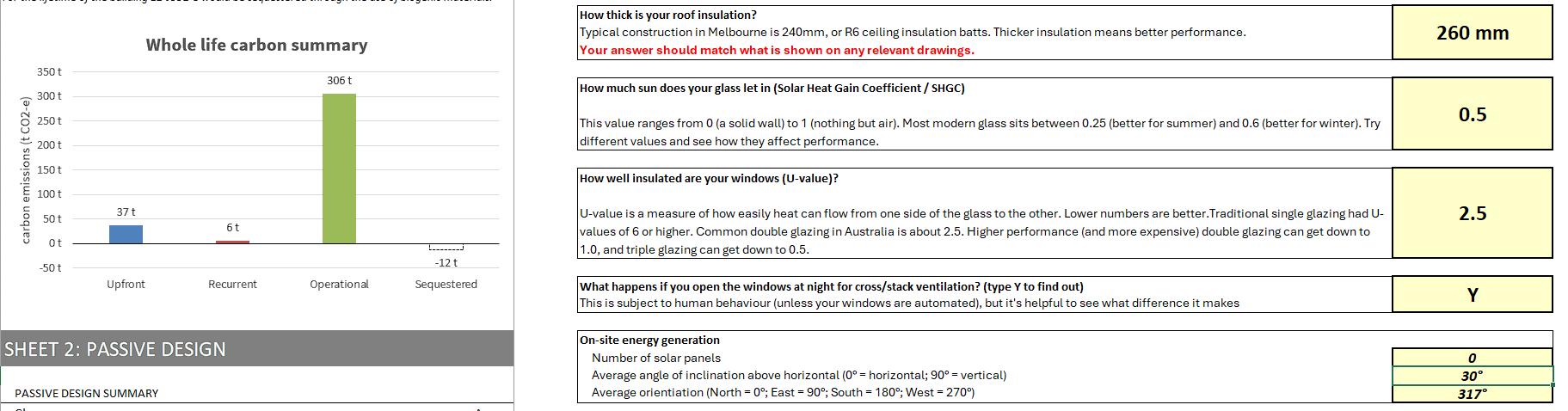

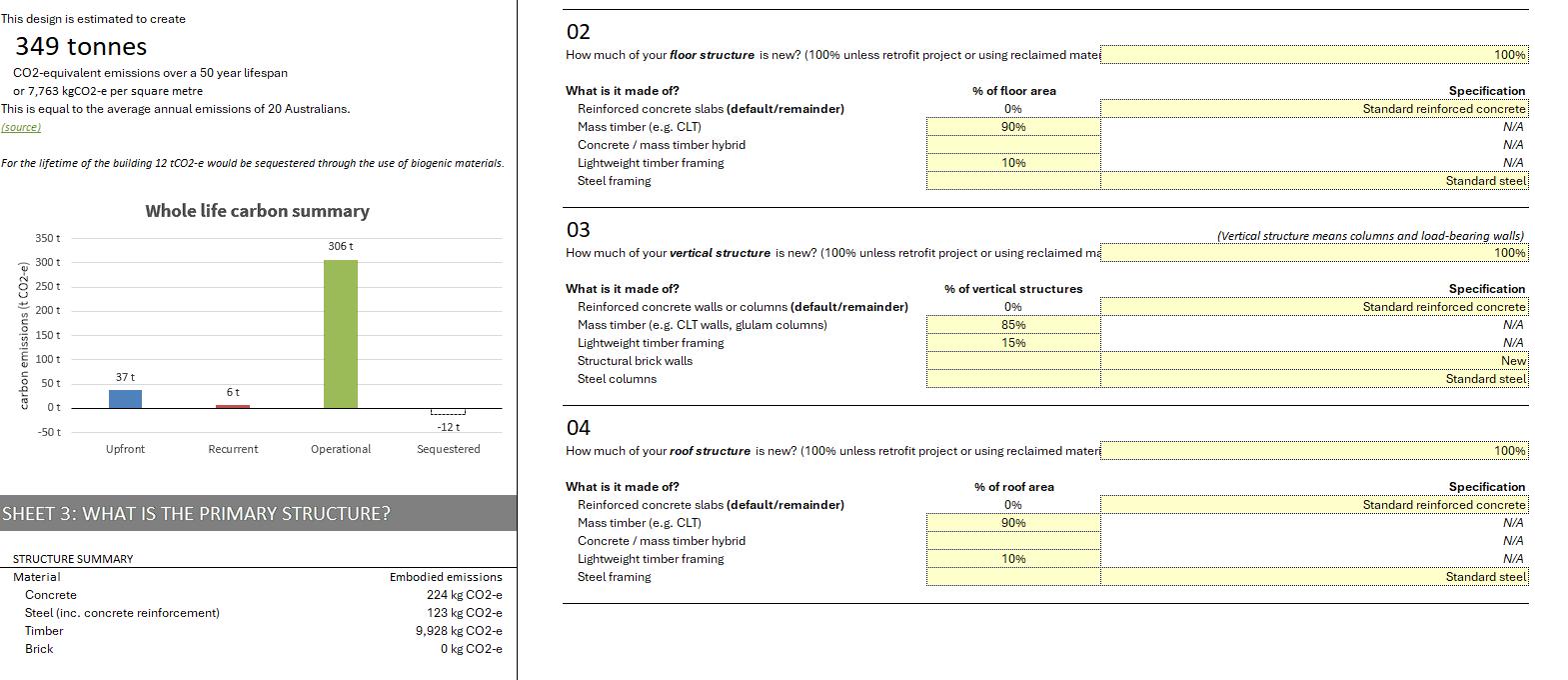

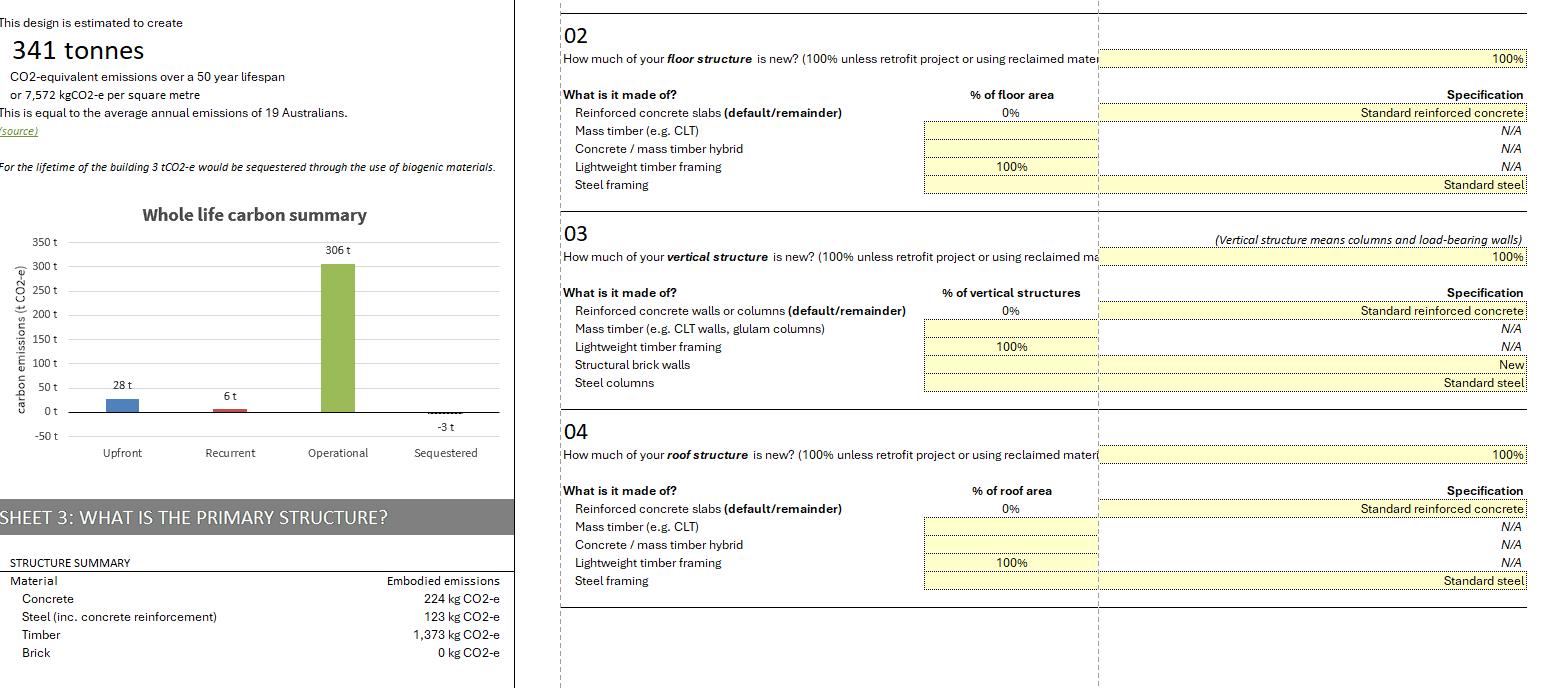

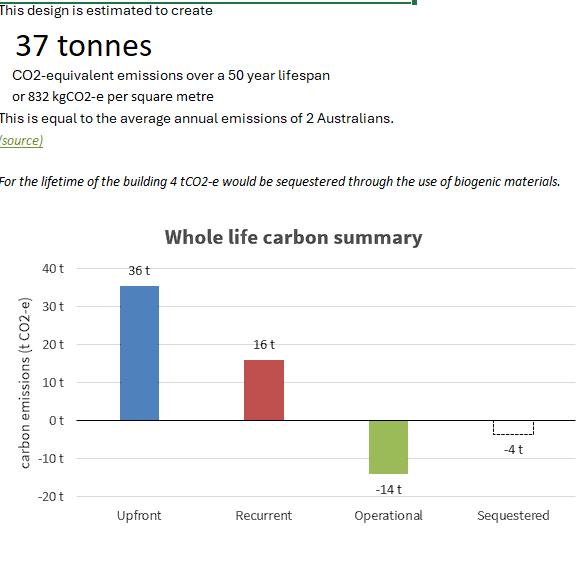

