Versatile Exolum Flies High

Exclusive Interview with Gorka Penalva, Commercial Director Northwest Europe

ALSO IN THIS ISSUE:

Exclusive Interview with Gorka Penalva, Commercial Director Northwest Europe

ALSO IN THIS ISSUE:

INDUSTRIAL CYBER SECURITY

RENEWABLE HYDROGEN LOOP

HONEYWELL EXPERION® PKS

Infinitely Scalable, Fault Predictive, HIVE®

INTEGRATED DIGITAL TWIN

Grid to Gate Power and Process Digital Twin

INTELLIGENT OPERATOR COCKPIT

AI Enabled Suite for Future Ready Operation

SAFETY & SECURITY

Fire and Gas Detectors Gas Cloud Imaging

PLANTWIDE OPTIMIZATION

Optimizing LCH and Derivatives in Realtime

WORKFORCE COMPETENCY

Competency, Safety and Productivity

HYDROGEN PASSPORT

Realtime Carbon Intensity Management

ADVANCED ALARM MANAGEMENT

Operations and Worker Safety

EQUIPMENT EFFECTIVENESS

Predictive Asset Performance Management

LEAN&MODULAR EXECUTION

Design, Integration, Implementation, Construction, Testing & Commissioning Modular, Flexible and Scalable Deployment

EDITOR Joe Forshaw joe@energy-focus.net

PROJECT MANAGER Tommy Atkinson tommy@energy-focus.net

PROJECT MANAGER David Hill david@energy-focus.net

PROJECT MANAGER Chris Bolderstone chris@energy-focus.net

ACCOUNT MANAGER Isabel Murphy isabel@energy-focus.net

LEAD DESIGNER Aaron Protheroe aaron@energy-focus.net

CONTRIBUTOR Manelesi Dumasi

CONTRIBUTOR Karl Pietersen

CONTRIBUTOR David Napier

CONTRIBUTOR Timothy Reeder

CONTRIBUTOR Benjamin Southwold

CONTRIBUTOR William Denstone

The innovation underway in the energy industry is simply unbelievable. Right now - today - companies are out there developing the future energy systems that will power life for centuries into the future. However, they are doing so in a way that will balance with our climate. Using hydrogen or other inputs, the future of energy looks exciting thanks to the ambitious businesses that are pioneering change. It is truly exciting to speak to industry leaders and understand their plans while sharing their enthusiasm.

Across Europe, Lhyfe – a leading green hydrogen company – is planning major rollout. Starting in Germany and France, the company will build smaller plants before growing to construct significant hydrogen production capability that can feed into industry and transport as well as other private off takers. The company is one of the few globally to have the skills and experience to build with the backing of financial institutions because it understands the risks and opportunities.

Landmark Power Projects is bridging the gap in the energy transition, using carbon capture technology to make its highly engineered natural gas turbine power generation facilities low carbon by definition. The company has secured its gas input and has agreed with buyers to take its energy, supporting local communities. The vision of Founder Michael Avison is being realised as the company’s second project gets underway in the UK’s north.

Published by

Chris Bolderstone – General Manager E. chris@cmb-multimedia.co.uk Fuel Studios, Kiln House, Pottergate, Norwich NR2 1DX +44 (0)20 3097 1743 www.cmb-media.co.uk

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

© CMB Media Group Ltd 2024

Enerproject, boasting the very best of Swiss engineering capability, is designing and manufacturing world-class compressor technology at its facility in the south of Switzerland. The company builds strong and lasting relationships with clients based on quality of delivery. The next stage in development is the manufacture of compressors to be used for modern solutions including ammonia, CO2, hydrogen, and helium. The company is looking to boost its presence in North America after building strong coverage around the world, especially in Europe and Asia.

Soly, a global renewable energy company that is expanding quickly, is busy establishing itself in the UK, onboarding new clients and introducing them to the Soly Brain – a modern and innovative EMS.

All of these companies and more and doing things today that will impact the way we engage with energy in the future. Whether it’s technology or routes to market, each is taking something that was previously not fit for purpose and remoulding it to suit the needs of a modern customer. For this, they must be applauded.

Get in touch and tell us how your business is changing industry for the better, we’re online all the time through LinkedIn

Joe Forshaw EDITOR

+44 (0)20 3097 1743

joe@energy-focus.net

6 14 22 30 38

EXOLUM

Versatile Exolum Flies High

LHYFE

Pioneering Powerful Progress in Green Hydrogen

LANDMARK POWER HOLDINGS

LMPH Achieves Milestones in Low Carbon Power Generation Mission

EVERRATI

Electric Icons Gaining New Traction

SOLY UK

Fast Moving Soly Warmly Welcomed in UK Market

PRODUCTION: David Hill

World leading bulk liquid fuel transportation and storage business, Exolum, is embracing its position at the market’s forefront, bringing consistently quality service while paving the way for energy transition products. Gorka Penalva, Northwest Europe Commercial Lead, tells Energy Focus more about ongoing innovation and expansion.

//Moving and storing liquid fuel products, at scale, with efficiency is the task for Exolum. With almost a century of experience, the Madrid headquartered multi-national is an industry leader, recognised as Europe’s leading logistics company in refined products, chemicals, biofuels, aviation fuel and more.

Today, the company is one of the world’s foremost organisations across pipeline transportation of liquid fuels, and its status was bolstered in 2020 when it acquired Inter Terminals, bringing 15 terminals in four countries into the CLH Group before dropping its CLH identity for Exolum in 2021.

But the landscape continues to change for this provider of energy

solutions. Demands from governments are changing as the public demand cleaner, more sustainable liquid fuel options. Companies have embraced ESG strategies and are looking to embed green power in portfolios where possible.

Gorka Penalva, Commercial Director Northwest Europe (NWE) at Exolum, tells Energy Focus that the company is working hard to develop new systems that can help deliver modern products for customers.

“Right now, we are busy with two products,” he opens. “Hydrotreated Vegetable Oil (HVO) is something we have seen a lot of clients asking us more about and where we have seen more tanks being turned. Sustainable Aviation Fuel (SAF) is also key as we have the

pipeline and a big network. We want to be a leader in that product and we want to blend and transport as much as clients need while giving them support that they require from new mandates.”

In February, the company was awarded a tender for work at Charles de Gaulle Airport in Paris. Exolum will operate and maintain the fuel terminal while investing more than €200 million to develop facilities that will cater to future demands for SAF and kerosene. Expansion of this nature is part of the Exolum strategy, and Penalva – a former trader who worked all over the world for a major energy business – says that management is keen on widespread, sustainable expansion.

At adi Group, we redefine the future of the energy industry with turnkey engineering service.

From project management and design to procurement, construction and maintenance, we deliver innovative and sustainable solution that enhance efficiency, reliability, and safety.

Our unwavering commitment to quality ensures every project meet the highest standards, adapting seamlessly to the evolving dema of the energy sector.

Partner with adi Group for excellence in energy infrastructure.

Comprehensive Engineering & Construction Solutions for the Energy Sector

www.adiltd.co.uk | info@adiltd.co.uk | 0121 451 2255

“Our growth has been exponential in the last seven years, especially through our aviation department where we have gained traction at significant airports. We are expanding and our goal is always to expand. We know how to do what we do very well, and geographic expansion is always important.”

Exolum is ISO14001 certified and is committed to changing with its customers. Central in this transition is the ambition to continue to move and store products in the same way as before, utilising a lot of the same infrastructure, while ultimately resulting in smaller carbon emissions.

In May 2024, evidence of its commitment was displayed when the company announced that it would spend €20 million at the Port of Bilbao to store biofuels alongside other bulk liquid products. Set for full operation

by 2027, the new facility will be safe and secure, and will connect into other company terminals. Built across multiple phases, the first will see five tanks built, able to store 29,000 m3. Further phases will expand the site, with biofuel being a key consideration.

Jorge Guillén, Exolum Lead in Spain said that the investment in Bilbao was “an important step towards Exolum’s strategy of investing in Spain to develop and operate the logistics infrastructures required by new sustainable fuels, making further progress on energy transition objectives.”

Also in May, the company announced it would spend €12 million

Gorka Penalva Commercial Director Northwest Europe

building a new fuel supply terminal at the main airport on the island of Lanzarote. With a capacity of 6000 m3, the new energy efficient facility will receive a complete overhaul adding new infrastructure and new efficiency.

Aldermaston Pipeline, UK

Penalva says that remaining agile in front of a quickly changing market is what helps Exolum to take important decisions that protect the future of the industry for clients.

“Our versatility is key, and we like to go into meetings and talk to clients with sufficient confidence so that they will tell us what they need. We can then adapt and deliver. Obviously, we are talking about significant infrastructure and it’s not something you can do from one day to the next, but we do try and be quick on our feet for our clients.

“We offer a holistic provision within the realm of logistics and storage – our expertise,” he adds. “We don’t limit ourselves to a list of services; we pride ourselves on versatility and an ability to adjust to the client’s

needs. We are trying to get into new sectors and therefore we sometimes go beyond our regular work. We have done that in hydrogen, but our core business remains logistics which we have been doing for 100 years. The market is difficult, and conditions are tough for our clients. We have to be efficient, versatile, and able to deliver on all the requirements of clients.”

Exolum was also busy recently at the Port of Gijon, committing €3 million to bulk liquid product storage terminal modernisation. The company gained the management contract of the 67,000 m3 capacity terminal on Spain’s northern coast, and will over a 15-year concession create capacity for tanks to transport and store modern products such as biofuel, eco-fuel, hydrogen, ammonia, methanol, carbon, and more.

