22 minute read

View from the Top

VIEW FROM THE TOP Peter Stockwell is managing director of Concept Energy Solutions

Unravel your energy data

Advertisement

In an era when utility costs frequently appear in comp anies’ lists of top three operational expenses, a structured process of tracking and reacting to energy data is vital to help building managers and FMs identify excessive energy spend – and do something about it.

Surprisingly, we find that this is far from being universally realised at present. We are in no doubt that many companies across different sectors are still not embracing the need for even basic management of their energy data.

The current push for ESOS (the Energy Savings Opportunity Scheme) compliance has introduced us to many new clients and this has highlighted just how many businesses still do no more than rely on invoices (and perhaps periodically updated spreadsheets) to gather details of consumption.

However, “information overload” is equally problematic. We work with companies that have had sub metering installed to gain a more granular picture of energy use - but all too often we find that this has not been supported by a decent metering strategy and the meter hierarchy may be incomplete or inconsistent, leading to misleading output data. With the cost of sub metering coming down, building operators should avoid the temptation of “saturation metering” where too much information can blur the picture.

There are also issues around interpretation of, and reaction to, the data, meaning that the potential of the investment can never be realised. If the inhouse team does not have the knowledge and/or resources to sift through the data meaningfully, then it can easily become an issue that is continually overlooked until rising costs become visible and the damage is done.

For all of these reasons, it makes sense for companies to think about adopting a full-circle approach to energy data – from the accruing and processing of information, through its interpretation, and on to developing a plan of action that enables energy usage to be optimised.

By defining a considered and structured Keeping a close watch on energy-related data requires careful thought, but it is essential if a company is to maintain operational efficiency, writes Peter Stockwell metering hierarchy, it is possible to see with clarity and confidence where, precisely, energy is being used, so that excessive consumption can be tackled in the right area. And when the strategic decision has been made to equip a building with sub metering, then it is also necessary to have the facility to interpret the data.

Modern software platforms go some way towards assisting with this, but from our experience there remains a need for “human intervention” and this is where the energy management consultant comes in. Site services managers and FMs may not have the time to interpret and respond to performance variation flagged via system alarms, so a well-trained energy bureau, with consultant input, can provide a valuable service supporting the on-site team with expert advice on minimizing excess usage and emissions quickly and effectively.

Beyond “basic” energy management, there is a growing movement towards gathering more information on a building’s indoor environment - internal temperatures, CO2 levels, lux levels, and occupancy rates and so on - which is all highly relevant in the building energy management context. Software analysis is becoming increasingly sophisticated in this area, and can even make some of the decisions through automation and machine learning – this is highly valuable to building operators looking to maintain a healthy environment for occupants.

However, in our view there remains a central role for the energy expert to work with the data, and data outputs, to ensure that occupant well-being and energy efficiency work in harmony with one another (improved air quality does not, for example, necessarily mean an increase in energy consumption). In these instances, wellbeing and energy efficiency opportunities can only reach their full potential with scrutiny from industry specialists.

This is bound to become even more critical as expectations of energy efficiency and climate control increase, which underlines the value of engaging with a specialist who can interpret new data and support hard-pressed personnel. As both internal and external factors oblige companies to monitor their use of energy more effectively, it is certain to be the best way to keep sight of what by its very nature will always be a moving target.

Stockwell: 'many companies are still not embracing the need for even basic management of their energy data' • Review your data sources - do they give you a clear picture of your energy use? Sub meters can collect information on specific assets, helping you to identify immediate savings. • Is your data complete? A comprehensive audit will identify errors and gaps in information. • Do you have an efficient way of extracting the data? Consider an energy monitoring platform which enables the performance of building systems to be assessed in an efficient way. • Interpreting your data is key – an energy expert can help you understand the ‘where, when and why’ of energy use for each asset and site. • Data is only king if you act on it – engage with a provider who can recommend tangible, cost-effective ways to reduce energy waste – with clear costs and RoI. From analysis to action: the potential of energy data

CHP & District Heating

For further information on Centrica Business Solutions visitwww.eibi.co.uk/enquiriesand enter ENQUIRY No. 140

Luke Bannar-Martin is product manager of generator solutions at Centrica Business Solutions

Biogas CHP is already being used by a range of sectors including water and sewage

Green gas to power CHP

High efficiency CHP will continue to play an important role as global economies work towards net-zero, says Luke Bannar-Martin H ow much we fly, what we consume, how we heat our homes and what we drive is coming under increasing scrutiny as the scale of the climate emergency starts to get widespread recognition.

