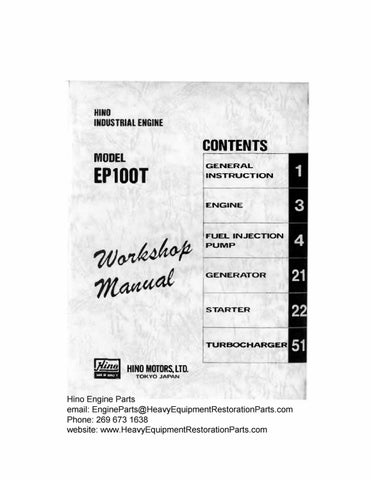

HIND INDUSTRIAL ENGINE

MODEL

EPlOOT

CONTENTS

GENERAL INSTRUCTION

ENGINE

FUEL INJECTION PUMP

I

GENERATOR

STARTER

TURBOCHARGER

l:mfi:l

HIND MOTORS. LTU TOK YO .JAPAN

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

FOREWORD This shop manual is a general description of the instructions and repairs required for HINO MODEL EP1 00T industrial diesel engine.

It also covers the constructions and operational

characteristics of the engine. Daily and periodical inspection and maintenance are the most important factors governing the high performance of the engine. The proper sequences and methods outlined should be followed in repairs. It is recommended that the customers make full use of this manual in order to attain the maximum efficiency maintenance and repair

NOTE:

All specifications appearing in this manual are based on the metric system. However. as ready reference, conversion has been made as shown below: mm (in), m (ft), km (mile) cm2 (sq.in) mm3 (cu.in). cc (cu.in), m3 (cu.ft), liter (lmp.gal/U.S.gal) g (oz). kg (lb) kg-cm (lb.ft.), kg-m (lb.ft.), kg/mm (lb/in), kg/cm2 (lb/sq.in) m/s (ft/s), km/h (mph)

1-100E-01

GENERAL INSTRUCTIONS GENERAL INSTRUCTIONS ................................... 1-1 CHASSIS & ENGINE SERIAL NUMBERS .......................... 1-2 SPECIFICATIONS .......................................... 1-3 BOLT TIGHTENING ........................................ 1-7 RECOMMENDED LUBRICANT LIST ............................. 1-9

1-1

GENERAL INSTRUCTIONS

Fig. 1-1

03-2252

1-2 ENGINE SERIAL NUMBER The engine serial number is engraved on the left side of the cylinder block.

ENGINE MODEL

SM3-1035

. Fig. 1-2

1-3

SPECIFICATIONS DIESEL ENGINE FOR INDUSTRIAL USE

EPlOOT

HIND APPLICATION:

e

8.821 liters, 4-cycle, 6-cyl., water-cooled

ELECTRICAL GENERATORS, WATER PUMPS, AIR COMPRESSORS, HYDRAULIC CRANES & SHOVELS, ROLLERS, TOWING TRACTORS, FORK-LIFT TRUCKS, SHUNTING LOCOMOTIVES AND OTHER GENERAL POWER PLANTS

PERFORMANCE & PERFORMANCE CURVE (STD. specs.) GENERAL USE (SAE J1349 Gross)

Max. torque

Output,

Output,

kW (HP) at rpm

kW (HP) at rpm

Nm (lbt·tt) at rpm

127 1170) at 2,200

711 (525) at 1,600

intermittent rating 149 1200) at 2,200

continuous rating

Ambient conditions: Intake air temperature Barometric pressure Water vapour pressure

SAE ° 25 C 100 kPa 1.0 kPa

GENERATOR USE (SAE J1349 Gross) Min. fuel consumption g/kWh (lb/HPh)

at rpm

215 10.353) at 1,600

Prime Power

Stand-by Power Output at 1,500rpm kW (HP)

Output at 1,800rpm kW (HP)

Output at 1,500rpm kW (HP)

Output at 1,800rpm kW (HP)

110 (.148)

129 1173)

94 (126)

110 (1481

DIN °

20 c 736 mmHg 10.5 mmHg

e ENGINE DESCRIPTION

1. Type 2. Combustion system 3. Cylinder Bore x Stroke 4. Piston displacement 5. Compression ratio 6. Direction of rotation 7. Dimensions (L X W x H) 8. Dryweight

e

Diesel, 4-cyc., 6-cyl., in-line, overhead valve, water-cooled, turbocharged Direct injection type 120 x 130 mm (4.72 x 5.12 in) 8.821 liters (538.3 cu. in) 17.0 Counter-clockwise viewed from flywheel Approx. 1,255 x 820 x 1,100 mm (49.4 x 32.3 x 43.3 in) Approx. 770 kg (1,700 lb)

FEATURES

1. Cylinder block 2. Cylinder head 3. Crank shaft

4. Piston and rings 5. Camshaft 6. Valves

Mono block cast iron with replaceable dry type liners Single piece cast iron Induction-hardened die forged special steel with counter weights Heat-resistance aluminum alloy Three compression rings, chrome plated One oil ring, chrome plated with coil expander Induction hardened carbon steel Heat resistance steel

1-4

e

STANDARD EQUIPMENT Flywheel housing Flywheel Fuel injection pump Governor Fuel injection nozzle Fuel filter Water separator Cooling system Lubricating system Oil filter Intake manifold Exhaust manifold with flange plate 13. Generator

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

14. Starter 15. Safety valve 16. Connectors of electrical equipments

e

HI NO own (SAE No.2 type) HINO own (SAE 11-1/2 in. type) BOSCH "P" type Centrifugal, all speed control type BOSCH hole type Paper element type Forced-circulation by volute pump Full-forced pressure feed by gear pump Paper element type (full flow & by-pass flow) Inlet position at front or right side Rearward exhaust Alternator with integral regulator 24V-20A 24V-6KW

OPTIONAL EQUIPMENT 1. Cooling fan (suction or blowout) 2. Main switch 3. Battery switch 4. Battery relay 5. Starter switch with key 6. Ammeter 7. Fuse box 8. Engine shut off solenoid 9. Emergency relay 10. Coolant temperature switch 11. Coolant temperature gauge sender 12. Coolant temperature gauge 13. Oil pressure switch 14. Oil pressure gauge sendet 15. Oil pressure gauge 16. Intake heater 17. Intake heater relay 18. intake heater indicator 19. Tachometer with hourmeter 20. Tachometer cable 21. Muffler ................2-3 type available 22. Air cleaner 23. Air cleaner cap 24. Radiator with cooling fan shroud

1-5

SM3-1033 FRONT SIDE VIEW

LJ SM3-1034 LEFT SIDE VIEW NOTE: 1 i 2) 3) 4)

These specifications are subject to change without notice. These specifications are for export models. All specifications of the products are with normal manufacturing allowances and tolerances. The performance and drawings are for standard specifications.

HIND MOTORS, LTD.

TOKYO, JAPAN

1-7 BOLT TIGHTENING Bolt tightening torque chart-for general purpose

Bolt indentification

0 0 0 0 0 0 e e

:�

Even tightening area. Bolt nut, coating, naked bolt, lubricant, etc. Optimum conditions.

Cast iron or aluminium tightening

surface, Washers. Medium conditions.

Tightening area having black coarse

surface. Rusty. Naked bolt or lubricant unavailable. Poor tightening conditions.

Even tightening area. Bolt nut, coating, naked bolt. lubricant, etc. Optimum conditions.

Unit: kg·cm (lb.ft)

4 10-15 10.8~1.01

14 ~ 20 (1.1~1.41

17

~ 25

(1.3 ~ 1.81

6 36

~ 53

12.7 ~ 3.81

48

~ 71

(3.5 ~ 5.11

60

~ 88

8 88

~ 128

17 ~ 91

117~172

10 174 ~ 255

304~ 445

113 ~ 181

122~ 321

232

~ 340

(9~121

(17~ 241

~ 2·14

290 ~ 425

146

14

12

405

~ 592

(30~421

506

~ 742

486

~ 712

(36 ~ 511

647

~ 950

(47 ~ 681

809~ 1,180

14.4~ 6.31

(11 ~ 151

(21 ~ 301

(37 ~ 531

16 ~ 24

58 ~ 83

138 ~ 201

273 ~ 400

477~700

11.2 ~ 1.7)

14.2 ~ 6.01

(10 ~141

(20 ~ 281

(35 ~ 501

{56 ~ 81)

75 ~ 110

183 ~ 270

364 ~ 533

636 ~ 932

1.020 ~ 1,500

127 ~ 381

147 ~ 671

~ 32

Cast iron or aluminium tightening surface. Washers. Medium conditions.

(1.6~ 2.31

Tightening area having black coarse surface. Rusty. Naked bolt or lubricant unavailable. Poor tightening conditions.

(2.0 ~ 2.81

Even tightening area. Bolt nut, coating, naked bolt, lubricant, etc. Optimum conditions.

(1.8 ~ 2.31

Cast iron or aluminium tightening surface. Washers. Medium conditions.

(2.4 ~ 3.0f

Tightening area having black coarse surface. Rusty. Naked bolt or lubricant unavailable. Poor tightening conditions.

(2.9

22

27

~ 40

24 ~ 32

32

~ 42

40 ~ 53

~ 3.8)

15.5 ~ 7.91

94

~ 138

114

~ 19)

229 ~ 336

455

~ 667

795~ 1,165

16.8 ~ 9.91

117 ~ 241

133 ~ 481

(58 ~ 841

82 ~ 110

200 ~ 267

397 ~574

694~ 925

(15 ~ 191

(29 ~ 411

(51 ~ 661

(6.0 ~ 7.91

110~146

267

~ 356

529

~ 706

925 ~ 1,230

(59 ~ 851

764 ~ 1.120

174~ 1081

1,270

~ 1,870

192 ~ 1351

1,010 ~ 1,480 (74~1071

16 758 ~ 1,110 155 ~ 801

1,010

~ 1,480

(74~ 107)

1,260~ 1,850 (92 ~ 1331

1,190

~ 1,750

(87 ~ 126)

1,590~ 2,330 1116 ~ 1681

1,990

~ 2,920

(144 ~ 2111

1,730 1126

~ 2,310 ~ 1671

18 1,040

~ 1,530

2,700

~ 3,970

2,560

~ 3,750

1$970 ~ 2,900 (143 ~ 2091

1,740~ 2,540

2,460 ~ 3,620 (178 ~ 2611

~ 4,950

4,260

(126~1831

(245 ~ 3581

1,640~2,400

2,320 ~ 3,410

3,180~4,680

4,020

1119~1731

(168~ 2461

(231 ~ 3381

(291 ~ 3871

2,180

~ 3,200

(196 ~ 2871

3,380

(186 ~ 2711

3,410

~ 5,000

(247 ~ 3611

~ 6,250

1309 ~ 4521

~ 5,360

3,100~ 4,550

4,250 ~ 6,210

5,360 ~ 7,850

(158 ~ 2311

(225 ~ 3291

(308 ~ 4491

1388 ~ 5671

2,730 ~4,000

3,870 ~ 5,680

5,310 ~ 7,800

(198 ~ 2891

(280 ~ 4101

(385 ~ 5641

3,380 ~ 4.510

4,630 ~ 6,170

(244 ~ 3261

(335 ~ 4461

(424 ~ 5631

4.510~ 6,010

6,170 ~8,230

7,790 ~ 10,390

2,380

~ 3,170

(173 ~ 2291

3,170

~ 4,230

2,310~ 3,080

(108~1421

(168~222)

(230 ~ 305)

137 ~ 183

334 ~ 445

662~ 882

1,160 ~ 1,540

1,850 ~ 2,470

2,890 ~ 3,850

3,970~ 5,290

(10,0~ 13.2)

125 ~ 32)

(48~ 631

(210 ~ 2781

(288 ~ 3821

~ 1781

~ 2,980 ~ 2151

1101 ~ 1471

1,480 ~ 1,970

(134

1147

2,030

1,390 ~ 2,040-

(67 ~ BBi

(84 ~ 111)

~ 2,170

24

1108 ~ 1561

(3!J~61)

~ 10.51

1,480

22

(76 ~ 1101

(19 ~ 25)

(8 .0

20

(327

5,640

~ 434)

~ 7,510

1408 ~ 5431

(447 ~ 595)

7,720 ~ 10,290 (559

~ 744)

6, 700

~ 9,850

1485 ~ 7121

5,850

1564

9,740 (705

~ 7,790

~ 751)

~ 12,990 ~ 939)

NOTE: The torque values given in this table should be applilld where bott torque is not IJM(:ifilld.

