29 minute read

The Warren Report

Andrew Warren is chairman of the British Energy Efficiency Federation

02.21

Advertisement

The UK ETS may be independent only in name

Although the UK has set its own emissions trading scheme it is likely that, as a result of Brexit trading advantage agreements, the difference from the European scheme will be little more than minimal

Just a few days before Christmas, it was officially confirmed that from January 1, the United Kingdom would have its very own emissions trading scheme. To be called, with stunning originality, the UK ETS.

All of the 1,400 UK installations, that had for the past 15 years participated in the European emissions trading scheme (the EU:ETS), overnight left that scheme. And joined the UK version.

This should have come as a surprise to nobody. For most of the past three years, all participating companies had been working on the assumption that this was the timetable, largely because that marked the end of the third official phase of the EU scheme. Wherever possible, most of the former UK allowances had increasingly been held by other branches of each company, based elsewhere in the other 31 participating countries.

There were after all formal public consultations concerning the possible UK scheme held in 2019 via the Committee on Climate Change. Last June the Business Department issued a formal document about the UK ETS concept. It was intended to “ensure a smooth switchover for businesses, and a more ambitious limit on carbon emissions on our road to net zero by 2050.” The frontispiece even expressed an ambition of “reducing the current cap by 5 per cent.”

During October the House of Commons Business Select Committee held a series of oral sessions specifically based around the operation of the UK ETS. They were focussed around this formal document which largely retained a common framework with its original parent.

Certain key parts, like verification of data, were to be retained wholesale. Methods of reporting could be altered a bit. But the official line was that, while it would not be imposed, the potential should remain for the “possibility and consideration of a link” between the two systems “if this suited both side’s interests...” Everybody has been very aware of how the previously independent Swiss ETS was becoming merged with the EU scheme.

The MPs cross-examined at length the then energy minister (now Business Secretary) Kwasi Kwarteng on the subject. He was very careful to say that, splendid idea as this might be according to the Business Department, it was not yet actually agreed to be Government policy.

Auctioning allowances delay

And nor was it resolved as such until late December. A key reason why the all-important auctioning of UK ETS allowances has had to be put off until the second quarter of 2021. And there is to be a further consultation this spring, on how that promised 5 per cent reduction on the current “cap” will be handled.

When she had to announce the December decision, one of the key participants, Wales’ energy minister Lesley Griffiths, wearily admitted to the Senned that “unfortunately there remains uncertainty in relation to the prospect of linking the UK ETS to the EU:ETS. I continue to press for a linking agreement... it is clearly in everyone’s best interests.”

Why this delay in announcing? Because in November 2018 the UK Parliament had voted to give the Treasury permission to replace the EU:ETS with a new domestic Carbon Emissions tax of £16 per tonne of

CO2 emitted from power stations and industrial sites.

That tax has yet to be introduced, but had been strongly promoted in the Treasury as another option, either in place of the UK trading scheme or, increasingly, additional to it. According to a Treasury technical notice issued when it was approved, “the new tax would maintain the carbon price for those stationary emitters currently covered by the EU:ETS.”

Clearly, with the EU carbon price already fluctuating around €30 per tonne, that commitment became nugatory. Simultaneously, increasingly loud noises were being made, both by national governments and by the European Commission, about the growing need to place import taxes upon those who seek to import into Europe goods and materials that do not reflect any pricing acknowledgment of their consequent carbon impact.

Since 2018, both the UK and the EU have adopted far more stringent carbon reduction targets, both for 2050 and now for the (far more immediate) 2030 target dates. This summer the European Commission is set to publish detailed proposals for border taxation on any and all goods and measures that are imported from countries where prices carry no comparable additions to reflect carbon emission externalities. There is every likelihood that such a border tax will be approved across the EU. It is inevitable that it will be opposed as anti-free trade by many outside Europe.

The UK has made it plain that its own climate policy will be more rather than less ambitious than those adopted by all other European countries. Under the terms of the Brexit agreement, we have also agreed not to diverge from EU policies that might provide a significant trading advantage. So I am prepared to bet that, by 2025, we will have introduced a very similar carbon border tax.