Following the Inter Terminals acquisition, Exolum now operates in 11 countries (Spain, the United Kingdom, Ireland, Germany, the Netherlands, Portugal, France, the United States, Panama, Ecuador and Peru) with a pipeline network of over 6,000 kilometres, 69 storage terminals and 48 airport facilities, and a total storage capacity of more than 11 million m3

Going forward, the energy transition is firmly on the agenda for Exolum and while the company remains committed to diligently fulfilling the needs of its clients, it is also innovating to ensure all options for low carbon products to be stored and moved are on the table.

In April, Exolum CEO Jorge Lanza confirmed that SAF was critical

in the future of the industry.

“We are adapting our infrastructure to the demand for clean fuels,” he said. “For example, at the Madrid and Barcelona airports we can store and transport SAF by hydrant, which reduces carbon dioxide emissions by 80%.”

He also discussed the inevitable growth of the hydrogen economy and how the company will look to adapt existing infrastructure to accommodate the element in the future.

“Last year we began operating the first and, for the moment, only hydrogen station in the Madrid region. We aim to provide hydrogen transport and storage services. For this reason, we have also entered the hydrogen market in the US, the world leader in adapting those supply chains,” he said Penalva agrees, and he explains

PRESSURE VESSEL MANUFACTURE AND INSTALLATION

that part of the new Exolum identity was embracing the New Energies division which forms a key part of the NWE structure.

“We must keep our eyes on the energy transition as it is where banks and others are investing. We know there will be a lot of money in the transition in the future, but to have a future you must have a present and that is where are working now,” he says.

“After the acquisition of Inter Terminals in 2020, we grew substantially, restructuring the business to create three business units. Firstly, the Spanish unit which has the traditional CLH pipeline and oil and storage terminals. Then we have Northwest Europe, headed from London, comprising all of the businesses that we have in the UK, Netherlands, and Germany.

The third unit is New Energies which focuses on energy transition products and although it is new and different, we all work very closely together.”

This lean and focused structure has allowed Exolum to boom, opening up discussions with more clients, and allowing for innovation across multiple new product lines.

In February 2024, the company joined Forética, a leading benchmark organisation across sustainability and corporate social responsibility. Forética calls on its more than 200 members (large global companies), typically across Spain and Latin America, to increase business ambition in sustainability, accelerate action around ESG matters, and to promote alliances that enable a sustainable, green and inclusive recovery.

“You have to look deeper than just revenues and become more efficient and better prepared for the energy transition,” says Penalva. “You have to look at costs. Clients don’t want to pay lots of money so we have to make sure we are the most efficient company we can be. We see ourselves as a top-quality service provider and we pride ourselves on the service we deliver. Where we might be slightly more expensive than others, we do offer a lot more value for money.”

In an uncertain world, with quicklychanging markets – many of which are interconnected – value for money and world-class quality standards are a must. That is why, when looking for confidence and assurance, Exolum continues to stand as an industry leader, driving its own growth but also

pushing boundaries across the sector.

“Our goal is to grow,” Penalva concludes. “We have demonstrated our willingness to invest, and we have units working including the HS units in Madrid and the ammonia plant in Houston. We are all about walking the walk. We understand that what we do is well done. We don’t lose focus on what needs to be done now or on what needs to be done three and five years down the line. We are not about big headlines or presentations; we want the business to grow on a yearly basis while making sure we are ready for the energy transition.”

PRODUCTION: David Hill

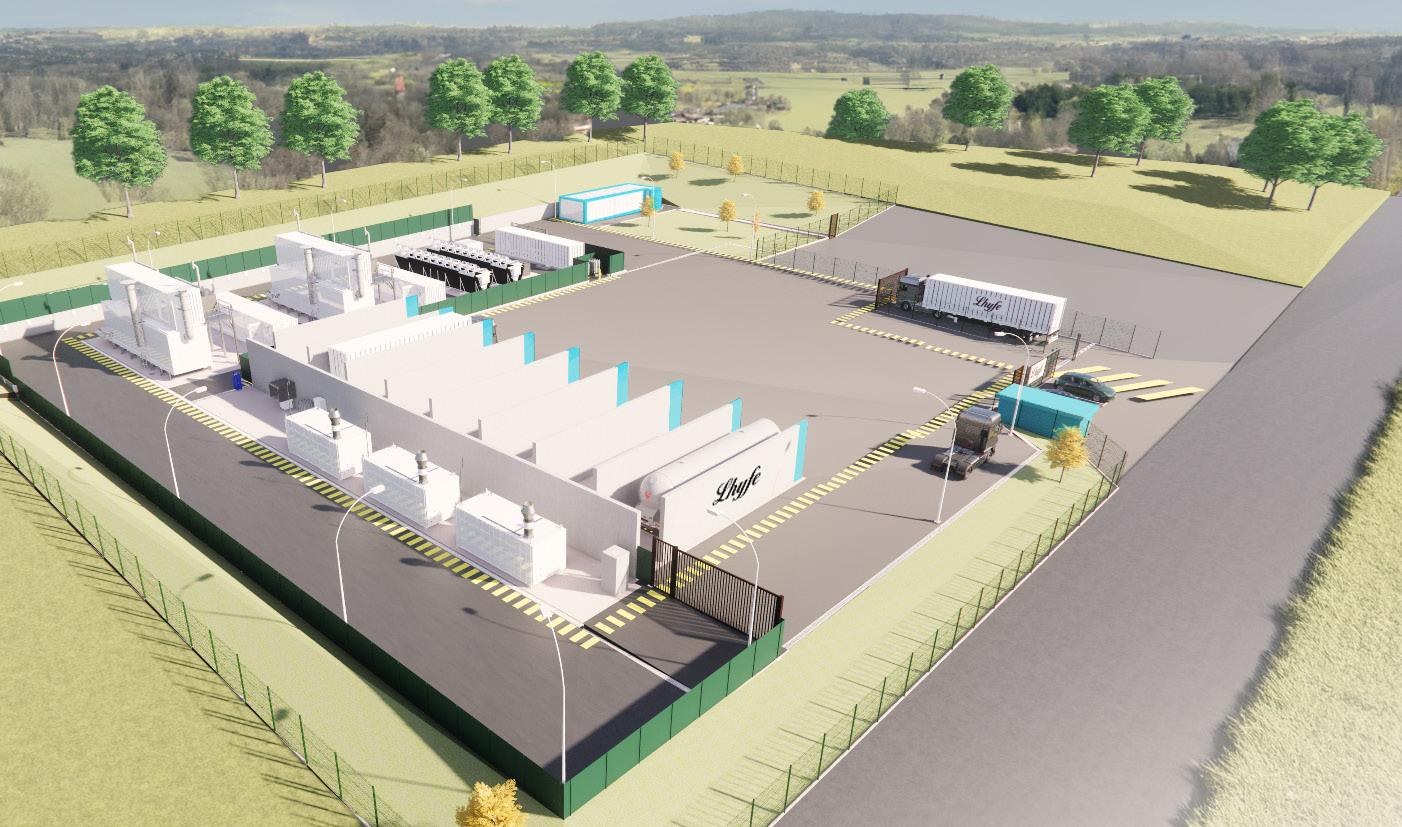

Lhyfe, a green hydrogen production company that is staunchly committed to the energy transition, is responsible for many world firsts across the industry. Soon, it will begin with several new projects, building significant production facilities that will be able to offer green hydrogen at scale for clients across all industries. Luc Graré, Head of Central and Eastern Europe at Lhyfe, talks to Energy Focus about nurturing experience and knowledge that others simply don’t have.

//Led by science, the hunt for the sustainable fuel of the future – one which can power home and industry for centuries to come, without an entire overhaul of existing infrastructure – is centring around hydrogen. While there will always be a mix, swapping out fossil fuels for a zero-emission alternative that is abundant and powerful and storable is already underway. Hydrogen offers an almost perfect option –plentiful, high-energy density, zero direct CO2 emissions, and able to be used at industrial scale. Importantly, hydrogen is already proven. It has been used for power generation since the 19th century. For real decarbonisation efforts, hydrogen is the frontrunner. But it’s not easy to convince investors. After all, fossil fuels are in use now; they are working today; they are generating returns at scale; and they are doing so safely. Environmental

impact aside, fossil fuels used for power generation are reliable and efficient.

European green hydrogen production company Lhyfe –established in 2017 by Matthieu Guesné – set about changing perceptions. Starting small and scaling carefully, the company has dedicated all of its knowledge and expertise to creating highly efficient and safe hydrogen production plants that can supply green hydrogen for industry, mobility, and more, in various useful packages. It has taken a lot of investment and a number of faithful leaps, but Lhyfe is now recognised as an industry leader and its work has furthered the reputation of hydrogen as a fuel of the future.

Luc Graré, Head of Central and Eastern Europe at Lhyfe, tells Energy Focus that the company is demonstrably committed to the energy transition and is creating a lasting legacy through the green hydrogen production plants

it owns and operates. He says that major projects are underway or in the pipeline, and the team – more than 200 spread across 11 countries – is one of the most ambitious in the world.

GREEN BY DEFINITION

“We are only active in green hydrogen and that gives a maximum focus - it has to work,” he smiles. “We don’t look at other things because they are easier or they are seen as low hanging fruit. We have 100% focus on green hydrogen and we do it at European scale. That means we can take advantage of economies of scale and repeat successes across multiple countries.”