RECOMMENDED LUBRICANTS FOR ALL HINO ENGINE LUBRICANTS

ATMOSPHERIC TEMP.

POSITIONS

ENGINE OIL Previous Class,fication

32' 190'

IA PI OSI

IMIL•L·2104CI

IA. P.1. CCI Previous Class1f1cat1on IA P.1 DMI IMIL-L-46152I IMIL-L-210481

132'

COOLANT PUMP BEARING GREASE

Coolan! Pump Bearing

(MIL-G-109248)

STARTER GREASE

Bushmg. Clulch. Onve Shah. P1nton Shih lever & Reduction Gear

GENERATOR & STARTER BEARING GREASE

Generator Bearing Si,rter Beanng

INJECTION PUMP TIMER GREASE

lnIact10n Pump Timer

ANTI FREEZE

Engine, Rad11to1

IMIL•G· 1092481

IMIL-H-5559AI

MOBIL

SHELL

TOTAL

Essolube 0-3 40. XD-3 40

Gulf Super Oury Motor 011 40. 1 SW-40

Mobd Oelvac 1 340 Mobil Oelvac Super 15W-40

Myr1na 0.1 40. 20W•40. 1 SW-40 A1mula X Otl 40 R1mula CT 40

TOTAL Aub,a S 40 TOTAL Rubra TM 1 SW40

32'F1

30

Vanellus C-3 30

RPM DELO 400 Oil SAE 30 or 1 5Wt40 RPM DELO 300 Cit SAE 30

Castrol or Otusol CRD 30 Castro, or Deusol AX Super 30. 1 SW/40

Essolube D-3 30. X0-3 30

Gutf Super Dutv Motor Oil 30, 1 SW-40

Mobtt Delvac 1 330 Mobtt Deh,ac Super 15W-40

Myrina Oil 30. 20W•40, 1 SW-40 Atmula X Otl 30. 10W•30 Atmula CTJO

TOTAL Rubia S 30 TOTAL Rubia TM 1 5W40

12'C 10'FI

20

Vanellus C-3 20W

RPM DELO 400 011 SAE 20120W. 1 SW:40 RPM DELO 300 011 SAE 20t20W

Castrot or Oeusol CAD 2ow,20 Castro! or Deusol RX Super 20Wt20. 1SW140

Essolube 0-3 20W. XD-3 1 SW,40

Gutf Super Duty Motor 011 20. 1 SW-40

Mobtl Delvac 1310 Mobtt Oelvac Super 15W-40

Myrina 011 20. 20W-40. 1 SW-40 R1mula X 011 20 A1mula CT20

TOTAL Rubia S 20 TOTAL Rubia TM 15W40

40

Vanellus M

RPM DELO 200 Oil SAE 40 RPM DELO 100 0,1

SAE 40

Castrol or Deusol CRX 40 Cawol or Deusol AX Super 40. 1 5Wt40

Essolube HOX 40. HOX Plus 40

Gulflube Motor 011 XHD 40. 1 SW-40

Mobil Oelvac 1240 Mobtl Oelvac 1 140

Rotella TX40.20W-50 Rotella SX 011 40, 20W·40

TOTAL Rubta H 40

o·c

Above 32'C I90'FI

o·

GULF

Castrol or Deusol CAD 40. Turbomu Castrol or Deusol RX Super 40. 1 SW/40

132'

32' 190'

ESSO

RPM DELO 400 Otl SAE 40 01' 1 5Wt40 RPM DELO 300 011 SAE 40

o·

ENGINE OIL

CASTROL

Vanellus C-3 40

IMIL-L-4519981

Cyhnde, Block tnIect10n Pump Air Cleaner

CALTEX

BP

40

Above 32'C I90'FI

IA PI. COi

S.A.E. NO.

HINO MOTORS. LTD. OVERSEAS OPERATIONS TECHNICAL DIV TOKYO. JAPAN

40

32'F)

30

Vanenus M 30

RPM DELO 200 Oil SAE 30 RPM DELO 100 01! SAE 30

Castro! or Deusol CRX 30 Castro! or Deusol RX Super 30. 15Wi40

Essolube HOX 30 HOX Plus 30

Gulflube Motor 0.1 XHD 30. 1 SW-40

Mobil Delvac 1230 Mobil Oelvac 1130

Rotella TX30.20W·50 Rotella SX Oil 30. 20W-40

TOTAL Rubia H 30

12·c 10-FJ

20

Vanellus M 20W

RPM DELO 200 Q,1 SAE 20t20W RPM DELO 100 Oil SAE 20120W

Castro! or Deusol CRX 2ow.-20 Castro! or Deusol RX Super 20W120. 15W 40

Essolube HDX 20. HOX Plus 20W-20

Gulflube Motor 011 XHO 20. 1 SW-40

Mobil Delvac 1220 Mobd Oelvac 1120

Rotelta TX20,20W-50 Rotella SX 011 20/20W.20W-40

TOTAL Rubia H 20

Energrease L·2

Marfak Multipurpose 2 o, Mar1ak All P\l"lpose 2

Castro! LM Grease

Esso Multipurpose Grease

Gulfle� Poly

Mob1lgrease MP,77.MS

Retina.: A Alvania Grease R2

TOTAL MULTIS 2

o·c

---

Molyt!!l Grease EP2

---

---

---

Mob1lgrease 29

A-,ro Shell Grease 1 7

---

Energrease LT 2

RPM Grease SRI 2

---

---

---

Mob,lgrease 2B

Aero Shell Grease 7

---

Energrease L-2

Mar1ak Multipurpose 2 or Marfak All PurposP. 2

Castrol LM Grease

Essa Mul11pwpose Grease

Gulflel Poly

Mob1lgrease MP.77.MS

Ret1nax A Alvama Grease R2

TOTAL Mult1s EP 1

An11 Fros1

AF Engine Coolant

Casl/OI An11-Freeze Cas11ol Long Lile Cool11nt

esso Anti Freeze Cootani

Cruise Master Antifreeze And Summer Coolant

Mobil Permazone

Shellzone!U S A.) Glycoshetl Plus (Europian Countries! Shellsafe Al'lt1-FrHze P281 CoolQuard

TOTAL ANTIGEL

Note: Lubricants were amended ,ccording to ntW clauifie1t1on by A P.l <Amencan Petroleum Institute)

'82-12-200 rT.S.DH!!I

3-17ESF-01E

ENGINE MOTOR MOTEUR SYMBOL MARKS SIMBOLOS SYMBOLES ............................................. · 3-1-1 A GLOSSARY OF TECHNICAL TERMS GLOSARIO DE TERMINOS TECNICOS LEXIOUE DE TERMES TECHNIQUES ........................... 3-1-2 INTRODUCTION INTRODUCCION INTRODUCTION .......................................... 3-1-5 SPECIAL TOOLS HERRAMIENTAS ESPECIALES OUTILLAGE SPECIAL ...................................... 3-1-12 OVERHAUL REPARACION GENERAL REVISION ENGINE OVERHAUL CRITERIA CRITERIOS SOBRE REPARACION GENERAL DEL MOTOR CRITERE DE REVISION OU MOTEUR ......................... 3-2-1 CYLINDER HEAD AND VALVE MECHANISM CULATA DEL CILINDRO Y MECANISMO DE VALVULA CULASSE ET MECHANISME DE SOUPAPE ...................... 3-3-1 TIMING GEAR AND CAMSHAFT ENGRANAJE DE LA DISTRIBUCION Y ARBOL DE LEVAS PIGNONS DE DISTRIBUTION ET ARBRE A CAMES ................ 3-4-1 CYLINDER BLOCK, PISTON AND CRANKSHAFT BLOOUE DE CILINDROS PISTON Y SIGUENAL BLOC-CYLINORES, PISTON ET VILEBREOUIN ................... 3-5-1

LUBRICATING SYSTEM SISTEMA DE LUBRICACION SYSTE:Mt DU G�lAISS/\G[ ........................... 3-6-1 COOLING SYSTEM SISTEMA DE ENFRIAMIENTO SYSTEM[ Of_ Rf·f·HOIUISSI fv1LNT ...................... 3-7-1 FUEL SYSTEM SISTEMA DE COMBUSTIBLE SYSTE ME. COMfllJS 11 Ill I ............................ 3-8-1 AIR CLEANER FILTRO DE AIRE � I L TR L A A I H .. . .... . . . . . .... ... . .. ..... ..... . .. . 3-9-1 TUNING THE ENGINE PUESTA A PUMTO DEL MOTOR GONFLAGE OE MOTEUR ............................ 3-10-1 TROUBLESHOOTING LOCALIZACION DE AVERIAS RECHERCHE DE LA PANNE ......•...............•... 3-11-1 SERVICE STANDARD NORMAS DE SERVICIO CARACTERISTIQUES DE REPARATION ................. 3-12-1

3-1-1 SYMBOL MARKS The following symbols have been adapted for simplicity and for easy comprehension. SIMBOLOS Se han adoptado las siguientes simbolos para simplidad y facil comprensi6n.

SYMBOLFS

LPs symboles suivants ont ete adoptes ,1fin de simplifier et de faciliter la comprehension.

1..1"1

ASSEMBLY ARMADO MONl!\(;1- IHfMONT/\GE)

l}�I

DISASSEMBLY DESARMADO DE MONTAGE:

B

E1 �

l!t1

INSTALLATION INSTALACION MISE EN PLACE (POSE OU REPOSE) REMOVAL REMOCION DE'POSE INSPECTION INSPECCION CONTROLE MEASUREMENT MEDICION MESURE

EJ E1 Iii 81 [I]

TIGHTENING APRIETE SER RAGE (RESSERRAGE) CLEAN LIMPIEZA NETTOYAGE IMPORTANT IMPORT ANTE IMPORTANT ADJUSTMENT AJUSTE REG LAGE (MISE AU POINT) LUBRICATION LUBRICACION GRAISSAGE

3-1-2 A GLOSSARY OF TECHNICAL TERMS GLOSARIO DE TERMINOS TECNICOS LEXIOUE DES TERMES TECHNIQUES

ENGLISH 1. 2. 3. 4.