CHP & District Heating

For further information on Veolia visitwww.eibi.co.uk/enquiriesand enter ENQUIRY No. 125

Denis Adelmant is technical director – energy at Veolia

Limited only by ambition

Denis Adelmant explores the benefits of coupling district heating with combined heat and power and the potential for zero carbon in the cities of the future

Access to affordable, reliable, and sustainable energy has a direct impact on modern life and is linked to fuel poverty and carbon emissions, and heat networks are a well-established technology in other parts of Europe, but suffered in the UK due to the legacy of poorly implemented inefficient schemes. However, in recent years the Government, energy services companies (ESCOs), developers and housing associations have started to recognise heat networks as a viable option for reliable and affordable low-carbon domestic heating.

In the UK heat networks and district heating schemes currently supply around 447,000 homes and other buildings with networks estimated at 1,800km, and this number of connections represents more than double the UK figure in 2013. This is good progress, but is small in comparison to the use of this technology across the world, for example Veolia alone now manages 600 schemes covering 7,000km of pipe networks.

A key benefit lies in the fact that district heating can improve the efficiency of energy use, and this is extended when the central heating plant employs cogeneration technology to generate electricity. With UK electricity consumption set to double by 2050 this aspect has become even more important to help achieve the Government’s latest plan to target net zero generation.

Combined heat and power plants (CHP) have now been used effectively in district heating for around 150 years. By simultaneously producing heat and power from a single fuel source, such as natural gas, biomass and non-recyclable household waste, this process increases fuel utilisation, thus shrinking the carbon footprint of the plant and network. Crucially, the heat that is produced as a byproduct of the electrical generation process is captured and used to heat water that is then distributed out into the District Heating Network.

Manufacturers of CHP units are making units compatible with new fuels that are coming to market

In the UK networks using CHP technology can range from those serving around 100 homes to those serving a few thousand. But as Europe has shown the scale is only limited by ambition, for example in the city of Łódz in Poland CHP based plant serves around 500,000 people, public buildings and industry by supplying renewable heat and electricity through delivery of 404MW of electricity and a 1624MW of heat.

Decarbonisation challenge

Uncertainty about the way in which heat will be decarbonised present a number of challenges to policy makers. Many of the existing schemes use mains gas fired, engine based CHP units as their energy source as it represents a highly energy efficient low carbon way of delivering the energy flows. But the natural gas network will reduce over time, potentially supplemented or replaced by biogas or hydrogen in order to meet carbon zero targets.

Around the world a green hydrogen race is underway, as many companies, investors, governments and environmentalists believe it is an energy source that could help end the reign of fossil fuels. Europe and other countries are already providing funding for construction of electrolysis plants and other hydrogen infrastructure, and in parallel more Anaerobic Digestion plants are injecting renewable biomethane on to the grid. At the same time CHP engine manufacturers have reacted to make their units compatible with the new fuels and provide a long-term vision for the established technology.

Another form of CHP technology that is expanding its role in supplying district heating is the use of energy from waste plants. These combust non-recyclable household waste as a fuel, effectively delivering energy for communities from the waste they discard. To virtually eliminate wastes and produce energy in its place is a win-win situation; by generating green electricity and heat from resources such as non-recyclable residual waste, resource efficiency is improved, landfill reduced and greater sustainability achieved as part of the circular economy. And with energy from waste plants poised to trial carbon capture the carbon advantages will be further enhanced.

As London’s first energy from waste district heating network the South East London Combined Heat and Power (SELCHP) facility, based in Lewisham, marked 26 years of providing 60,600 homes with lowcarbon energy, and a sustainable solution for their non-recyclable waste. Further developments are currently in planning to expand the system to supply more residents, and to charge the new fleets of electric bin lorries using electricity generated from the household waste they collect, and boosting carbon savings even further.

By addressing industrial, commercial and domestic energy efficiency we already have the proven ways to make major cuts in emissions today, and are ready to apply the emerging new technologies to help achieve the target ahead of 2050. Ultimately the organisations involved in heat decarbonisation need to start the process now using available, and operationally viable, low carbon technologies as part of the two phase investment model between now and 2050. Waiting for the next technology to emerge simply means more carbon is released to the environment - and the planet can’t afford delay.