And while emissions from electricity generation have fallen by nearly 70 per cent since 1990, there quite rightly remain questions over how the energy sector will hit net zero.

CHP can play two key roles in the net zero transition. The first is providing significant cost savings for UK businesses. With a return on investment in the region of two to three years, CHP drives cost efficiencies in to the organisation that can be used to fund pure green technologies with longer paybacks and more marginal economics. In addition, moving to a fully renewables-based grid will take time. As we transition, there is no more efficient method of generating power from natural gas than cogeneration - the production of usable heat and electricity in a single process reaches total efficiencies of around 90 per cent.

As a local, onsite generation process, it is much cleaner and more efficient than standalone gas power stations, where more often than not the heat is wasted and around 7.5 per cent of power is lost in transmission and distribution.

In the vast majority of cases, natural gas CHP displaces higher carbon centralised gas and coal power plants and rarely displaces renewables or nuclear. This is due to a Merit Order that determines the economics of the wholesale power markets and the sequence in which generators are dispatched to meet demand at minimal operating cost.

The most widely used current assessment methodologies undervalue CHP’s carbon-saving benefits because they look at average carbon emissions from the grid, therefore making the false assumption that CHP is displacing renewables. This doesn’t reflect the reality of market optimisation strategies, where CHP actually displaces more carbon-intense sources.

While almost 70 per cent of CHP schemes in the UK currently run on natural gas, green gas CHP will play an increasingly important role as the grid decarbonises. This solution combines the efficiency benefits of CHP with a carbon neutral fuel source.

Green gas is generated through anaerobic digestion and the biogas produced through this process is purified to form biomethane (by removing impurities). Biomethane is predominantly methane (>97 per cent). It has similar characteristics to natural gas but must be treated before it is of pipeline quality by removing water vapour and adding propane and odorant. Three primary waste sources There are three primary waste sources used to produce biogas: food waste, slurries and sewage; plant waste and animal manure; and energy crops.

Biogas CHP is already being exploited by water and sewage companies, food and drink manufacturers and agribusinesses, which have access to organic food waste as a potential source. However, the use of anaerobic digestion is under exploited.

Most businesses won’t be in a position to generate biogas on-site, but green gas offsetting is available. Centrica has a 50 per cent stake in Barrow Green Gas, the UK’s largest supplier of biomethane – shipping almost half of the green gas used by British homes and businesses. Through this partnership, customers have access to accredited Green Gas Certificates which represent an amount of biomethane that has been created and injected into the gas grid.

Green Gas certificates can be used to offset natural gas used on site – both for running CHP systems and wider gas usage. This provides a robust route to hitting carbon targets and enables scope 1 emissions for that gas volume to be reported as zero. Centrica’s CHP and green gas supply option comes with Green Gas Certificates built in.

To further decarbonise grid power, we’ve asked Government to consider establishing a ‘green gas’ obligation on retail gas suppliers, designed to incentivise a gradually increasing percentage of green gas in the supply mix.

In the medium-term, significant carbon emission reductions can be achieved by incorporating CHP within a mix of distributed energy technologies. These may include solar PV, battery storage, demand side response and the generation of insights through real-time data analytics.

New uses for CHP and other distributed energy solutions are being demonstrated via local smart grids. As an example, Centrica’s Local Energy Market project in Cornwall is connecting technologies such as CHP, solar, battery storage and using monitoring and proprietary software to energise the local community.

The potential to cluster CHP with other assets in a decentralised smart-grid or virtual power plant is exciting and likely to become more commonplace in the future.

A recent report on the future of the UK’s energy sector by The Association for Decentralised Energy (ADE), explained how onsite generation and energy management from thousands of businesses and millions of homes are vital to achieving a net zero future.

In its analysis, ADE reported that CHP (using low-carbon fuels in line with the Net Zero goal and capturing otherwise wasted heat) could increase from over 5GW today to 15GW. This capacity equates to more than seven large power stations.

Bridge your energy gap with our temporary solutions.

With reduced costs and lower carbon emissions, decentralised energy is the way forward. But finding the right solution takes time. That’s where our risk-free, short and long-term hire packages come in. With no capex and no payback period, the cost savings are immediate. We offer a range of products, including CHP, gas and battery solutions, providing you with the power you need, when you need it, for as long as you need it.