5.

6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43.

Air compressor gear Approx. (Approximately) Arc welding Assembly standard Bushing inside diameter Cam height: A Case bushing inside diameter Cam gear Clearance Clearance between valve stem and guide Clearance between liner and piston Coolant pump gear Cooling jet Correct Crankshaft gear Crankshaft matching Crank pin Cut-off valve Cylinder block Cylinder liner Cylinder head Cylinder head lower face Deflection Dimension Dimension of fillet R Difference between cylinders Drive shaft Drive gear shaft outside diameter Driven gear shaft outside diameter Driven gear bushing inside dimaeter Engine speed (r.p.m.) End play Exhaust Exhaust manifold 1st ring 1st step Force about Free length Gasket Groove breadth Idle gear Incorrect Injection pump

ESPANOL 1. Engranaje del compresor de aire 2. Approx. (aproximadamente) 3. Soldadula electrica 4. Estandard de armado 5. Diametro interio del casquillo 6. Altura de levas: A 7. Diametro interior del casquillo de caja 8. Engranaje de eje de levas 9. Holgura 10. Holgura entre vastago de valvula y guia 11. Holgura entre camisa y piston 12. Engranaje de la bomba de enfriador 13. Chorro de enfriamiento 14. Correcto 15. E ngranaje del ciguenal 16. Rectificaci6n del ciguenal 17. Codo de ciguenal 18. Valvula cierra 19. Bloque del cilindro 20. Camisa del cilindro

21. Culata del cilindro 22. Superficie inferior de la culata del cilindro 23. Defleci6n 24. Dimension 25. Dimension de filete R 26. Diferencia entre cilindros

FRANCA IS 1. Pignon du cornpresst�ur d'a1r 2. Approx. (Appru>:i1n;Jtivement) 3. Soudure a l'arc electrique 4. Norrne rJe montaqe r· Diametre interipur de la bague 6. Hauteur de la came A

�-

7. Diametre interieur du carter de baque 8. Pignon de l'arbre cames

a

9. Jeu 10. .Jeu entre la tige de soupap1-, et le guide 11. Jeu entre la chemise et le piston 12. Pignon rJ'entraineinent de la pompe eau 13. G icleur de refoidissement 14. Correct

a

�-

p·

Pignon du vilebrequin

16. Equilibrage de vilebrequin 17. Maneton de vilcllrequin 18. Soupape de detente 19. Bloc-cylindres 20. 21. 22. 23. 24. 25.

Chemise de cylindre Culasse Face inferieure de la culasse Flex ion Dimension Dimension de rayons de

27. Eje impulsor 28. Diametro interior del eje de engranaje impulsor 29. Diametro exterior del eje de

raccordement 26. Difference entre les cyl incl res 27. Arbre d'entrainemenl 28. Diametre exterieur de l'arbre de pignon d'entraInement 29. Diametre exterieur de l'arbre de

engranaje impulsion 30. diametro interior del casquillo de engranaje impulsion 31. Velocidad del motor (r.p.m.) 32. Juego longitudinal

30. Diametre interieur de la bague du pignon entralne 31. Regime de moteur ( tr/mn) 32. Jeu axial

33. Escape 34. Multiple de escape 35. Aro 10 a 36. 1 etapa 37. F uerza aprox imadamente 38. Longitud libre 39. Junta 40. Anchura de ranura 41. Engranaje loco

pignon entra1ne

33. Echappement 34. Collecteur d'echappement 35. Segment coup de feu (Segment 1) 36. 1 ere et ape 37. 38. 39. 40.

Effort approximatif Longueur libre Joint Largeur de la rainure

41. Pignon intermediaire

3-1-3 Inner spring Intake Inside diameter Journal kg,cm (lb.ft) kg/cm 2 (lb/sq.in) Less Less than Lower seat More than No.1 - No.5 bearing inside diameter 55. No.1 - No.5 journal outside diameter 56. Not easily measured 57. Nut

44. 45. 46. 47. 48. 49. 50. 51. 52. 53. 54.

58. Oil clearance

59. Oil pump drive gear 60. 0-ring 61. Oil ring 62. Oil seal sleere 63. Outer spring 64. Outside diameter

65. Piston pin bore inside

66. 67. 68. 69. 70. 71. 72. 73. 74. 75. 76.

77. 78. 79. 80. 81. 82. 83. 84. 85. 86. 87. 88. 89. 90. 91. 92. 93. 94. 95.

diameter Piston pin outside diameter Power steering oil pump gear

Regulator valve Relief valve Repair limit Repair limit of bent Repair limit of twist Ring breadth Ring gap Rocker arm bushing inside diameter Rocker arm shaft outside diameter Rotating torque Roundness 2nd ring 2nd step Service limit Setting length Setting load Shim thickness Sleeve Spacer Special tool Standard Stem cap Tappet outside diameter Tappet guide inside diameter 3rd ring 3rd step Tightening torque Unit

45. 46. 47. 48. 49. 50. 51. 52. 53. 54.

55. 56. 57. 58. 59. 60. 61. 62. 63.

64. 65. 66. 67. 68. 69.

70. 71.

72. 73. 74. 75. 76. 77. 78. 79. 80. 81. 82. 83. 84. 85. 86. 87. 88. 89.

42. 43. 44. 45. 46. 47.

lncorrect(e) Pompe d'injection Ressort interieur Admission Adomisi6n Diametre int�rieur Diametro interior Tourillon Muiion 48. kg-cm kg-cm (lb.pie) 2 49. kg/cm 2 kg/cm (lb/pul.cuad) 50. Moins Menos 51. lnferieur(e) a Menos de 52. Coupelle inferieure Asiento interior 53. Superieur(e) a Mas de 54. Diametre interieur du coussinet Diametro interior de\ cojinete du palier nOl - n05 No.1 - No.5 exterieur du tourillon Diametre 55. Oiametro exterior de\ muiion n05 n01 No.1 - No.5 56. Difficilement mesurable No puede medido facilmente 57. Ecrou Tuerca 5 8. Film d'huile Holgura de aceite Engranaje impulsor de la bomba 59. Pignon d'entra1nement de la pompe a huile de aceite 60. Joint torique Anillo-0 61. Segment racleur d'huile Aro de aceite 62. Manchon de bague d'etancheite Manquito de\ sello de aceite 63. Ressort exterieur Resorte exterior 64. Diametre exterieur Oiametro exterior 65. Oiametre interieur de l'alesage Oiametro interior de\ oriticio de \'axe de piston de pasador de piston Diametro exterior del pasador de 66. Diametre exterieur de l'axe de piston piston Engranaje de la bomba de aceite 67. Pignon d'entra1nement de la pompe a huile de la direction de la direccion hidraulica assistee Valvula regulador 68. Soupape regulatrice Valvu\a descarga 69. Soupape de surete Limite de reparaci6n 70. Limite de reparation Limite de reparaci6n de comba 71. Limite de reparation de voile flexion Limite de reparaci6n de 72. Limite de reparation de torsion corcedura 73. Largeur du segment Anchura de\ aro 74. Jeu a lacoupe de segment Entre chierro de aro 75. Diametre interieur de la bague Diametro interior de casquillo du culbuteur del brazo de balaci n 76. Diametre exterieur de l'axe de Diametro exterior del eje del culbuteur brazo de balanci n 77. Couple de rotation Par de rotacion 78. Rondite Redondez 79. 1 er segment d'etancheite Aro i2 (Segment 2) 21J. etapa 80. 2e etape Limite de servicio 81. Limite d'utilisation Longitud de ajuste 82. Longueur comprimee Carga de ajuste 83. Sous charge de Espaciador de lamina 84. Epaisseur de la cale Manguito 85. Manchon Espaciador 86. E ntretoise Herramienta especial 87. Outil special Estandard 88. Normal(e) Tapa de\ vastago

42. lncorrecto 43. Bomba de inyeccion 44. Resorte interior

3-1-4 96. 97. 98. 99. 100. 101. 102.

Upper seat Valve clearance Valve guide inside diameter Valve stem outside diameter Wear Within Wrong

90. Diametro exterior de levanta-

valvula

91. Diametro interior del guia de 92. 93. 94. 95. 96. 97. 98. 99. 100. 101. 102.

levantavalvula Aro 3Q ďż˝ etapa Par de apriete

Unidad Asiento superior Holgura de valvula Diametro interior de la guia de valvula Diametro exterior del vastago valvula Desgaste Dentro de Err6neo

89. Capuchon de queue de soupape couple de serrage 90. Diametre exterieur du poussoir 91. Diametre interieur du guide de poussoir 92. 2 e segment d'etancheite (Segment 3) 93. 3 8 etape 94. Couple de serrage 95. Unite 96. Coupelle superieure 97. Jeu de soupape 98. Diametre interieur du guide de soupape Diametre exterieur de la queue de 99. soupape 100. Usu re 101. a l'interieur 102. Mauvais(e)

3-1-5

ENGINE {Model EP100T) INTRODUCTION Model EP100T industrial diesel engine is 4-cycle, direct injection type diesel engine having 6 cylinder in-line water cooled and overhead valves.

DIFFINITION OF TERMS The terms adopted in this Workshop Manual are defined as follows.

Rotation: This engine rotates clockwise seen from the timing gear side. Nominal dimension: Basic dimension excluding tolerance. Nominal clearance: Space allowed between two parts on account of difference of tolerance when fixed together. Repair limit: Parts which reach this limit should be repaired. The mark (+)or (-) expresses increase or decrease as compared with the nominal dimension. Serviceable: The utmost that can be serviceable and parts which reach this limit should be replaced. The mark (+)or(-) expresses increase or decrease as compared with the nominal dimension.

