ELEMENT5’S TEAM

OF MASS TIMBER PROFESSIONALS

IS A LEADER IN SUSTAINABLE OFF-SITE-MANUFACTURED WOOD CONSTRUCTION

Element5 is an off-site mass timber manufacturer and service provider committed to making a positive contribution to the environment, communities, and future generations. We use sustainably sourced lumber to produce high-quality cross laminated timber (CLT), Glulam and other engineered products to improve the comfort, quality, and sustainability of the built environment.

WELCOME TO ELEMENT5!

Fabrication Excellence

Our 137,000-square-foot, highly automated mass timber manufacturing facility in St. Thomas, Ontario, Canada, produces up to 50,000 cubic meters of high-quality CLT and Glulam per year to exacting standards. We manufacture glulam and edge-glued CLT panels up to 3.4m (11.1’) wide, 380mm (15”) thick, and 15.8m (51.8’) long to a tolerance of +/3mm (1/8”). Our wide CLT panels allow greater design flexibility, reduce the number of “picks” on-site, speed assembly, and therefore reduce the cost of construction.

Professional Servicies

We provide services either in-house or via our network of third-party experienced mass timber service providers as a single-point solution for the design, engineering, supply, and construction of mass timber projects. In-house experts in modern timber construction, provide Cost Consulting, Design Consulting, Timber Engineering, 3D & Building Information Modelling (BIM), Shop Drawings, and Assembly Assistance services.

Industry Leadership and Innovation

As leaders of change and innovation in the construction industry, we also manufacture complementary engineered products including prefabricated envelope Cross-Laminated Insulated Panels (CLIPs) to quickly enclose buildings, Boxx Panels (Hollow Core CLT Floor Cassettes) to span long distances cost-effectively against concrete or steel alternatives, and Ribbed Panels that bond CLT panels and Glulam beams for use as floors and roofs to speed construction.

Commitment to the Environment, Communities, and Future Generations

We are a team of approximately

100 highly educated, skilled, and experienced mass timber professionals who share a common purpose - to change the way in which buildings are designed and constructed to make a positive contribution to the environment, communities, and future generations. We take pride in using Ontario Forest Stewardship Council® (FSC®) lumber in our sustainable, high-performance wood buildings, and are proud recipients of a Forest Stewardship Council Leadership Award for uncommon excellence in responsible forest management and conservation.

Element5 Introduction

01

ABOUT US

The

The Conditioning Klin is used to bring the lumber to the required moisture content. After 3 days, the

MANUFACTURING

The panel is loaded into the X-PRESS. Overhead airbags apply with a pressure up to 110 PSI

The end of the line is for value-add, handwork, storage, and loading for shipping.

1. Bulk shipments of spruce-pine-fir 2x6 lumber are delivered

2. Lumber is sorted based on structural grade and visual quality

wood is brought back into the factory.

