Storage, Handling and Delivery Guidelines

•Element5 CLT panels and glulam members are shielded from moisture and debris with tarps while being transported.

•If panels or beams are kept on site, the storage space must be dry and have a sufficient bearing capacity to support the products.

•Element5 provides several delivery options depending on the project size, location, schedule and installation method.

• Just-in-Time (Sequenced) Delivery: CLT panels and glulam members arrive on the project site as needed for installation. Just-in-time delivery is Element5’s most common delivery method and minimizes the risk of damage.

• One-Time Shipment: All CLT panels and glulam members are shipped to a project site and stored prior to installation. Large staging spaces might be necessary, depending on the magnitude of the project.

•As specified by the design team, installers, and Element5, CLT can be transported in accordance with the phases of design and construction.

•Element5 CLT panels may be delivered to a project site using several transportation methods. The primary methods of shipping are by truck, rail, or by ship. Shipping plans are crucial to the overall success of the project as transportation modes and costs could dictate panel sizes used for design. Each state in the U.S has its own set of transportation rules and legislation. The state in which a project is located should be taken into consideration while developing the transportation system. Element5 will issue a Project Shipping Checklist that will gather the necessary information to define the shipping method for the project.

•If the mode of transport is by flatbed truck, then an overweight permit may be required from the Government of Ontario as well as any other permits from the provinces/states the route goes through.

•More information about these permits can be found here: https://www.ontario.ca/page/guide-oversizeoverweight-vehicles-and-loads https://www.ontario.ca/page/get-oversizeoverweight-permit

•Before unloading a shipment at the jobsite, thoroughly examine the condition of the materials delivered. Before accepting the delivery, note on the bill of lading any missing units, the types of damage, and the total number of units affected. Keep a record of the driver's comments, if any, on any unit damage.

•Element5 will not be held responsible for missing or damaged materials not reported within 24 hours of delivery.

•Element5 supplies products in either brand-new or nearly-new condition. CLT panels or glulam members that appear to be weakened or damaged must not be placed in the structure; instead, they should be taken out of service and inspected by a professional.

•Proper inspection of Element5 CLT panels should include, but not be limited to, looking for these common types of damage:

Cracks around Openings

Missing and/or Damaged Material

Cupping Exceeding ½”

Mold or Fungal Growth

•CLT and glulam are fabricated using dimensional lumber that is susceptible to swelling and shrinking due to variations in moisture content. Surface gaps may develop as wood shrinks, and internal stresses may result in surface and end checking. This phenomenon is part of the naturally occurring seasoning process of wood and typically has no effect on the structural performance of the Element5 CLT panels.

• It it the purchaser's responsibility to ensure the building site is suitable for a flat-bed trailer. The purchaser must ensure that the public roads leading to the construction site can accommodate a semi-trailer with a total length of approx. 80ft.

• The purchaser is responsible for arranging all offloading of product on-site, including any specialized equipment or personnel that are required. If Element5 is also engaged to install the product the liability of off-loading product goes to the subcontracted installer.

•By default, material is loaded onto trucks in reverse order, so that the first desired pick or item to be installed on site is placed at the bottom of the flatbed. This is done to facilitate immediate offloading of the material. Time allocated for offloading varies by carrier and can range from 1-3 hours. Depending on the carrier, additional charges may apply if the truck is not offloaded in the allocated time. Most carriers do not allow flatbeds to be dropped and left on site for extended periods of time and will apply additional charges if this is done. Any additional fees for dropping the flatbed for an extended period or if the flatbed is not off loaded in the allocated time are not the responsibility of Element5. In cases where it has been coordinated and agreed upon ahead of time to drop the flatbed for an extended period, material supplied by Element5 can be placed on the flatbed in the desired order of install.

• Panels can be unloaded flat or vertically depending on their orientation in the structure.

• Unloading and lifting may cause stress on panels that they were not designed for, especially around windows, doors, openings, or mechanical penetrations.

• Improper unloading methods can negatively impact the structural integrity of panels and cause irreparable damage.

• It is the responsibility of the installer and/or contractor to ensure that lifting equipment is adequately sized to safely handle the material delivered. Panel weight can be obtained by contacting Element5. Inadequately sized lifting equipment can result in panels being dropped, significant damage, and death.

• Protect the wood during unloading. The method and type of protection required depends on the equipment and machinery used for unloading.

• Never dump or drag panels off trucks or drop panels from heights.

•The contractor or installer is responsible for materials once delivered to site. Damage and/or loss is minimized by following proper handling and storage guidelines.

•All panels are wrapped in a 100% recyclable Lumber Wrap material.

• Lumber Wrap provides UV protection.

•The wrap is meant to be left on the panels until the panels are ready to be installed.

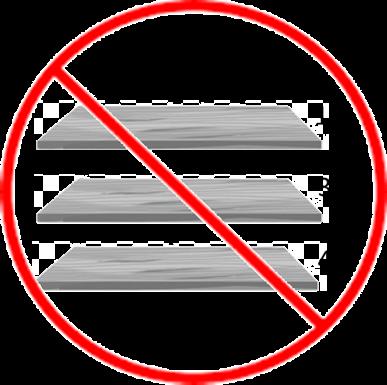

• To protect panels from rain, snow, sun, and mechanical damage, storage locations must be suitably elevated off the ground (6–12 inches). They should also be level and enable air to flow around the panels.

