Elevating people.

Elevating business.

Elevating society.

Elevating people.

Elevating business.

Elevating society.

BDO and Cavalier have been partners since 2017. BDO provides expert auditing to support tomorrow’s agro-processing innovations. The Cavalier group is a leader in this sector. Our relationship is built on our joint obsessions with clarity, quality and exceptional client service. Cavalier benefits from:

X Long-term partnership – consistent auditing support enables the Cavalier Group to maintain the highest standards of financial integrity and compliance, which is crucial for ongoing expansion and operational success

X Strategic investment support – when a significant investment of approximately R50 million was made in energy solutions for the business, BDO ensured the required financial due diligence

X Expert industry knowledge and guidance – BDO understands the particular challenges and opportunities the agriculture sector faces in South Africa and tailors solutions accordingly

X Future-focused strategies – BDO is always looking beyond the immediate to what will assist our clients in the long term

X Risk management – agriculture is no stranger to risk: climate change, drought, flood, exchange fluctuations, regulations – and BDO can advise in that context.

Experience the BDO difference in auditing – visit our website to see how our expertise can elevate your business into the future.

To view our latest facts and figures scan the code

www.bdo.co.za

EDITOR Joe Forshaw joe@enterprise-africa.net

SENIOR PROJECT MANAGER Sam Hendricks sam@enterprise-africa.net

SENIOR PROJECT MANAGER James Davey jamesd@enterprise-africa.net

PROJECT MANAGER Harry Webster harry@enterprise-africa.net

PROJECT MANAGER Jamie Waters jamie@enterprise-africa.net

PROJECT MANAGER Chris Bolderstone chris@enterprise-africa.net

SALES MANAGER Tommy Atkinson tommy@enterprise-africa.net

LEAD DESIGNER Aaron Protheroe aaron@enterprise-africa.net

ACCOUNT MANAGER Ellie Davies ellie@enterprise-africa.net

CONTRIBUTOR Manelesi Dumasi

CONTRIBUTOR Timothy Reeder

CONTRIBUTOR Benjamin Southwold

CONTRIBUTOR William Denstone

Sticking to a vision is tough. Of course, when you start out in business, the first thing you decide on is your vision – what you will offer your customers, why you are making this offering, how you will do it, and what impact it will have – and deciding these things is the fun part. But sticking to a vision over a long-term, having the staying power to repeatedly do the good things well, and ensuring that stakeholders are also part of the journey, is very difficult.

This month, we hear from companies that are doing just that. As hard as it is, and as much as it feels like a never-ending road, sticking to the vision is a key element in business success.

B2Gold Namibia, the leading gold mining operation in the country, is a perfect example. The company is headquartered in Vancouver but came into Namibia to make the region of its Otjikoto mine a better place than it found. Country Manager John Roos tells us that the vision is being rolled out by investing heavily into CSI campaigns that will provide the community with income long after the mine closes. This vision has been realised over the last decade and continues to be refined.

Plato Coffee, a Pretoria-based coffee shop franchise, has always had the vision of building communities through excellent coffee in a clean and vibrant environment. The company is busy rolling out new stores and a new app to help further bring people together and reward them for participating in community groups such as running clubs and cycling teams. While some of the large coffee chains have focused only on profit, the vision of Plato has been considerably more community focused, but Founder Stephan Bredell says it has not been easy.

Sanji Electronics, one the most innovative and unique companies that Enterprise Africa has had the pleasure of dealing with, set out its stall years ago: to use technology to protect vehicle assets. Today, the company is working with OEMs and owners to shield them from car theft and hijacking. The vision was a big one in the South African context, and has without a doubt been challenging, but MD Steve Easton is proud of sticking to and achieving that vision.

Published by

Chris Bolderstone – General Manager E. chris@cmb-multimedia.co.uk

Fuel Studios, Kiln House, Pottergate, Norwich NR2 1DX

+44 (0) 20 3097 1743

www.cmb-media.co.uk

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

© CMB Media Group Ltd 2024

Jotun Paints SA is also holding a strong vision as it grows across southern Africa. Providing the best possible products for demanding industries is a logistics and manufacturing dilemma but the team is also operating with the vision in mind. A new HQ, new partnerships, and new products will allow the ‘penguins’ the keep their vision alive.

Get in touch and let us know how your company is following its vision and not just hunting for profits. Purpose is the real advantage. We’re on LinkedIn

Joe Forshaw EDITOR

PLATO COFFEE

Hot Plato Coffee Brand Brews National Success

NANDO’S SA

Fiery Nando’s Ambitious as Ever in Tough SA Market

CAVALIER GROUP

Farming for the Future

COLUMBIT

Honesty, Quality and Innovation Key Ingredients for Columbit

B2GOLD NAMIBIA

B2Gold Digs Deep Into Sustainability

KANSANSHI MINE

Responsible Copperbelt Mining to Reinforce Zambia’s Global Significance

ARCELORMITTAL SOUTH AFRICA

Hardy AMSA Plans for Return to Profitability

JOTUN PAINTS SA

Strategy Masterstrokes Take Jotun Across Southern Africa

SANJI ELECTRONICS

The Cutting Edge in Curbing SA Car Crime

ALLIGATOR MANUFACTURING

Building Brands With Added Bite

DOGON GROUP PROPERTIES

Dogon Naturally at Home in Cape Town’s Luxury Market

PRODUCTION: Jamie Waters

Stephan Bredell, CEO and Co-Founder of Plato Coffee, is an ideas man. He enjoys an innovative and entrepreneurial mind that helps to develop concepts that continue to create positivity for South Africa. Currently, he is scaling Plato Coffee to reach significant national status, and he tells Enterprise Africa that the success is always down to the communities in which a business operates.

//In the 1800s, transport riders moving between the coast and the mining towns in South Africa’s north stopped in the Free State to grind coffee beans by hand, boiling natural spring water, and brewing up refreshment. Coffee – moerkoffie - has long been a fuel for workers here.

Through history, as the big metros have grown, and big coffee businesses have taken hold, South African’s love for the caffeine hit has warmed. But for baristas and coffee shop owners, life is not easy. Despite public love for beans, whether at home or at work –where 95% of South African workers

// WE FOCUSED ON SITES SMALLER THAN 50M 2, AND KEEPING CAPEX LOW THEREFORE REDUCING RISK //

see good coffee as a crucial aspect of the environment – getting the product right while fostering a thriving business model has been challenging. Even some of the world’s biggest names in the coffee space have struggled.

Growing a brand is tough. Too hands-on and personality is lost, too distant and quality is diluted. Too corporate and a brand becomes soulless. Too individual and expansion is limited. Finding the perfect balance across owned, franchised, and supply chain is key.

Stephan Bredell, CEO and CoFounder of Plato Coffee, thinks he has discovered the ideal way to deliver the level of quality that customers want while scaling quickly. Starting out in 2019, while still employed full time in a corporate position, he took his passion from idea to 60 stores, employing 350 people, and providing opportunity, alongside great coffee, all over South Africa.