We need to act today. We can all go further, and by having a bold vision we can reap the environmental, community and financial benefits CHP based district heating can bring.

CHP & District Heating

For further information on Vital Energi visitwww.eibi.co.uk/enquiriesand enter ENQUIRY No. 126

Lee Moran is associate director at Vital Energi

Smart data for better heat networks

New metering and billing requirements for heat networks have triggered a renewed focus on the role smart data can play in communal energy generation, says Lee Moran

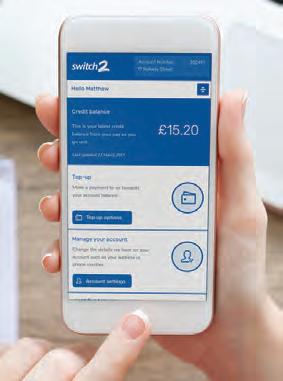

Heat network operators are looking to explore the benefits real time data can deliver when driven by smart energy platforms supported with end user apps and portals.

These platforms are helping network providers build a more accurate pattern of behaviour and energy consumption, allowing them to improve efficiency, lower carbon emissions and better serve customers across their network.

More than ever, integrated end user apps and portals are giving heat network customers greater visibility of their energy consumption and control of their spend at a time when fuel poverty is a major challenge for thousands of energy users and many of us find ourselves at home more often than before.

As COP26 beckons and with district heating networks set to play an important role in Britain’s Green

Industrial Revolution, the ways in which smart data can help both network operators and end users improve energy efficiency, reduce wastage and combat fuel poverty by lowering bills, has never been more important.

Access to real time data is the key to network operators building a clear understanding of a system’s diversity profile. Visibility of energy consumption across a demographic allows for future energy usage to be more accurately predicted and this affects the size of both the infrastructure and energy supply needed to efficiently serve a system.

Historically, energy generation and district heating systems were often oversized because people didn’t really understand diversity across networks. As a result, boilers and low- or zero-carbon technologies supplying heat to the network were too big, controlled poorly and would often need to dump excess heat from the system.

Additionally, traditional heat meters would log readings only every 30 minutes and the data produced

Real-time data can help spot potential problems with district heating system performance

would be infrequently downloaded and reviewed by operators.

Fast forward to today and we understand both the importance of the efficiencies of these systems and regular engagement with meter data. Smart energy platforms can allow the gap between readings to be practically instantaneous, and operators can now view real time data instantly to drill down into the performance and use of a system.

By using this data to build a snapshot of geography and demographic, heat network operators can take the stress off demand peaks by incentivising end users to use heat and hot water when other people are not. By setting cheaper tariffs during off-peak hours, operators can flatten the demand curve at key times across the day. With the increased visibility afforded by end user apps and portals, this has the added benefit of helping customers manage their energy spend more effectively, by giving them the flexibility to use cheaper tariffs that can reduce their bills.

Additionally, if system operators can effectively spread demand like this, it allows existing infrastructure to be expanded to serve more people without the need for further investment to maximise a network’s potential. The more efficient operators can make a system ultimately has an effect on how much cheaper end users’ bills can be and, for those struggling with fuel poverty, these fractions can make a significant difference over both the short and long term.

Incentivising customers

Many other utility sectors have been successfully incentivising customers to shift their energy consumption to off-peak hours like this for decades. What’s needed is for this to be more widely replicated across heat networks and there are potentially significant benefits for both operators and customers alike.

The analysis of smart data has tangible benefits beyond advising customers when best to turn heating on or take a cheaper shower. From a technical point of view, real time data allows systems to be optimised by identifying where a demand curve suddenly dips, spikes or goes completely flat. Regular data aggregation can help identify meter failure and allows for a significant portion of problems like these to be identified, remotely diagnosed and resolved quickly.

Previously, engineers would have to manually run diagnostic checks on site, download and review data information and then put a service plan in place - all of which is time consuming and potentially intrusive for the end user. Realtime data supported by smart apps and heat interface units negates the need for engineers to be on-site and, as a result, reduces costs for both operators and customers. Additionally, this level of insight greatly increases the speed at which operators can react to system issues as a result.