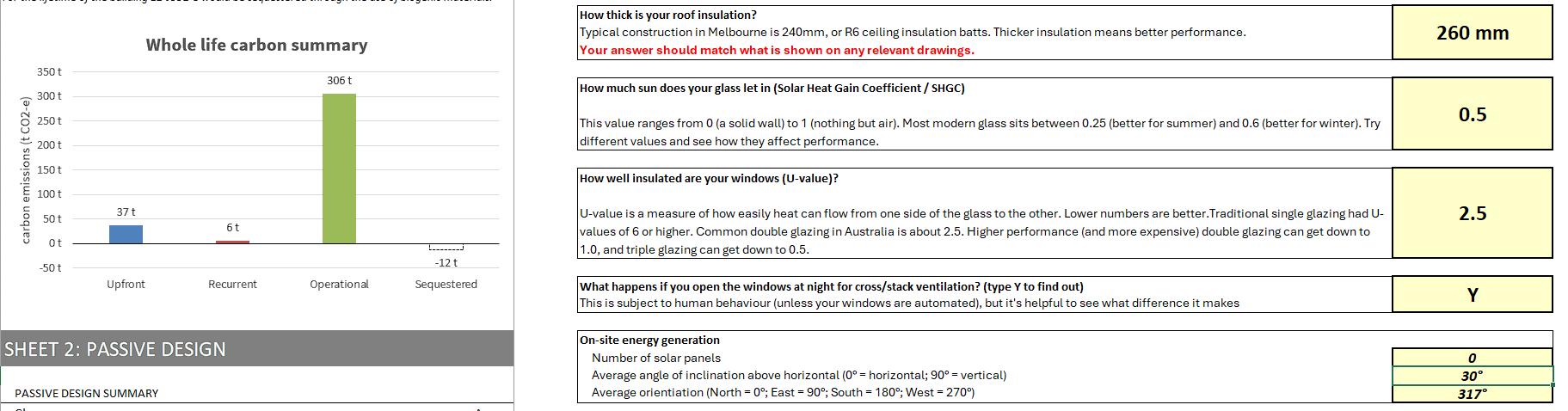

It is possible to reduce whole life carbon emission drastically just by applying solar panel in both cases.