This entrepreneur found that having fully owned corporate

stores alone does not work. But having only a franchise operation is not ideal. Most importantly, he discovered that community must be the golden thread that runs through the entire business, across supply chains and customer networks, and through staff and management.

“We project that we will have 85 stores by the end of the year,” smiles Bredell. “In 2026, we want to reach 150 and by the end of 2027 we want to have 225-250. This is just local, we are in discussions with potential partners in the UK, UAE, and USA. We are also looking at the Netherlands, and it is interesting to see the different franchise applications that come in. We receive around 10 per day and they come from all over the world.”

Plato’s success, says Bredell, is down to two things: community and simplicity. In his previous role, he was tasked with creating a café/restaurant concept for his employer’s HQ in

Pretoria. After doing so successfully, he realised the opportunity in coffee.

“I saw that there were 1000 employees buying around 600 cups of coffee. I quickly had the idea of stripping out the coffee from the rest of the offering and keeping it very simple but in corporate locations.”

The first Plato opened in 2019 and the core of the idea was that things must always be small and simple. Bredell wanted to remove all complexity from the model which he likens to a traditional lemonade stand. “You shouldn’t need more that coffee, water, and some other small inputs,” he smiles. “We focused on sites smaller than 50m2, and keeping capex low therefore reducing risk. We wanted to keep the rent below a certain amount while still being accessible and visible.”

After opening across multiple corporate locations, the company gained traction. The coffee was appealing to the local consumer, and the branding was highly effective. Despite opening during perhaps

the toughest period for a traditional hospitality/retail business with the onset of the Covid pandemic and the restrictions that came with it, Bredell explains that the situation reinforced belief in the model of small, quality, community-involved operations.

“No one was going to the office so we decided to not only look at corporate shops. We always say that

if we had 30 stores before Covid, we would have likely ended up closing because we would have had to close all of those at a very fragile moment.

“We refocussed on community centres, where people meet, rather than big malls. All of our stores are now street facing and, while we don’t have a big walking culture like other countries, we picked locations – such as school

runs – where people come together. How many times do you go to a big mall? Not a lot. How many times do you drop your kids at school? Five times a week. We chose very deliberately to create community shops where we are very easily accessible.”

Working closely with franchisees, Bredell was also certain that smaller towns – outside of the city centres –could benefit from something different.

Typically old mining towns, locations where Plato has thrived have been for too long underserved with good coffee.

“They have large populations, but they are often not well provided for with many things, including proper coffee. There is high disposable income and little competition. Our top five best stores are in these smaller towns.

“We have a shop in Rustenburg and when we opened the shop, there was

a man standing outside looking up at the store saying that he felt like he was in a different country. These towns are so often neglected and they don’t have many things with great design. Bringing the ‘big city’ nicety to the smaller towns has given us a lot of traction. The locals then take pride in what they have and that brings a different kinds of traction.”

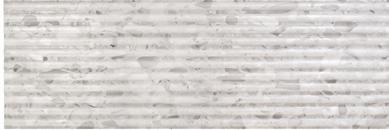

The Plato brand is not your traditional neighbourhood coffee shop. There is no cosy sofa or bookcase; there is not an extensive menu. The colours are white and bright, the minimal marketing is fresh and tidy, and sites are expertly tiled by Stiles to offer that clean and finished look that others can only strive for. Simple but popular coffee styles are the only items on the menu, aside from locally made pastries to accompany the perfect cup. It’s cleverly done, but Bredell explains that it is all deliberate and not an attempt to be ‘cool’ in the short term. This is part of a wider strategy.

“We believe that is why some of the big chains have not been successful in SA as they have gone straight into the centre of Sandton with R250k monthly rent, creating essentially a free coworking space.

“There has been a focus on an

At Stiles, we’re all about keeping things stylish, in your home, your office, your restaurant, and any space you can imagine! Our goal at Stiles is to be exclusive and unique, offering only the best quality tiles and sanitaryware in South Africa.

Quality and style will always outweigh price when we select products. Along with importing products from top tile and sanitaryware factories across the globe, we pride ourselves in being a community-driven South African company. Stiles supports local industry, artisans and artists from South Africa. We believe in the tiles and sanitaryware we market, and employ creative people with an enthusiasm to keep all things stylish, making us leaders in service, technical advice, creative ability and innovative ideas. We are picky when it comes to our brands and only stock the most stylish tiles and sanitaryware you can find in the country. A lot of brands are exclusively available to us like Italy’s Monocibec and Newform or Spain’s Realonda and Brazil’s Ceusa. We also pride ourselves in stocking top quality well-known brands like Duravit, Hansgrohe, Blutide and Geberit. To see our full range of brands, Visit our Shop by Brand section.

Get In Touch - info@stiles.co.za | Shop Online - www.stiles.co.za

industrial type of look – steel, dark wood, piping etc. We went completely opposite. We are minimalist and we were inspired by South Korean and Japanese design, we chose white and clean. We had the vision of an Apple store where everything has its place and there is no clutter. People told us you cannot put white lights in a coffee shop as it should be intimate, but ours is refreshingly bright. People always walk in with their first reaction being around how clean the place is,” he says.

In the beginning, Bredell onboarded Co-Founder and brother Petrus to bring the ultimate coffee to match his idea for a modern and efficient operation. “I didn’t know much about coffee,” he admits. “I have a marketing background so I approached my younger brother

and said: ‘I will make sure the brand and marketing is lekker, please make sure the coffee is good’. You can get someone into a nice space quite easily, but if the product is crap, they will not come back. Our coffee and our brand are equally important. I don’t think one could live without the other.”

There isn’t a shortage of quality coffee establishments across the larger South African cities, and with the likes of KZN, Mpumalanga, and Limpopo home to small coffee production operations, there is an authenticity for some that traverses the entire value chain. This is why Plato had to stand out as a brand beyond crafting super coffee. Plato, of course, an ancient Greek philosopher is credited with innovation around written dialogue. His work was complicated and challenging.

Plato Coffee unlike its namesake is refreshingly simple and easy.

“Our approach has always been around community,” reminds Bredell. “Our slogan is ‘coffee sculpted; community included’. It was clear through Covid when we were allowed to open. We saw a ‘watering hole’ type of situation where everyone gathered at the store. It was obvious that coffee and community go hand-in-hand.”

Going forward, community will remain at the heart of the business as Plato grows aggressively.

Next on the agenda for Plato Coffee is a new location in Silver Lakes, Kempton Park. Other fresh spots will follow quickly as franchisees come on board quickly. Bredell is also confident about

two offshoots that will bolster the offering – Wello, a water brand and wider wellness offering, and a burger brand which is yet to be named. His concept here is again to keep things simple and deliver a high-quality service directly to communities.

