9 minute read

Mining’s Green Hydrogen Consortium TACKLING HYDROGEN’S COST RIDDLE

For the past couple of years, no mining and energy event has been concluded without a mention of hydrogen. Though this isn’t exactly new technology — the first fuel cell was invented in 1839 — hydrogen has garnered renewed interest in recent years, thanks to its potential to decarbonize heavy industry. In mining, no other one technology can do what hydrogen could achieve: as an alternative fuel, it could displace diesel even on the heaviest vehicles, and for long-haul routes; as storage, it could hold excess renewable energy for longer than batteries, allowing for time-shifting; and as a processing element, it could replace coking coal and sulphuric acid.

Advertisement

Various organizations and governments around the world have taken note of this opportunity: Australia, for instance, wants to become a top exporter of hydrogen as an alternative fuel by 2030. To this end, it is supporting domestic initiatives to test different use cases and expand production capacity. And in 2017, the first large-scale industry collaboration was launched at Davos: the Hydrogen Council, formed of 60 multinational corporations with the same interest in accelerating the development of hydrogen technology.

But every praise for hydrogen’s tremendous decarbonization potential comes with the caveat that, at the current price, this technology is far from competitive. “In mining, there are three key areas where hydrogen can achieve decarbonization: baseload power, material movement, and ore reduction and processing,” explains Michel Carreau, Director of Hybrid Power and Microgrid at Hatch. “And in all three cases, green hydrogen is expensive. Compared with other solutions like batteries or natural gas, even in the best-case scenario, green hydrogen is an expensive decarbonization solution at the moment. But it is also the one that has the potential to displace 100% of emissions”.

In order to bring prices down, industry must send a signal to the hydrogen sector that commercial demand is there. And this is where the Green Hydrogen Consortium comes in. Launched in March 2020, the consortium is formed of only four members, all operating in the mining space: Anglo American, BHP, Fortescue Metals Group (FMG), and Hatch. Its primary goal is to “collectively help to eliminate the obstacles to the adoption of green hydrogen technologies and encourage innovative application”. Energy and Mines speaks to representatives of the member companies to find out exactly what this means.

To each their own (project)

The first principle by which the Green Hydrogen Consortium abides is that each member should have its own hydrogen project: the goal is not to bring together joint funding for a collaborative pilot project. With strategic and financial decisions belonging solely to the owner of the individual project, development can happen faster, and each company’s intellectual property is protected.

Anglo American, for instance, is focusing on the transportation side of the hydrogen equation: through its partnership with Engie, the company is developing the world’s largest hydrogen-powered mining truck. This is part of Anglo’s FutureSmartMining Project, which applies innovative thinking and technological advances to address mining’s major sustainability challenges.

“The development of the world’s largest hydrogen-powered mine haul truck forms part of our SmartPower project, where we analyzed our mine site power requirements and applied a unique decision process on how we look at renewable energy systems and their benefits, we came up with a mix that allows us to be carbon neutral and have a very different footprint,” explains Julian Soles, Head of Technology Development, Mining and Sustainability.

According to him, ‘first motion’ of the hydrogen-powered truck is expected in early 2021, followed by a testing and validation programme at Anglo American’s Mogalakwena platinum group metals mine in South Africa, after which the trucks are expected to be deployed at Anglo’s other operations.

“We will use the testing programme to demonstrate the performance of this system in the mine environment and the ability to capture energy from the wheel motors as we travel back into the pit. Each system within the vehicle will be validated and tested as part of the process to get the vehicle running on site,” adds Soles.