27 Studio E-07 Backyard Futures: Movable Homes Studio 26 Research Journal By Dristi Chakma | 1420680

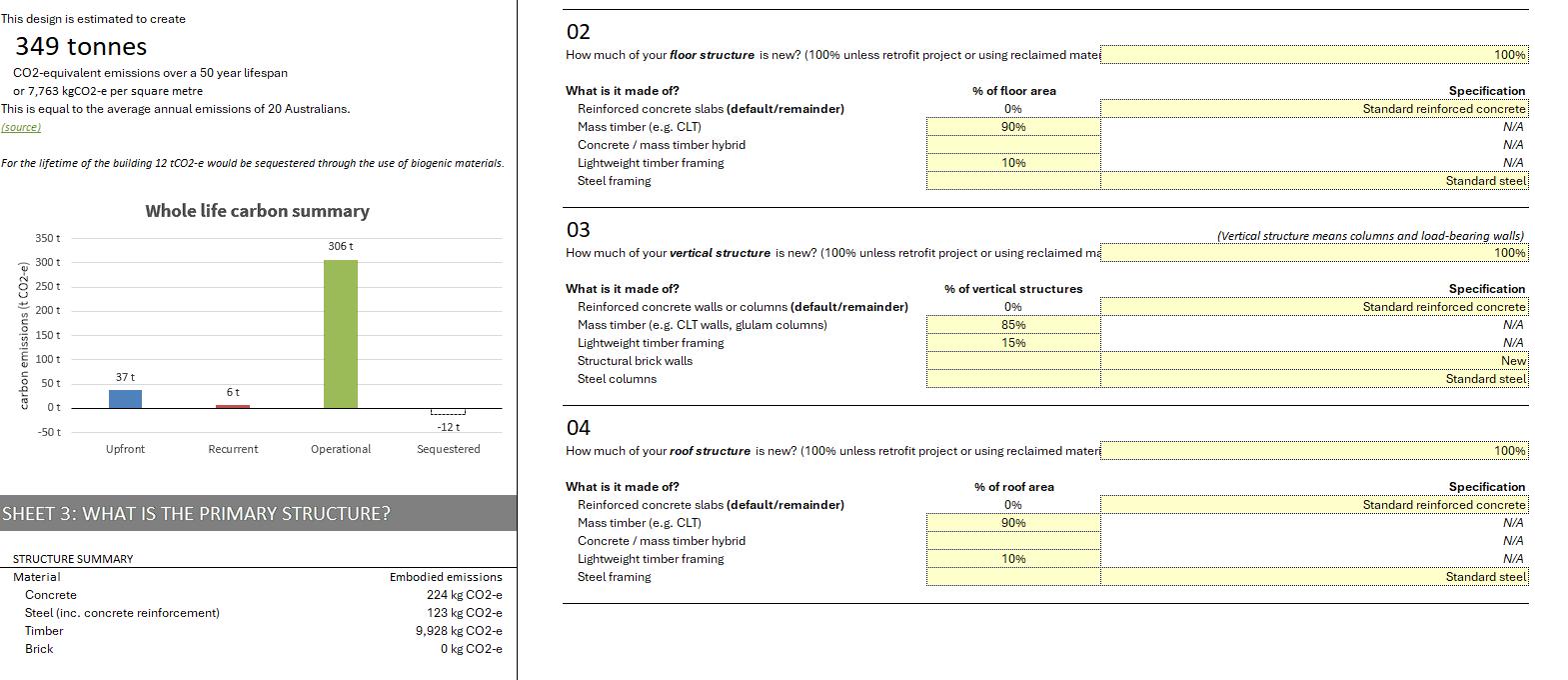

Light

needs more interior and

Mass Timber Structure (CLT &

GLT)

wight timber structure

exterior finishes Higher Upfront carbon due to use of steel and need interior and exterior finishes.

Higher Upfront carbon due to use of steel and need interior and exterior finishes.

Steel Structure

RESEARCH & ANALYSIS

Lightwight Timber Structure

Mass Timber Structure (CLT & GLT)

Without Solar Panel

Lightwight Timber Structure

With

Without Solar Panel IMPLEMENTATION

With 12 Solar Panel

12 Solar Panel

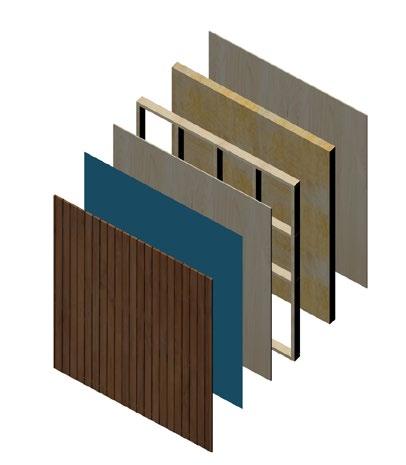

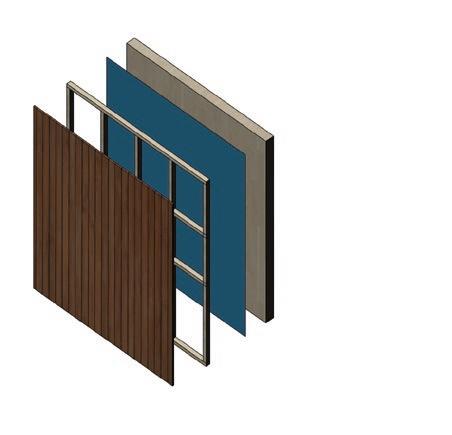

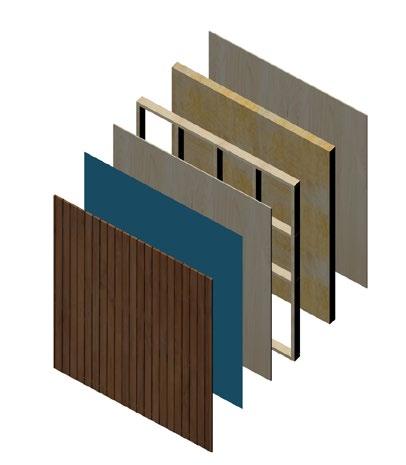

EPIC GRASSHOPPER

+ TIMBER CLADDING

+INSULATION + TIMBER CLADDING

Studio E-07 Backyard Futures: Movable Homes Studio Research Journal By Dristi Chakma | 1420680 29 28