“Wello will go across all of our stores,” he says. “It is real spring water and we will also have a reverse osmosis

// OUR COFFEE AND OUR BRAND ARE EQUALLY IMPORTANT. I DON’T THINK ONE COULD LIVE WITHOUT THE OTHER //

side where we will have shops. After that, we are looking at a burger brand which we will likely launch in Paarl. We want three brands that can live together. When you get a site and you negotiate with a landlord, you can potentially look at bigger sites and your franchisee gets three different options.”

Bredell is also keen to make the most of technology and changing consumer behaviour, brining his offering inline with that of some of the world’s most advanced economies and corporations. Again, this all comes back to engaging a community and encouraging that group of people to take action.

“We are creating communities and when you do that sales become easier because there is trust,” he says, adding that the newest Plato app

is set to be launched later this year alongside a new loyalty scheme with all 60,000 current users needing to be migrated to the new system.

“There will be rewards for certain actions – we will launch a cycling club and a running club. When you subscribe to the running club, you will get 20% off at different locations – there are so many layers you can build. The idea would be to earn points for completing certain activities, making it fun. We are also looking at subscription coffee where you pay a large up front annual fee and get, say, 500 coffees for the year alongside other merchandise and perks,” he explains, detailing inspiration from the Discovery model, pioneered in South Africa and enjoyed worldwide.

“The cool thing is that we are putting the point of sale in the user’s

hand. If you wake up every morning at 07:30, you know you are 10 minutes away from Plato, you can order your flat white and we can see through geotagging when you are five minutes away so that we can create the order and you simply drop in, pick up and walk out. That allows us to see behaviours and build a profile. We can then send a push notification and start to incentivise people to return,” he says of the most exciting developments going forward.

Ultimately, Bredell wants Plato to become the industry leader through the use of technology. He is ambitious and believes all customers can benefit from modern commercial tools.

“My dream is to be the first cashless coffee chain in South Africa,” he declares. “We would love to see all of

our customers on our app, that is truly valuable. That is where we build real scale as users can credit their account with whatever they want, maybe even Bitcoin. The more we incentivise people, the more people will go cashless and use the app. In time, we expect to announce that you cannot order with cash anymore, and we will rather just have a team of friendly baristas making coffee as orders come in, handing them over as customers arrive, completely transaction free.”

Bringing innovation and pioneering thinking to communities that have otherwise been ignored will be a wake up for other coffee businesses in South Africa that aimlessly franchise their brand around the obvious metros. Plato is a business that is future proofing itself. In the communities that this

exciting young team calls home, brilliant coffee fuels people. Clean and inviting spaces offer an alternative to the norm. And the business model remains simple but effective. Bredell is already achieving a mission of fostering communities by offering a haven to bond over an extraordinary coffee brew. The challenge now is to remain focussed on achieving the growth that is set out over the next two years. Where better to sit, relax, be inspired and plan the next step than a bright and motivating Plato Coffee.

PRODUCTION: Sam Hendricks

Nando’s remains a firm favourite in South Africa, and around the world, thanks to a complete focus on excellent customer experience. Food, service, environment, community involvement, and a little bit of the x-factor help to make the brand hotter than others. “Bom proveito” is the company’s invitation to all.

//Nando’s is one of the true South African business success stories. Now a global operation enjoyed by millions, the PERi-PERi flavour competes among the elite of the fast-food giants. But less transactional and more experiential, Nando’s has carved out a niche as a restaurant among a league of over-the-counter competitors.

Established in South Africa in 1987, the secret sauce in the Nando’s story comes from Mozambique. The African bird’s eye chilli grows under the hot sun becoming tear-inducingly spicy. Combined with lemon and garlic, the chilli sauce – recognised as PERi PERi – became the signature for Nando’s expansion. In Rosettenville,

south of Johannesburg’s CBD, the first Nando’s opened serving chicken lathered in the fiery goodness, and as the blend of Mozambique, Portugal, and South Africa hit people’s lips, there was no looking back.

Today, Nando’s is in more than 20 countries around the world with more than 1100 restaurants. The spirit of South Africa follows the brand, with clever marketing and uncompromising community focus.

Showing the strength of the brand globally, Nando’s announced at the end of 2023 that it would open 14 new sites in the UK with profits increasing as diners returned to the market after the pandemic. Sales were up against a loss in the previous year, displaying the draw

of the company’s warm environment.

In May, the company announced a new JV with K Hospitality in India with the aim of strengthening its presence in one of the world’s most prominent economies.

The company is also keen on further penetration in the Middle East, specifically in Dubai where a recent expansion programme was undertaken. Upgrades and improvements to existing sites in Dubai Festival City Mall, Mirdif City Centre, BurJuman, Deira City Centre, and Shams Boutik in Abu Dhabi, have create a more comfortable experience for those looking for that PERi-PERi kick. An upgrade to the Marina Walk location in Dubai, and a new opening in Nshama – a new urban lifestyle region – will

further enhance the brand reputation in the UAE. In Abu Dhabi, new openings are set for Al Wahda Mall and Khalifa City by the end of 2024. Qatar now has its 12th restaurant, in the Tawar Mall, where an appreciation of shared culture was highlighted as a drive of success. In the USA, the company is cooking up plans for new sites in Atlanta, adding Georgia to the five other states home to Nando’s chicken and sauce.

At home in South Africa, Nando’s has been looking internally at processes, products, premises, and profits as it looks to perfect its positioning in a market where it is well-recognised as an industry leader.

From a property perspective, there are now more than 300 Nando’s in SA, and each tastefully displays the company’s brand. This is not a colour scheme or a logo, but an ethos behind which is the entire employee base. Working closely with local creatives,

// FROM A PROPERTY PERSPECTIVE, THERE ARE NOW MORE THAN 300 NANDO’S IN SA, AND EACH TASTEFULLY DISPLAYS THE COMPANY’S BRAND. THIS IS NOT A COLOUR SCHEME OR A LOGO, BUT AN ETHOS BEHIND WHICH IS THE ENTIRE EMPLOYEE BASE //

each restaurant displays artwork that highlights South African heritage. Locally sourced equipment and furnishings are complemented by open and comfortable settings. At Nando’s, you can gather as a family, team or group, or you can sit as a couple or even alone and always feel at home. This is what makes South African tourism so appealing, and what keeps Nando’s atop a list of strong competition.

Product-wise, the company has, like most, introduced a strong vegan and meat alternative menu. This is, in part, to remain up-to-date with

market trends, but also to help drive a wider sustainability initiative that sees the company aiming for a significant reduction in its carbon footprint by 2030. Since 2014, the company has reduced its carbon footprint by 40% and Nando’s hopes to half that once again before the end of the decade.