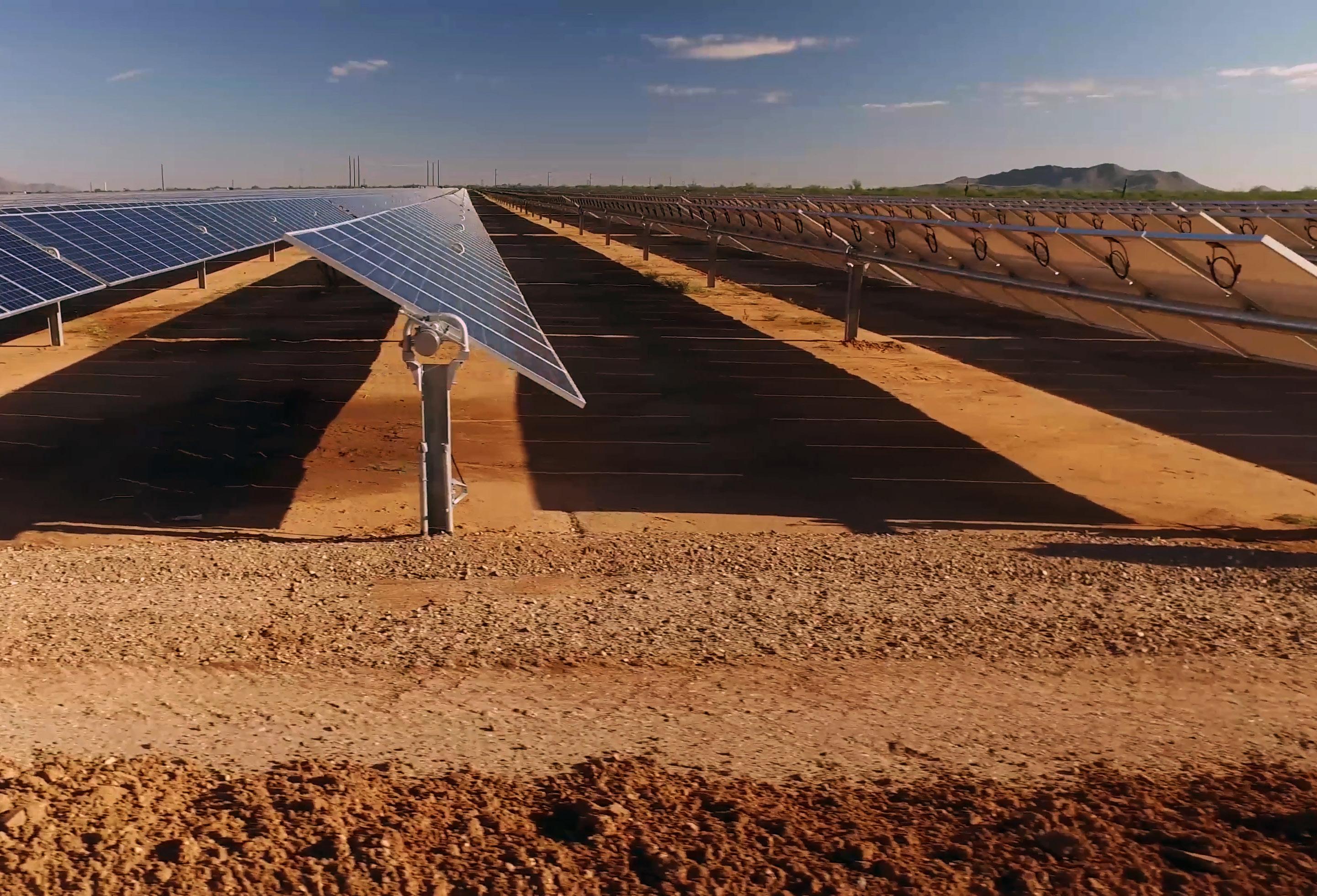

Others in the consortium are focusing on different areas: FMG, for instance, is hoping to capitalize on the hydrogen export opportunity. This involves increasing renewable energy production at its sites: the company recently announced the US$700mn Pilbara Energy Connect project, comprising the Pilbara Transmission Project (275 km of high-voltage transmission lines connecting FMG’s mine sites in the region) and Pilbara Generation Project (a hybrid gas and solar power plant supplemented by a battery), to enable lower-cost power to be delivered to the Iron Bridge Magnetite Project.

“Combined with the Chichester Solar Gas Hybrid project which will see up to 100% of daytime stationary energy requirements at our Chichester Hub operations powered by renewable energy, these projects will enable the significant uptake of renewable power into Fortescue’s energy network. It is estimated that 25–30% of stationary energy will be powered by solar on completion of these developments,” says Michael Dolan, FMG’s Hydrogen Manager.

Additionally, the company is involved in a number of industry collaborations to facilitate the export of hydrogen: these include a landmark partnership agreement with Australia’s Commonwealth Scientific and Industrial Research Organization (CSIRO) to develop its metal membrane technology, which provides the potential for the bulk transportation of hydrogen through ammonia, and an agreement with ATCO Australia to deploy hydrogen vehicle fuelling infrastructure in Western Australia. According to Dolan, FMG’s involvement in the Green Hydrogen Consortium builds on these other industry collaborations.

“As a significant energy consumer within our operations, we continue to actively pursue opportunities to reduce our carbon footprint and cost base, and we expect hydrogen will play a key role in this decarbonization journey. Our history of developing and adopting innovation and technology has been key to Fortescue achieving its industry leading cost position, and we are applying this technology-first strategy to our hydrogen initiatives to ensure we capitalize on the economic opportunities associated with hydrogen,” he adds.