3-1-6

DATA & SPECIFICATIONS GENERAL Model ........ : ........................ HINO EP100T Model . . . . . . . . . . . . . . . . .. . .. . . . .. . . .. . . . Diesel, 4 stroke cycle, vertical 6 cylinder in-line, overhead valve, water-colled direct injection type Bore and stroke . . . . . . . . . . . . .... . . . . . . . . . . 120 x 130 mm (4.72 x 5.12 in) Piston displacement· . . . . . . . . . . . . .. . . . . . . . . . 8.821 liters (538.3 Cu.in) C ompression ratio. . ...... . . . . .. . ..... . . . . . 17.0 : 1 Firing order ............................. 1-4-2-6-3-5 Compression pressure . . . . . . . . . .. . . . . . . . . ... 2 8-30 kg/cm 2 ( 399-426 lb/sq.in) at 200 rpm Maximum revolution (at full load) . . . . . . . . . . . . . . 2,200 rpm Idling speed . . . . . . . . .. . . . . . . . . . . .. . . . . . . . 700 - 750 rpm Weight ................................ 770 kg (1,700 lb) CYLINDER HEAD Type . . . . . . . . . . .. . . . . . .... . . . . . . . . . . . . Single piece casting Material . . . . . . . . . . . . ... . . . ...... . . .. . . ... C ast iron VALVE MECHANISM ° Valve seat angle; Inlet .................. 30 ° Exhaust ............... 45 ° Inlet .................. 30 Valve face angle; ° Exhaust ... . ...... . .... 45 Inlet.. . . . . . . . . . . . . .. . . Heat-resisting steel Valve material; Exhaust Special heat resistance steel ° Valve timing (flywheel travel); Inlet opens .... . 6 before T.D.C. ° Inlet closes ..... 22 after B.D.C. ° Exhaust opens .. . 32 before B.D.C. ° Exhaust closes .. . 6 after T.D.C. Inlet .......... 0.40 mm (0.0157 in) Valve clearance (when cold) Exhaust ....... 0.50 mm (0.0197 in) Tappet ................................ Special cast iron Push rod . . . .. . . . . . . . . . .. . . . . . . . . . . . . . .. Hollow, carbon steel CYLINDER BLOCK, CYLINDER LINER AND CAMSHAFT Cylinder block ........................... Mono-block, 6 cylinder, cast iron Cylinder liner . . . . . . . . . . . . . . . . . . . . .. . .. . . . Dry type, replaceable, special cast iron, centrifugally cast Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Induction hardened die-forged carbon steel in material Camshaft bearing; Number and material ........7, white metal with carbon steel back metal

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-1-7 CONNECTING ROD AND PISTON Connecting rod . . .. . . .. . . .. . . .. . . . . . . . . . . 6, carbon steel Small end bearing, Material .. . .. . .. . . . . . . . . . . . Leaded tin bronze Large end bearing, Material . . . . . . . . . . . . . . . . . . . Thin-kelmet with lead alloy Piston . . . ....... . . . . . . . .. . . . . . . . . . . . . . . Heat-resistance aluminum alloy Compression .................. Three with chrome-plated Piston ring; Oil ring ..... . . .... . . . .... . ... One, chrome-plated with coil expander CRANKSHAFT AND CRANKSHAFT BEARING Crankshaft .. . . ... . . . . . . . . . . . . . . . . . . . . . . Induction-hardened die forged special steel with counter weights Crankshaft bearing: Material . . . . . . . . .. . . . . . . . Lead indium and kelmet over steel back metal TIMING GEAR Timing gear drive . . . . . . . .. .... . . . . . . . . . . . . Helical gear FUEL SYSTEM Fuel injection pump Injection timing (flywheel travel) ............... Governor .............. .... . ........... Fuel feed pump Nozzle . .. . . . . . . . . . .. . . . . . . . . . . . . .. . . .. Nozzle holder ........................... Fuel filter . . . . . . . . . .. . . . . . .. . . . . . . . . . . . .

BOSCH line type, driven by engine, 1/2 x engine rpm, clockwise seen from the drive side ° 16 before 1st cyl. T.D.C.(Top dead center) BOSCH type, mechanical all speed control (RSV) Piston type, driven by injection pump camshaft, max. feeding pressure 3.4 kg/cm2 (48.3 lb/sq. in) Multi-hole nozzle type Injection pressure 220 kg/cm 2 (3,125 Ibis.in) Replaceable paper element type

LUBRICATING SYSTEM Type . . . . . . . .. . . . . . . . . . . . . . . . .. . . . .. . . Forced-feed lubrication with oil pump Oil capacity ............................. 26 liters (5.72 Imp. gal/6.87 U.S. gal) Oil pressure ............................. 0.5-5.0 kg/cm 2 (7.11-71.1 lb/sq.in) Oil filter . . . . . .. . . . .. . . . . . .. .. . . . . .. . . . . Full flow type using paper element and bypass type using depth element COOLING SYSTEM Type . . ... . . . .. . . . . . . . . . . . . . . . . . . . . . . . Radiator cap pressure ..... ................. Water boiling temperature . . . . . . . . . . . . . . . . . . . Cooling system water capacity (only cylinder block) .. Coolant pump . . . ..... . . . . .. . . . . . . . .. . . . . Fan: Type . . . . . . ... . . . . . . . . . . . . . . . . . . . Drive . . . . . . .. . . . . . .. . . ... .. . . . . . .

Forced recirculation type 0.5 kg/cm2 (7.11 lb/sq.in) than atmospheric pressure ° ° 106 - 110 C (222.8-230 F) 15.5 liters (3.41 lmp.gal/4.10 U.S.gal) Centrifugal, belt-driven by engine crankshaft Mounted on coolant pump, 2-3 type available 6-blades type, fully shrouded belt-driven by engine crankshaft pulley Radiator: Type .... . ................. .... Corrugate type Mounting .... .. . .. . . . . . .. .. . . .. Rubber shock insulators ° ° Thermostat ............................. Wax type, bottom by pass system, open at 76.5 C (169 F) ° ° max. lift 10.0 mm (0.393 in) at 90 C (194 F) AIR CLEANER Type .... ...... ................. ...... Dry type (paper element), 2-3 type available

3-1-8 PERFORMANCE & PERFORMANCE CURVE

Output, intermittent rating KW (HP) rpm ........... 149 (200) SAE J1349, Gross (without cooling fan) 139 (186) 129 (173) 118 (153)

at 2,200 rpm at 2,000 rpm at 1,800 rpm at 1,600 rpm

Output, continuous rating KW (HP) at rpm .......... 127 (170) SAE J1349, Gross (without cooling fan) 119 ( 159) 110 (148) 100 (134) Max. torque Nm (lb.ft) at rpm .......... 711 (525) NOTE:

Outputs are converted to SAE J1349 standard ambient conditions; ° Intake air temperature 25 C Barometric pressure 100 KPa Water vaper pressure in atmosphere 1.0 KPa

E z

SAE Jl349 (Gross)

�....__

�.,,,,..200 <(

180

150

140

130

Intermittent

160 120 z <( ::::> z (/) a. w 110 l-1-� ::::> 0 ::i 140 0 a.. 100

1-u

t;

at 2,200 rpm at 2,000 rpm at 1,800 rpm at 1,600 rpm at 1,600 rpm

(L

120 100 80

90

80 70

60

/ / ..... 1,000

-

/

/

1,200

\

/

/

\y,... V .. "'/

,

..

/

;1'

1,400

�600

/

/

--..

V

/

.. � .. .. I/

700

+-

550

500

LU W ::::> 0 a: cc ::i <(0 600 450 0 I- a.. u

650

V

w

_j a)

\continuous

1,800

ENGINE SPEED (r.p.m.)

i--

-

240 230 220 210

2,000 2,200

VELOCIDAD DEL MOTOR (r.p.m.) REGIME DU MOTEUR (tr/mn)

Fig. 3-1-1 Engine perfomance curves Curvas caracteristicas del motor Courbes des performances du moteur

_j

(L

04 0 038 l 0·36 0·34

w C/l ..J ::i Ill ro -2 1-Q (/) u Z�z 2�w I-OZ a..uo � I-W ::) Cl> 0 <( Z02 0�2 U::::>o ..J wzz ::::>OO LL (.) U Cl)(/)

SM3-1036

3-1-9 Output, intermittent rating

188 (138.3) at 2,200 rpm

PS (KW) at rpm

180 (132.3) at 2,000 rpm

DIN 62708 (with cooling fan)

166 (122.1) at 1,800 rpm 151 ( 111. 1) at 1,600 rpm Output, continuous rating

160 (117.4) at 2,200 rpm

PS ( KW) at rpm

151 (111.0) at 2,000 rpm

DIN 6270A (with cooling fan)

141 (103.7) at 1,800 rpm 129 ( 94.9) at 1,600 rpm Max. torque

Kgm (Nm) at rpm . . . . . . .

68 (666.8) at 1,600 rpm

NOTE: Outputs are converted to DIN 6270 standard ambient conditions; °

Intake air temperature

20 C

Barometric pressure

735 mmHg

Water vaper pressure in atmosphere

10.5 mmHg

---

DIN 6270 (/)

a.

150

200 I........

14 130

��

t-u z ::> z <! Q. w (/) t-1-� ::> 0 :J 0 Q. a.

120

90

180

60

60

160

627 08

140

120

100

I

V

V

/

y A ,. ..,,

/ /

/ ., ,.,, /'

' ..........

j

80

V 1,000

1,200

-�__..,.l---'"'... 1,400

1,600

� w 600 o � a: cc :J

soo

e 6: s

/

t\6270A

I /

I /

700

400

✓

80 70

70

50

II 0 100

E z

.,,.,,,

I80 I 70 I 60

1,800 2,000 2,200

ENGINE SPEED (r.p.m.) VELOCIDAD DEL MOTOR (r.p.m.) REGIME OU MOTEUR (trs/mn) SM3-1037 Fig. 3-1-2

Engine performance curves

Curvas caracteristicas del motor Courbes des performances du moteur

3-1-10

DESCRIPTION (General views)

SM3-1034

LEFT SIDE VIEW

SM3-1033

FRONT VIEW

Fig_ 3-1-3

3-1-11

(Remarkable tightening torque positions) ¢12P1.75 1,100-1,200 kg·cm

I ¢10P1.5 I 300-500 kg•cm I

¢17 P2.0 c/>10 Pl.5

3,300-3,500 kg•cm 650-750 kg•cm

¢14P2 1,000-1,300 kg-cm

¢16P1 .5 2,600-2,900 kg•cm

c/J22P1.5 5,500-7,000 kg•cm

,,....._--------1 ¢30P1 .5 I 1,000-1,200 kg•cm I

SM3-588

¢8 P1.25

c/>8 P1.25

190-270 kg•cm

q,14 P2.,0 ¢16 P2.0

¢15 P1.5 Fig. 3-1-4

2,200-2,400 kg·cm

190-270 kg•cm

1, 100-1,500 kg•cm

2,700-2,900 kg•cm SM3-1039

3-1-12

SPECIAL TOOLS

Prior to starting an engine overhaul, it is necessary to have the following.

Illustration

Tool No.

/ 09442-1200 I / \ ,..____...,,,.,,,...

0

Tool name

./PISTON RING EXPANDER

Usage

For removing and install the piston rings

964507-435 985136-104

O-RING

09470-1022 09433-1061

VALVE SPRING PRESS

For installing or removing valve spring and lifting cylinder head

09420-1442

SLIDING HAMMER

For removing the nozzle holder (Used with nozzle holder puller 09462-1130)

0�402-1140.

PRESS

For camshaft end plug

WRENCH

To tighten the cylinder head bolt

/

)

(Used with 09402-1280) (Used with 09402-1161)

··�-----

0$839-2205

3-1-13

Illustration

Tool No.

w

c,·""

Tool name

Usage

09444-1210

V-BEL T TENSION GAUGE

For V-belt tension

09482-1350 .'