CLT

CLT

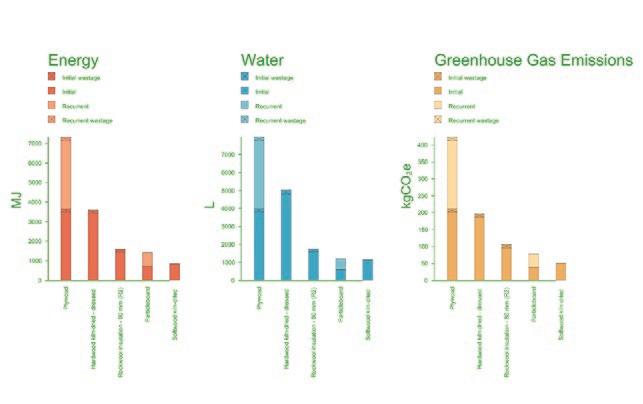

GHG Total 850 kgCO2e STEEL Structure GHG Total : 4000 kgCO2e TIMBER Structure GHG Total 1000 kgCO2e GHG Total : 1000 kgCO2e GHG Total : 650 kgCO2e GHG Total : 550 kgCO2e

VS STEEL CLT TIMBER CLADDING CLT

TIMBER

GHG Total 850 kgCO2e STEEL Structure GHG Total : 4000 kgCO2 Total kgCO2e GHG Total 1000 kgCO2e GHG Total 650 kgCO2e kgCO2e GLULAM VS STEEL RESEARCH & ANALYSIS CLT

TIMBER CLADDING CLT +INSULATION

TIMBER CLADDING STUD WALL+INSULATION

TIMBER CLADDING GHG Total : 850 kgCO2e STEEL Structure GHG Total 4000 kgCO2e TIMBER Structure GHG Total : kgCO2e GHG Total : kgCO2e GHG Total : 650 kgCO2e GHG Total : 550 kgCO2e STUD WALL+INSULATION

CLADDING GLULAM VS STEEL

GLULAM

+INSULATION +

CLADDING

+

+

+

+ FIBRE CEMENT

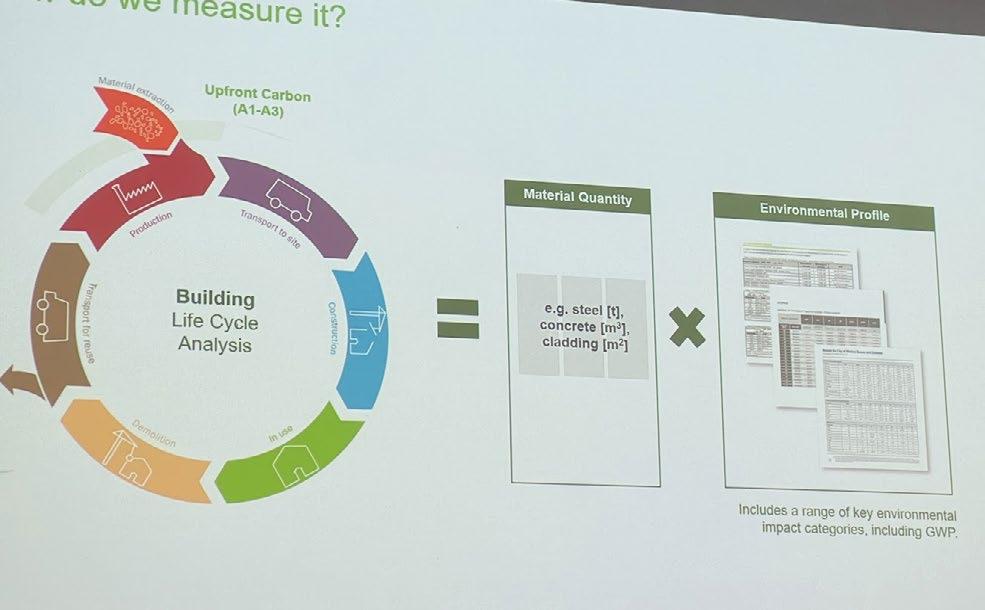

Without Solar Panel

No of solar Panel : 0

Solar Angle: 0

Orientation: Operational Carbon: 306t

Solar Panel (North-West)

No of solar Panel : 11

Solar Angle: 30

Orientation: North-West Operational Carbon: -15t

Solar Panel (South-East)

No of solar Panel : 13

Solar Angle: 10

Orientation: South-East Operational Carbon: -14t

Solar Panel (North-Wast)

No of solar Panel : 4

Solar Angle: 10

Orientation: South-East

Solar Panel (North-Wast)

No of solar Panel : 8

Solar Angle: 30

Orientation: North-West Operational Carbon: -15t

Total Kwh =12x440W= 5Kwh

Reduced Opertional Carbon 320tonnes

31 Studio E-07 Backyard Futures: Movable Homes Studio 30 Research Journal By Dristi Chakma | 1420680 RESEARCH & ANALYSIS Solar Panel No and Orientation

IMPLEMENTATION

Studio E-07 Backyard Futures: Movable Homes Studio Research Journal By Dristi Chakma | 1420680 33 32 IDEA GENERATION