Real-time data can also help spot potential problems not just with system performance but with irregularities in residential use. Heat network providers can proactively flag when meter readings from a property unexpectedly dip or stop altogether and this can help network operators ensure vulnerable end users who may be experiencing difficulties paying their bills are adequately safeguarded.

The increased visibility and insight that real time data and smart energy systems provide can be a catalyst for operators to take greater control of how they engage with both heat network systems and the people connected to them. By using insight from the data they can work to improve system efficiency and engage meaningfully with end user behaviour to better serve customers.

Ian Allan is head of market strategy for Switch2 Energy

CHP & District Heating

For further information on Switch2 Energy visitwww.eibi.co.uk/enquiriesand enter ENQUIRY No. 127

All change for heat networks

Big changes are coming to heat network regulations. Ian Allan explains the recent changes and the steps heat suppliers must take to reach compliance

In less than 10 months’ time, heat network suppliers must complete assessments to determine whether they need to retrofit heat meters to buildings supplied by district or community heating. This is one of the major new updates to the Heat Network (Metering and

Billing) Regulations (HNMBR).

The regulations were first introduced in 2014 to align with the EU Energy Efficiency Directive.

HNMBR is enforced by the Office for

Product Safety and Standards (OPSS), with civil and criminal penalties for non-compliance. Legislation applies to all sites that distribute thermal energy for heating, cooling or hot water from a central source to more than one end user, building or location.

The updated regulations, which came into force on 27 November 2020, introduce new arrangements relating to the legal requirement to install final customer meters on existing unmetered networks, where this is demonstrated to be cost effective.

It has been mandatory to install final customer meters on new builds and most buildings undergoing major renovation since the regulations were first introduced in 2014, but the requirement to install heat meters within existing properties was delayed. This was due to issues with a feasibility tool to assess the economic and technical viability of retrofitting metering.

The revised cost-effectiveness/ feasibility tool is now available, which enables operators and owners of unmetered networks to assess whether or not they are required to retrofit final customer meters or heat cost allocators into individual homes.

New building classes have also been introduced (viable, open and exempt), with a requirement that the cost-effectiveness assessment must be completed by 27 November 2021 for all buildings that fall into the ‘open’ class. Individual meters must always be installed in viable class buildings, but a small number

Heat network suppliers must complete assessments to determine whether they need to fit heat meters

of properties types, such as prisons, hotels and purpose-built student accommodation, will be exempt.

Other key updates relate to the heat network notification template, and guidance to help operators determine whether their network meets the criteria of newly created metering and billing exemptions.

To give heat suppliers time to comply with the changes, a ‘transition period’ (from 27 November 2020 to 1 September 2022) has been introduced. Any operators who are subject to the four-yearly re-notification deadline during this time must take action by 2022.

Corrective action to install heat meters or heat cost allocators into viable unmetered properties must also be completed by 1 September 2022. In addition, suppliers who installed final heat meters prior to 27th November 2020 must comply with meter accuracy requirements by this deadline.

Reduce energy spend by half

Switch2 has identified that installing smart heat meters inside residences reduces energy spend by 35 to 50 per cent, compared to flat rate unmetered schemes.

There are three key aspects to the regulations: • Notification: Heat suppliers must use the revised notification template to inform the OPSS about the location of any heat network or communal heating scheme – as well as its capacity and supply figures. Each building that forms part of the network must also be identified and classified, along with the number of customers using it and details of the billing information they receive. Registrations must be updated every four years. • Metering: It is compulsory for all heat networks to install point of entry meters, or building level heat

Smart heat meters in residences have been shown to reduce energy use considerably meters, which record the amount of heat delivered into a building from the plant room or energy centre. In addition, the updated legislation will make it compulsory to install final heat meters, or heat cost allocators, in all unmetered properties. This applies unless it is economically or technically unfeasible to do so, or the buildings fall into the exempt classification.

Inevitably, this will mean making plans to install final heat meters in thousands of ‘open class’ properties that are currently unmetered. Assessment will take time and it is vital that heat scheme operators and owners start the process soon to meet the strict regulatory deadlines and avoid non-compliance penalties.