CHP & District Heating

For further information on Switch2 Energy visitwww.eibi.co.uk/enquiriesand enter ENQUIRY No. 141

Richard Slee is CEO of Switch2 Energy

Heat networks and a net-zero future

Heat networks can play a key role in the tough and urgent challenge of decarbonising the UK’s heat supply, says Richard Slee A s global businesses and governments develop action plans for a net-zero future, communities must exploit the full potential of heat networks as an affordable and sustainable solution for heating homes and businesses.

The latest UK energy trends statistics show that domestic energy use contributes approximately 18 per cent of CO 2 emissions, which come mainly from natural gas used for heating, hot water and cooking.

While huge strides have been made in decarbonising power, there has been little progress in eliminating greenhouse gas emissions from heating. Urgent solutions are required, including wider use of heat networks and improving the efficiency of existing district heating schemes. However, most existing heat networks still use gas as their main fuel. The challenge is to make them more efficient and replace gas on existing networks.

The government’s Clean Growth Strategy states that heat networks could meet 17 to 24 per cent of UK heat demand, which is a massive increase on the current 2 per cent. Heat networks are a key element of the proposed Future Homes Standard, which aims to ensure that future new build homes emit 75 to 80 per cent less CO 2 .

The Future Homes Standard identifies that heat networks, heat pumps, hydrogen and biogas are some of the key low carbon solutions required to radically improve emissions performance of domestic heating.

The proposals take into consideration heat decarbonisation recommendations by the Committee on Climate Change (CCC), including a proposed ban on gas boilers in new homes from 2025. We believe that this radical proposal must go even further if the UK is to meet its net-zero 2050 target. To put this in context, the UK is one of the few European countries to rely on fossil fuel gas as the main source of heating. By comparison, the Netherlands (which is one of the only other gas-reliant European countries) banned new gas boilers in 2012 and is now replacing existing gas boilers. Mature technology A major advantage of heat networks is that this is a mature technology that can be deployed

Heat networks could meet up to 24 per cent of UK heat demand Wolverhampton Homes, which manages more than 23,000 homes for Wolverhampton Council, has partnered with Switch2 to develop a complete digital heat metering strategy.

Residents previously paid for their heating through a flat rate charge included within the rent, but agreed to transition to a more flexible, smart, pay-as-you-go system combining heat interface units, heat meters and smart meters. By giving residents full visibility of how much heat they are using and their minute-by-minute energy spend, they have moderated consumption. This has reduced the average heat bill to £18 per month, delivering projected savings in excess of 30 per cent.

The accurate, transparent metering data is also helping to inform efficient operation of the energy plant, leading to optimised performance, higher efficiency operation and lower emissions. now to address the decarbonisation challenge. Wherever there is a dense heat requirement, such as in urban areas, district and community heating should be considered. This is particularly important where there are opportunities to utilise waste heat or tie into other local heat sources.

The UK wastes more heat than it requires to meet its entire demand, so it’s vital that this ‘lost’ heat must Complete digital heat metering strategy

be captured and re-used locally. Heat networks provide an effective solution by using heat productively close to the point of generation.

The Scottish Government is making significant progress in its zero carbon policy and Local Heat & Energy Efficiency Strategies (LHEES). This includes a zoning policy that allows local authorities to demand that buildings connect to a heat network both to export their own surplus heat or to consume heat from the network. This could be replicated across the wider UK.

Another advantage of heat networks is that they are fuel agnostic, so can accommodate cleaner, new fuels and technologies, such as hydrogen and heat pumps to reflect future advances in technology.

While hydrogen is an immature technology that is still evolving, the heat pump market is much better developed. However, one of the barriers to rolling heat pumps out at scale relates to the wider challenge of weaning the UK heating system away from natural gas. This is partly due to the economics of cheaper gas prices relative to electricity, which is used for heat pumps. Gas incurs little carbon tax, with electricity bearing the major taxation burden of decarbonising the grid. This disparity will slow the transition to cleaner heating methods.

The transition to cleaner new heat network technologies and 4th and 5th generation systems, which work at lower temperatures and more efficiently, will take time. Meanwhile, improving efficiency across existing schemes is crucial.

Residents and businesses, who consume the heat, are key to improving environmental performance. The citizen-led Extinction Rebellion demonstrates the will of the people to impact the climate emergency and this public will is being harnessed in the heat network sector.

By combining sustainability awareness campaigns with compliant smart metering technologies that give customers visibility, control and management of their energy consumption, huge emissions savings are achieved.