4. A vacuum lift pulls a

5. Operators trim the knots at the end of the boards.

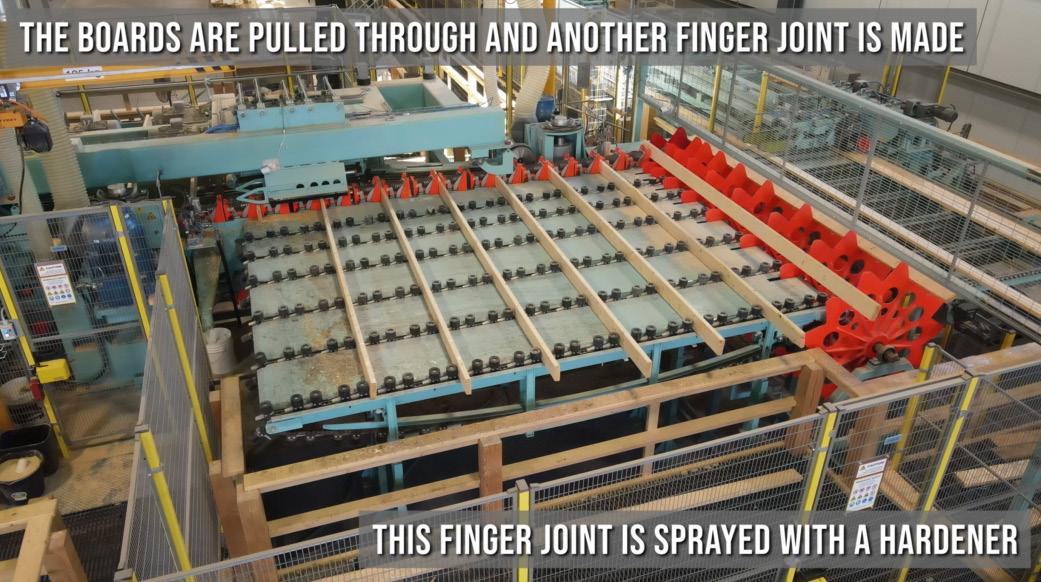

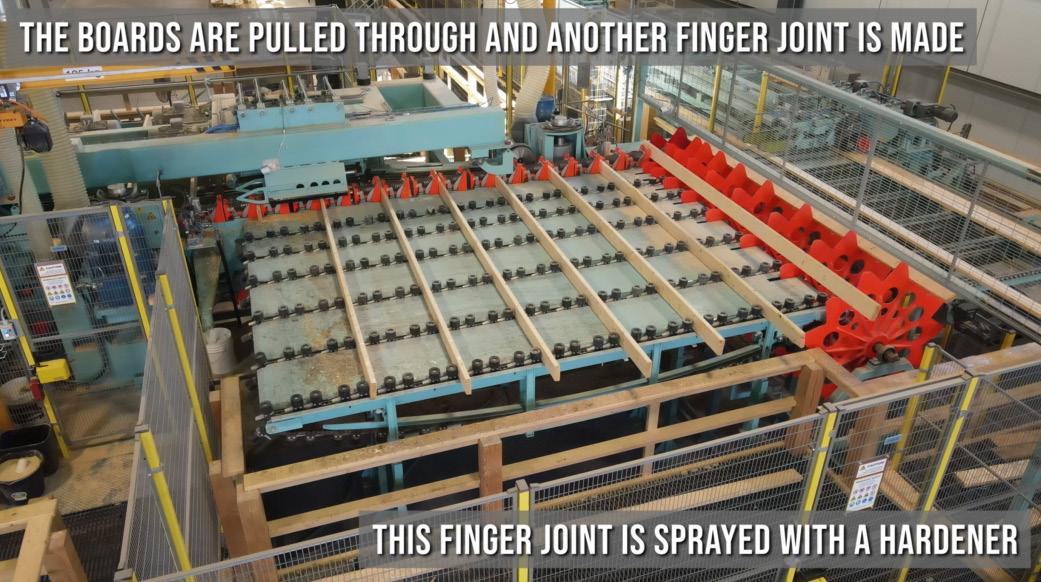

boards are pulled through and another finger joint is made and sprayed with a hardener.

8. This two-part epoxy is forced together via a 50-tonne press. The flying saw speeds up to match the board and cuts it at the desired length.

9. Boards are grouped into layers and separated in the cure zone.

10. Each board is planed to allow for

Advanced Mass Timber Manufacturing, St. Thomas, Ontario.

11. Longitudinal and transverse layers are glued. (3,5,7, or 9 layes)

13. The sander uses an 80-100 grit belt to achive a clean wood finish.

14. The panels are loaded into a 5-axis CNC machine. A variety of tools cut the panel to size and add penetrations.

2-minute Factory Tour

1. Bulk shipments of spruce-pine-fir 2x6 lumber are delivered

2. Lumber is sorted based on structural grade and visual quality

wood is brought back into the factory.

4. A vacuum lift pulls a

5. Operators trim the knots at the end of the boards.

boards are pulled through and another finger joint is made and sprayed with a hardener.