There are two versions of the costeffectiveness tool. The reduced input tool is applicable where plant room fuel consumption is known and requires quotes for the installation of meters, while the full input tool applies where energy consumption is estimated. In most instances, heat suppliers will be able to use the simpler reduced input tool, which requires 29 inputs compared to 63 inputs for the more complex full input tool version.

If the tool shows that metering is not cost effective, the test must be repeated every four years and it is expected that all heat networks will need to be fully metered over time. • Billing: End customers must be billed using actual meter readings (not estimates) at least once a year, but electronic bills must be invoiced each quarter. At a minimum, bills must contain current energy prices and total consumption figures (with previous year comparison, if applicable), together with general energy efficiency advice.

Pay-as-you-go (PAYG) smart meters can simplify the compliance process and drive behavioural change by giving customers full visibility of how much energy they are using and how much it’s costing them.

CHP & District Heating

For further information on Enel X UK visitwww.eibi.co.uk/enquiriesand enter ENQUIRY No. 128

Wayne Davies is energy markets programme manager at Enel X UK

Trade your spare capacity

Wayne Davies discusses the options available to CHP operators for improving efficiency and participating in new flexibility markets

Most experts would agree that the key to achieving optimum efficiency from a CHP plant is to correctly size and specify it to meet site demand.

However, according to our research, four out of every five CHP assets in the UK were commissioned three or more years ago, and one in three were specified to meet the site’s past energy needs.

Energy managers who optimised their CHP to meet the site’s past needs may now find themselves with power capacity to spare, especially where energy efficiency measures have reduced demand.

This spare capacity can be traded in a number of ‘flexibility’ markets and become a source of revenue for the organisation.

Grid operators value sources of flexibility because they can call on it to help balance supply and demand.

Furthermore, flexible capacity is the key to enabling more renewable energy; it provides locational resources to grid operators allowing them to better manage the variable output from distributed renewable assets that electrify the wind and sun.

Generating heat and electricity that will be surplus to requirements simply wastes energy, reduces site efficiency and is bad for the environment.

By retrofitting intelligent software controls to optimise management of CHP plant, energy managers can improve the efficiency of their CHP units. Optimisation also maximises the revenues they can generate by trading surplus energy.

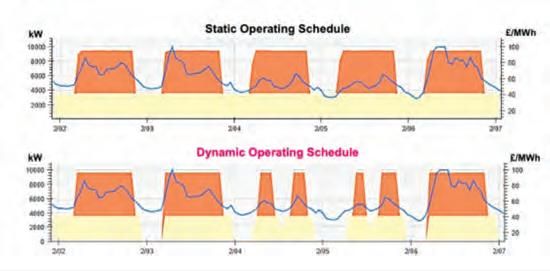

Compared with deploying a static operating schedule, using intelligent software to control the CHP unit dynamically minimises energy waste and maximises the value of flexible capacity (see box).

Today’s energy markets offer

CHP units that haven’t been optimised to serve variable site loads typically operate at sub-optimal performance and so offer sub-optimal economic returns

multiple value opportunities to trade flexible capacity. These include trading in the capacity market, ancillary market, spot energy markets and balancing mechanism.

As grid operators continue to deploy more renewable energy, they will need more flexible capacity to balance supply and demand. Aurora Energy Research forecasts that revenue for flexible technologies will grow 13 per cent (compound annual growth rate) to create a £2.3bn market by 2030.

The GB electricity system has seen a number of price spikes in both spot energy markets and the balancing mechanism due to variable wind and load profiles. In September, for example, wholesale power prices peaked at over £500/MWh due to a combination of low levels of wind generation and high demand. While these events are relatively uncommon, they do demonstrate the need for grid operators to maintain

Static and dynamic operating schedules

The static schedule shows two CHPs – a 3.6MWe CHP unit in yellow and a 6MWe unit in orange, alongside the power price (blue line). The 3.6MWe CHP operates at 100 per cent output 24x7, while the 6MWe unit operates at 100 per cent during business hours. The dynamic operating schedule shows how the same units would respond to changes in power prices. The 3.6MWe CHP operates at 100 per cent during business hours (8am – 8pm) but reduces output midday on 2/04 and 2/05 reacting to a dip in power price. The 6MWe CHP operates at 100 per cent during business hours but shuts off completely midday 2/04 and 2/05 reacting to the dip in power price. sufficient capacity to achieve a safe operating margin. Such events are an opportunity for organisations to monetise their flexibility capacity.