These products are, alongside the company’s world-famous chicken offering, can be enjoyed within an impressive Nando’s restaurant, or at home through various delivery apps. Lufil Packaging, a Bidvest company and a partner of Nando’s for more

il Packaging established itself 40 years ago and supplies paper bags, wraps and serviettes to the QSR and Retail markets. Lufil has been the supplier of Nando's branded paper bags and serviettes in South Africa.

The paper and serviette material are food grade and FSC certified that is supplied from Sappi, a Local Paper Mill supplier

Did you know - Lufil has been on a fantastic journey for the last 36 years with Nando's.

than 35 years, supplies Nando’s with a range of recycled packaging including PrimePak Unbleached (PPU) which offers strength and durability for the modern environment where food can take knocks en route.

Chicken is the nation’s favourite fast food, and research from consumer insights and data science firm, Eighty20, found that 20 million individuals chose to eat at one of

the country’s top 10 quick service restaurants (QSR) at least once a month. Nando’s is often associated with delivery or drive through quality, and the superior packaging combined with clever marketing could be a driver behind this success.

To encourage interaction between the Nando’s brand and its customers,

// WHEN YOU SAY HOWZIT, HEITA OR HELLO AT A NANDO’S, THE ONE THING YOU’RE GUARANTEED TO FIND, BESIDES OUR LEGENDARY CHICKEN, IS A WARM SOUTH AFRICAN WELCOME AND A SMILE TO MAKE YOU FEEL AT HOME //

the company has launched a new interactive game. The goal here was to encourage increased orders through the app as Nando’s launched its new Shisanyama flavoured Cabo Sosatie and Chips. This skewed chicken coated in smoky Shisanyama spices and Nando’s PERi-PERi is a popular springtime offering from Nando’s and the game is a fun way to advertise in a typically different way. South Ah Sosatie Catch is similar to Tetris with users aiming to catch ingredients on a skewer as they fall down the screen. Success here can help customers achieve discounts for their next order while they await their delivery.

At Nando’s restaurants, the experience is slightly different. The company has invested in

5G connectivity to stabilise communications. Helping to support back-office IT infrastructure as well as customer experiences, the new 5G is delivered through modern E300 routers. Some restaurants are already rolling out a digital ordering system where customers can place their order through the app before arriving, helping the company to be efficient while creating a profile of users for a more targeted experience.

The whole idea is about scaling up, or down, depending on demand in restaurants. When operating on different systems or competing technology, this became difficult for Nando’s SA. Now, the system is strong, cloud-based, flexible, and makes new options available when it comes to

improving the customer experience. Initiatives such as this, combined with historically developed flavours that are well-loved, are helping Nando’s to build further momentum in South Africa. As the brand booms around the world, achieving growth that others could only dream of, the South African operation – the home of it all – must be aggressive in its bid to retain and grow market share. Upgraded restaurants, improved delivery, better technology, cheekier marketing, and a genuine connection with customers has the brand cooking nicely. In May, it was announced that Nando’s was labelled as the fourth most valuable African brand by Brand Finance Africa. The world’s leading brand valuation consultancy lauded

the company’s culinary innovation and celebration of African heritage.

“When you say howzit, heita or hello at a Nando’s, the one thing you’re guaranteed to find, besides our legendary chicken, is a warm South African welcome and a smile to make you feel at home,” the company says.

“We’ve set the eating experience on fire and we can’t wait for you to join our table because if there’s one thing we love as much as PERi-PERi, it’s lots of people to enjoy it with.”

PRODUCTION: Jamie Waters

A fully-integrated, vertical red meat value chain, since 1998 Cavalier Group has been realising its vision to bring only the best meat to South Africa’s tables. Specialists in everything from the procurement to packing and distribution of the highest-quality beef and lamb products, “everything we do centres around bringing meat eaters the very best, from farm to fork,” sets out CEO LJ Viviers.

LJ Viviers, CEO

//Cavalier Group (Cavalier) operates a fully integrated red meat value chain with a national footprint, specialising in the procurement, feed lotting, slaughter, packing, processing and finally distribution of beef, lamb

// PRODUCING IMPECCABLE QUALITY MEAT FOR SOUTH AFRICA’S MEAT LOVERS IS SOMETHING THAT WE PRIDE OURSELVES

and pork products. Its overarching mission is to create the shortest and most cost-effective route for the freshest red meat products directly from farm to fork, centred around its core values of quality, efficiency, teamwork and integrity.

“Here, we believe in quality, and in the integrity of our products, striving to bring nothing but the very best to your plate,” Cavalier Group stresses. “We always serve only the best quality that we can source from the farms right until it’s on your table. Producing impeccable quality meat for all of our meat lovers in South Africa is something that we pride ourselves deeply on.

to do more with less, while making every effort to ensure that all of our meat is of a quality that is unmatchable; this is our first and foremost principle, with no compromise.”

Today, the Cavalier Group delivers superior product and service via eight integrated companies, details CEO LJ Viviers. “It all starts with Cavalier Livestock,” he begins, “where our team of industry experts works hand in hand with the best farmers in South Africa and feedlots that adhere to the most stringent animal welfare protocols and modern rearing programmes, to

ON // Continues on page 24

“As life-long students of learning, a core pillar of efficiency drives us to strive

Elevating people.

Elevating business.

Elevating society.

BDO and Cavalier have been partners since 2017. BDO provides expert auditing to support tomorrow’s agro-processing innovations. The Cavalier group is a leader in this sector. Our relationship is built on our joint obsessions with clarity, quality and exceptional client service. Cavalier benefits from:

X Long-term partnership – consistent auditing support enables the Cavalier Group to maintain the highest standards of financial integrity and compliance, which is crucial for ongoing expansion and operational success

X Strategic investment support – when a significant investment of approximately R50 million was made in energy solutions for the business, BDO ensured the required financial due diligence

X Expert industry knowledge and guidance – BDO understands the particular challenges and opportunities the agriculture sector faces in South Africa and tailors solutions accordingly

X Future-focused strategies – BDO is always looking beyond the immediate to what will assist our clients in the long term

X Risk management – agriculture is no stranger to risk: climate change, drought, flood, exchange fluctuations, regulations – and BDO can advise in that context.

Experience the BDO difference in auditing – visit our website to see how our expertise can elevate your business into the future.

To view our latest facts and figures scan the code

www.bdo.co.za

Continued from page 22

raise healthy and happy animals.

“We have livestock agents across the country, that procure both the beef and lamb processed through our supply chain with not only quality, but also sustainability, at the fore,” he

//

furthers, “and our countrywide trading house deals in all different categories of production animals such as goats and sheep, as well,” he says, adding that Cavalier has, too, its own lamb feedlot, which ensures year-round supply without any compromise to quality.

“Cavalier Feeders has its own in-house feed factory and is purposebuilt to add final growth to lamb before entering the meat production chain,” Viviers explains, “which is situated on Boekenhout Farm just outside of Pretoria and houses 20,000 head of sheep. Our dedicated in-house team, working with industry experts, assures the very best possible feed and care for each lamb, guaranteeing their wellbeing and health.