CHP & District Heating

For further information on Hysopt visitwww.eibi.co.uk/enquiriesand enter ENQUIRY No. 142

Chris Davis is UK sales manager at Hysopt

Maximise CHP operation

Creating a ‘digital twin’ of a CHP installation using simulating and optimisation software can provide energy managers with an insight into more economical operation, says Chris Davis

CHP has traditionally scored well from both economic and environmental perspectives, due to the high “spark-gap” energy cost difference between electricity and natural gas; and at the same time high electricity grid carbon emissions, which until recently have been considered to be around 0.5kgCO 2 /kWh, compared to less than half this for gas.

But with carbon savings increasingly becoming the primary Key Performance Indicator for many energy managers, coupled with rapidly decreasing carbon intensity of the UK electricity grid as a result of cleaner forms of generation replacing high carbon intensity coal fired power stations, CHP is becoming less attractive as a solution to deliver carbon savings in new builds and across large commercial and public sector estates.

But despite the rapidly changing landscape from a carbon perspective, for those with CHP already installed, the ability to generate on-site electricity which can offset the cost of imported electrical power means that the technology continues to deliver cost savings.

The high differential between the cost of purchasing grid electricity and the cost per unit of fuel to produce both heat and power in a CHP unit means that from an energy savings cost perspective, CHP can still make a lot of sense.

However, the way in which CHP and boilers are sized and hydraulically connected has an enormous impact on the number of operating hours and thus the electrical generation possible. Also the size of the CHP, the system temperatures and the controls must be taken into account.

Hysopt has many years experience of optimising installations that feature CHP, and we’ve found that clients who have invested in CHP - especially in hospitals and universities - are simply not maximising the economic benefit of their installation - often due to poor design, control strategy and commissioning; inappropriate CHP plant or thermal energy storage sizing; or inefficient hydraulic integration between the boilers, thermal store and CHP.

Understand performance By using HVAC modelling and simulation software, it’s possible to properly understand how these systems perform and how they can be improved to optimise their performance.

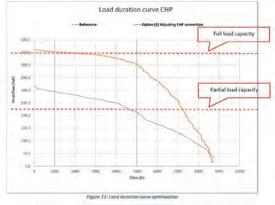

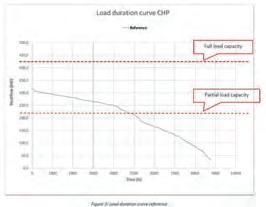

Fig. 1 shows an example of a typical CHP installation from a recent hospital optimisation project where the CHP engine is unable to operate at its full load capacity. As a result it is producing limited financial benefit for the client in the form of electricity cost savings.

In the example, the CHP has a thermal full load capacity of 447kW and is able to modulate down to 225kW. Modelling and simulation

of the CHP and associated hydraulic system using Hysopt’s HVAC optimisation software, illustrates the load duration curve, which shows the full load capacity is never achieved so the CHP system will spend most of its life short-cycling inefficiently and producing very little low-cost electricity.

The CHP thermal load share is 11 per cent while the electrical production from CHP is 1,052,759 kWh/yr. The annual (net) energy cost (including electricity production cost saving) is £223,567.

Modelling of the installation in the Hysopt HVAC optimisation software helps engineers identify areas where hydraulic optimisations can be applied and measure their impact in terms of energy and cost savings.

In the example, the insights provided through system simulation enabled engineers to recommended a number of hydraulic system design modifications - including reconfiguring the connections

Fig. 1 Software allows identification of when CHP is not operating at full load capacity

between the CHP and boilers; changing the hydraulic regime from constant to variable flow; and correctly rebalancing the installation. The CHP now operates at its full load capacity for much longer, increasing its share of the thermal load and subsequently the amount of “free” electricity produced, which has a direct annual energy cost saving.

The results include: • CHP thermal load share: 45 per cent • electrical production from CHP: 2,276,157 kWh/yr; • annual (net) energy cost (including electricity production cost saving): £117,371; • annual energy cost saving: £106,195 (48 per cent) • investment cost: £257,000; and • payback: 2.4 years.

Correct hydraulic design, configuration and control strategy is crucial to ensure HVAC systems achieve optimal energy efficiency and minimal running costs. And as systems become increasingly complex – particularly with the drive towards the integration of more sustainable sources of heat and energy such as CHP – system efficiencies are increasingly sensitive to correct hydraulic and control strategy.

Creating a ‘digital twin’ of a CHP installation using simulating and optimisation software can provide energy managers and building owners with a significant opportunity to increase the financial yield from their installation. All too many systems are designed using rules of thumb with additional safety margins to cover unknowns. Also, they are based on fullload design conditions without transparency of how systems will operate under partial load.