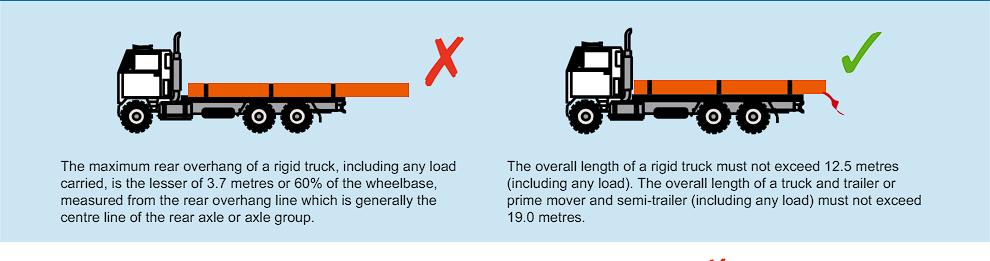

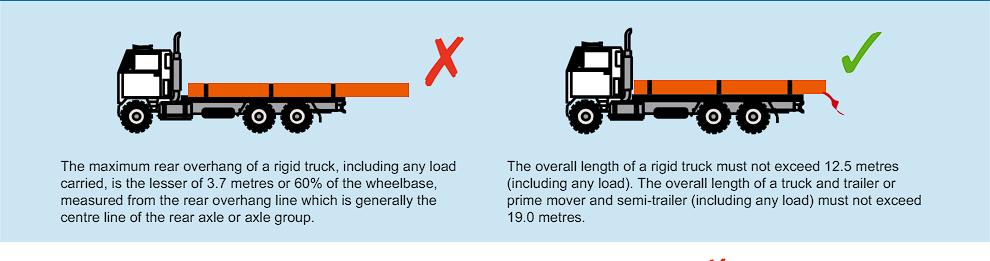

35 Studio E-07 Backyard Futures: Movable Homes Studio 34 Research Journal By Dristi Chakma | 1420680 Crane Use and Movable Unit / Plug-and-Play Studio 7 - Category 1 Jesse 694973 Unit modules all optimized to fit the 2.5m truck width Additional Cost for portal to portal rental needed 10 Tonne Hino Tray, Smaller crane allows for cheaper cost while still allowing easy installation 18 Tonne Franna Crane, All terrain crane with moderate lift height over fences and obstacles 50 Tonne Hydrolic Lift Crane, Largest type of crane, for lift over any obstacles (such as powerlines) with lift height of 40m IMPLEMENTATION RESEARCH & ANALYSIS

37 ADDITIONAL RESEARCH

Suburban Site

Address: 17 CAMPASPE CRESCENT, KEILOR 3036

Local Government Area (Council): BRIMBANK

Planning Scheme: Brimbank

Site Features and Constrain

The backyard of the existing house is has a slope of 2m from the road level.

A significant constrain for the site is accessibility having 60m long plot with only one sided access road.

80T CRANE is suggested to assure maximum reach of 52m.

Site Overlays

Development Contributions Plan Overlay

Design and Development Overlay

Aboriginal Heritage Overlay

• Low impact Building

• Touching the ground Lightly

• No harm on existing vegetation

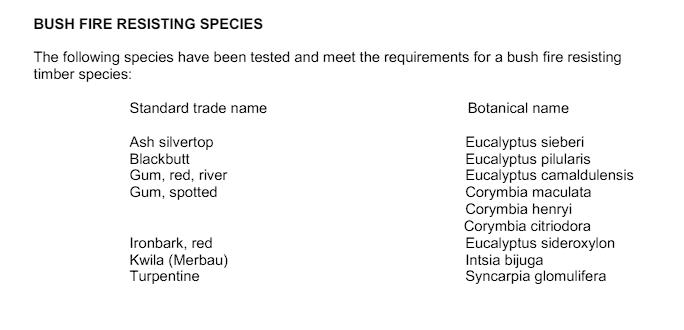

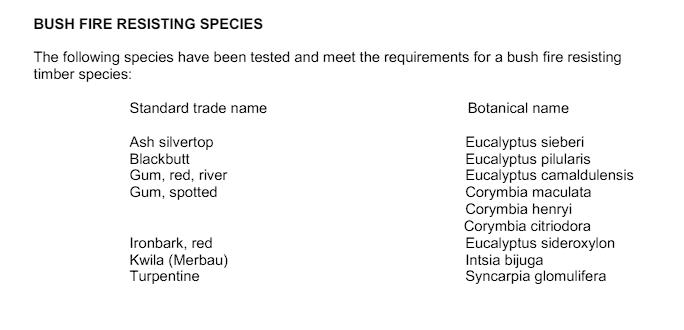

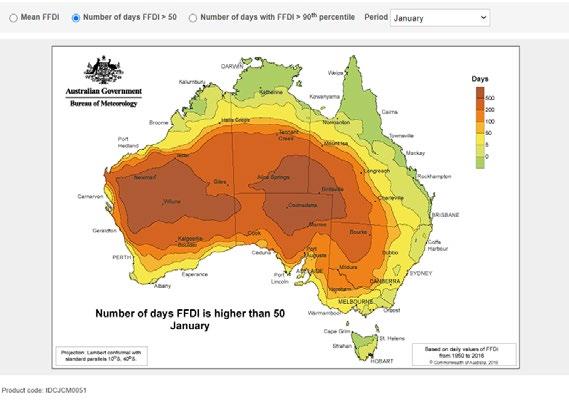

Bush fire Overlay

• Provision for Fire rated material

• Fire Rated Timber (Silvertop Ash BAL rating of 29 )

• Fire Rated Glass

• Fire-resistant Insulation (Mineral wool)

Airport Overlay

• Noise attenuation Measure

• Double Layer Glass

• Insulated wall

CampaspeCres Studio E-07 Backyard Futures: Movable Homes Studio Research Journal By Dristi Chakma | 1420680 39 38 CONCEPT SITING SITE SELECTION

Site B : Suburban

Address: 17 CAMPASPE CRESCENT, KEILOR 3036

Local Government Area (Council): BRIMBANK

Planning Scheme: Brimbank

Site Features and Constrain

The backyard of the existing house has a slope of 2m from the road level. A signi cant constrain for the site is accessibility having 60m long plot with only one sided access road. 80T CRANE is suggested to assure maximum reach of 52m.