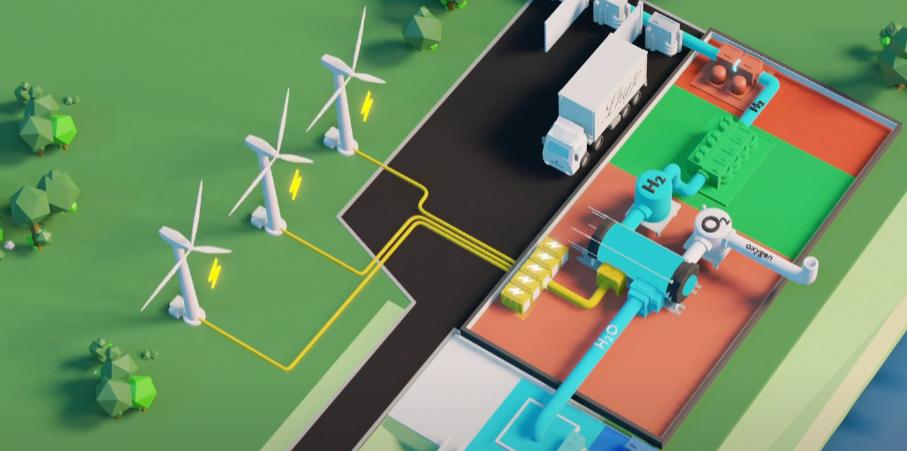

Green hydrogen, as opposed to blue or grey hydrogen, is produced using renewable energy sources (typically wind or solar) to power an electrolyser which separates water molecules, creating hydrogen and oxygen at the anode and cathode.

It’s now simple science, but it costs money. However, many are willing to front the cost to ensure environmental progress, but it is critical that green hydrogen meets the new definition outlined by EU lawmakers. This means hydrogen production must be powered by renewable electricity.

“It is green, it is renewable – it is made through electrolysis. Solar or wind energy powers the electrolyser,” explains Graré.

“We invest in production plants which we then own and operate. We sell the hydrogen to different offtakers across industry and mobility.”

Demonstrating its industry leading capabilities while satisfying growing demand for decarbonisation and reliability, Lhyfe is investing in green hydrogen production plants that are both innovative and proven. The

company has projects in its pipeline across Europe and has experimental ideas at advanced stages to further improve and advance the industry.

Graré highlights Germany as a forward-thinking nation when it comes to hydrogen policy,

focused on industrialisation through decarbonisation while remaining globally competitive.

But the first stages in scaling are underway in France, where small projects are being used to build knowledge and experience,

removing risks and developing robust business cases.

“We are busy with a project in France where we have approval from IPCEI (Important Projects of Common European Interest) as part of their subsidy project funding of €149 million to build a 100MW plant in Le Havre. We will produce green hydrogen there in 2027,” explains Graré.

The French company built its first production plant in France in 2021 – a small scale 1MW facility designed as a pathfinder project for the company to develop best practice. “We learned how to operate, what are the issues, how to debug, and how to build in efficiency,” he says. “Today, we are building six projects, three in France and three in Germany. Each in France is 5MW and one of the German builds is 10MW.

Our strategy is certainly to scale up.”

Understanding the risks, and then developing plans to mitigate them, is critical in the process. The engineering involved in even the smaller projects is on a scale not seen by many, and Graré highlights Lhyfe as one of the only companies to boast such experience.

“Many companies in the market announced big plans like 200MW or 500MW but they have never built anything small. How can this work when you don’t understand the risks? How can you discuss with the bank? You have to go through the industrial roadmap to learn. In Le Havre, we will build a 100MW plant, but before that we will have several smaller projects already coming online which will fill us with experience.”

In Germany, in the south of the country, Lhyfe is building a significant

project capable of delivering 3.2 tonnes of hydrogen for clients across multiple industries. “Our 10MW project in Schwäbisch Gmünd is under construction today,” details Graré.

Germany presents many opportunities for Lhyfe, and beyond Schwäbisch Gmünd there are significant plans in the pipeline. Lubmin, in the German north, is an exciting location for Lhyfe for a number of reasons. On the coast, facing the Baltic Sea, close to German connections with Denmark and Poland, Lubmin was previously agreed as the landing site for the Nordstream pipeline project brining natural gas from Russia to Europe. But with Russian ties severed and business relations strained, the region now sits somewhat forgotten.

“There is a lot of capacity there,”

Hiperbaric, on the way to becoming the leader in Hydrogen Compression

Hiperbaric, world leader in the development of highpressure industrial equipment, has doubled its hydrogen compressor business in Europe. Specifically, the company based in Spain, has generated a business portfolio of about 30 new hydrogen equipment to different customers, both sustainable mobility and industrial. In this way, it aims to become the European leader in high-pressure hydrogen compression.

The company offers complete and advanced containerized Hydrogen compression solutions of up to 1,000 bar / 14,500 psi for sustainable and decarbonized mobility and industry storage.

The basic way to densify hydrogen is to compress it at very high pressure. For this reason, Hiperbaric has developed a range of H2 compressor units with a plugand-play solution, adaptable to any level of production and demand.

It is safe, efficient, and reliable equipment, capable of compressing hydrogen with an inlet pressure range from 20 bar to an outlet pressure up to 500 or 1.000 bar. This wide range of inlet and outlet pressures allows it to be positioned both in the production stage, being able to be fed directly from an electrolyzer, or a medium pressure storage tank (such as tube trailers at 200 bar).

Hiperbaric has an agreement with Lhyfe to supply renewable hydrogen compressors that the company is implementing in projects in France and Germany for renewable generation, compression and filling of hydrogen at high pressure.

Hiperbaric is the global leader in high pressure technologies (up to 6,000 bar) for different sectors for more than 25 years and has 1,000 water compressors installed in 50 countries on five continents. “With our experience in high-pressure applications, we intend to be part of the solution for a sustainable energy transition and contribute our Hydrogen High-Pressure Compression Technology to the hydrogen value chain,” says Andrés Hernando, CEO at Hiperbaric.

For more information visit Hiperbaric.com

says Graré adding that the area is also the home of a decommissioned Soviet nuclear power plant and therefore a large substation.

“The available infrastructure makes it a very interesting site,” he continues. “We will build an 800MW plant to be operational in 2029 and the hydrogen can enter the network for supply across Germany. There is a huge substation still there as the nuclear plant was, at the time, the largest in Europe. The substation is intact and that is why lots of offshore wind energy comes online there. Access to pipeline networks, alongside access to the substation infrastructure is why we decided to build there, after FID and approval processes are complete.”

The project in Lubmin will come off the back of a 200MW production facility set to go up in Delfzijl in the Groningen region of the Netherlands in 2028. Again, Lhyfe will use all of the experience developed to date to create a highly sustainable and efficient site that can be truly green, using renewable power from the Dutch North Sea. From here, the connection into Germany can be easily made via pipeline. In Germany, more than 7000km of pipe network is set to be dedicated to the transport of hydrogen as former gas pipes are converted as a result of a drop in consumption of natural gas.

“We have the experience to know how things will work and that project will be connected to the hydrogen backbone network across the Netherlands through Gasunie. It will also connect into the German network and that means we can produce hydrogen in the north of the Netherlands, using power from offshore wind, and we can deliver that all the way to Germany,” Graré explains.

Currently, the majority of truly green electricity in Europe is generated through wind infrastructure (15%). As this share increases with the number of wind farms going up aggressively,

Reciprocating piston compression technlogy of up to 500 - 1,000 bar

Effective cooling thanks to piston compressor innovative design

Safe and reliable solution thanks to the venting system

green hydrogen producers are looking at further improving efficiency by pairing production facilities with green electricity generation on the same site. This is no easy task and that is why Lhyfe is busy exploring options through pilot projects on the ocean.

“In Germany, there is 8GW offshore wind capacity and, after many years, it has still not been made clear how we can bring all the gigawatts produced in the north, in the sea, down to the south,” says Graré. “It is not only the case in Germany – we also see it in Scotland where offshore wind fails to supply a totally congested grid network. A solution is needed as the German government wants to add another 60GW of offshore wind capacity. Same in Scotland, Ireland, and the Netherlands. It will not work by bringing power across the land