“Under constant supervision, the growth of our lambs is continuously monitored to achieve a tender, great-

tasting product with the minimum possible impact on our planet.”

The next stage of the allencompassing value chain is the Cavalier Abattoirs, Viviers goes on, possessing slaughter capacity of 300 cattle and some 2,700 sheep per day. “The slaughter systems that we have implemented at our three abattoirs - two sheep and one cattle, housed on the same premises as our packaging factories and feedlot - are state-of-the-art, and we place top priority on the lasting product integrity and unparalleled shelflife of carcasses and primal cuts.

“Our commitment to the welfare of animals continues here; we employ only the best and most humane and stress-free practices

Continues on page 26

Continued from page 24

in the processing of each animal.

“The process then moves into its final steps of retail packing. We operate three retail packing facilities in Cullinan, where we produce retail packed lamb, beef, pork and biltong for one of South Africa’s leading retailers. This represents around 50% of our business. We also retail pack salami in Germiston and produce beef patties for Burger King and Spur in a dedicated factory in Cape Town. Like our partners, Cavalier is synonymous with quality, echoed through our promise to

customers in every pack produced with unparalleled care and consideration.

“Innovative packaging and processing equipment, combined with our team of expert butchers, has long seen Cavalier an industry leader in retail-packed protein and globally competitive beef and lamb primal cuts.”

“Having the whole chain within our stable is a key differentiator,” Viviers opines of a vertically-integrated value chain which is economically sustainable, environmentally-conscious and people-orientated. “Also setting us

apart is that we go into the premium markets in South Africa,” Viviers underlines. “We offer farmers a unique channel for their product, from both a beef and a lamb perspective.”

Cavalier Group also owns and runs an arm of around 35 butcheries situated within our retail partner. “Even though this represents a small portion of the business,” Viviers says, “it gives us a unique opportunity to access that elusive final link of the vertical chain and gives us direct interaction with, and feedback from, consumers,” he relates. “It allows us to see when things are successful, and then operationalise them on a much larger scale.”

Load shedding has been a preoccupation for businesses and industries across South Africa, but as Viviers points out, has been arguably most keenly felt by organisations where

We provide engineering services for the power sector focusing on:

Renewable Energies Medium and High Voltage Power Systems Building Electrical Services Industrial Plant System Optimization Mining Sector Distribution Systems

keeping products cool and fresh 24/7 is primordial, and entails very high energy consumption. “To combat the impact of this,” Viviers counters, “we have invested in the region of R50 million in alternative energy, in particular solar panels and battery systems. Harnessing the African sun, huge parts of our factories are now powered by solar, and as a company we are stepping up to mitigate, and counteract, whatever carbon footprint and environmental impact may arise from our operations.

“In spite of the prevailing challenges, we have managed to sustain our growth throughout, and are currently busy with three key expansions,” Viviers reveals. “One is at our biltong factory in Cullinan, as well as a substantial expansion of our Germiston salami plant, while we are building a whole new

factory in the Western Cape for pork and pork-related products.”

“We have been fortunate to have seen growth and opportunities come our way in the face of the many challenges our industry, and our competitors, have faced.” The current expansions are set to give Cavalier Group a pipeline of growth spanning the next couple of years, Viviers explains, “and then it is all about optimising and growing, seizing more and more opportunities, which we come across even in tough times, to grow further within the country.

“Cavalier Group has known right from the beginning that, in order to achieve in our bid to bring the best meat via the shortest, most efficient end-to-end red meat value chain in South Africa, the grass-roots development of procurement and

production disciplines would be required,” Viviers sums up, “based on proven international best practice but tailored to the unique Southern African industry and all of the opportunities, and challenges, which it presents.

“From land to table, Cavalier Group has established itself as a market leader in all sectors of the meat value stream through our peerless subsidiaries, each specialising in its own value-adding process to seamlessly deliver the best quality meat in the country.”

PRODUCTION: Sam Hendricks

A dynamic, diversified operation, Columbit prides itself on being a world-class market leader, supplying top quality consumables, equipment and service to the wine, food and beverage industries in South Africa. Cutting-edge equipment bringing together functionality and innovation alongside strong partnerships with leading manufacturers allow it to endlessly redefine the art of food and beverage service, year after year.

//As it closes in on a monumental century at the helm of supplying the South African food processing industry with the very best in machinery and technology, Columbit still manages to strike the perfect balance between applying the full weight

of its extensive, historic experience and remaining adaptable and able to find opportunity in challenge.

“We are confident and bold in what we do, yet flexible and sensitive to the needs of our customers,” the company abridges at the outset.

“We apply our energy and

ingenuity, to build a growing, continually improving business from which all stakeholders will benefit.”

The spirit of constant improvement has been arguably the key ingredient in Columbit’s success, and longevity,

over such a sustained and lengthy period. Founded in 1937 by the late Mr Ernest Zeh, a German immigrant from Meinz, the company was officially registered in 1938 to explore the many opportunities identified to introduce European technology and know-how to the African market.

This turned out to be an astute observation, and over the years the company has built a reputation based on integrity and sound values in its steadfast commitment to suppliers, customers and staff.

“We have succeeded as a business over the last 80 years through a simple blend of honesty, integrity, hard work and dedication” Columbit reasons. “Our simple philosophy is that one cannot buy a good name in business; one needs to earn a good name by being honest.

“We strive to only market and support the finest quality products, and have built our business through keeping our commitments in terms of the performance of our products,” Columbit further explores, with an unbending commitment to customer satisfaction and service also firmly on the menu.

“Always attentive to the needs of our customers and their continuous search for quality, we are constantly on the look-out for the latest technological developments that will provide value added opportunities to our customers and keep their business at the forefront of technology in its specialist field.

“Strong ties with suppliers keep us at the forefront of technological developments and allow Columbit to offer competitive pricing.”

Today Columbit is a dynamic, diversified operation supplying top quality consumables, equipment and service to the wine, food and beverage industries in South Africa, Australia and New Zealand. “All divisions are ably supported by a knowledgeable sales team, qualified technicians, and superb aftermarket spares and support staff,”

Revolutionizing meat and sh processing e ciency, quality and innovation in one machine

Columbia adds, noting that it actively fosters a thriving entrepreneurial spirit within the fold. “As brand custodians we employ professional people who are enthusiastically committed to service excellence and sustainable profitability.”

Columbit attains the ideal equilibrium between size and service, the company makes clear, living by the maxim of ‘large enough to make a difference, but small enough to care,’ across everything from meat processing, including trimming, skinning, dicing, cooking, injecting and smoking to pumps, labelling, sleeving, and capping, an unmatched range supplied by the world’s best manufacturers.