1. Development Contributions Plan Overlay

2. Design and Development Overlay

3. Aboriginal Heritage Overlay

a. Low impact Building

B : Suburban

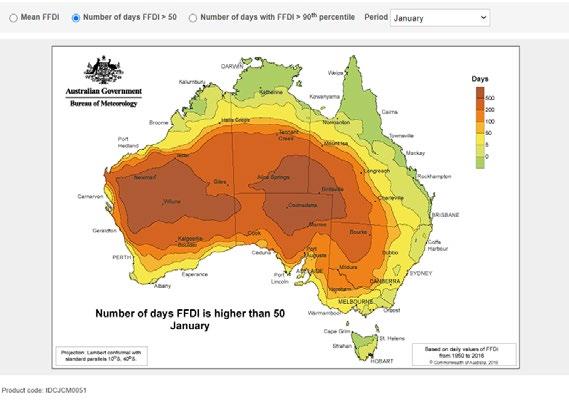

Bushfire Attack level Calculator

https://best-practices-assessment-tool.herokuapp.com/calculator?slope=-10&vegslope=-30&FFDI=100&vegtype=Rainforest

https://mybuildingcertifier.com.au/forms/MBC-BAL-29-Summary.pdf

https://www.bushfiredesignconsultants.com.au/bal-29

https://ash.com.au/blog/specifying-ironash-timber-cladding-in-bal-29-bal-40-and-balfz-rated-fire-areas/

b. Touching the ground Lightly

c. No harm on existing vegetation

4. Bush fire Overlay

Address: 17 CAMPASPE CRESCENT, KEILOR 3036

a. Provision for Fire rated material

Local Government Area (Council): BRIMBANK

b. Fire Rated Timber (Silver top Ash BAL rating of 29)

c. Fire Rated Glass (AS 1530 compliance, FRL of -120/120.)

Planning Scheme: Brimbank

d. Fire-resistant Insulation (Mineral wool)

Site Features and Constrain

5. Melbourne Airport Environs Overlay

a. Noise attenuation Measure

b. Double Layer Glass

c. Insulated wall

The backyard of the existing house has a slope of 2m from the road level. A signi cant constrain for the site is accessibility having 60m long plot with only one sided access road. 80T CRANE is suggested to assure maximum reach of 52m.

1. Development Contributions Plan Overlay

2. Design and Development Overlay

3. Aboriginal Heritage Overlay

a. Low impact Building

b. Touching the ground Lightly

c. No harm on existing vegetation

4. Bush fire Overlay

a. Provision for Fire rated material

b. Fire Rated Timber (Silver top Ash BAL rating of 29)

c. Fire Rated Glass (AS 1530 compliance, FRL of -120/120.)

d. Fire-resistant Insulation (Mineral wool)

5. Melbourne Airport Environs Overlay

a. Noise attenuation Measure

b. Double Layer Glass

c. Insulated wall

41 Studio E-07 Backyard Futures: Movable Homes Studio 40 Research Journal By Dristi Chakma | 1420680

RESEARCH & ANALYSIS

Unit / Plug-and-Play Site B_ Overlays and Features -1m -2m -3m -4m -5m -6m -7m -8m -9m -10m

Construction Standards to Comply with AS3959:2018 (Construction of building in bushfire-prone areas) for Bushfire Attack Level (BAL) - 29 (High) Construction Standards to Comply with AS3959:2018

(Construction

of building in bushfire-prone areas) for Bushfire Attack Level (BAL) - 29 (High)