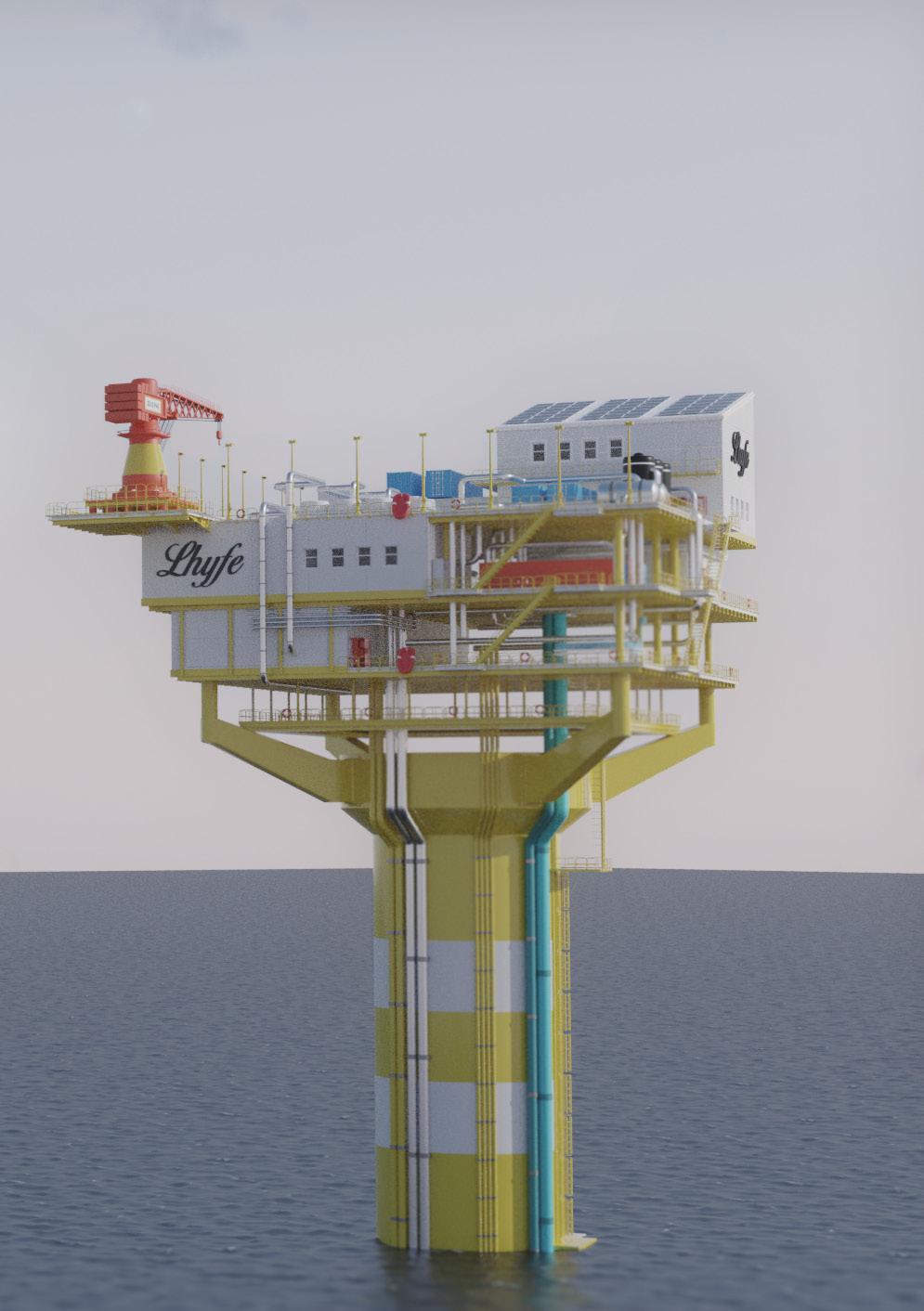

because it is so congested. The only solution is to directly produce hydrogen at sea from electricity generated at sea, bringing the hydrogen to land via pipeline before transporting energy as hydrogen to different customers. We are investing a lot in how we can produce green hydrogen at sea and we have completed a lot of tests in the Atlantic in our project, Sealhyfe.”

Lhyfe positioned an electrolyser capable of 1MW production in a remote location, on a floating barge connected to an offshore wind turbine.

Returning to dock in November 2023, the pilot showed production stats just as high as on land facilities, and the ability to operate in rough, remote environments, while utilising advanced technology, was extremely positive.

“We needed to test the impact of the seawater environment when

producing hydrogen, but also if it’s possible to run such a plant remotely,” says Graré. “This kind of structure on the sea would not have people all the time, and travelling offshore to these structures is very expensive. We had a lot of positive outcomes from this test, and we are busy preparing the next scale for offshore hydrogen production which will come in Ostend in Belgium. That project, called HOPE, will be operational in 2026 and we will produce 10MW from a jack-up rig, bringing hydrogen to land via a very innovative flexible pipeline. On land, we will compress and then transport in tube trailers. It is subsidised by the EU and the Belgian government.”

HOPE has been selected by the European Commission to receive a €20 million grant as part of the Clean Hydrogen Partnership. Lhyfe and its partners also received €13 million from the Belgian government with the eventual goal of producing four

tonnes of hydrogen every day at sea. If developmental progress continues, the company will become the world leader in a vital industry sector, claiming first-mover advantage and opening up opportunities for green hydrogen production the likes of which has never been seen before.

One of the key challenges for Lhyfe and others involved in green hydrogen production is sourcing reliable electricity supply from legitimately green sources. The demands of producers of green power are monumental, and this drives the continued rollout of projects all over the world. Green hydrogen production can require more than 53 kWh of electricity to create just one kilogram of hydrogen. That kilogram can hold around 40 kWh of usable energy. Buying power in volume is essential.

“We have to look at economies

of scale,” admits Graré. “There is large demand in the market and there are opportunistic companies that want to make green hydrogen through signing PPAs for renewable power. But we have several plants in several countries and we buy renewable energy in a portfolio which creates economies of scale with one large portfolio rather than many small deals. We are expanding so we look to sign more and more PPAs at a lower rate with prices coming down. This means that the average across the total portfolio is coming down. That is undoubtedly what differentiates us from others.”

Across its procurement process, Lhyfe is focused on quality and longevity in relationships. The company is technology agnostic and able to design plants of different sizes in different locations with proven methods and a verified international supply chain. Because it has garnered a reputation as a go-to name in green

hydrogen, Lhyfe is often approached by industrial companies to discuss construction of production facilities on site. “That onsite production is a facility that we would own and operate on the site of the customer,” says Graré.

This approach can make a lot of sense for the big emitters and is likely the direction of travel for major industrial customers under pressure from stakeholders to address sustainability challenges and remove fossil fuels, replacing with green alternatives.

“The most important industry to target right now is the steel industry,” says Graré. “It is a big CO2 emitter that needs to be decarbonised. We have signed a MoU with steelmaker UGITECH to show our commitment to that industry. We are also working with the fertiliser industry which is another big emitter, and more sectors

that could embrace green hydrogen.”

Usable green hydrogen remains a relatively scarce resource, with little production at scale operational. As more production comes online – with the EU targeting 10 million tonnes of annual production by 2030 – the industry will continue to boom but right now there is need to be efficient. For this reason, Lhyfe has again been innovative, developing a hydrogen trading platform, a Marketplace, which it launched at Hannover Messe in April.

“It is enormously innovative,” Graré lauds. “This is like Air BnB for hydrogen. If you have too much, you can use the Marketplace to offload. It brings buyers and sellers together and that is innovative - no one has ever done this before.”

The Marketplace will be delivered across Lhyfe’s Heroes digital platform dedicated to green hydrogen,

developed entirely inhouse.

By being proactive in the energy transition and adopting the ideas of tomorrow, Lhyfe is a company that is doing more than most to deliver tangible results. Sustainable energy from a renewable source, endless in potential, and developed and delivered through proven and dependable channels – it’s what governments, industry, and the general public is calling for. The question now is not about how it is done but more about how quickly Lhyfe can scale. Graré is enthusiastic.

“It’s a very, very exciting time. For some renewable hydrogen is the future, for us it is now”, he concludes.

PRODUCTION: David Hill

Michael Avison, CEO at Landmark Power Holdings, tells Energy Focus that swift progress is being made across its first two major developments as it rolls out natural gas-powered electricity generation but with carbon capture technology, creating low carbon energy for residential and industrial clients in the communities around its pioneering projects.

//In 2019, Michael Avison saw an opportunity. Active in the energy industry for his entire career, this engineer knew that gas generation will, for the foreseeable future, continue to deliver reliable power for a UK grid that is beset with challenges. As the energy transition continues, technology will bridge the past and the widespread use of fossil fuels with the future and the rollout of renewable energies and green concepts.

Avison established Landmark Power Holdings (LMPH), a developer of highend technology low-carbon generating assets, based in London, with the aim of achieving circularity in the generation of energy and sustainable fuels. The company began its journey in 2020, while many others were slowing down or struggling, and quickly went from

start up to respected player following the speedy ramp up of its first project – Rhodesia – in Nottinghamshire.

Rhodesia sees LMPH partner with Victory Hill – a specialist investment firm – to build a 10MW capacity carbon capture power plant, powered by natural gas, that has the ability to power more than 10,000 homes in the local area. £42 million was invested in the site near Worksop, and local businesses were also included in the offtake arrangements. Expected to be fully operational, including the carbon capture element, by the end of this year, Avison is happy with progress and reiterates the company’s commitment to supporting the energy transition.

“We use natural gas which is a transition fuel,” he says. “The point of what we’re doing is about flexile power generation with carbon capture

to support the renewable industry. As more wind farms come online, the grid becomes more unstable and therefore you need gas-fired technologies to support the grid.”

LMPH utilises advanced gas engines from carefully selected partners, including Rolls Royce MTU, and combines carbon capture technology from ASCO Carbon Dioxide to clean emissions through a liquid system, creating a usable liquid CO2 product suitable for us in the food and beverage industries. The plant will also create heat which can be utilised to improve efficiency across the system in what is a first for the UK market.

“We focus on local and independent, low carbon power generation. Our preference is to keep

it small and go local – that is our key USP. Using carbon capture, the CO2 footprint is reduced by 95% and we remove all NOx. We produce CO2 for the drinks industry where it is required but is currently produced in a much more polluting way,” says Avison.

The build of Rhodesia began in 2023 and first power has already been supplied to the grid. Avison explains that the process was a challenge, but the team in place at LMPH ensured the smooth rollout using its extensive industry experience.

“We financed the first project in 2021 and we went through the construction period while one of the key contractors went bust,” he recalls. “We then had to take on the mantle and we managed to get everyone together and keep the project on track. We have fired the first four engines, and they

are now connected to the grid capable of producing electricity. We are going through the rest of the installation and commissioning of the whole plant. We will be doing molecule to molecule, methane to CO2, by September.”

World leading industrial companies are active across the supply chain. LMPH takes a modular approach to technology implementation, using advanced engineering and project knowledge to install the right elements in the right place at the right time. The focus is always on output efficiency as well as cost effectiveness.

“There are various contractors and sub-contractors, all the way from big international companies to the local business providing civil engineering and construction services, such as Buildings UK who is our preferred steel structure buildings contractor. We work with the

likes of Rolls Royce MTU, and we have an offtake agreement for CO2 with a large German gas business. We work with Turboden for organic Rankine cycle turbines, and we work closely with ASCO Carbon Dioxide who provide us with the equipment to capture CO2. We also work closely with smaller consultancies including environmental businesses that are very important in what we do,” Avison explains.