“Columbit represents a number of first-class European equipment manufacturers and, in most cases, such

YOUR SIDE. AT YOUR SIDE. to

Signi cant savings in process time and energy of up to 50 %

representation has spanned over many years - some as long as 60 years,” the company details. The cutting-edge, European-manufactured technology and equipment supplied by Columbit is known for durability and advanced and is of the highest quality, able to withstand the harsh manufacturing conditions synonymous with food and beverage production in Africa.

“We strive to develop and maintain strong relationships with our customers and pride ourselves as a quality supplier and service provider. When our customers succeed, so do we.”

At Columbit, it all boils down to a deep and unquenchable desire to boost productivity, precision and efficiency, all through the provision of tailored solutions to meet unique business needs, the company summates. The food processing industry is in the

midst of a critical period in its quest to expand dramatically to aid in South Africa’s drive for localisation.

With more, and better, equipment, long-held expertise and ever-improving efficiency, Africa could take advantage of appetising economic opportunities while simultaneously addressing food security and job creation.

“At Columbit we understand the critical role reliable equipment plays in the food and beverage industry,” the company closes. “Join us, and let’s redefine the art of food and beverage service together.”

PRODUCTION: Jamie Waters

B2Gold Namibia, Namibia’s largest gold mining company, showcases its excellent recovery and financial statistics alongside a deep drive around sustainability that will see commercial activity and employment continue long after the life of mine comes to an end. Country Manager John Roos tells Enterprise Africa more about the initiatives underway at the famous Otjikoto mine.

John Roos, Country Manager

//In Namibia’s north, within the bountiful and beautiful Otjozondjupa Region, a modern mining company is taking a different approach to managing the unearthing of precious metals.

B2Gold, a low-cost international gold producer with headquarters in Vancouver and operations around the world, has cemented sustainability at the forefront of all thinking in Namibia. Its Otjikoto Gold Mine is home to world-class production standards

and high-quality output, but Country Manager John Roos tells Enterprise Africa that gold mining here is about so much more than just atomic number 79.

300km north of Windhoek, Otjikoto is the largest gold mine in the country, producing up to 200,000 ounces of gold annually. Thankfully, Namibia is a shining star in African mining, boasting clear and transparent regulation and developed infrastructure and society.

“The Otjikoto Mine employs around 800 permanent employees and

FOOTPRINT SPANNING OVER SOME 3,000

//

around 300 contractors,” says Roos. “Apart from employing a workforce comprising of 98% Namibians, we make a significant contribution to the Namibian economy in terms of taxes, not to mention our Corporate Social Investment (CSI) programmes which ranks as one of the largest investment portfolios in Namibia.

“Local procurement is high on our agenda and, of everything we do – in the billions of Nambian dollars -, 61% of goods and services are procured locally.”

In 2024, B2Gold expects the Otjikoto Mine to process a total of 3.4 million tonnes of ore at an average grade of 1.77 g/t with a process gold recovery of 98%, delivering gold in a guidance range of between 185,000 and 205,000 ounces.

Open pit mining has been

underway on site for more than a decade with mining activities commencing in 2013 as part of the initial development of the mine.

“Otjikoto’s first gold pour was in December 2014; commercial production was achieved a mere three months later on 28 February 2015,” remembers Roos. “We have been producing a steady 150,000 – 200,000 ounces per annum since then.

The year 2022 was a transformative year for us when started production from our Wolfshag Underground Mine. Looking ahead, the Otjikoto Mine will be transitioning to 100% underground mining as of 2026 as the open pit deposit is depleted towards the end of 2025. B2Gold is a mining expert and understands how to transition seamlessly from open pit to underground, keeping loads

flowing consistently to the mill.

Globally, B2Gold has a number of new projects and expansion projects in various stages of development. A significant development project is currently underway in Nunavut in Canada where the company is advancing one of the highest grade undeveloped open pit and underground mines in the world.

The positive PEA results on the Company’s 100% owned Gramalote Project, located in the Department of Antioquia, Colombia, outlines a significant production profile with average annual gold production of 234,000 ounces per year for the first five years of production, and strong project economics with an after-tax NPV5% of $778 million and an after-tax IRR of 20.6% over a 12.5-year project life. As a result,

B2Gold has commenced feasibility work with the goal of completing a feasibility study by mid-2025. In Namibia, exploration continues as the company looks to find new resources around its current site. Recently, the Otjikoto mine has had some very exciting exploration results, and on 20 June 2024, the company released an initial Inferred Mineral Resource Estimate for the Springbok Zone, the southernmost shoot of the recently discovered Antelope deposit, located approximately three km south of the Otjikoto Phase 5 open pit. The company determined that the initial Inferred Mineral Resource Estimate was sufficient to initiate a PEA on development of the deposit by underground mining methods, similar to the Wolfshag deposit. Subject to the receipt of a positive PEA and permit,

The SmartROC D65 surface drill rig from Epiroc is the perfect balance between productivity and efficiency. A proven and dependable rig for DTH drilling in mining and large quarry applications, the SmartROC D65 is rugged and multifunctional. It’s built to take on the toughest drilling demands and is ready to exceed your expectations. For any additional information, please contact our Business Development Manager in Namibia, Ryno Blaauw: ryno.blaauw@epiroc.com I +264 81146 0098 United. Inspired.

epiroc.com/en-na

mining of the Springbok Zone, coupled with the exploration potential of the greater Antelope deposit, could begin to contribute to gold production at Otjikoto in 2026. Delivery of a positive PEA and development of the Antelope Zone beyond 2025 could see Namibia’s gold mining industry in the area furthered for years, relieving pressure on the company that began to see end of mine life on the horizon. For Roos, this is particularly

//

exciting as he plans for the future in what he labels “the most amazing country to live in, work in and mine gold in, in Africa”.

B2Gold’s visionary management team is keen to lead in sustainability and so has invested heavily in projects that are not directly linked to the bottom line. In Namibia, the company wants to leave a legacy in an area that is remote and

AT INTERNATIONAL LEVEL //

often lacking in opportunity. Away from mining, the local economy is reliant on agriculture, and this is where the company has applied its expertise.

“In Namibia we own a land package of around 18,000 hectares with the Otjikoto Mine’s footprint spanning over some 3,000 hectares of this area,” Roos details. “Adjacent to the Mining Operations we own a 3,800 hectare farm which has been developed through stages into becoming a mid to large scale agricultural farm. The remaining 11,000 hectares comprise of a game reserve area where a wide range of animals roam freely.”

“We acquired the entire land package between 2011 and 2013 when we commenced with the construction of the Otjikoto Mine.

When we acquired the land, the farms were traditional cattle operations with bush encroachment being prevalent - not a lot of grazing and not a lot of animals. Over the past decade we have allowed the nature reserve to rehabilitate itself, and we have encouraged it back to health.

B2Gold constructed a large facility on the Otjikoto Nature Reserve which serves as a centre where school children and teachers alike can learn about nature. This centre is also open for researchers from Namibian Universities and abroad to perform various forms of research programs. We are very proud of the fact that we’ve hosted in excess of 5,000 school children at this facility over the past couple of years.