PRESS

For the injection pump drive shaft sleeve

09420-1180/

PULLER

For the injection pump drive shaft sleeve

ADAPTOR

For with drawing the idle gear shaft (Used with 09420-1442)

STOPPER

For tappet hold

09412-1080

WRENCH

For water pump vane puller

_09552-1030

PRESSURE GAUGE ADAPTER

For the compression gauge

Is,

'--

�

-�·""

.� -" ·

_

.. -··

/09462-1410

\

' \

09451-1040

)

3-1-14

Illustration

Tool name

Tool No.

Usage

09420-1450

CYLINDER LINER PULLER

For removing the cylinder liner and measuring the protrusion of the cylinder liner

09402-1290

DUST SI LINGER P�ESS

For pressing the dust slinger to crankshaft pulley

09402-1161

PRESS

To install the front oil seal sleeve

09480-1100

CY,LINDER LINE'ft ) Gl:JIDE I

,

...-····

··---.\

To install the cylinder liner

(

\ i

09441-1051

P,ISTON RING/ HOLDER

09482-1420

,PRESS

09482-1430

.· PRESS

,/

For piston installation

For front oil seal to timing gear cover

For rear oil seal

3-1-15

Illustration

Tool No.

Tool name

Usage

09402-1220

PRESS

To install rear oil seal sleeve

09420-1111

PULLER

For injection pump drive gear

09431-1010

VALVE LAPPING TOOL

For valve lapping

09819-1707

W.RENCH

Tightening or retightening injection pump coupling

09472-1210

NOZZLE SLEEVE BAR

For installing.the nozzle sleeve (Used with 9800-06100)

9800-06100

STEEL BALL

For expanding the nozzle sleeve (Used with 09472-1210)

09408-1010

COMPRESSION ADAPTER

For measuring engine compression pressure (Bolt size PF 3/8)

3-1-16

Illustration

Tool No.

Tool name

/

For with drawing the nozzle holder (Used with 09420-1442)

STEM SEAL PRESS

To install the valve stem seal

ENGINE HANGER

For lifting the engine

09482-1210

PRESS

For pressing the oil seal of water pump

9001-24265

CONNECTOR BOLT

For inspection of the piston cooling jet

TARGET PLATE

For inspection of the piston cooling jet

ADJUSTER BAR

To adjust the jet nozzle

/

./·

· 09472-175(Y

.6�405-1190 ..,.,.....

,

l

)

ADAPTER

//

09462-11JQ/

(

Usage

,,/

,I

··

, , 09470-1090 ·�--., - . .

09472-1620 .· .·

3-2-1 OVERHAUL ENGINE OVERHAUL CRITERIA

1. Factor which determine when an engine overhaul is needed. 1) Lowered compression pressure.

NOTE:

1. 1I 2) 3) 4) 2. 1) 2)

Fig. 3-2-1 09408-1010 09552-1030

Special tool

Before measurement. Correct the valve clearance ° ° Warm up engine (about 80 C, 176 Fl Charge the battery fully Remove the air cleaner Measurement Remove the six nozzle holder Install the gauge adapter

REPARACION GENERAL REPARACION GENERAL DEL MOTOR

Unit: kg/cm 2 (lb/sq.in) Standard value

Limit

Difference between each cylinder

28-30 (399-426)

26 (370)

Less than 3 (43)

Engine speed (r.p.m.) 200

1. Factores que determinan la necesidad de efectuar una reparaci6n general del motor. 1) Presi6n de compresi6n insuficiente.

NOTA: 1. Antes de la medici6n 1) La holgu ra de la val vu la esta correcta ° ° 2) La temperatura del agua es de 80 C (176 F) 3) Cargue la bateria por completo 4) Remueva el filtro de aire

2. Medici6n 1) Remueva los seis portainyectores 2) Revise la revoluci6n del motor

REVISION

REVISION DU MOTEUR

1. Facteurs dont depend la prise de decision sur le moment ou ii faut envisager la revision du moteur. 1) Baisse de la pression de compression.

N.B.: 1. 1) 2) 3) 4) 2. 1) 2)

Avant prise de mesure Le jeu de soupape est correct ° La temperature de l'eau de refroidissement est de 80 C Charger la batterie pleinement Deposer le filtre a air Mesure Deposer les six porte-injecteurs Verifier le regime du moteur

2) Oil pressure decreases.

2) La presi6n de aceite disminuye. 2) La pression d'huile diminue.

Fig. 3-2-2 Service limit

SM3-590 2

0.4 kg/cm (5.7 lb/sq.in)

3-2-2 3. Other factor a. The blow-by explacive gas in the cylinder block will increase. b. The engine will not start easily. c. Engine output decrease. d. Fuel consumption increases. e. Engine makes a larger noise.

3. Otros factores a. Aumento de_ las gases de "blow-by" en el bloque de ci I i_ndros. b. El motor no arranca con facilidad c. La potencia del motor disminuye. d. Aumento del consume de combustible. e. El motor produce un ruido excesivo. 3. D'autres facteurs a. Le gaz explosif par soufflage (blow-by) dans le bloc-cylindres sera augmente. b. Le moteur ne demarrera pas facilement. c. Perte de la puissance du moteur. d. Augmentation de la consommation en carburant. e. Le moteur fonctionne avec un bruit plus mar quant.

3-2-3

,44 ..,

ENGINE COMPONENT PARTS PIEZAS COMPONENTES DEL MOTOR PIECES COMPOSANT DU MOTEUR Disassembly Desarmado De montage 1. Drain the water and engine oil.

NOTE: After drain the ,water and engine oil, retighten the each drain plug.

2. Dismount the following component parts. 1) Remove the cooling fan. 2) Fuel filter 3) Engine oil level gauge 4) Remove the fuel pipes and oil pipes 5) Remove the starter

Fig. 3-2-3

03-1034

.El Fig. 3-2-4

EPIT-046

El Fig. 3-2-5

6) Remove the generator (1) Loosen the belt tension adjusting bolt,@. (2) Remove the nut, G) . (3) Loosen the through bolt, @. (4) Remove the V-belt.

SM3-1040

7) Remove the oil filter with oil cooler.

3-2-4 8) Remove the fuel pipes, oil pipes and fuel leakage pipes. 9) Remove the fuel injection pipes.

Fig. 3-2�

03-2255

10) Di'sconnect the coupling (1) Loosen the through boltG). (2) Remove the coupling bolts and nuts.

Fig. 3-2-7

03-2261

11) Remove the injection pump.

Fig. 3-2-8

04-1322

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-3-1 HINO EP100 EP100T CYLINDER HEAD AND VALVE MECHANISM CULATA DEL CILINDRO Y MECANISMO DE VALVULA CULASSE ET MECHANISME DE SOUPAPE HE11-087-00X01 (1320)

INTAKE AND EXHAUST MANIFOLD 1. 2. 3. 4. 5. 6. 7.

Intake manifold Intake manifold gasket Exhaust manifold Exhaust manifold gasket Seal ring Intake pipe Air hose

MULTIPLE DE ADMISION Y ESCAPE

1. 2. 3. 4. 5. 6. 7.

Multiple de admision Junta del multiple de admision Multiple de escape Junta del multiple de escape Aro reten Tubo de admisi6n Manguera de aire

Fig. 3-3-1

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-3-2

HE11-087-00x01 (1000)(2/2) â&#x20AC;¢ 8

CYLINDER HEAD & RELATED PARTS 1. 2.

Cylinder head cover Cylinder head cover gasket

3.

Cylinder head gasket

4.

Oil filler cap

5.

Ventilator

6.

Cylinder head bolt

7.

Cylinder head bolt

8.

Vent pipe

CULATA DEL CILINDRO Y PIEZAS RELACIONADAS

1. Cubierta de la culata del cilindro 2. Junta de la cubierta de la culata del cilindro 3. Junta de la culata del cilindro 4. Tapon de relleno de acei te 5. Ventilador 6. Perno de la culata del cilindro 7. Perno de la culata del cilindro 8. Tubo de ventilacion

CULASSE ET PIECES CONNEXES

1. Couvercle de culasse 2. Joint du couvercte de cu tasse 3. Joint de culasse 4. Bouchon de remptissage d"huile S. v.,11tilateur 6. Bouton cJe fixation cle cutasse 7. Bou Ion de fixation de culasse 8. Rer,iflard

Fig. 3-3-2

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-3-3

HE11-094-00X02 (1310)â&#x20AC;˘

HINO EP100 HINO EP100T VALVE SYSTEM 1. Inlet valve 2. Exhaust valve 3. Valve stem cap 4. Valve spring lower seat 5. Valve spring outer 6. Valve spring outer seat 7. Valve stem key 8. Tappet 9. Push rod 10. Rocker arm support 11. Rocker arm 12. Adjusting screw 13. Adjusting screw nut 14. Support bolt 15. Rocker arm shaft

SISTEMA DE VALVULA 1. 2. 3.

4.

5. 6.

7. 8.

9. 10. 11. 12. 13. 14. 15.

Valvula de admisi6n Valvula de escape Tapa del vastago de la valvula Asiento inferior de resorte de la valvula Resorte de la valvula exterior Asiento exterior de resorte de la valvula Chaveta del vastago de la valvula Levantavalvula Varilla de empuje Soporte del brazo de balancin Brazo de balanci n Tornillo de ajuste Tuerca del tornillo de ajuste Perno de soporte Eje de brazo de balancin

MECANISME DE SOUPAPES Soupape d'admission Soupape d'echappement 3. Capuchon de tige de soupape 4. Siege inferieur de ressort de soupape 5. Ressort de soupape exterieur 6. Siege exterieur de ressort de soupape 7. Demi-cone de soupape 8, Poussoir 9. Tige-poussoir 10. Support de culbuteur 11. Culbuteur 12. Vis de reglage 13. Ecrou de vis de reglage 14. Bou Ion de support 15. Axe de culbuteurs 1. 2.

Fig. 3-3-3

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-3-4

HE11-087-00X01 (1000)(1/2)â&#x20AC;¢

CYLINDER HEAD 1. 2. 3.

4. 5,

6.

7.

Cylinder head Valve guide Inlet valve seat Exhaust valve seat Nozzle seat (copper sleeve) O-ring Expansion plug

CULATA DEL CILINDRO 1. Culata del cilindro 2. Gu ia de valvula 3. Asiento de la valvula de admisi6n 4. Asiento de la val vu la de escape 5. Asiento de inyector (manguito de cobre) 6. AnilloO

CULASSE 1. Culasse Guide de soupape 3. Siege de soupape d'admission 4. Siege de soupape d'echappement 5. Siege d'injecteur (chemise en cuivrel 6. Joint torlque

2.

Fig. 3-3-4

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-3-5

El Fig. 3-3-5

1. Cylinder head. 1) Remove the intake manifold.

SM3-1048

El Fig. 3-3-6

2) Remove the exhaust manifold.

SM3-1041

El

El J:J���K�/'.: � Fig. 3-3-8

Disassembly

SM3-1042

3) Remove the coolant pump.

4) Remove the thermostat case.

3-3-6

13 -----L

Fig. 3.3.9 Special tool

SM3-356 09462-1130, 09420-1442

6) Remueva la cubierta del balancin. 6) Deooser le couvre culbuteurs.

7) Remove the rocker arm shaft assembly. Remove the valve stem cap. Remove the push rod.