MILL HILL

LMPH’s second project, and one which will confirm its status as an innovator and long-term player in the market, is located in County Durham. Mill Hill is a 35MW carbon capture project that has already secured gas input and grid connection for electricity export. With construction expected to start later in the year, the £90 million

project in Peterlee will cover around four acres in an industrial estate.

“The second project, which we own and control, is going through the pre-financing as we speak. We will be working with a big EPC contractor and we already have the gas supply identified. We are negotiating a 20-year supply agreement for natural gas and we have an offtaker who will send power through the grid or to our private offtakers. We innovate the contracts as well as the technology - this is the first time this has been done,” says Avison.

The site will be home to LMPH’s original FLEXPOWER PLUS® technology which is a method of modularising construction of plants to combine high efficiency power generation alongside carbon capture with the result being a low carbon electricity that can provide baseload power and other useful products. This system, says Avison, allows for a world-class

supply chain at a local level.

“Our FLEXPOWER PLUS® tech is patented and that helps us to work in the way we like – with well-known industry leading companies on a longterm basis. We are not for tendering for every project. We are not talking about 1000MW CCGT, we are talking about 1030MW plants and when we choose our partners, we like to stick with them and build long lasting relationships,” he says.

Longer-term, utilisation of this model will help the company to develop further product lines including the production of e-methanol, widely recognised as the fuel of the future in transportation, and hydrogen which most recognise as the obvious industrial replacement for fossil fuels.

“CO2 is a major part of that from a chemical point of view. We work with technology suppliers that help us produce hydrogen from synthetic gas, and we have signed an MoU with a

big-name brand for CO2, hydrogen and methanol production equipment.”

If the company can demonstrate its capabilities to full effect in County Durham, it will make raising further funding easier. Projects on the ground, showing practical delivery, help financiers to realise the potential returns of investing in projects that are novel. LMPH is busy with a funding campaign in which it states that it will prove its technology as a project developer before becoming an industry-leading technical company.

“That is what our fundraising is based around,” confirms Avison. “We started as an IPP but we are progressing and developing very quickly.”

Ultimately, the offering from LMPH can help to reduce pricing for customers and this is something that will never be ignored.

Continues on page 28

ASCO is proud to be a selected partner of Landmark Power Holdings! Together, we have developed the UK’s first power plant with carbon capture in Rhodesia, Nottinghamshire, contributing to the UK’s net-zero strategy. For decades, our proven carbon capture technology has been helping hard-to-abate industries like power plants, as well as cement, steel and chemical production, to decarbonise their processes.

Capacity range from 500 to 50’000 kg/h (1’100 to 110’000 lb/h)

Captured CO 2 meets ISBT specifications (food and beverage quality)

Low energy usage offering greatly reduced OPEX

Flexibel layout for modular component design possible

Continued from page 26

“We absolutely want to keep it local and work with local communities to stabilise their power pricing,” Avison states.

“It’s all about economics as well as the environmental aspect,” he adds. “The last two years has been a real shock for companies. On our first project, we are buying power in at 33kV and that is costing 35p per kilowatt hour. The wholesale power price is 8p. We have done all the analysis and we know how the price is made up, but some companies are paying a huge amount of money to their supplier. We can literally cut costs in half. When you are looking at spending £5 million per year on electricity, that is quite a significant saving to the bottom line.”

LMPH has been growing quickly since its beginning in 2019. Avison describes

the growth as a “rapid maturation” and says the team has grown to include new disciplines as progress has been made. In the future, low carbon energy systems will be essential in the transition, and the ability to produce by—products including methane, hydrogen, ammonia, carbon dioxide and more will only open up new revenue streams for successful organisations.

In Sweden, LMPH is a shareholder in Nordbex – a distributed carbon negative power generation business, utilising a unique bio energy carbon capture and storage solution Avison says that by using existing ideas in a novel way, the company will produce hydrogen-rich synthetic gas for use in medium-speed engines from biomass gasses before sequestering any carbon emissions in North Sea gas wells. Clearly, the ambition for becoming a technical company is materialising.

“That is moving quickly, we have a lot of traction, and investors are already

coming in,” he says. “We recently tested the engine on the syngas and we managed to achieve what we think is a world record of 45% electrical efficiency using synthetic gas. That project should go live in 2028 but we have a lot of investment going into the development of that. It’s an offshoot of what LMPH is doing but it is part of our technology and we will be applying to make that a patented process technology as well.”

LMPH is also receiving numerous requests from industry for production of synthetic aviation fuel and Avison is again confident that LMPH has the expertise and partnerships to provide it.

“That is where the market is leading us right now, and that is where methanol becomes more important,” he says, highlighting FLEXPOWER PLUS® as an important differentiating factor.

“ASCO does a lot of market research and they see the enquiries roll in about their equipment so that their clients can produce CO2 that can be

combined with hydrogen. The standard method of producing hydrogen is PEMS or electrolysis. We can do it in a different way but only on a small scale right now. Our method will be 24/7, not reliant on wind blowing, and will be 100% on site, with no need to pressurise or transport [hydrogen].”

// TODAY, WE ARE AN IPP. WE DEVELOP POWER PROJECTS CONNECTED TO THE DISTRIBUTION NETWORK. OUR PREFERENCE IS TO KEEP IT SMALL AND GO LOCAL –THAT IS OUR USP //

While the rest of the carbon capture and storage industry has been slow to move, and many opportunities have passed or been missed, LMPH has been making things happen. This innovative and ambitious company is already an IPP, and has already created infrastructure and ecosystems that can successfully produce power while removing emissions from the process. The speed of implementation from concept to working plant is remarkable, and this is why investors are regularly in touch. Avison says that the speed of progress has been surprising, but he has no intentions of slowing down.

“Starting two years ago, we have achieved our five-year goal of building at least one carbon capture plant. We then said we wanted to produce methanol for the zero-carbon cycle by 2032 but things are moving so fast that

it looks like that will be ready in 2027/28.

“By 2030, we hope to be the technical company that provides solutions, installing on third-party developments. We will operate assets and we will be a partner that can backfit carbon capture tech on existing assets while helping to run those assets.”

Bridging the energy transition with low carbon baseload power using innovative engineering is the task for LMPH and Avison, and so far the company is more than capable of delivering.

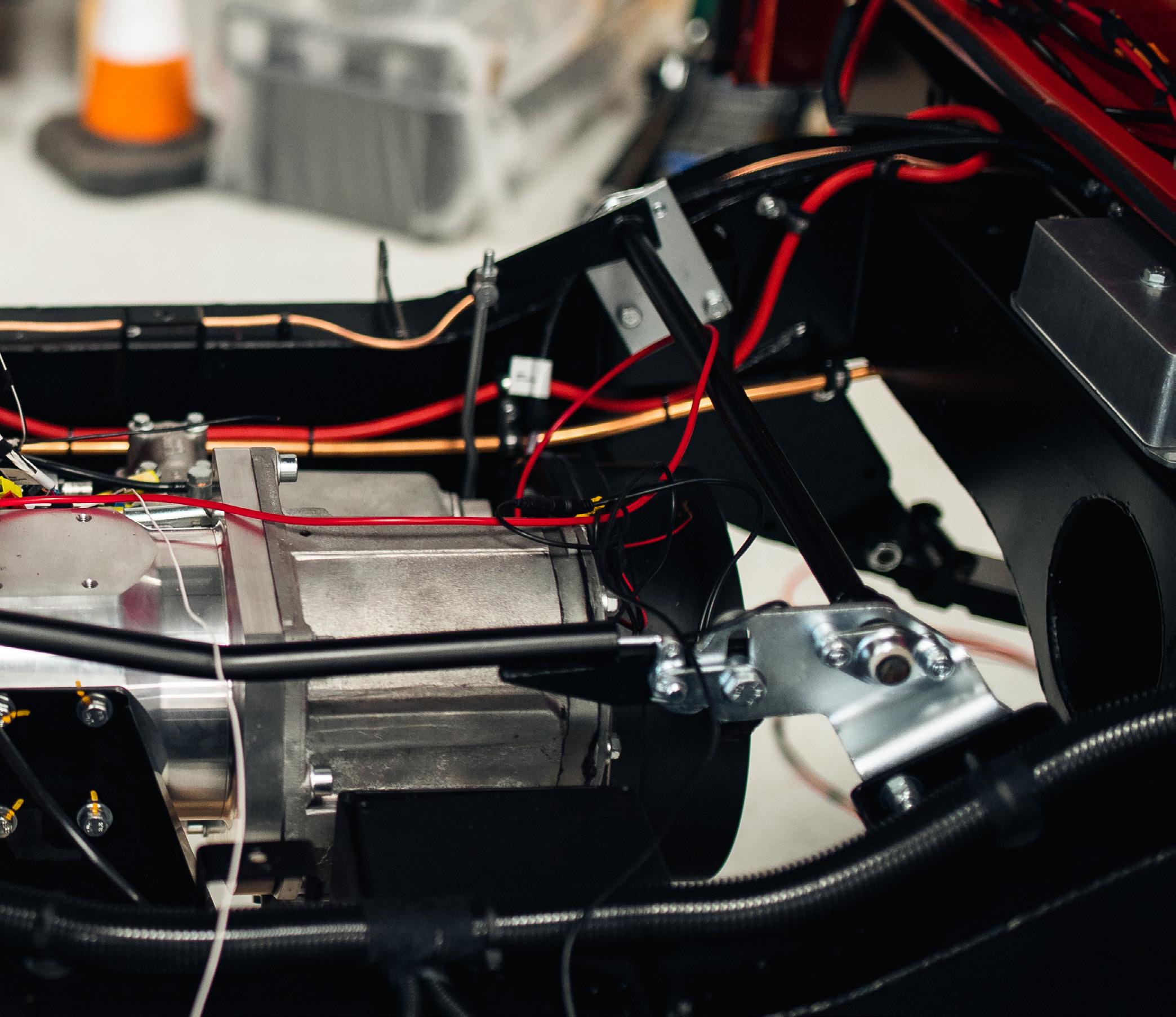

PRODUCTION: David Hill

Everrati is redefining the classic car space – changing what it means to own and drive an iconic car, helping people to think differently about their passion. CEO and Founder Justin Lunny tells Energy Focus that, like a fine tailor, the company is creating custom offerings for clients. “Complex packaging, high in componentry – it’s a bespoke offering,” he says of the switch zero emissions.

relationships with suppliers are now exclusive and the very best products and services available anywhere in the world are offered up only for Everrati.