Iron Ash Timber Cladding

Site

CampaspeCres

Studio 7 - Category 1 -1m -2m -3m -4m -5m -6m -7m -8m -9m -10m 5m 10m 20m 0

IMPLEMENTATION

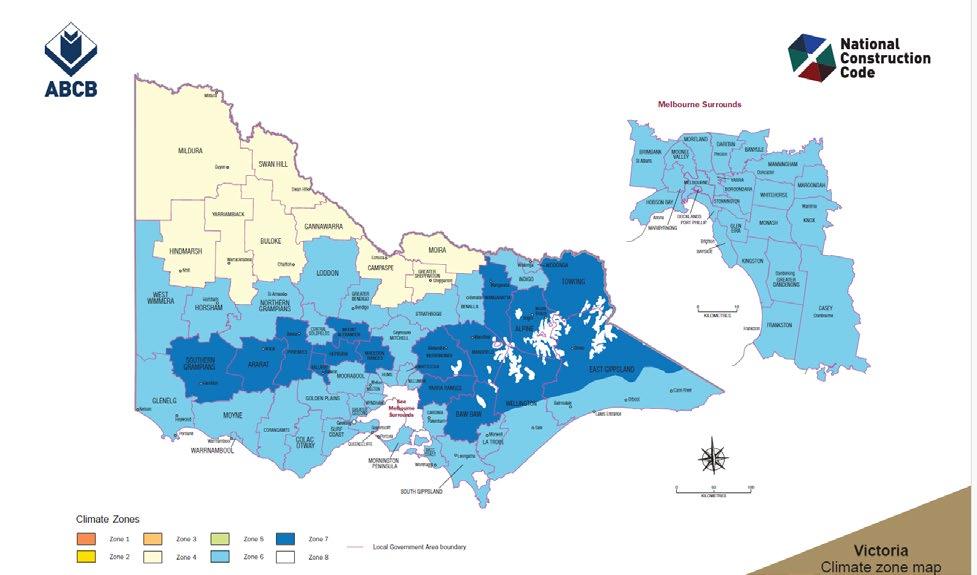

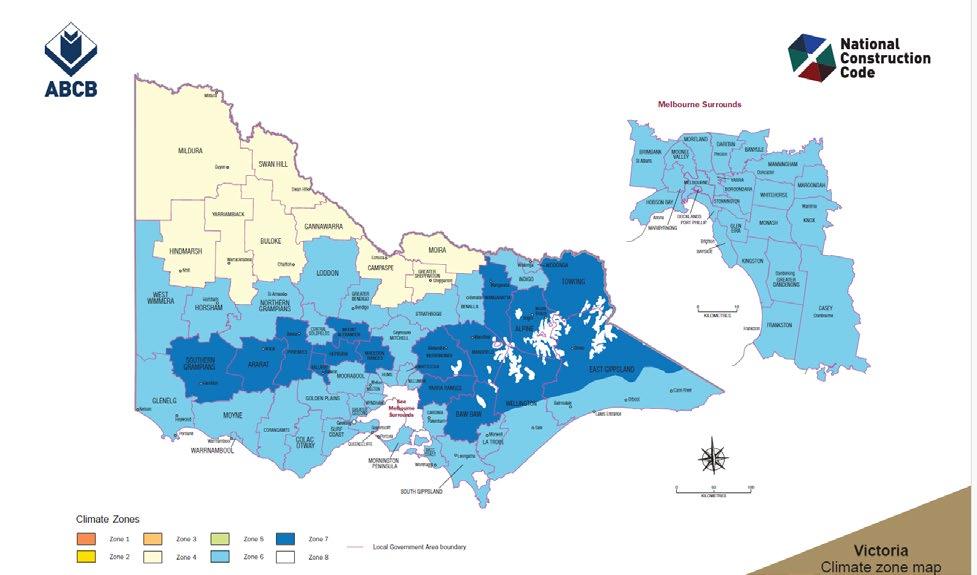

43 Studio E-07 Backyard Futures: Movable Homes Studio 42 Research Journal By Dristi Chakma | 1420680 Climatic zone

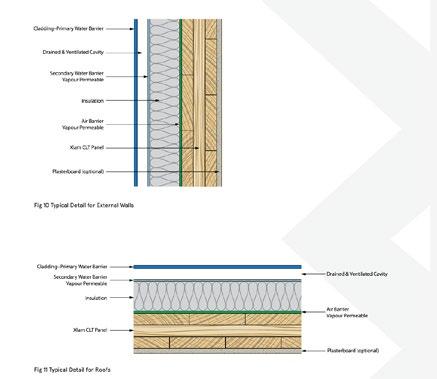

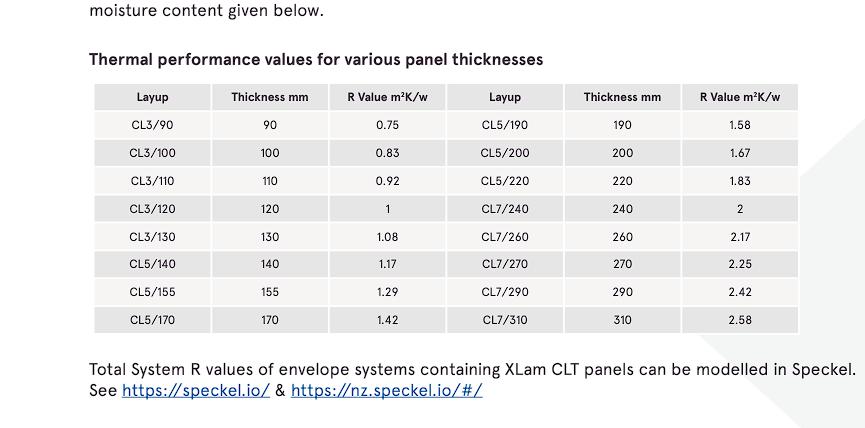

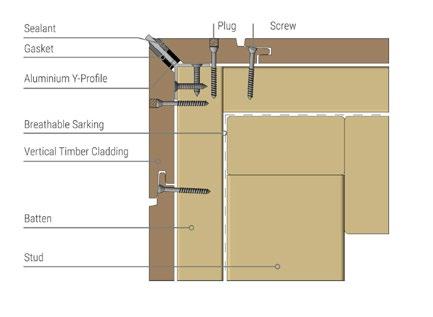

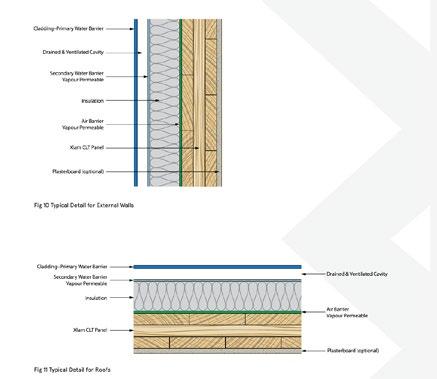

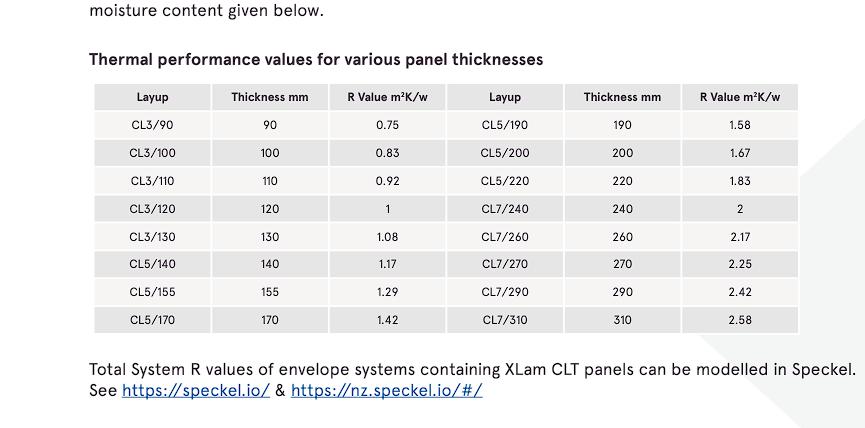

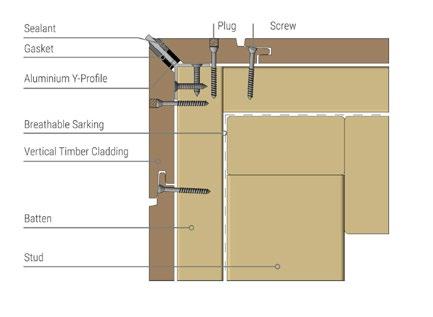

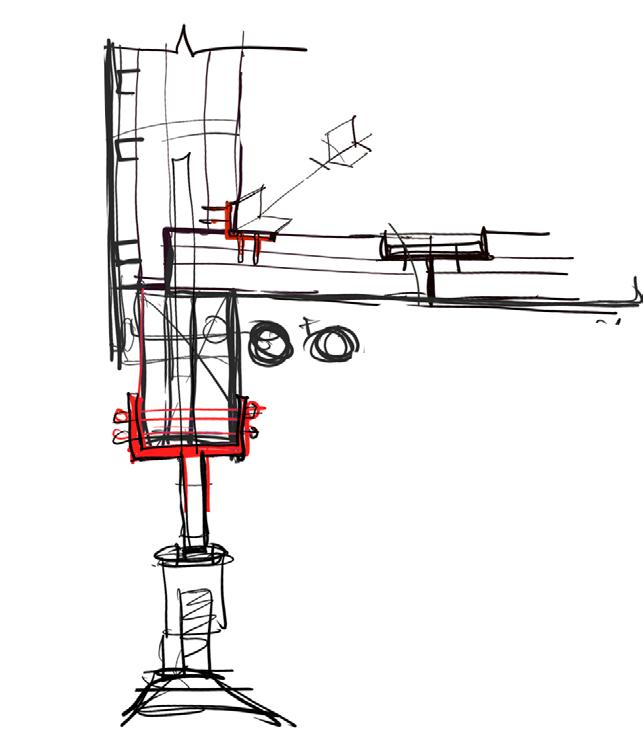

Required R Value 190mm insulation 90mm CLT (3 layer) 22mmTimber Fibre Sheathing Colorbond Enseam - 265mm Metal sheet cover .55 bmt Bracket to hold Module Floor and Wall M8 x 50mm Theraded Bolt with plate to attach Module with Main Frame GLT Beam 120mm x 400mm 90mm CLT wall 190mm Insulation 35mm x70mm Timber Std 40mmx 190mm Timber Stud 5mm Rubber Gasket 90mmm CLT 3 Layer 90mmm Insulation 18mm Fire Proteced Board 45mmx 90mm Timber Stud 400mm x200mm Galvanized Steel Plate 120mm x400mm Glulam Beam 90mm Rockwool Insulation 45x90mm Timber Stud Threaded Insert Bolt with plate to join Floor and Wall Roof R Value: 5.97 19mm Colorbond Housewrap Membrane 18mm Sheathing Board .22 190mm Insulation R5.0 90mm CLT9 (3 Layer) .75 Wall R Value: 2.85 19mm Timber Cladding House Wrap Membrane 75mm Insulation 2.1 90mm CLT9 (3 Layer) .75 Floor R Value: 3.25 90mm CLT9 (3 Layer) .75 90mm Insulation 2.5 22mm Boardex Bal-Bushfire System IMPLEMENTATION

and

45 Studio E-07 Backyard Futures: Movable Homes Studio 44 Research Journal By Dristi Chakma | 1420680 RESEARCH & ANALYSIS

Construction system of DimesionX CLT Construction

system of DimesionX CLT Construction Placement of insulation at outside provide better Insulation.

has been choosen for my project Insulatted CLT Timber Panel 90mm NeXTimber NX3 CLT Panel FRL 90/90/90 KITCHEN MODULE TOILET MODULE MAIN MODULE Click-in Cladding System 75mm Rockwool Insulation GLT Column 120mm 300mm Timber Stud 70mmx35mm Waterproof membrane BOLTS – M6 100mm – GRADE 8.8 Champion Parts Steel Screw M-Common Wood NailSide Penny Steel Bracket 5mm Rubber Gasket CONCEALED FLUSH VALVE CLT Wall system utilising Glulam insulated Panel for column and CLt 90mm for wall. Module Joint using threaded bolt and plate inspired from dimension X. CLT Wall system IMPLEMENTATION

Dimension x Prefabricated House