7) Remueva el conj unto de eje de balanci n. Remueva la tapa del vastago de la valvula. 7) Deposer !'ensemble axe de c,iltuteurs. Deposer le capuchon de la tige de soupape.

03-1826

13 Fig. 3-3-12

6) Remove the rocker arm cover.

03-1825

13 Fig. 3-3-11

5) Remueva el inyector. 5) Deposer les injecteurs.

i,

13 Fig. 3-3-10

5) Remove the injection nozzle.

03-1827

8) Loosen the cylinder head bolts.

8) Afloje los pernos de la culata del cilindro. 8) Desserrer les boulons de fixation de culasse.

3-3-7 9) Loosening sequence of cylinder head bolts.

9) Orden de aflojamiento de los pernos de la culata de cilindro. 9) Ordre de deserrage des boulon de culasse.

Fig. 3-3-13

SM3-506

El Fig. 3-3-14

1.

Chisel

2.

Cylinder block

A

Place the chisel only at this

B

Hit up and down

10) Remueva el conjunto de la culata del cilindro. 10) Deposer I 'ensemble culasse.

SM3-552

1. Cincel 2. Bloque de cilindros A Coloque el cincel solo en este angulo B Golpee arriba y abajo

corner

El Fig. 3-3-15 Special tool

10) Remove the cylinder head assembly.

SM13-425

09433-1061

1. 2. A B

Ciseau Bloc-cylindres Placer le ciseau uniquement ace coin Frapper ve,s le haut et vers le bas

11) Lift the cylinder head from the block.

3-3-8 2. Remove the valve spring. 2. Remueva el resorte de valvula. 2. Deposer le ressort de soupape.

SM3-824

Fig. 3-3-16 09470-1022

Special tool

! ! ! ! ! 11 !1 !1 !1 !11 !1

IN � �

A�I

·� :iJ

.,.

i,

�

�

� iJ ·� �

IAl"

.

:t��i:!:J ;:_ e

lves and springs arranged in the sequence

. 3 Conserve las valvulas y los resortes dispuestos en la misma secuencia que los cilindros. 3. Disposer les soupape et les ressorts suivant l'o,·dre des cylindres.

EX

2

Fig. 3-3-17

3

4

5

6

SM3-598

4. Disassemble the rocker arm shaft. 4. Desarme el eje de balanci n. 4. Demonter l'axe de culhuteurs

Fig. 3-3-18

03-2034

5. Remove the valve guide. 5. Remueva la gu[a valvula. 5. Deposer la guide de soupape.

Fig. 3-3-19

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 03-674website: www.HeavyEquipmentRestorationParts.com

C:1 c::.J

O=

3-3-9 6. If necessary, replace the valve seat.

/1

__J_

2 8

SM3-553

Fig. 3-3-20

1. Valve seat 2. Valve A Arc welding points Grinding portion

1. Siiige d,, soupaµ,i

1. Asiento de val vu la

2. Valvula

A Soldadula electrica B Corte estas porciones

2. Sour,ap8

A Souuer a I ·arc Fl MP.ulez ici

7. If ne,,e,sa,y, ,epl"" the nmle "''· , .... ,

Fig. 3-3·21

03-677

3-3-10 Inspection and repair

1. Cylinder head and valve 11 Clean the mounting surface of cylinder head. I nspecci6n y reparaci6n

1. Culata del cilindro y valvula 1) Limpie la superficie de montaje de la culata del cilindro.

Controle et reparation

1. Culasse et soupape 1) Nettoyer la surface de montage de la culasse.

Fig. 3-3-22

SM3-825

2) lnsepect for cracks and damage.

21 I nspecione en cuanto a grietas y dafios. 2) Controler la culasse a la recherche des felures et de l'endommagement.

Fig. 3-3-23

SM3-832

3) Check the cylinder head surface for flatness.

03-667

Fig. 3-3-24 Standard

Repair limit

0-0.05 mm (0-0.0019 in) 0.1 mm (0.0039 in)

4) Measuring process and situation. B C

E'

F'

G'

A' -f---""1-ďż˝-----+-------:;rl"'---t-C'

Fig. 3-3-25

SM3-554

3-3-11 Inspect the valve contact surfaces for contacting

r::;;]5) condition.

1:::1

Fig. 3-3-26

If necessary, hand-lap the valve and valve seat.

NOTE: Lightly apply lapping compound to the valve face. Install the valve with a special tool, tap and rotate the valve against the seat.

SM3-364

I Special tool

09431-1010

6) Measure the valve sink. 6) Mida el sumidero de la valvula. 6) Mesurer le fonc;:age de la soupape

03-535

Fig. 3-3-27

A

Fig. 3-3-28 Standard Service limit

SM3-236 A

0-0.2 mm (0-0.0078 in}

7) Correct the valve seat. 7) Corrija el asiento de la valvula. 7) Rectifier le siege cle soupape

Fig. 3-3-29 Standard

SM3-708

Inlet Exhaust

째

째

30 -30 15' 45째 -45째 15'

3-3-12 8) Correct the valve face. 8) Corrija la cara de la valvula. 8) Rectifier la face de la soupape.

SM3-707

Fig. 3-3-30

Standard

Inlet Exhaust

° ° 29 45'-30 ° ° 44 45'-45

u 45° INLET Fig. 3-3-31

EXHAUST

SM3-555

9) Measure the oil clearance between valve stem and guide.

Fig. 3-3-32

SM3-834

Fig. 3-3-33

SM3-835

3-3-13 10) Measuring position of valve guide and valve stem.

2 A

B

C

UNIT: MM Fig. 3-3-34

SM3-556

1. Inlet 2. Exhaust

1. Admisi6n 2. Escape

Standard 9.938-9.950 mm (0.3913-0.3917 in) 9.921-9.943 mm (0.3906-0.3914 in)

Inlet valve stem outside diameter Exhaust valve stem outside diameter

� Inlet Exhaust

1. Admission 2. Echappement Service limit 9.88 mm (0.389 in) 9.88 mm (0.389 in)

Repair limit mm (in) A&B C

Clearance mm (in) 0.040-0.077 (0.0016-0.0030) 0.057-0.094 (0.0023-0.0037)

0.12 (0.0047) 0.14 (0.0055)

0.18 (0.0071) 0.20 (0.0079)

Valve spring 1) Check the valve spring for straightness. NOTE: Runout maximum should be less than 7 mm (0.275 in). Straightness should be less than 3.5 mm (0.137 in)

Fig. 3-3-35 Limit

SM3-303 A (max.)-A (min.) � 7 mm (0.275 in) B (max.)-B (min.) �7 mm (0.275 in) 2) Measure the free length.

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com SM3-557

Fig. 3-3-36 Free length 77 (3.03)

mm(in) Service limit 7.5 (2.953)

J-3-14 3) Measure the valve spring force.

3) Mida la fuerza del resorte de la valvula_ 3) Mesurer l'effort du ressort de soupape

-------

Fig. 3.3.37

Setting length mm (in) Setting load kg(lb) Service limit kg (lb)

03-680

Outer spring Intake Exhaust 54.3 52.8 (2.077) (2.136) 46.9-51.5 43.2-47.8 (95.26-105.4) (103.4-113.5) 45.5 41.8 (92.17) (100.3)

4) Check the valve spring seat for wear (upper and lower).

4) I nspeccione el asiento del resorte de la valvula en cuanto a desgaste (superior e inferior.) 4) Verifier le siege de ressort de soupape a la re cherche d'usure. (superieur et inferieur)

Fig. 3-3-38

SM3-371

3. Rocker arm and rocker arm shaft 1) Measure inside diameter of the rocker arm.

3. Brazo de balanci n y eje del brazo de balanci n 3. Culbuteur et axe de culbuteur

Fig. 3-3-39

SM3-291

3-3-15 2) Measure outside diameter of the rocker arm shaft.

Fig. 3-3-40

03-682

3) Measuring position.

----

Fig. 3-3-41

Outside diameter Inside diameter Clearance

SM3-558

Standard mm (in)

24.16-24.18 (0.9512-0.9519) 24.21-24.26 (0.953-0.955) 0.03-0.101 (0.0012-0.0039)

Repair limit mm (in)

Service limit mm (in)

0.15 (0.0059)

-

-

24.12 (0.9496) 24.28 (0.9559)

4) Inspect the valve stem contact point of the rocker arm for wear. 4) I nspeccione el pu/lto de contacto del vastago de la valvula del brazo de balancf n en cuanto a des gaste.

� � 1:::::7

Fig. 3-3-42

SM3-930

4) Controler I 'usure de la partie de contact de la tige de soupape avec le culbuteur.

3-3-16

Fig. 3-3-43

SM3-292

Service limit

0.5 mm (0.0196 in)

Check the adjusting screws and push rod for wear, or damage.

I _.,./)

, Fig. 3-3-44

SM3-419

Intake manifold. 1) Measure the flatness of flange face.

Fig. 3-3-45

03-1829

Standard 0.1 mm (0.004 in)

Service limit 0.5 mm (0.02 in)

Exhaust manifold 1) Measure the flatness of flange face.

Fig. 3-3-46

03-1830

Standard Service limit 0.1 mm (0.004 in) 0.5 mm (0.02 in)

3-3-17

Hino EP100 EP100T Exhaust Seal Rings ©OJ 45•

Fig. 3-3-47

2) Inspect the wear or damage of seal ring.

SEAL RING

SM3-943

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-3-18

El Fig. 3-3-48

SM3-826

Assembly

1. Install the valve seat Heat the cylinder head in boiling °water and put the valve seat in liquid nitrogen (-196 C).

Armada 1. Montaje del asiento de la valvula Caliente la culata del cilindro en agua hirviendo y ponga el asiento de la valvula en nitr6geno liquido ° (-196 C). Remontage 1. Montage du siege de soupape Chauffer la culasse dans l'eau bouillante et mettre le ° siege de soupape dans le liquide nitrogene (-196 C).

Install the nozzle sleeve. 1) Set the O-ring into the cylinder head Apply adhesive (Super Three Bond No. 1210 or equivalent) to the lower part of the new copper nozzle sleeve and carefully insert the nozzle sleeve into the cylinder head. NOTE: A damaged 0-ring may cause leaks and lead to over heating or cracked heads.

SM3-390

Fig. 3-3-49 Special tool A

09472-1210

Special tool B

9800-06100

2) Measure the protrusion of nozzle from the cylind er surface.

• CYLINDER HEAD

Fig. 3-3-50

SM3-391

Tightening torque 130-190 kg·cm (10-13 lb.ft) Protrusion

2.75-3.25 mm (0.1083-0.1279 in)

3-3-19 Install the valve guide 1) Setting position of the valve guide.

2

B

SM3-562

Fig. 3-3-51

1. Inlet

2. Exhaust

Cylinder head upper face Cylinder head lower face

1. Admisi6n 2. Escape A Superficie superior de la culata del cilindro B Superficie inferior de la culata del cilindro

1. Admission

2. Echappement

A Surface superieur de la culasse B Surface ,nferiP.ur de la culasse

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

E3

4. Install the valve stem seal.

4. lnstale el sello del vastago de valvula. 4. Poser I 'etanchei te de tige de soupape.