8. This two-part epoxy is forced together via a 50-tonne press. The flying saw speeds up to match the board and cuts it at the desired length.

9. Boards are grouped into layers and separated in the cure zone.

10. Each board is planed to allow for

Advanced Mass Timber Manufacturing, St. Thomas, Ontario.

11. Longitudinal and transverse layers are glued. (3,5,7, or 9 layes)

13. The sander uses an 80-100 grit belt to achive a clean wood finish.

14. The panels are loaded into a 5-axis CNC machine. A variety of tools cut the panel to size and add penetrations.

2-minute Factory Tour

Today’s construction sector is experiencing increasing complexity, shrinking profit margins, labour shortages, disruptions in the supply chain, and low productivity. Couple that with the climate crisis and the need to make construction less carbon-intensive and it’s clear that the construction industry needs transformative solutions.

Prefabricated mass timber construction, where buildings are manufactured and assembled instead of being strictly site-built, reduces a building’s environmental impact, helps reduce risk, improves quality, and shortens construction timelines, leading to a better overall return on investment.

WHY OFFSITE MANUFACTURING AND MASS TIMBER

Faster to Market

In a prefabricated mass timber project, the building components can be manufactured at the same time as the site and foundation work. Depending on the size and complexity of the manufactured components, this has the potential to considerably reduce a construction schedule.

Higher Return on Investment (ROI)

Time is money. Prefabricated, modular mass timber structures go up much faster than strictly site-built projects and a shorter timeline means, decreased carrying costs, quicker close-out, and faster occupancy. This streamlined construction approach increases overall project ROI.

Lower Risk

Mass timber building c omponents are prefabricated in a controlled indoor setting. It leads to improved worker safety, freedom from the negative impact of bad weather, and consistent, high-quality material. It reduces risk and significantly increases efficiency and quality, improving both scheduling and cost predictability.

Simplified Construction

The building industry today faces a growing scarcity of skilled labour. Prefabricated mass timber construction requires fewer material and labour resources, delivering buildings quickly and economically, while still offering exceptional performance and customization.

High Performance

The superior quality control of the factory means a site-assembled building performs better than a site-built one. Innovations like our CLIPs envelope products exceed the energy efficiency standards of the 2015 National Energy Code for Buildings and can be customized to achieve any standard, even Passive.

Healthy Research shows that the materials we use in construction contribute significantly to health and happiness. Incorporating wood, other natural materials and biophilic design principles in our buildings can have a significant, positive impact on occupant health and well-being.

PARADIGM SHIFT

Element5 Introduction 03

PROJECTS

In addition to the supply of mass timber components for the selection of projects shown below, Element5 provided or is contracted to provide Cost Consulting, Design Consulting, Timber Engineering, 3D Modelling, Shop Drawings and / or Assembly Assistance.

Element5 Introduction 04

1 Oakville Firehall

2 Golden Avenue

6 Passage House

7 Port Stanley Fire Station

8 Orillia Waterfront Centre

3 SOAHAC

2

4 YWKW 1

5 YWKW

9 Café Palmier 15 Code 440 17 Coda Detroit 21 Kalamazoo Country Club 22 Trinity College 23 Adelaide Point 24 Kresa School 18 Liberty Street 19 Heartland Veterinary 20 1650 Dupont 10 Bureau OHO 14 55 Franklin 13 TRCA 16 St. Thomas Daycare 11 Princeton University Hub 12 Martha’s Vineyard

PRODUCTS

Cross-Laminated Insulated Panels (CLIPs)

Cross-laminated timber (CLT)

Multi-layer solid wood panels used for floors, walls, and roofs. Our CLT is made from sustainably sourced Ontario wood.

Glulam

Glulam has been used in North America for nearly a century in a range of applications including columns, beams, rafters, purlins, braces and even decking.

Prefabricated CLIPs are a cost-effective, complete building envelope solution made from CLT.