Businesses with small to mediumsized CHP assets, typically up to 10MW, may not have a specialist resource responsible for optimising the CHP. In this case, and where there is a need to augment the capabilities of the in-house team, a technologybased approach to optimisation and trading is worth considering.

Using intelligent software to combine knowledge of operating parameters with grid signals and market indicators, such as energy market price information, it’s possible to create the best running schedule for the CHP plant. The algorithms can then identify opportunities to trade any flexible capacity in the most appropriate markets.

Dispatch signals from the energy markets can be sent to CHP assets by interfacing with SCADA or local control rooms, making it possible to realise market value within short notice periods.

By optimising the operating schedule, organisations can maximise the return on their investment by fully utilising all of the capabilities of the assets. This approach enables new streams of revenue from trading excess capacity; a benefit often previously only available to larger teams.

Deploying intelligent, dynamic management technology increases control and monitoring over the whole CHP system. This enhanced level of visibility provides clarity over site energy costs; helps energy managers to understand and accommodate site and contract constraints; and minimises energy costs by reducing waste and inefficiencies.

This approach enables operators to identify when it’s best to plan maintenance to minimise revenue loss and provides insight into how to size new CHP plant to maximise profitable operation.

Transformer Technology

For further information on Wilson Power Solutions visitwww.eibi.co.uk/enquiriesand enter ENQUIRY No. 137

Get ready for transformer regulatory changes

Big changes are ahead later this year in the transformer market. Don’t get left behind

Tier 2 EU Ecodesign Regulation for transformer losses will become effective from the 1st July 2021 replacing Tier 1 that has been in place for the past six years. From this date onwards, Wilson Power Solutions, along with all transformer manufacturers and distributors, will not have the right to transfer ownership or deliver any Tier 1 transformers.

Tier 2 was introduced to further improve the efficiency of transformers across Europe. The new specifications for transformer losses aspire to reduce the energy waste by 10 per cent compared to Tier 1 levels. There will be a few concession cases allowing for Tier 1 to be installed after that date. Just to mention a few, having production delays, space and weight constraints for transformer replacements, power transformers with disproportionate costs associated with their transportation and/or installation and more.

We collated data from different policies and member trade organisations in one document to help you navigate through the regulatory changes. The Frequently Asked Questions has details about relevant timelines, concession cases, refurbishment, hire, Tier 1 transformers in stock and more. It could be found in the downloads section on our website: www. wilsonpowersolutions.co.uk/ downloads. And we are hosting a webinar on the 16th Feb to walk you through the changes and answer your questions. You can request an invitation by contacting our Energy Policy Manager, Ayah Alfawaris, on ayah@wilsonpowersolutions.co.uk.

Wilson Power Solutions will provide Tier 2 compliant transformers for both its power and distribution transformers. We manufacture two Tier 2 compliant distribution transformers; a) Wilson T2 Ecotrans, made with CRGO metal core and meets Tier 2 losses, and b) Wilson e3 Ultra Low Loss, made with amorphous metal core and far exceeds Tier 2 losses. Being the UK’s most energy efficient transformer, Wilson e3 sets the bar for Tier 3 and provides additional carbon and energy savings.

CHP & District Heating

For further information on products and services visit www.eibi.co.uk/enquiries and enter the appropriate online enquiry number

Upgrade enables biomass plant conversion to combined heat and power

Leading Swedish renewable energy pioneer Againity AB and Swedenbased brazed plate heat exchanger manufacturer, SWEP, have joined forces on a pioneering power initiative in southern Sweden.

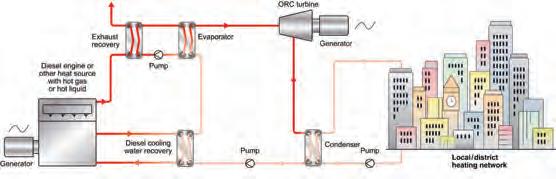

The initiative has enabled local district heating provider Perstorps District Heating to upgrade its 12MW biomass-fired heat plant to become a combined heat and power (CHP) plant. The upgrade, a joint venture between the E.ON group and Perstorp’s municipality has been achieved by installing an Againity Organic Rankine Cycle (ORC) unit at the energy centre.