“Our main motor provider is a UK company, Helix Motors, that is known to be one of the highest power dense motors in the world. Their motors

power the Lotus Evija and the Aston Martin Valkyrie and they are high performance which you cannot just go and buy. Our batteries in front engine rear drive for the likes of the Mercedes Pagoda are gen-5 batteries and are not available to anyone else in our space.

We have some very high-end inverters and we are setting up a relationship with a new partner to ensure we offer the very best technology. When we have the supply chain in place, we can offer that across B2B or B2C.”

The B2C element of Everrati is where the genesis of the business came. Being able to take history and nostalgia, and redefine it for the future was the spark that moved

Lunny – a serial entrepreneur and successful businessman in fintech – to move into the EV sector.

He watched from his home in Windsor, west of London, when Prince Harry married and drove away in a converted electric powered Jaguar E-Type. “I realised the opportunity was there to offer the ability to drive these cars to a wider audience. It was rolling art and such a beautiful piece of engineering. I wanted to invest in a business, but none had the level of quality I was after,” he remembers. “The journey so far has been amazing. Covid was not straightforward, delaying things and making them more expensive, but we did hire some engineers that we may not have done otherwise. The reception we’ve had has been amazing.

We are now selling cars to very highprofile people in multiple countries off the back of them reading some PR.”

But the longer-term future for this pioneer sits largely in the B2B arena. Lunny and his small team of experts see the company able to offer something completely different to what is available elsewhere. ‘Powered by Everrati’ is a B2B concept that sees the company able to offer alternative power systems and designs, similar to the high-end tuning companies recognised in the ICE industry. For example, companies that have been at the forefront of developing industry leading ICE vehicles are being pushed into developing modern solutions as regulations bring an end to fossil fuel power. Powered by Everrati is

the perfect solution for those who want to adapt what they have but not fundamentally change their brand.

“Maybe a lower volume manufacturer, who has been in the combustion industry, and now wants to develop their EV proposition,” describes Lunny. “Rimac is too expensive, and they don’t want to go right down to a generic converter. We sit in a really nice space – OEM-

“WE REDEFINE EACH CAR THAT WE LOOK AT – IT’S FAR MORE THAN JUST BATTERIES AND MOTORS”

grade, OEM-quality, OEM-process but at a price point that is realistic. We are also a very agile business. The way we have developed our battery control unit (BCU) means that we can deliver a vehicle proposition far quicker than most and at a standard that is acceptable for a production run. Everything from an idea through to certification is where we fit in.”

International expansion has been quick for this relatively young business, and like Savile Row, the company is showcasing British talent around the world with customers emerging from the USA and Canada all the way through Europe and on to the UAE and around the Middle East. Typically, people in technology who want to drive innovation and be part of ‘world firsts’, Lunny is appreciative

of the forward-thinking client base for being part of an industry and energy transition without losing the valuable ‘petrol head’ mentality.

In May, Everrati partnered with W Motors in Dubai to create a regional manufacturing powerhouse. A luxury hypercar manufacturer and mobility solutions provider, the W Motors agreement is the perfect demonstration of Everrati’s ability to play in the B2B space. “We see a lot of opportunities to develop our Powered by Everrati proposition – the underlying EV solutions, integration, and provision – into the MENA region. We are busy working on another partnership in North America on a similar basis.”

“Everrati’s electrified icons and its proprietary powertrains set new standards – we are proud to partner with such a trailblazing brand, playing a key role in its further expansion

in the Middle East and beyond, at the same time taking advantage of its technical expertise to support W Motors’ growth in the creation of bespoke electric vehicles, across both the luxury and sustainable mobility sectors,” said W Motors Chairman, Founder and CEO, Ralph R. Debbas.

Currently all Porsche builds are handled by the company’s partner in Irvine, California but the British engineering remains the underpinning fabric that holds entire concept together. “All of the EV and mechanical engineering and CAD development is our core,” says Lunny. “That forms the basis of the business. We have our own BCU and we have our own OEM-grade supply chain. Because the team is ex-Maclaren, ex-JLR, ex-Rimac, ex-Singer, ex-Bentley etc, we have a good interaction with the supply chain from those businesses. That allows us

“WE CAN GET NEW TECHNOLOGIES INTO A ROAD-GOING VEHICLE QUICKER THAN THEY WOULD EVER GET TO MARKET WITH AN OEM”

to deliver OEM-grade level solutions for our cars and for the B2B market.”

When successful - like with Land Rover, Porsche, GT40, Mercedes Pagoda and soon the Lamborghini LM002 - Everrati is delivering high-performance cars that have a classic edge, but equipped for the modern road and beyond. Clean, reliable, fast, and venerated.

“After we redefine these cars, they come out as a version of themselves had the modern technology been available when it was originally designed by the OEM. We are trying to recreate something that has very similar characteristics but in a modern world,” says Lunny.

Thanks to the small Everrati team, some of the world’s most iconic cars will live on, and the way powertrains are imagined for EVs will continue to evolve. In order to remain nimble through the innovation and engineering process, the company commits to a technology-agnostic approach so that new, pioneering ideas can be implemented wherever possible.

“Battery technology is improving all the team and we are therefore looking at new technologies all the time. That is part of the reason we developed our BCU in the way we did. If you are an OEM, you are generally looking at a production run of some thousands of vehicles and you have a consistent configuration of battery technology and battery chemistry. When you do low volumes across different models, you have to be very flexible. We can

Helix develops and manufactures high performance electric powertrains to IATF16949 automotive quality. The Scalable Core Technology in our compact, efficient motors and inverters delivers car makers industry-leading power and torque density in a flexible range of configurations. Helix platforms offer classic vehicle architects the best fit drive for their design concept. The future in motion.

To find out more scan the QR code or visit ehelix.com

say ‘there is new technology coming through, let’s look at it and take it on in this project’. That is an interesting position for the battery companies themselves as we can get new technologies into a road-going vehicle quicker than they would ever get to market with an OEM,” Lunny highlights.

While Everrati remains a relatively young company, it is learning much about a quickly changing EV industry while applying its engineering and business knowledge developed in ICE. Importantly, the passion for the industry continues to shine through and employees, customers, suppliers, and all stakeholders are becoming increasingly excited about the opportunities for this catalyst company.

“The buzz it gives our team and the people we talk to is what makes me proud,” Lunny smiles. “We have created

a movement and that is exciting. I go to Pebble Beach Concours d’Elegance every year with my children and they love it, and it is something we are all passionate about. The fact that we are building things that people are exciting about is hugely pleasing.

“This year has been substantially better than last year, and we are expecting better next year. We are growing the team – it’s a really exciting space.”

In 2025, Everrati will display on Savile Row again, not as a business making things look good but as a global organisation of innovation and car culture, reimagining icons for a modern industry.

PRODUCTION: David Hill

Growing the UK arm of the international renewable energy business, Soly, is going well for Country Manager Neil Anderson. He tells Energy Focus more about building a supply chain, onboarding customers, and generating positive results.

//In November 2022, a new clean energy brand was emerging from the Netherlands. Brothers Patrick and Milan van der Meulen had established their business, focused on solar PV rollout. Soly, came about as the pair knew they must use their entrepreneurial energy to address the climate challenges with a novel solution. Milan told Energy Focus more about the drive behind the company and how solar power for all would quickly become possible.

Solar panels over car parks, solar panels on rooftops, solar energy across cities, and a range of additional offerings saw the company boom, commanding a strong position in the Dutch market before growing into new international geographies.

In September 2023, the UK operation commenced. The energy mix across England, Scotland, Wales and Northern Ireland is made up mostly of natural gas and oil, with supporting stats from nuclear and

biofuels. However, growing contributors include the renewable mainstays of other nations – wind and solar.

Soly UK shares the mission of its international parent: to make solar energy accessible to all, working towards a world with affordable, carbonneutral and decentralised energy.

“Things are going pretty well,” smiles Country Manager, Neil Anderson

The Soly brand has grown since the company was founded in 2013 because of a simple commitment to quality. The founders have always been clear that excellence in delivery, through a digital-first strategy, is the core of Soly’s success. Anderson says that in the UK, an unwavering commitment to quality in every part of the business, helps to fuel the company’s fixation on delivering for its clients.

“One of our core values is customer obsession,” he details. “We take a much more consultative approach

with our clients rather than hard selling. We are genuinely trying to find the best bespoke solution and we fully believe in our proposition.”

Anderson was the perfect choice to lead the Soly expansion in the UK, with experience across a number of big-name brands including online and offline leadership roles, and exposure to various technologies. He has a rare mix of start-up, scale-up and corporate experience, allowing him to navigate through challenges at the different phases of any business. Throughout his career, he says that he has always been entirely focussed on customer success and that helped him to secure his new role.