“Going forward, this facility will

continue to serve as a research hub where international organisations can partner up with us to further their research activities. We are very excited about the opportunities that this worldclass nature reserve holds for the future.”

In 2019, the Company commenced with the process of developing one of its farms, farm Erhardshof, from a traditional cattle farm to an agronomic hub. Following a detailed feasibility study, a proof-of-concept project was launched for the development of 30 hectares of pivot irrigation systems with the objective of producing maize in the summer and wheat in the winter. “Maize is a staple food for the Namibian people – our ultimate aim was to make

a meaningful contribution to staple food security in Namibia. Further to this, our objective was to prove that a large-scale agricultural farm could be established that can sustain its own operations financially and contribute to our CSI programmes post mine closure. The proof of concept was a resounding success, and today the company has 90 hectares of irrigated land developed.

“In the 2023/2024 maize season, the B2Gold agronomic project was the largest maize producer in the country for Namib Mills, Namibia’s leading grain milling company. Transitioning from gold mining to agriculture has indeed been a very interesting story,” Roos smiles. Development is currently underway to expand the project by a further

SPS & Partners provide 10 MW Solar Solution to B2Gold’s

Sustainable Power Solutions (SPS), together with its Namibian partners, Fortitude and the Oelofse family, are pioneering the latest development in Namibia’s energy and mining sector.

N$200 Million Renewable Energy Flagship Project

SPS is leading the development and funding of a N$200 million investment in a 10MW solar plant, which will generate approximately 26 360 MWh of clean renewable energy per year.

This will be one of the first wheeling projects implemented under NamPower’s Modified Single Buyer (MSB) framework. The framework empowers Independent Power Producers (IPPs) to produce and sell electricity directly to regional electricity distributors, large industrial and mining companies, as well as municipalities.

The solar plant is being constructed on Maxwell Farm situated in North Central Namibia, and is set to be operational by the end of 2024.

Championing

Sustainable Energy

SPS is a leading Sub-Saharan African funder, developer, and asset manager of solar PV & and battery storage plants in the commercial & industrial market.

The company is partnering with Fortitude, a multi-disciplinary property development and project management firm, as well as the Oelofse family, known for their long-time dedication to Namibian wildlife conservation.

Fortitude will play an integral role in the engineering, value-engineering and quality control processes during the construction phase of the power plant.

Sustainable Mining Excellence at B2Gold’s Otjikoto Gold Mine

B2Gold’s Otjikoto gold mine will be one of Namibia’s greenest mines, with the aim of offsetting an additional 26 360 tonnes of CO2 annually. This aligns with B2Gold’s climate strategy, to achieve a 30% reduction in Greenhouse gas emissions by 2030 & progressing towards a net zero operation at the Otjikoto mine.

SPS and partners will provide further updates as the Maxwell Solar Power Plant is being constructed and paves the way to a greener energy future.

contact@sps.africa | www.sps.africa

90 hectares, scaling the agronomic project to a large-scale project which will play a meaningful role in the local production of maize in Namibia.

“B2Gold’s post closure vision is a top priority for the local management team and is driven by an overarching strategy at international level,” says Roos. “Our CSI activities follow the company’s wider commitments that fall into four separate categories - health, education, environment and livelihoods.

“Through development of the agriculture project and a number of other initiatives underway, we are crafting a structure that will fund CSI projects long after the mine has shut down. We are excited about

this next chapter of crafting a postclosure land use model tailored for long-term sustainability,” he adds.

From a carbon footprint perspective, operating a gold mine is a challenging task when the pressure is continuously on reducing the operation’s carbon footprint. Intense in electricity usage and a generator of significant CO2 emissions, the energy required is costly from both a financial and environmental point of view.

In 2023, B2Gold Corporate set a target to reduce its Scope 1 and 2 greenhouse gas (GHG) emissions by 30% in 2030 against a 2021 baseline. As a company, B2Gold recognises

that climate change is a critical global challenge and understands that it must act accordingly. B2Gold has been an innovative leader within the mining industry with respect to the management of sustainability issues and this commitment to GHG emissions reduction forms a key part of its Climate Strategy, incorporating climate management as a part of its business strategy and planning process.

“In Namibia we are leading the charge when it comes to our transition to green energy on the mine,” Roos states.

“Our journey began in 2017 when our corporate office approved the funding for the construction of a 7mWdc solar plant at the Otjikoto

Mine. The plant was successfully commissioned in 2018 and now contributes to 13% of the total energy requirement on site. On the back of the success of this plant, B2Gold, shortly after commissioning the Otjikoto Solar Plant, approved the construction of a larger solar plant at its Fekola Mine in Mali. We are investigating various forms of renewable energy at our sites now, including wind power at our Goose Project in Nunavut. We are truly walking the talk when it comes to the green energy transition, Roos explains.”

Integrating solar into the Otjikoto Mine’s energy mix was not the end of the journey; in 2022, the Otjikoto Mine was connected to the NamPower grid following an investment of N$200M into new substations and a 20km overhead line. This connection to the grid weaned the mine from dirty and costly HFO completely. The Otjikoto Mine now produces 13% of its energy from its owned solar plant and the remainder is procured from NamPower. NamPower produces its own hydroelectricity and renewable energy whilst importing the remainder of is requirement from Zambia and South Africa, and within that mix there is a large renewable energy component.

Currently, a 10MW solar farm is in development 20km from the Otjikoto Mine; in terms of this arrangement,

B2Gold will not own the asset but will procure green energy through a power purchase agreement (PPA) from an Independent Power Producer (IPP). “This plant will supply an additional 25% of the operation’s total energy requirement in green energy. The Eldorado Solar Plant will be commissioned in December this year,” enthuses Roos.

Going forward the Otjikoto Mine could see increasing its renewable energy consumption further, displacing NamPower energy, depending on the change in market rules as determined by the Namibian Electricity Control Board (ECB).

Proud of the progress that has been made on site, B2Gold’s management have managed to achieve what few other gold mining companies across Africa have – delivering strong financial results, building robust regional relationships, and being a responsible mining company that will leave a lasting legacy in Namibia.

“From an ESG perspective, the Otjikoto Mine is a showcase of how a mining operation can produce gold responsibly whilst being a leader in mine rehabilitation practices, a leading force in the green transition and a leader in solving for sustainable post closure land use opportunities, using

the non-mining assets it owns and making them financially productive. These industry leading initiatives will continue as we have exceptional teams on the ground,” says Roos, adding that the company absolutely wants to be a leader in all things ESG in Namibia.

A qualified Chartered Accountant, Roos has been with B2Gold in Namibia for a decade, overseeing various financial roles and numerous renewable energy projects that have strengthened the position of Otjikoto in Namibia. “At B2Gold we believe that we need to leave the area in which we mined gold in a better state than what we had found it when we got there – the initiatives we are pursuing in terms of a post closure legacy are founded on this simple principle.”