• To avoid fungus formation, the staging area must be clean, flat, with sufficient surface drainage and with enough airflow. Never store panels on the ground or in close proximity of standing water. Dunnage or blocking is included on the trucks to allow lifting and stable placement of the material on the flat beds. It is the recommended that this material be used to facilitate proper storage of the material to facilitate air flow between members and allow for picking of the material afterwards.

•It is the responsibility of the Contractor to dispose of any dunnage or sledge required for packing the CLT panels and glulam elements on the flatbed and at their own expense.

•Do not walk on unprotected panels or handle with soiled hands or equipment. Slit the tarping during storage and installation or puncture the wrapping by the bottom panel (when provided) to allow for drainage. Cover Element5 CLT panels units with moisture resistant material or canvas tarps as soon as possible.

• Avoid using plastic covers since they will lead to moisture buildup on the panel. Avoid using transparent covers since they can cause UV damage.

•Once installed, Element5 CLT panels and glulam members may remain exposed to environmental conditions for a period before the structure is “dried-in”. Tarp the installed panels as needed until the building is enclosed and the panels are covered to avoid damage from adverse weather.

•Protect any visually exposed faces when handling members.

•Use wide belts made of cloth, plastic, or other materials that won't damage or stain the wood. Provide protective blocking or cushioning to safeguard members from harm if chains or cables are utilized. Do not crush materials together when lifting by straps.

• Avoid walking on exposed CLT panels and glulam members, and refrain from handling the material with dirty hands or tools.

• Element 5 cannot be held responsible for rectifying any staining which occurs to material once the panels have arrived on site.

•Use lifting equipment to unload trucks and shift panels. Panels must not be dropped, dumped or dragged.

•It is the responsibility of the installer and/or contractor to ensure any lifting devices used to move material are adequate for the material delivered. It is recommended to contact a third-party engineer to design any lifting devices. Lifting devices are readily available from MTC (https://mtcsolutions.com/)

•Corner blocking should be used to prevent the corner edge from being crushed.

•Utilize a crane and proper rigging. It is the responsibility of the installer and/or contractor to ensure any cranes used to move material on site are adequate for the material delivered. It is recommended to contact a third-party engineer to review the capacity of any cranes used on site.

•Since Element5 CLT panels and glulam members are vulnerable to adverse weather, steps must be taken to always protect them.

•Rain and moisture will discolor Element5 CLT panels or glulam members if left uncovered.

•If rain or moisture does stain wood members during the installation, there are several ways or methods available to remove it. Remedial work to clean, repair, sand or remove stain from members once delivered to site is not Element5's responsibility.

•Use a belt or palm sander to sand stained areas. It is recommended to start with 60 or 80 grit sandpaper, complete an additional pass with 100-120 grit paper, and a final pass with 200-240 grit paper.

•Alternatively, there are solvents which can be applied on site using a power washer, although this option will potentially affect the moisture content, is considered messy, and can damage material. Contact an Element5 project manager for additional guidance.

• To prevent staining or discoloration, ensure that any bolts used with steel to wood connections or wood to concrete connections are oil-free. If the connection is to be exposed to the elements, galvanized or stainless-steel connectors are highly recommended.

• Uncovered and/or unprotected steel may rust, leach and stain Element5 CLT and glulam elements. Stains caused by steel which leaches onto wooden surfaces can be very difficult or impossible to remove without significant effort.

•“Sun tanning" may happen if a section of the panel has been exposed to the sun for an extended period. Sun tanning is the result of exposing wood fiber to sunlight. When wood fibers are exposed to direct or indirect sunlight, the coloration permanently changes. A rip in the wrapping or poorly covered materials may cause sunburn.

•Note that one or more coats of Sansin KP-12 UVW sealer can optionally be applied to Element5 products prior to shipping to site at an additional cost. (https://sansinfactoryfin-ish.com/products/undercoattreatment/kp-12/)

• To prevent abrupt changes in the moisture content of Element5 CLT panels and glulam members, care must be given throughout transportation, storage, and all phases of construction.

•Before applying any finishes to or encapsulating mass timber elements, it is recommended that moisture content be less than 15%.

•If a moisture barrier is to be applied around the exterior envelope of the building, it is recommended that a “smart” vapour barrier be used which breathes both ways. Moisture content in members varies by season. In dry seasons, moisture within each member must be allowed to escape. Smart vapour barriers help ensure this occurs.

•When applying heat to buildings, use the following procedures:

•Over the course of two to three weeks, gradually increase the heat in the building to normal temperatures. The slower the materials equalize to the moisture content of the air, the lower the likelihood of cracking, splitting, or checking. Do not forcibly increase or decrease the moisture content of members quickly.

•Control all heating systems while keeping in mind that hot air rises, and ceiling temperatures can reach 100 degrees F (37.8 degrees C) or more.

•Maintain the building's relative humidity at a typical level and monitor as needed.

•**Important** To help regulate change in moisture content, it is advised to apply a final coat of protective sealer to the Element5 CLT panels and glulam members before heating them.

For more information, contact:

1 888-670-7713

info@elementfive.co