Fig. 3-3-52 I Special tool

SM3-984 09472-1750

El Fig. 3-3-53

03 G87

5. Install the valve.

5. I nstale la valvula. 5. Poser la soupape.

3-3-20

El

6. I nstale el re so rte de valvula. 6. Poser le guide de ressort rle soupape.

SM3-824

Fig. 3.3.54

Special

6. Install the valve spring.

09470-1022

tool

PAINT MARK CYLINDER HEAD

INTAKE Fig. 3.3.55

EXHAUST

SM3-402

El

8. Mount the cylinder head assembly.

NOTE: Replace the c"l'.linder head gasket with new one.

8. lnstale el cojunto de la culata del cilindro.

NOTA: Reemplace la junta de la culata del cilindro con otra nueva.

8. Monter !'ensemble culasse.

N.B.: Remplacer le joint de culasse par une piece neuve.

Fig. 3-3¡56

SM3-425

El

9. Install the cylinder head bolt and tighten them temporarily. NOTE: Applying the engine oil.

9. lnstalelos pernos de la culata del cilindro y apriete los temporalmente. 9. Poser les boulons de fixation de culasse et serrer les temp ore I lement.

Fig. 3.3.57

03-689

3-3-21 10. Install the valve push rod. 0 NOTE: Applying engine oil. �10. I nstale el empujador de la valvula. NOTA:

10. Poser la tige-poussoir. N.B.:

Fig. 3-3-58

B 03-690

Fig. 3-3-59

··•:.\l.·.. 1 I .I t::rit:a:sr:irif

p:

. ,. .

12. Assemble the rocker arm. 12. Arme el balanci6n. 12. Ensemble le culbuteur.

I

i . . 1:; .;;;;;;..;:c;;

03·664

Fig. 3-3-60

UP

m 1£=.1

�

TIMING-+ GEAR SIDE Fig. 3-3-61

11. Install the stem cap. 11. lnstale la tapa del vastago de valvula. 11. Poser le capuchen de la tige de soupape.

SM3-938

13. Make sure that the rocker arm shaft is installed with the "UP" mark the shaft upward. NOTE: Lubricate the rocker arm shaft and arm bush.

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 SM3-357 website: www.HeavyEquipmentRestorationParts.com

3-3-22

El

El

14. Poser l'ensemtJle axe de c:ulln1teurs.

,s.

Tightening sequence of rocker arm support. NOTE: Tightening sequence 3-4·5·2· 1 ·6

03-322

Fig. 3·3·63

1, 100-1,200 kg-cm (80-86 lb.ft) 2,400-2,600 kg-cm (174-188 lb.ft)

El Fig. 3.3.54 Special tool

14. lnstale el conjunto del eje de balancin.

03-1826

Fig. 3·3·62

Tighting torque

14. Install the rocker arm shaft assembly.

16. Tighten the cylinder head bolt and rocker arm support bolt.

03-1831 09839-2205

17. Tightening sequence of Hino EP100 Hino EP100T cylinder head bolts. 17. Orden de apriete de los pernos de la culata de cilindro. 17. OrcJre de serrage des I.Joulons de r:t1lassri.

INTAKE

Fig. 3.3.55 Outside diameter 16 1.1m 10 mm

SM3-506 Hino EP100 T Tightening torque 3,300-3,500 i<g•cm (239-253 lb.ft) 650-750 kg-cm (47-54 lb.ft)

3-3-23 18. Install the injection nozzle. 18. lnstale la tobera del inyector. 18. Remettre l'injecteur en place.

03-2159

Fig. 3-3-66 I Tightening torque I

130-190kg.cm(10-13Ib.ft)

[BJ'"·

Adjust the valve clearance. 1) Set the each piston at top dead center of the compression stroke and adjust the valve clear ance. Firing order: 1-4-2-6-3-5

19. Ajuste la holgura de la valvula.

1) Coloque cada piston en el punto muerto superior de la carrera de compresion y ajuste la holgura de la valliula. Orden de encendido: 1-4-2-6-3-5

19. Regler le jeu de soupape.

1) Regler chaque piston au point mort haut de la phase de compression et regler le jeu de soupape. Ordre d'allumage 1-4-2-6-3-5

SM3-519

Fig. 3-3-67 Valve clearance

0.40 mm (0.157 in) 0.50 mm (0.0197 in)

Inlet Exhaust

2) 2-time adjustment Set the No.1 piston to top dead center of com pression stroke, adjust the valve clearance and set the No.6 piston to top dead center, adjust the other valves. 2) Ajuste de 2-tiempos Coloque el piston N °, 1 en el punto muerto superior de la carrera de compresion y ajuste la holgura de la valvula, luego coloque el piston N °, 6 en el punto muerto superior y ajuste las demas valvulas. 2) Reglage en deux reprises Regler le piston N ° 1 au point mort haut de la phase de compression et regler le jeu de soupape et regler le piston N ° 6 au point mort haut et regler d'autres soupapes.

Fig. 3-3-68

Valve arrangement With No. 1 piston at T.D.C. on compression stroke With No. 6 piston at T.D.C. on compression stroke

2

1

Cylinder No.

I

4

3

I

I

I

E

1

2 3 4 5 6 7

E

E

• •

• • 0

0

I

E

I

E

8 9 10 11 12

• 0

6

5 E

•

0

0

0

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-4-1 HINO EP100 EP100T TIMING GEAR AND CAMSHAFT ENGRANAJE DE LA DISTRIBUCION Y ARBOL DE LEVAS PIGNO NS DE DISTRIBUTION ET ARBRE A CAM ES HE11-094-00X01 (1110)

1. Timing gear cover

2. Timing gear cover gasket 3. Oil seal

4. 0-ring

5. Seal plate 6. Timing gear plate

1. Cubierta de! engranaje de la distribuci6n 2. Junta de la cubierta del engrenaje de la distribuci6n 3. Sella de aceite 4. Anillo-O 5. Placa retenadora

Fig. 3-4-1

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

1. Couvercle du carter de distribution 2. Joint du couvercle du carter de distribution 3. Rondelle de retenue d'huile 4. Joint torqieu 5. Plaque d'etancheite

3-4-2

3

4

5

SM3-593

HINO EP100 EP100T GEAR TRAIN

1. Crankshaft gear 2. Idler gear 3. Camshaft gear 4. Injection pump drive gear 5. Oil pump drive gear 6. Coolant pump gear 7. Match mark

GREN DE ENGRANAJES

1. Engranaje del cigi.ienal

2. Engranaje loco

3. E ngranaje del arbol de levas 4. Engranaje impulsor de la bomba de inyeccion

5. Engranaje impulsor de la bomba de aceite

6. Engranaje de bomba del

enfriador

7. Marcas de Alimeati6n

Fig. 3-4-2

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

PIGNONS DE DISTRIBUTION 1. Pignon du vilebrcquin Pignon intermediaire de distribution 3. Pignon de I 'arbrn a carnes 4. Pignon d'entrainement de la pompe a injection 5. Pignon d'entrainement de la 6. Pignon de pompe a eau 7. Marques d'appariement 2

3-4-3

HE11-087-00X01 (1300)

1. Camshaft

2. 3. 4. 5. 6.

7.

8.

9.

10.

Camshaft gear Idler gear Injection pump drive gear Spacer Thrust plate Plain washer Idler gear shaft Bushing Thrust plate

1.

Arbol de levas Engranaje del arbol de levas 3. Engranaje loco 4. Engranaje impulsor de la bomba de i nyecci6n 5. Espaciador 6. Placa de empuje 7. Arandela plana 8. Ene del engranaje loco 9. Casquillo 10. Placa de empuje

2.

1.

Arbre

a cames

2. Pignon dentrainement de

3. 4. 5.

6. 7.

8. 9.

10.

Fig. 3-4-3

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

a

l'arbre cames Pignon intermediaire de distribution Arbre d'entrainement de la pompe d'injection Cale d' epaisseur Plaque de butee Rondelle plate E'.nsemble axe de pignon intermediaire de distribution Bague Plaque de butee

3-4-4 Disassembly

1. Remove the crankshaft pulley.

1. Remueva la polea del ciguefial. 1. Deposer la poulie d'arbre a cames.

Fig. 3-4-4

SM3-935

2. Râ&#x20AC;˘mo,o th, 0;1 pan. ,.... ,

Fig. 3-4-5

03-1835

t;;I ďż˝: c:J

Remove the timing gear cover.

Remueva la cubierta del engranaje de la distribuci6n.

3. Deposer le couvercle de pignons de distribution.

Fig. 3-4-o

03-1836

Fig. 3-4-7

03-2058

3-4-5

El Fig. 3-4-8

I Special tool

5. Remove the idler gear. 5. Remueva el engranaje intermedio. 5. Deposer le pignon intermediaire.

03-571

09420-1442, 09462-1410

•· Remove the ;n;,ct;on pump dd,e .,., and ,halt. ,...... ,

Fig. 3-4-9

03-1840

03-1841

Remove the camshaft. 1) Remove the valve lifter (tappetI chamber cover.

El

2) Install the tapper holder and remove the camshaft. 3) Using a special tool, lift up the tappets and sus pend them above the camshaft. 4) Lubricate all journals of the camshaft and insert the camshaft assembly into the cylinder block.

NOTE: 0 Insert the camshaft, slowly turning while insert ing so that the bearing will not be damaged.

Fig. 3-4-11

I Special tool

SM3-952

SM3-839

09451-1040

3-4-6

E3

5) Remove the tappets (1) Remove the special tool (stopper). (2) Remove the tappets.

NOTE: Be sure to arrange the tappets in correct order.

03-2066

Fig. 3-4-12

8. If nooo,,a,y, ,omo,o tho oam,hoft d,;,. goa,. .

... , ..

03-1845

Fig. 3-4-13

I

,

Special tool

09420-1111

•· Romo" tho ;n;,ct;on pump d,;,. ,hoft boa,;ng. ,

Fig. 3-4-14

I

Special tool

..

... ,

03-1847

03-1846 09420-1180

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-4-7 Inspection and repair 1. Measure the clearance between the idler gear shaft and the idler gear bushing.

03-1848

Fig. 3-4-15

Fig. 3-4-16 Standard Repair limit

03-1849 0.030-0.090 mm (0.0012-0.0035 in) 0.20 mm (0.0079 in)

2. Measure the idler gear end play. 2. Mida el juego longitudinal del engranaje intermedio. 2. Measurer le jeu en bout du pignon intermediaire.

Fig. 3-4-17 Standard Repair limit

03-578 0.049-0.140 mm (0.0019-0.0055) 0.30 mm C0.0118 in)

lu 1 Fig. 3-4-18 Camheight Service limit

SM3-347 54.85 mm (2.1594 in) 54.05 mm (2.1280 in)

SM3-563

··

MeHure th• cam h,;ght.

3-4-8

l!tl Fig. 3-4-19

4.

Measure the clearance between the camshaft journal and the bearing. (Refer the table of page 3-118, 3-119).