Understaing

Understaing Construction

CL3/90

https://www.schneider-holz.com/en/products/timber/open-box-element/clt-box-roof/

47 Studio E-07 Backyard Futures: Movable Homes Studio 46 Research Journal By Dristi Chakma | 1420680

Heat Loss due without Membrane

RESEARCH & ANALYSIS IMPLEMENTATION

Installion of Floor Membrane

49 Cost Analysis

51 Studio E-07 Backyard Futures: Movable Homes Studio 50 Research Journal By Dristi Chakma | 1420680 Type pcsmm2m3Unit priceTotal PriceDescription CLT Floor 3.19$2,150.00 $6,858.50 Decking 23.09 $122.22 $2,822.06 Gum KD Decking - Linear Metre Floor Sheathing 30.14 $14.58 $439.44 1200mm H2 Non-Structural Panelling Total$10,120.00 CLT 60mm 1.05$2,150.00 $2,257.50 CLT 90mm 918.19$2,150.00$17,608.50 Insulation 75mm 86 $94.77 $8,150.22 Paroc Rockwool R2.1 80kg 75mm 600×1000 5pk (3m2) Cladding 86 $94.20 $8,101.20 Grey Gum Shiplap Cladding 95 x 19mm(BAL 12.5-19) Membrane 86 $1.50 $129.00 Ametalin 1350mm x 60m SilverWrap MD Reflective Wall Insulation - 60m Stud wall 70x35 264 $4.25 $1,122.00 70 x 35mm Framing MGP10 Untreated Pine 3.0m 344.4 $4.35 $1,498.33 Total$38,866.75 Window 9.9 $695.00 $6,880.50 Door 2 $900.00 $1,800.00 Total $8,680.50 Column 1.31 Glulam L Timber Stud 38x89 101 $8.06 $814.06 90 x 45mm Outdoor Framing H3 Treated Pine - 2.4m Timber Stud 190x45mm 180 $15.16 $2,728.80 190 x 45mm Outdoor Framing H3 Treated Pine 6.0m Glulam Beam 120x400 3.29$660.00 $2,171.40 366 x 80mm Beam GL13 H3 Pine Glulam B Grade 2.4m Total $5,714.26 CLT Roof 90mm 443.96$2,150.00 $8,514.00 Insulation 190mm 44 $171.00 $7,524.00 Roof Sheating board 22mm 49 $33.00 $1,617.00 Zincalume roof 70 $86.00 $6,020.00 COLORBOND® Enseam 265 cover x 38mm high (4m) Gutter 12 $15.00 $180.00 Total$23,855.00 Base Footings 14 $400.00 $5,600.00 Join Round plate 24 $50.00 $1,200.00 Join plate square 200 $20.00 $4,000.00 Total$10,800.00 Total $98,036.51 Add 25% $24,509.13Installation+ Manufacture $2,800.00 Trasnportation Crane Rent+ Site Installation $12,534.56 GST 10% Grand Total $137,880.20 Roof Other Structure Door Window Wall Floor Cost Analysis Approximate Price for 1Movable Unit (60sqm) $$5,000 $10,000 $15,000 $20,000 $25,000 $30,000 $35,000 $40,000 $45,000 Overall Cost

53

Physical Model

Studio E-07 Backyard Futures: Movable Homes Studio Research Journal By Dristi Chakma | 1420680 55 54

Detail

3d Printed

MDF Board Laser

1:10 Scale

Model

Model (HP Multijet Fusion) 1:50 Scale Model

Cut