It is no surprise then that real-life performance often does not meet expectations and that hydraulic optimisation can typically yield between 30-50 per cent annual energy cost savings, with return on investment in 1-3 years.

For further information on products and services visit www.eibi.co.uk/enquiries and enter the appropriate online enquiry number

CHP helps fitness facilities to healthier energy costs

Veolia is now helping Total Fitness achieve a 32 per cent reduction in gas consumption using c ombined heat and power, CHP, acr oss 17 health and fitness facilities in the north of England and Wales.

The 15-year contract will install the latest technology to achieve a 22 per cent increase in electrical efficiency compared to the existing CHP units, lower energy costs and further reduce CO2 emissions from the 134,000m2 of building space.

Total Fitness operates 17 Health Clubs in the UK, advising over 100,000 members on their health and wellbeing. The company’s continual commitment to drive down energy consumption, utility costs and further reductions in carbon emissions, is one of the key drivers of the company’s business strategy.

Under the new c ontract each of the Health and Fitness centres will benefit from new co-generation plants that efficiently generate

electricity and heat from a single fuel source to cover their energy demands. Each onsite plant provides electricity and heat for the whole building, gyms, pools, showers, saunas, steam rooms, sanariums and domestic hot water. To match the location’s base electrical and thermal loadings the plants are individually sized, ranging from 140kWe to 250kWe and will take the total co-generation capacity across all the sites to 3.17MWe - equivalent to the power demand from 8,400 homes.

The contract covers a fully engineered package covering installation and operation of the CHP units that will take pressure off the local electricity infrastructure and provide stable energy costs that are less susceptible to energy market price changes. Also included in the contract is a 15-year operation and maintenance service.

ONLINE ENQUIRY 143

Council provides metering and billing services for communal heat systems

Nuneaton and Bedworth Borough Council has appointed Switch2 Energy to provide metering and billing services for five communal heating schemes.

Switch2 will retrofit its pay-asyou-go G6 smart meters to 170 homes across five residential sites – all served by communal heat systems. The initial five-year contract will also include meter maintenance, a pay-as-yougo (PAYG) facility and customer service provision.

Nuneaton and Bedworth Borough Council is one of the first councils in England to purchase metering equipment using the Fife heat network (metering and billing) procurement Framework. The framework enables an efficient delivery of heat metering projects to participating local authorities directly with approved suppliers. This provides assurance that a rigorous assessment and duediligence process has already been completed via an OJEU compliant tender process.

The new metering at the five Nuneaton and Bedworth Borough Council heat networks will comply with the Government Heat Network (Metering & Billing) Regulations.

The metering technology incorporates a display unit that shows precisely how much energy has been consumed and costs incurred, together with the resident’s credit status. An audio notification feature is included, which advises if credit is running low and an emergency credit facility is required. These features will help customers to improve budgeting and energy management, potentially leading to a reduction in their energy consumption and carbon footprint.

The G6 also uses smart wireless technology to replace the traditional corner shop/ tokenbased pre-payment system. Residents can instead ‘top-up’ by a smartphone app or online.

ONLINE ENQUIRY 144

Student accommodation feels the benefit of combined heat and power solution

Helec Ltd, a specialist in the specification, design and installation of CHP systems, has completed the supply and commissioning of a CHP solution at Crown Place Norwich (formerly St Stephen Towers), which has been converted by Crown Student Living into student accommodation.

The system is expected to save an estimated £38,000 in energy costs and 204,000kg of CO2 emissions per year. Helec specified and supplied two 33kWe Energimizer EM33NG CHP systems, which were installed in the plant room by building services company F P Hurley in June 2019. The r efurbishment of the 705-bedroom accommodation block opened in September 2019.

ONLINE ENQUIRY 145

Meanwhile, in December 2018, Helec were brought in to commission a solution to the hot water requirements and to help reduce electrical power consumption of Crown Student Living’s Crown Place Cardiff, a 374-bedroom student accommodation block

The requirement was to ensure consistent hot water throughout the year while keeping costs to a minimum per residence. Taking into account all individual requirements, an Energimizer EM22NG CHP unit was specified and installed within the building’s plant room. This system is expected to lead to annual fuel savings of £9,900 and reduce annual CO2 emissions by 56,500kg.

IMPROVED ACCCESS FOR EVEN EASIER MAINTENANCE UP TO 10% REDUCED LIFT WEIGHT

NEW FRONT PANEL DESIGN BUILT IN NON-RETURN VALVE,

INCREASING SAFETY

UPDATED CONTROLS NEW CASCADE

CONTROL