Againity provides a range of ORC turbines and so far have installed 20 units for district heating networks and industrial estates across Scandinavia. Any heat source with a temperature of 90°C and over can be utilised in the system. The source can be heat from a boiler that burns wood chips, landfill gas or household waste, waste heat from a gas engine, hot water from solar panels, or excess heat from an industrial process. electrical efficiency up to 20 per cent can be achieved for the largest plants that, for example, utilise waste heat from large gas turbines. If there is a local heat demand, the rest of the energy will be delivered as heat to the local heat network, meaning the total efficiency of available heat source is close to 99.5 per cent. SWEP BPHEs play an important

The efficiency of the ORC system role in the process. One set of heat is dependent on the temperature exchangers work as the evaporator, difference between the system’s enabling the refrigerant to convert from hot and cold side. ORC technology liquid to vapour and another set of heat includes a turbine set in motion by exchangers operate as the condenser the pressure of a vaporised internal (as such in reverse), condensing vapour working medium. The rotating turbine to liquid. then drives a generator that produces electricity. In optimal conditions ONLINE ENQUIRY 129

Smart energy app puts heat network customers in control of energy use

Vital Energi has launched a smart energy app and portal that gives heat network customers greater control of their energy consumption and spend. It has already helped service operators at one pilot project to reduce debt by 12.5 per cent in under six months.

Named Glass, the software gives heat network users the visibility and control to better manage their energy and allows users to top-up or pay their bills anytime, anywhere. Additionally, heat network operators can access energy consumption and financial data via a dedicated portal that allows them to better serve customers and optimise network performance.

Housing associations, local authorities, developers and other service managers can view data across multiple sites as well as individual properties. This can help identify and proactively support residents by providing energy saving and payment advice to reduce debt and ensure bills are paid on time. Operators and service managers will be able to send payment reminder alerts and notifications to residents through the app to help aid their financial management, and recent pilot schemes have shown Glass has helped improve revenue collection by up to 44 per cent within weeks of being implemented.

Glass has been successfully trialled across four projects being delivered by Vital Energi, and it is currently working with residential rental company UNCLE to support over 200 properties as part of a £100m build-to-rent development at Wembley.

From early next year, Glass will support 137 homes to manage and reduce their energy use at Peel L&P’s Liverpool Waters as part of a £5bn regeneration project to transform the city’s northern docks.

Since 27th November of this year, the Government’s new Heat Metering & Billing Regulations has ensured that energy customers only pay for what they consume. Glass will give users and operators the ability to view real time consumption data and support operators in achieving compliance.

App cuts capital cost of energy metering

KURVE, the UK’s first digital pay-as-you-go (PAYG) web app for heat networks, has delivered significant savings on the capital cost of energy metering at Greenside Views, a newly completed development of flats in Mitcham, south west London.

The managing agent, Lotus Trident, was presented with three PAYG options: KURVE and two in-home display-dependent solutions. KURVE achieved an average saving, covering installation and hardware, of 60 per cent or £33,000 compared to the alternatives and was chosen as the preferred solution for the 89-unit development.

KURVE is the fruit of a joint venture between heat network metering and billing specialist, Insite Energy, and SAV Systems, provider of low carbon, energy efficient heating solutions. It is designed to make smart metering more accessible for heat network users, to reduce costs and improve their access to consumption data. The cost of installation and hardware is a major barrier discouraging the up-take of PAYG smart meters by housing providers operating heat networks, even though individual heat meters are now a legal requirement in most instances.

“The savings are genuinely impressive. There is no trade-off with taking the more affordable option as one might normally expect,” said Arjun Shah of Lotus Trident. “Not having to fit hard-wired in-home displays is a huge advantage and we’re getting a great level of energy data. The real value to residents lies in the fact they can easily access their energy usage data and manage their account anywhere, from any internet device.” ONLINE ENQUIRY 131