BOXX Panels

Boxx panels are hollow core floor and roof cassettes that offer a materially efficient way to achive long clear spans in the multi-storey buildings.

nanoCLT

nanoCross-laminated timber

nanoCLT is a natural, sustainable and versatile wood panel product that can be used in many creative applications.

Element5 Introduction 06

Element5 provides services either in-house or via our network of third-party experienced mass timber service providers as a single-point solution for the design, engineering, supply, and construction of mass timber projects. Our In-house Services Team of 26, provides Cost Consulting, Design Consulting, Timber Engineering, 3D and BIM Modelling, Shop Drawings, and Assembly Assistance.

Cost Consulting

We rely on 3D Building Information Modeling (BIM), parametric design tools and integrated cost databases to develop fast, accurate and reliable construction budgets. Cost estimates include line items of materials, connections, timber engineering, shipping, assembly assistance and schedules to make it easy for customers to compare mass timber against other forms of construction, decide whether mass timber is within budgets, and make informed decisions.

Fabrication

Off-site manufactured buildings are assembled rather than constructed on-site, which is beneficial in many ways. We produce high-quality edge-glued CLT, Glulam, and other engineered wood products to exacting standards in our state-of-the-art, highly automated, 137,000-square-foot mass timber manufacturing facility using Ontario-sourced FSC (Forest Stewardship Certified) raw materials. We have the capacity to produce 50,000 cubic meters of CLT and Glulam per year, or in relative terms, approximately 20, 20-storey buildings per year. From St. Thomas, Ontario we serve largely the central and eastern half of both Canada and the United States.

Assembly Assistance

We deliver internationally, optimizing flatbed or container shipments for timely delivery. Parts are packaged in the order of assembly and are protected with weather-resistant transport tarps. We have extensive experience working with independent, third-party install crews which, when hired, are mass timber-experienced and ensure safe, quick, and organized assemblies. Alternatively, on-site supervisory services or detailed assembly plans are available for an owner’s own crew.

Design Consulting

We work with Owners and Developers, Architects, Engineers, General Contractors, and others at any stage of the design process, from conceptual design to working drawings to provide mass timber design guidance. Our team of in-house Architects, Engineers, Designers, Detailers, and 3D and BIM modellers works alongside customers to help optimize the design of their building, taking into consideration factors such as grid pattern, connections, mechanical integration, shipping, site constraints, and constructability to reduce cost and speed construction.

Timber Engineering

Engineering is the key to a safe, practical, and cost-effective mass timber project. Mass timber buildings can cost less than more conventional buildings, particularly when designed in mass timber at an early stage. To reduce the cost of a mass timber project, our engineers work with customers to achieve the perfect balance of aesthetic preference, space requirement, building code, building performance, fire and acoustic performance, member sizes, connections, mechanical system integration, constructability, shipping and/or site constraints. Services offered include stamped shop drawings and site supervision.

Element5 Introduction 07 SERVICES

AFFORDABLE HOUSING

We believe that part of the solution to the affordable housing crisis involves industrializing the supply of multi-unit residential buildings in the form of off-the-shelf, repeatable though modifiable, kits-of-parts. We set out two years ago to design and optimate a mass timber structural solution targeted at the affordable housing sector and since then, we’re proud to say, three of our supportive housing projects are occupied.

The following images are a collage of three of Element5’s Sustainable Affordable Housing Solution Profile projects. Two of the buildings are for the YWCA in Kitchener and one is for the Regional Municipality of York, both in Ontario Canada. The first building was designed as one-bedroom units for single women, the second building as two-bedroom units for single women with children, and the third, called Passage House, for single men at risk of homelessness.

Element5 Introduction 08

2-minute, 20 Day Install Video

BUILDING PROFILES

We believe that certain types of buildings in the future will be constructed using prefabricated, off-the-shelf though modifiable mass timber kits-of-parts. Element5 developed its first Building Profile targeted at the affordable housing sector. Based on the success of Element5’s Sustainable Affordable Housing Solution, we customized our structural solution to the needs of other market sectors.