Finally, BHP has set its eye primarily on the processing applications of hydrogen. Kathryn Horlin, Principal Innovation, Sustainable Operations at the firm, explains that BHP’s current view is that other forms of electrification, such as battery-electric, are more likely to achieve the majority of its diesel displacement in mining equipment, though there may be potential for green hydrogen in hard-to-electrify ancillary equipment.

“BHP has clear goals in place to reduce its operational greenhouse gas emissions, in line with the Paris Agreement. There are many potential options for decarbonization at our operations and we take a technology-agnostic view. For us, green hydrogen has the potential to address some of the more challenging areas of emissions reduction: industrial processing, where you use hydrogen for its chemical properties, not its energy content; process heat; and some applications in material movement,” she adds.

The company is currently reviewing the feasibility of onsite green hydrogen production and use for one of its operations in Australia. “We’re in the process of assessing the technical and economic aspects and we’re hoping to be able to conduct that trial onsite in the coming years, depending on the feasibility study results,” Horlin points out.

Sharing knowledge to the best-case reduce costs scenario, green

The variety of case studies explored by hydrogen each consortium member is what makes is an expensive its strength: each successful pilot project could lead to much faster commercial implementation for all members — and the rest of the industry.

“Each company in the consortium has a different view on where the best commercial applications of green hydrogen will be, which I think is really positive. It means we will each be testing different applications of emissions and openly sharing our learnings with the consortium to accelerate development. By having that seat at the table, understanding the process that another company has gone through, and hearing first-hand how they’ve developed and executed it, it does make it a lot faster for us to execute if we want to do something similar,” says Horlin.

This, in turn, will speed up the cost reduction of hydrogen equip- ment, including heavy-haulage trucks and electrolyzers. According to Bloomberg New Energy Finance (BNEF), the cost of electrolyzer technology has already fallen by 40% in the last five years. In its lat- est Hydrogen Economy Outlook, BNEF notes that clean hydrogen could be deployed in the decades to come to cut up to 34% of global greenhouse gas emissions from fossil fuels and industry at a manageable cost.

The report’s findings suggest that renewable operational hydrogen could be produced for US$0.8 to US$1.6/kg in most parts of the world before 2050, making it competitive with current natural gas prices in Brazil, China, India, Germany and Scandinavia on an energy-equivalent basis. When including the cost of storage and pipeline infrastructure, the delivered cost of renewable hydrogen in China, India and Western Europe could fall to around US$2/kg in 2030 and US$1/kg 2050, BNEF adds, warning that industry scale-up and supportive government policies will be necessary to achieve hydrogen’s full potential.

At Hatch, Carreau believes that this is the perfect time to do pilot projects, innovate, learn, and get an understanding of the economics, even though it doesn’t necessarily break even yet. “Because within 10 years, we believe that the cost of hydrogen production is going to be cut by at least half and that the price on carbon will increase significantly, which will enable a lot of business cases, particularly in mobility. The idea is that there will be a lot of small pilot projects supported by subsidies, but with the notion that the next stage will be 100 MW and more project.”

For Soles at Anglo American, the Green Hydrogen Consortium, by creating lines of communication and knowledge sharing between miners exploring hydrogen opportunities, can help with the industry’s scale-up. “Due to the large scale of mines, we are able to justify the investment in green hydrogen infrastructure and provide a better solution for the entire mine site power system to enable a move to net-zero carbon emissions. In the mobile application, hydrogen is well suited to the 24/7 activities at the site where production is paramount and asset utilization needs to be very high. We can now generate our own fuel on site, eliminating reliance on importing fuels and decoupling ourselves from the oil price as we transition.”

Growth potential

For now, the Green Hydrogen Consortium is going to focus on this sharing of knowledge, as well as some lobbying activities. “Together we can sensitize the governments, at state level and federal level to adopt legislation or focus grant support to enable green hydrogen development,” explains Carreau. While the consortium has an immediate focus on Australia projects, with most members’ teams based in Perth, all the lessons learned can and will be applied on projects elsewhere.

The Green Hydrogen Consortium is not opposed to other companies joining, but any prospective members should already be working on a hydrogen project, have a commitment to net-zero emissions in the future, and abide by the terms of reference defined by founding members. Hatch has been appointed as the project management and governance facilitator of the Green Hydrogen Consortium, so any request to join should be directed to them.

In any case, membership to the consortium is a clear signal that green hydrogen forms an integral part of the decarbonization pathway for companies. “Hydrogen is among the key pillars to achieve zero emissions by 2050,” adds Carreau. “If you move from coal or LNG for instance, you’re reducing emissions in the range of 35% but you still emit 65%: your investment in decarbonization doesn’t go very far. In comparison, hydrogen can be 100% green. You cannot think of a zero-emission world without hydrogen.”