03-575

03-574

0.03-0.12 mm (0.0012-0.0047 in) 0.3 mm (0.0118 in)

ltJ

Fig. 3-4-20 Repair limit

I

0. Mea'"'eth, <amshaft ,un out.

03-573

0.10 mm (0.0039 in)

g-

Fig. 3-4-21

6. Measure the camshaft end play. 6. Mida el juego longitudinal del arbol de levas. G Mes11rtcr le jeu en 110111 de l'arhre a ra111es.

03-576

0.10-0.23 mm (0.004-0.009 in) 0.30 mm (0.0118 in)

IÂŽ I

Fig. 3-4-22

03-1850

7. ln,peot thâ&#x20AC;˘ ;njoot;on pump d,;,.,haft beadng.

3-4-9

�� ,�irF.,

/.'.o• ... ,,

•/'

0) ,

I

lg:]

8. Measure the clearance between the tappet and' the tappet guide.

.

-..:2./' '\.. '

l

....___,"--2.,,_,'...'

'..___ / Fig. 3-4-23 Standard Repair limit

SM3-325

SM3-420

0.020-0.066 mm (0.0008-0.0025 in) 0.10 mm (0.0039 in)

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-4-10

El Fig. 3-4-24

I

Pre-road

Assembly

1. Install the injection pump drive shaft and bearing. NOTE: Adjust the bearing pre-load using the shims.

03-1852 4-12 kg-cm (0.29-0.86 lb-ft)

l. Install tho timing goa, plat•. ,....,

I

Fig. 3-4-25 Tightening torque

03-1853 190-270 kg·cm (14-19 lb-ft)

J. Install tho injoction p"mp boa,ing holdo,. ,....,

Fig. 3-4-26 Tightening torque

03-2083 190-260 kg·cm (14-18 lb.ft)

3-4-11 4. Install tho ;nject'•o� pump drive gear . . 1) Align the m1ect1on pump drive gear matching mark with the camshaft ·,di er gear. , ....., NO TE.. Incorrect installation can resu Its in engi ne d amage or lowering of 8ngine • performance b V causing • . . improper inJection timing.

Fig. 3-4-27

SM3-575

5. Install the tappet.

El

6. Install th e camshaft and tighten the bolts of thrust plate.

03-1856 Special tool Tightening torque

0 9451-1040 190-260 kg·cm (14-18 lb.ft)

03-1857 Tightening torque .

1 , 100

450

1, 200 kg·cm (1 00 -861b.ft) 5 kg·cm (33-36Ib.ft)

oo

l••.,I

'·

ln,tall tho 0;1 pump.

3-4-12 8. Install th• ;do, ,,.,. ,.....,

Fig. 3-4-31

03-1858

Be sure that matching marks of the crankshaft gear, camshaft gear, injection pump drive gear, and idle gear aligned correctly.

I L--

Fig. 3-4-32

SM3-593

9. Hghtoo tho ;o;,ct;oo pump d,;,. ,.., out. IJ

Fig. 3-4-33 J Tightening torque

rl

03-1859 2,000-2,200 kg•cm (145-159 lb-ft)

El Fig. 3-4-34 J Tightening torque

03-1860 1,800-2,000 kg·cm (130-144 lb.ft)

10. Tighten the idle gear bolt.

lu I

Backlash

Unit: mm (in)

Gears

Assembly allowance

Crank gear - idle gear

0.08 - 0.23 (0.0032-0.0090)

Camshaft drive gear - Idle gear

0.08 - 0.23 (0.0032-0.0090)

Idle gear - Injection pump drive gear

0.08 - 0.23 (0.0032-0.0090)

Camshaft drive gear - Oil pump drive gear

0.14 - 0.32 (0.0055-0.0125)

Fig. 3-4-36

Service limit

A

,C.,,. , �

"·

3-4-13 M,asure the tim;ngg,.. backla,h.

12. Standard gear backlash and service limit.

�

0.30 (0.0118)

0.35 (0.0138)

03-2058 200-250 kg·cm ( 15-18 lb.ft)

El

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 03-587 website: www.HeavyEquipmentRestorationParts.com

Fig. 3-4-37 I Special toi;,I

13. Install the timing gear cover oil seal.

09482-1180

3-4-14

03-1862

Fig. 3-4-38

1•••1

�I

••·

Install tno oH pan.

-=-----

Fig. 3-4-39

SM3-393

1•·•1

Fig. 3-4-40 Tightening torque

03-2259 5,500-7,000 kg•cm (398-506 lb.ft)

'"·

Install tho o,ank,haft pulley.

3-5-1

HINO EP100 EP100T CYLINDER BLOCK, PISTON AND CRANKSHAFT

BLOOUE .DE Cl LIND ROS, PISTON Y SIGUEl'JAL BLOC-CYLINDRES, PISTON ET VILEBREOUIN HE11-087-00X01

( 1100) (2/2)

4

2

1. Cylinder block 2. Oil level gauge guide 3. Oil level gauge

4. Valve push rod cover 5. Gasket 6. Oil pan

7. Gasket

8. Drain plug 9. Gasket

1. Bl oque de ci Ii ndros 2. Gu ia del indicador de nivel de aceite 3. lndicador del nivel de aceite 4. Cubierta de la varilla de empuje de la valvula 5. Junta 6. Colector de aceite 7. Junta 8. Tap6n 9. Junta

Fig. 3-5-1

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

1. Bloc-cylindres

2. Guide de jauge a huile 3. Jauge d'huile 4. Couvercle de la tige-poussoir r·0. Joint 6. Carter d'huile 7. Joint 8. Bouchon 9 Joint

3-5-2

LE17-094-00X05X06X07 (1100) (1/2)

CYLINDER BLOCK

1. 2. 3. 4. 5. 6. 7.

Hino EP100 EP100T Cylinder liner

Cylinder block Bearing cap Bearing cap bolt Strai ght pin Camshaft bearing Oil jet

BLOOUE DE CILINDROS 1. 2. 3. 4. 5. 6_ 7.

Camisa del cilindro Bloque de cilindros Tapa del cojinete Perno de la tapa del cojinete Pasador recto Cojinete del arbol de levas Injector de aciete

BLOCCYLINDRES 1. Chemise de cylindre 2. Bloc-cylindres 3. Chapea,J de palier 4. Boulon de fixation du chapeau de paliP.r !:°L GoupillP. 6. Pdli,•r r1"arbre a cames 7. Gicleur d'huile

Fig. 3-5-2

Hino Engine Parts email: EngineParts@HeavyEquipmentRestorationParts.com Phone: 269 673 1638 website: www.HeavyEquipmentRestorationParts.com

3-5-3

HE11-087-00X01 (1200)

2!;}

7

17��,.

16

8

15 From Engine No. EP100T 00012570

2

HINO EP100 HINO EP100T CRANKSHAFT AND RELATED PARTS 1. 2. 3. 4. 5. 6. 7.

8. 9. 10. 11. 12. 13. 14. 15. 16. 17.

18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29.

Crankshaft Crankshaft gear O-ring Crankshaft sleeve, front Dust slinger Crankshaft pulley center Pulley Bolt Collar O-ring Bolt Key O-ring Crankshaft sleeve Oil seal Gasket Retainer Flywheel dust cover Crankshaft bearing set Thrust bearing set Piston Piston ring Piston pin Retainer ring Connecting rod assembly Piston pin bushing Connecting rod bolt Ring gear Flywheel

Fig. 3-5-3

SM3-1043 CIGUENAL Y PIEZAS RELACION ADAS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29.

Cigi.ieiial Engranaje del cigi.ieiial Anillo 0 Mangu ito del cigi.ieiial, delantero Deflector de polvo Centro de la polea del cigi.ieiial Polea Perno Collar in Anillo 0 Perno Chaveta Anillo 0 Manguito del cigi.ieiial Selle de aceite Junta Retenedor Cuvierta de contra del volante Juego de cojinete del cigi.ieiial Juego de cojinete de empuje Piston Arcs de piston Pasador de piston Anillo retenedor Cojunto de biela Casquillo del pasador de piston Perno de la,biela Engranaje angular Volante

VILEBREOUIN ET PIECES CON NEXES 1. 2. 3. 4. C,. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29.

Vilebrequin Pignon de vilebrequin Joint torique Manchon de vilebrequin, AV deflecteur de poussiere Cone epaule de poulie de vilebrequin Poulie Boulon Collier Joint torique Boulorr Clavette Joint torique Manchon de vilebrequ in Rone.Jelle de retenue d'huil<, Joint Support de joint Couvercle pare-poussiere de volan t Jeu de coussi,1ets Jeu de flasques Piston Segment de piston Ax,; de pisto11 Circlip Ensemble biellP. Bague de l'axe de piston Boulorr r:le fixation de bielle Couronne de volant Vol11nt

3-5-4

E1

Disassembly 1. Remove the flywheel assembly.

Desarmado

1. Remueva el conj unto de volante.

Demontage 1

Fig. 3-5-4

03-2169

E1 Fig. 3-5-5

2. Remove the flywheel housing. 2. Remueva el carter del volante. 2. Deposer le carter de volant.

03-1865

E1 Fig. 3-5-6

3. Remove the oil seal retainer. 3. Remueva el retenedor de sello de aceite. 3. Deposer la rondelle de retenue d'huile.

03-1866

E1 Fig. 3-5-7

Deposer. I 'ensemble vol ant.

03-727

03-1867

4. Remove the piston with connecting rod. 4. Remueva el piston con la biela. 4. Deposer le piston avec la bielle.

3-5-5

E)

Fig. 3-5-8

5. Remueva el ciguenal. 5. Deposer le vilelJreqLJin.

03-556

E)

Fig. 3-5-9

6. Remove the connecting rod. 6. Remueva la biela. 6. Deposer la bielle.

SM3-294

El

7. Remove the piston rings. 7. Remueva los aros de piston. 7. Deposer les segments de piston.

SM3-295

Fig. 3-5-10 Special tool

5. Remove the crankshaft.

09442-1190

Remove the cylinder liner.

NOTE: Put the line-up marks on the cylinder block and I iner flange.

Remueva la camisa del cilindro. NOTA: Ponga les marca de coincidencial bloque de cilindros y el reborde de la camisa del cilindro.

Deposer la chemise de cyl incJre. N.B. ¡ Faire les marques d'alliance sur le bloc-cylindres et la col lerette de la chemise de cylindre.

Fig. 3-5-11

SM3-851

3-5-6

a.

Romo,e tho oyhndo, 1;no,.

,......,

Fig. 3-5-12

03-539

Special tool

09420-1430

Inspection and repair

1. Measure the clearance between the small end bushing and the piston pin.

Fig. 3-5-13 Pin diameter Clearance

SM3-296

SM3-297

47.0 mm ( 1.850 in) I Service limit 46.95 mm ( 1.8485 in) Standard I 0.025-0.043 mm (0.0010-0.0016 in) 0.10 mm (0.0039 in) Repair limit I

Measure the spread dimension of the connecting rod bearing. Mida la dimension de la amplitud del cojinete de pie de biela. 2. Mesurer la dimension d'ecartement du conssinet de hielle.

Fig. 3-5-14 I Standard