“I started my career at Costco, who are globally known for excellent customer service. As the business is based on a recurring membership model, customers are at the forefront of all planning and

Continues on page 42

Continued from page 40

decision making. That embedded a sense of customer centricity for me a long time ago – and that continues to be my foundation and core.”

He then moved to digital retailer Groupon, working across various leadership roles including a stint in Amsterdam. In 2021, he joined JD.com, tech giant and China’s largest retailer by revenue, as Acting Country Manager in the Netherlands. Here, he was responsible for driving a commercial strategy that helped the company launch its new omnichannel concept in Europe. His next move was back home to London, to work for Disney where he led commercial sales across tech, gaming and sports all over Europe, the Middle East, and Africa.

“I have always been very passionate about sustainability and the energy transition. I had reached a moment in my career where I wanted to feel more purpose in my work,” he says.

After multiple meetings with

the founders to align on vision and strategy, he took charge of Soly UK, aiming to grow the business across all mediums. Today, almost one year after its establishment, the company has shown impressive growth with a team of 30 people and is looking for further expansion via its product offering and new market entries.

“We are a digitally-led business, centred around online consultations, talking to customers through the various benefits of renewable energy so that we can find a bespoke and relevant solution for them. Depending on their level of knowledge and what the client is looking for, these consultations can take anywhere between 30 mins to an hour. We offer both digital and onsite surveys, and we work with a fully-vetted team of installation partners across the UK to ensure we deliver an excellent service. Our goal is to help everyone in the UK access and transition to renewable energy whilst saving money on their energy bills,” says Anderson.

He explains that the company

is currently well-positioned across most of the UK but there are plans for further expansion and growth.

“We have plans for Northern Ireland and Ireland, but we had to ensure we have operational efficiency in England, Scotland and Wales first.”

The modern offering from Soly includes renewable power generation capability paired with smart energy optimisation with the new Energy Management System, the Soly Brain. “With the Soly Brain, you gain complete insight into your energy usage, maximize the consumption of your solar-generated power, and save more by controlling appliances during low electricity rates. This is our way of making sustainability both affordable and more accessible.

“We absolutely want to build on our smart solutions, and as seen in some of our other markets, we will look even further to dynamic energy contracts and virtual power plants, where people can actually benefit from negative energy prices if they use our products in the best way possible,” says Anderson.

“We are not just a renewable energy business focused on solar PV and battery storage, we also see ourselves as a utility of the future.”

To date, Soly has installed more than 800,000 solar panels for more than 31,000 customers, generating more than 21,7500,000 kWh of solar energy globally. The company’s rise has been remarkable but Anderson points out that support from a booming supply chain has been critical in realising achievements. From tech partners to installation companies, Soly has been keen to treat the supply chain as an extension of its business, building lasting relationships.

“We are a global player,” he says. “At the same time, we are very much in touch with local installers and always keep an ear on the ground.

“The supply chain is an incredibly important part of our customer journey

and we have to make sure we have the best quality products available at the best possible prices. We work with national and global hardware companies, forging great relationships across the industry. We are always looking to innovate, perhaps through our own hardware in the future.

However as of right now, we have laser focus on making sure the supply chain is the absolute best it can be.

“We have fantastic relationships on a global level, and that allows for economies of scale as we launch into different countries and territories. We can pass savings onto our customers, as for us, it’s about giving a frictionless experience with a product offering with significant value.”

He explains that the Soly onboarding process for partners is rigorous and the goal is to affiliate with ‘fewer, bigger, better’, creating mutually beneficial environments where both companies work as partners.

“It’s not just us dictating what and how we want things,” he says, “we have to make sure our agreements work for all parties. The whole process is cohesive and collaborative.

“We are a fast-moving business within an expanding, ever changing industry – the team certainly have to work at pace. Within supply chain, we have to make sure we are able to get what we need, on time, every time.”

This dedication to world-class standards has allowed the company to achieve several certifications that Anderson is particularly proud of including B Corp status, MCS-certified, TrustMark and HIES accreditation as well as being a Which? Trusted Trader.

The operational success of the business, locally and globally, has helped attract new investment as Soly looks to grow beyond its current markets of the Netherlands, Belgium, Germany, the UK, Italy, Austria, and South Africa. By the end of this year, Soly have plans to open in yet another

placed to expand even further.

“We finished series B funding in January and we bought on two large and experienced venture capital companies from North America –ArcTern and Fifth Wall. These are climate-tech focused investors and prior to that we have investment from Shell Ventures and ABP – the largest pension fund in the Netherlands. That kind of backing establishes credibility with customers and partners alike.”

Going forward, the UK business will continue to leverage the technological innovations developed out of the Netherlands HQ, to drive efficiency and cost-effectiveness for clients. They are also in discussions with other UK companies within the

opportunity to use Soly’s services.

For Anderson, almost one year into the job, things are going very well. He is confident about what is to come and is certain that the future looks bright.

“We are so pleased to see our approach resonating in the market. Together with our team, partners and customers across the UK, we are making significant strides towards achieving Net Zero. There’s a lot to be done, but we can all take pride in our collective contribution,” he concludes.

PRODUCTION: David Hill

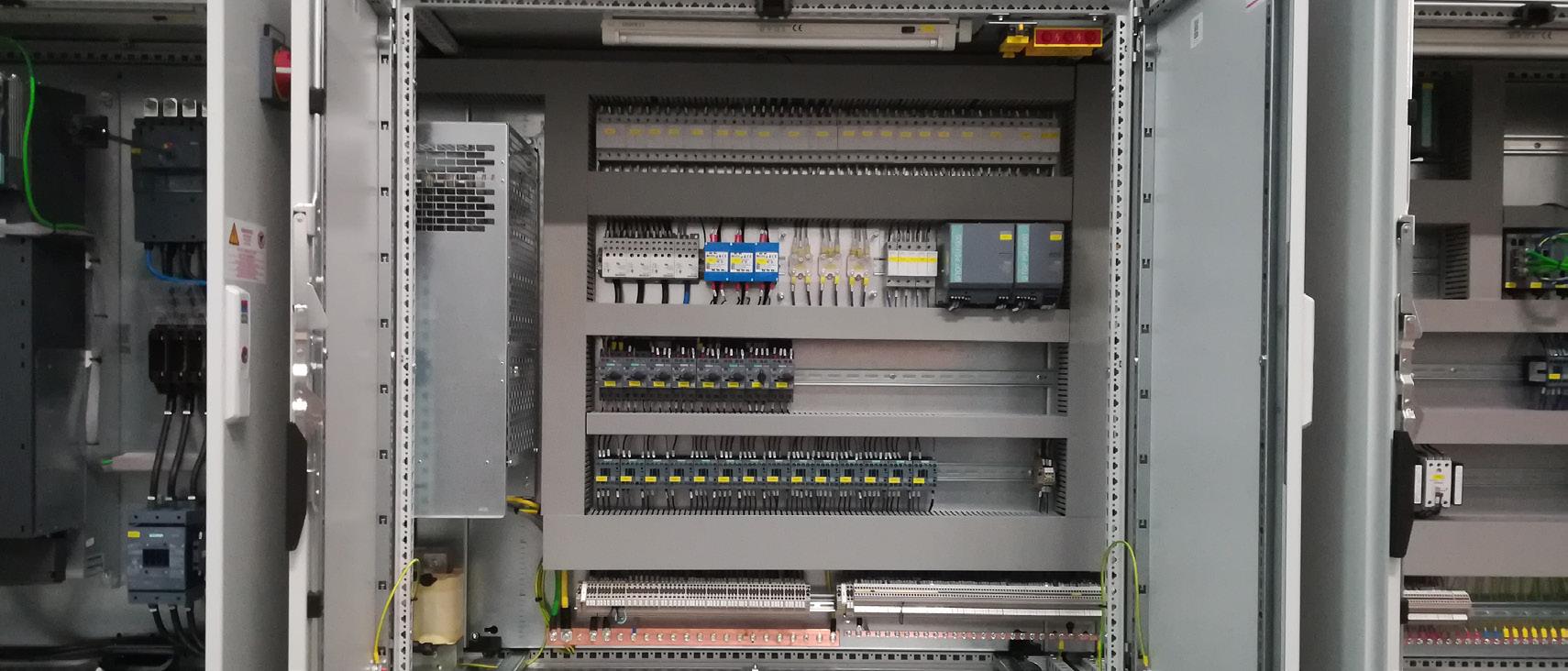

Switzerland’s Enerproject continues to engineer some of the world’s best gas compression solutions displaying almost 30 years of experience. GM Business Development, Vito Notari tells Energy Focus more about the company’s unique but wide-ranging offering, and its strategy for ongoing growth.

//In 2023, the Global Innovation Index found for the 13th consecutive year that Switzerland is a global leader in innovation, encouraging pioneering thinking through a highly skilled workforce, world-class research capability, many patent applications, and a strong support for business from the state. This environment supports entrepreneurialism and technological development, and it is against this backdrop that a global expert in industrial technology has grown.

Over the past three decades, Enerproject has made its name as one of the world’s foremost manufacturers of gas compressor packages and associated technology. With certification

from numerous global industry bodies, Enerproject’s work is proven, and its technology is verified.

Recent projects have seen Enerproject busy around the world, in Thailand, Australia, USA, China, Norway, Vietnam, Turkey and more as the company continues to build on its already sterling reputation for quality, reliability, and technical knowhow.

According to Enerproject’s GM Business Development, Vito Notari, the company has set it sights on energy transition products in the gas space, while also driving collaboration in new geographic markets.