The following Building Profiles are adaptations of our multi-unit structural model targeting Market Rate, Retirement Living, Student Residence, and Affordable Housing sectors.

Our building profiles have proven to be cost effective, quick to construct, and are healthy for occupants and the environment.

Element5 Introduction Retirement Living Student Residence Market Rate Affordable Housing 09

HEALTHY PEOPLE, HEALTHY PLANET

Substituting conventional building materials for mass timber reduces construction C02 emissions by 69%. Mass timber used in half of the expected new urban construction could provide as much as 9% of global emissions reductions needed to meet 2030 targets for keeping global warming below 1.5 °C (i).

Research shows that the materials we use in construction contribute significantly to health and happiness. Incorporating wood, other natural materials, and biophilic design principles into buildings can have a significant positive impact on occupant health and well-being including mental stimuli, energy, physical comfort levels, cognitive ability, attention, and memory. (ii)

GRADUAL RELEASE

CARBON ABSORBED CO₂

Growing forests absorb carbon dioxide and release oxygen

OXYGEN RELEASED O₂

Natural regeneration and planting begin the cycle

Carbon storage plateaus in older forests and can slowly be released as trees decay or burn Wood buildings store carbon and it remains stored over the lifetime of the building

Harvesting for wood products ensures that carbon continues to be stored

Element5 Introduction 10

CO₂

(i)Austin

GreenWood Resources, Inc., United States, respectively. Published by Elsevier Ltd, 4 October 2020. (ii)Liz O’Brien, Richard

“Forest School and its impacts on your children: Case studies in Britain”, Urban Forestry & Urban Greening, Published by Elsevier GmbH, 15 November 2007.

Himes, Gwen Busby, “Wood Buildings as a Climate Solution”. Mississippi State University, Department of Forestry, United States, and

Murray,

YOU FOR YOUR INTEREST IN ELEMENT5

We welcome the opportunity to answer any questions you may have about our products, services, or the design and development of mass timber projects.

Please join us in our effort to make a positive contribution to the environment and vibrant, sustainable communities.

CONTACT US TODAY Patrick Chouinard VP Market Strategy & Corporate Communications 1-705-801-8041 patrick@elementfive.co www.elementfive.co Element5 Introduction 11

THANK

1. Bulk shipments of spruce-pine-fir 2x6 lumber are delivered

2. Lumber is sorted based on structural grade and visual quality

wood is brought back into the factory.

4. A vacuum lift pulls a

5. Operators trim the knots at the end of the boards.

boards are pulled through and another finger joint is made and sprayed with a hardener.

8. This two-part epoxy is forced together via a 50-tonne press. The flying saw speeds up to match the board and cuts it at the desired length.

9. Boards are grouped into layers and separated in the cure zone.

10. Each board is planed to allow for

Advanced Mass Timber Manufacturing, St. Thomas, Ontario.

11. Longitudinal and transverse layers are glued. (3,5,7, or 9 layes)

13. The sander uses an 80-100 grit belt to achive a clean wood finish.

14. The panels are loaded into a 5-axis CNC machine. A variety of tools cut the panel to size and add penetrations.

2-minute Factory Tour

1. Bulk shipments of spruce-pine-fir 2x6 lumber are delivered

2. Lumber is sorted based on structural grade and visual quality

wood is brought back into the factory.

4. A vacuum lift pulls a

5. Operators trim the knots at the end of the boards.

boards are pulled through and another finger joint is made and sprayed with a hardener.

8. This two-part epoxy is forced together via a 50-tonne press. The flying saw speeds up to match the board and cuts it at the desired length.

9. Boards are grouped into layers and separated in the cure zone.

10. Each board is planed to allow for

Advanced Mass Timber Manufacturing, St. Thomas, Ontario.

11. Longitudinal and transverse layers are glued. (3,5,7, or 9 layes)

13. The sander uses an 80-100 grit belt to achive a clean wood finish.

14. The panels are loaded into a 5-axis CNC machine. A variety of tools cut the panel to size and add penetrations.

2-minute Factory Tour