Notari knows about growing the business. He spent over a decade developing business across energy

and oil and gas. And in his time at Enerproject he has developed the orderbook significantly.

“The company was born and grew in the provision of fuel boosters for gas turbines – this was the main product. We still excel in this area but in 2015 we decided to create a new business development department for customer applications including helium, CO2, ammonia, LNG and more.”

As a leader in fuel gas compression packages for power generation plants, Enerproject has grown its expertise to deliver solutions for oil and gas, petrochemical, refrigeration, renewable energy and biogas. More recently,

the company has entered upcoming industries that are paving the way for the future including hydrogen, helium, LNG and CCU and CCUS applications.

By 2023, more than 700 units had been built at Enerproject’s facility in Ticino, in southern Switzerland. Successful installations around the world have driven customers to ask modern questions of Enerproject, and Notari says the company has used its in-depth engineering knowledge combined with innovative spirit to develop solutions.

“We are a leading packager of gas compressors for industry, that is not debated,” he says. “We work with any type of compressor – methane, ammonia, CO2, LNG etc. We focus on three key markets – power generation where we provide fuel boosters for gas turbines or gas engines of any size. Second is the maritime industry where we provide different type of compressors for LNG. Also, in closed loop or open cycle ammonia compressors with CO2 capture projects is where we can provide CO2 or mixed refrigerant compressors.

“Another big market is helium compression which we compress for scientific and research purposes applications,” he adds.

The company can provide compressors of any size, from small and convenient to large oil-based systems. Installation, commissioning, after-sales, troubleshooting, and ongoing maintenance are all included as part of the package for clients, and Enerproject is often able to monitor remotely. This can reduce unnecessary maintenance and therefore offer an overall lower cost through the lifecycle

“Considering the business opportunities and trends, ammonia as a fuel is something everyone is talking about. We have developed a specific product for this market and it is an area we want to focus on in the coming years,” confirms Notari.

“There is also a lot of talk about carbon capture, but few projects have been realised. We have developed our solution for that market and there is ongoing promotion.”

Using a modular approach to technology integration, fitting carbon capture units will eventually allow the compressors to be considered low-carbon, and Notari is keen to build on this in markets where the company sees potential for further growth.

“We started in Europe because we are based here,” he says, “but we have a strong presence in southeast Asia. We are strong in the Middle East and pushing more to get into the US market. We are already generating interest there, but we are looking for additional contacts in the power generation space with innovation at the front of mind.”

In the market for critical equipment in power generation, there is no margin for error. Health and safety standards are globally recognised, and quality is non-negotiable. To ensure its excellence continues, and the brand’s key value of customer satisfaction is upheld, Notari explains that a lot of work goes into building last relationships with reputable suppliers with a shared vision of superiority.

“We have strategic partnerships and approved vendors in our supply chain across what is a regularly checked relationship where we analyse quality, price, delivery etc. It’s all about quality and we are very focussed on maintaining that throughout our execution,” he says.

“We work a lot with EPC contractors, and also the end users. They all bring us opportunities and we enjoy becoming part of a larger team. We can work with any company and we are happy to invest time to understand applications and opportunities in the market through new products,” he adds. “We are a medium-sized company and so the resources are limited. We have to use them carefully and we cannot afford any wastage. We are all about opportunities that create further opportunities rather than singular transactions.”

The after sales team is responsible

E.A.SY. 2000 S.R.L. in the electrical automation business for over 30 years

ELECTRICAL DESIGN

SWITCHBOARDS, PANELS & WIRING

ATEX DIRECTIVES COMPLIANT

UL-CSA COMPLIANT

SOFTWARE DESIGN & DEVELOPMENT

for ongoing maintenance of complex machinery, and this team of local personnel offers an extended service and speedy reaction should issues arise. For this reason, working with trusted and proven partners forms a key part of the strategy going forward. Whether it’s off-the-shelf compressors, BOG systems, or open cycle concepts with carbon capture, supply chain relations are as important as customer relations.

“Procurement is centralised because all of the units are built in Switzerland. We work with vendors from around the world but wherever we go we always need numbers to ensure we can gain competitive pricing.

“The packager, the bare shaft compressor, the vessel, the motors, piping, enclosures etc. Everything we purchase gets engineered by us, in house. Almost all of our vendors have

been on our list for four or six years and some even 20 years. They know what we need and they are happy to adjust. They all know that we have a defined specification, and we are all happy to work to that together.”

Successful demonstrations of this start-to-finish approach to quality comes from around the world. At the start of the year, Enerproject completed an ammonia refrigeration unit for installation at a CO2 plant in Australia.

In May, the company celebrated the commissioning of a pilot flare recovery system for a big-name client in Thailand. In March, a tail gas compressor unit to be used in an Olefins expansion project in Europe was sent out from the Enerproject HQ. And in July, the company announced that it would participate in a pyrolysis project to convert used tyres into carbon black,

tyre pyrolysis oil, and steel wire in Thailand. Last year, Enerproject was demonstrating its capability on site in USA, supplying compression units for helium application in Massachusetts.

Across the power generation industry, compressor technology is still widely overlooked as an essential component in wider systems. In Switzerland, the most innovative of nations, with engineering ability rarely matched elsewhere, Enerproject continues to move the market forward. Notari is clear: “If you want reliability, if you want efficiency, it you want truly world-class, we are here to support.”

PRODUCTION: David Hill

Always at your service, the Gibraltar Port Authority is a centre of excellence for vessels travelling around the world. Positioned on one of the world’s busiest shipping routes, this port has to operate to world class standards. CEO and Captain of the Port, John Ghio, talks to Energy Focus about consistently delivering the very best possible service.

//As the key to the Mediterranean Sea, Gibraltar’s strategic position has long made it a hub for vessels travelling around 87 seaports across the region, including to Valenica, the major Spanish operation responsible for more than 12 million tonnes of goods in 2023.

The Gibraltar Port Authority (GPA) on the 200-million-year-old Jurassic Limestone rock looks after 60,000 vessels that traverse the Mediterranean and Atlantic crossroads every year. A maritime centre of excellence, the 12 km coastline comes to head at the port on the west of the territory where a range of world-class facilities are on offer.

But this is not simply a port on the Rock. The GPA is taking a leading position on transformation, as more and more stakeholders look to chart a new course when it comes to fuelling and operational sustainability.

Currently undergoing a re-

strategisation, the GPA is developing a fresh masterplan to welcome more traffic than ever while driving efficiency with every interaction.

GPA’s CEO and Captain of the Port, John Ghio, tells Energy Focus about how the masterplan will leverage commercial opportunities to build long-term sustainability.

“We are a very specialised port being service-oriented rather than a port that has a captive client base in discharge or loading. That means we are much more focused on trying to deliver a quality service,” he opens. “The flagship of this quality aspect is our bunkering regulatory framework where we have our own code of practice alongside an LNG code of practice, which covers everything from licensing to enforcement, to checks and balances on supply chain, safety, and ethics.

“We are busy working with the government team to focus on how

we can make better use of the limited space that we have on the port estate. It is about reorganising to make the port even more efficient. Most of our operations take place at anchorage but we are trying to squeeze more efficiency out of landside operations so that we can carry on supporting high efficiency at the anchorage, but also increase efficiency of everything happening landside. The government has launched a new study labelled the port masterplan where we are looking at available land and infrastructure to see how we can optimise to further support our operations.”

With an operations room open 24/7 365, the GPA is constantly moving and changing to accommodate industry requirements. But its unique position as a British Overseas Territory, attached to the Spanish mainland, make it critical

for comprehensive processes to be in place when making decisions.

“Our people cover the remit of a port authority as well as being the coastal state duty holder, so we have coastal state responsibilities for Gibraltar. That includes the safety of navigation aspect, regulation and licensing of port operations, and search and rescue and oil spill response,” reminds Ghio.

Some changes that are underway include increased bunkering of biofuels and LNG as more vessels opt for modern energy to drive systems. At the same time, the GPA is also looking at how to most effectively manage traditional fuels to ensure maximum efficiency.

“Being a service port, it is important that we keep sight of how we can support the industry and the transition to sustainability,” offers Ghio. “I am a believer that the shipping industry is intrinsically green – it is the most efficient mode of transport there is. Reputationally, it has taken a few blows because of perception rather than fact. Having said that, the industry is very much on track to increase sustainability measures dramatically. We are working hard to make sure we support that transition going forward.”

LNG is often cited as a strong return on investment for seafarers compared to traditional marine fuels and, despite still creating a carbon footprint, the environmental impact is significantly reduced. Some reports suggest reductions of greenhouse gas emissions of 23% and NOX emissions reductions of 80%.

“LNG is a bridge but has been identified as a cleaner fuel,” Ghio confirms. “We have been taking significant steps to ensure we overcome the chicken and egg scenario. We are a major bunkering hub which can offer a whole range of conventional fuels as well as LNG by way of having two independent suppliers with their own LNG barges. How that transitions into us supporting the industry taking steps forward is very important.”

For the industry to become more sustainable it is paramount that new, cleaner fuels are available for vessels, he adds. Modern vessels passing Gibraltar, but with no option for refuelling with the right fuels, would be a major missed opportunity for both the port and the industry.

“Not only those operating in a liner market, but also those in the spot market. They need to know they can call here and that we have availability of these fuels,” he says. “We put a lot of work into that, and that together with the ramping up of biofuel availability is very important. We are one of the few ports right now that has both LNG and biofuel together with conventional fuels. The importance of the supporting infrastructure – bunker barges that are able to supply B24, B30, and soon full biofuel cargoes

– is also very important in how we support industry sustainability.”