B2Gold Namibia is a glowing example to follow, and whether gold, diamonds, uranium, copper, zinc, silver, magnesium or any other precious or rare earth metal, mining houses here can see evidence of activity being completed with positive impact. This fresh approach to longevity is the way forward.

PRODUCTION: James Redwell

First Quantum Minerals is busy expanding its Kansanshi Mine operations with various projects designed to increase output responsible as the government calls for more and more copper to be unearthed. But doing things responsibly and with sustainability in mind is the goal for this historically successful company.

//The global energy transition continues to take hold across all nations. Resistance is nothing compared to the level of ambition and uptake. Renewable energy rollout, and all the associated infrastructure, combined with traditional growth of electrification and communication assets have helped to drive insatiable demand for natural resources, and atop those lists are elements such as copper, lithium, silicon, and manganese.

Of course, Africa is a major contributor of these essential materials and its bountiful natural resources continue to drive progress in the likes of electric cars, modern computing technology, and green energy generation equipment.

Copper in particular is in the spotlight right now. It is required for

effectively carrying electricity and has electrons arranged in such a way that free movement across its body provides improved conductivity.

In Africa, the copperbelt through Zambia and the DRC is known as a global hub for copper mining. Rich is deposits, and loaded with mineral wealth, global miners have long scrambled to take advantage of the area since 1895 and the promotion of the sizeable affluence that laid beneath the soil.

One of the most important mines in Zambia is the Kansanshi Mine in Solwezi in the country’s north. With Zambia recognised as one of the world’s most important nations for mining activity – mainly because of activity on the copperbelt – Kansanshi has realised significant investment over the years, and there is more to

come as its Canadian owners, First Quantum Minerals (FQM), looks to extend its life significantly.

The investment makes sense with the country labelled as the 11th most important mining destination in the world, with mineral production volume estimated at $21.7 billion annually.

Kansanshi employs more than 13,000 people, mostly local Zambian people, and produced 41,507 tonnes of copper in Q2 2024 alone. The mine covers a vast site with much state-of-the-art technology used to drive efficiency.

The copper price currently sits at a decade long high as demand continues to outstrip supply, and

Continues on page 44

ACTOM Turbo Machines, a subsidiary of ACTOM (Pty) Ltd is a leading service provider of turbomachinery and high-speed rotating equipment services, offering comprehensive workshop and site services to the petrochemical, mining and steel, and power generation industries in South Africa, Africa, and internationally.

24/7 emergency breakdown response service

Specialising in:

• Steam and gas turbines, gas expanders

• Compressors: centrifugal, axial and integrally-geared compressors

• Reciprocating, screw and lobe compressors

• Pumps, multi-stage, single-stage, highpressure pump, large water pumps

• Blowers and fans, ID/FD fans, gas and

• Gearboxes ; high - speed , epicyclic and mill gearboxes

• Centrifuges and separators

• All mechanical peripherals and auxiliaries

• Steam, gas, and oil piping and fabrications

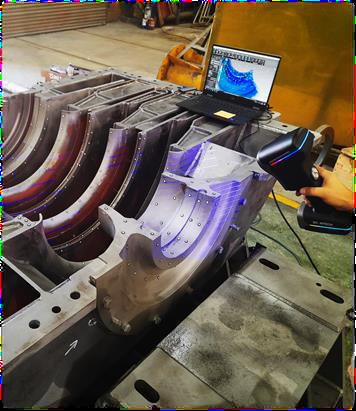

• 3D measuring, general machining and fabrication

• Complimentary electro-mechanical services by Marthinusen & Coutts and the ACTOM Group

18 Venus Street, Naledi Industrial Park, Sasolburg 1947

Postal Address: PO Box 1579, Sasolburg, 1947, South Africa

Tel. +27 (0) 16 971 1550 | Email: commercial@actomturbo.co.za

Website: www.actomturbo.co.za

Continued from page 42

FQM is aware of its chance to provide product for a market that needs it.

CEO Tristan Pascall said: “We are already halfway through the 2024 year, and it has certainly been a challenging period for First Quantum. The copper price has been surging and we have had challenges in Zambia with the drought and the situations with food security and power.

“During the second quarter, we continue to see that world markets understand the scarcity of copper available for world supply chains; not

just for development of renewable energy and the transition to greener economies but also in AI data centres and the continued upliftment of societies through greater electrification and communications,” he added.

“However, copper mining has to be done responsibly and it’s a contingent on all of us to ensure good standards of safety, environmental performance, and community engagement. At First Quantum, we have the projects but also the capabilities, skills and expertise to deliver those projects into the market.”

Recently, the company partnered with Hitachi Construction Machinery

// WE FOCUS ON INNOVATION, EFFICIENCY AND ENVIRONMENTAL FACTORS WHICH ENABLE US TO MEET THE GROWING DEMAND FOR COPPER WHILE MINIMIZING THE IMPACT ON THE PLANET //

to deploy a battery powered dump truck – the first in Zambia – in a bid to reduce emissions. Initially, the dump truck will be used on a trial basis – beginning in June 2024 – to understand the viability of an ultra-large full battery rigid frame dump truck on site. Currently, the company is excited by potential, mainly encouraged by the fact that the dump truck has not required any scale down in payload or production and the truck has helped contribute to FQM’s zero emissions goal.

With Zambia largely reliant on renewable energy, FQM is keen to use its position to contribute in a meaningful way, weaning Kansanshi from emissions producing fuel as quickly as possible.

Earlier in 2024, the company – the largest power user in the countryannounced that it was partnering with international companies to bring further capacity to the national grid. Currently, the company spends

$250 million on electricity from State provider Zesco annually. And President Hakainde Hichilema has put out a vision to increase coper production to three million tonnes per year. FQM was clear that more green power would be required. Under exploration now is a 430 MW hybrid solar and wind energy project (230MWp solar PV and 200MW wind) with offtake agreements in place to help build the grid further. This would follow progress from the end of last year when FQM signed a PPA for Kansanshi over a 10-uyear period that helped to solidify expansion plans.

Growing capacity at the mine is key for FQM, and its S3 expansion project is expected to be complete by mid2025. A $1.25 billion investment, the pit and fleet will be expanded and a new processing plant will be installed alongside upgrade to the smelter. A

production increase of 200,000 tonnes per year will be the result, extending the life of mine into 2040. Encouragingly for local stakeholders, FQM said that it saw Kansanshi and Zambia as a cornerstone of its portfolio over the past 20 years and wanted to see this continue for the next two decades.

“We remain highly optimistic about the prospects and outlook for the mining industry in Zambia, and our unwavering commitment to Kansanshi is demonstrated through our substantial investments in the S3 project, smelter upgrade, mine fleet enhancement and other strategic initiatives totalling over $1 billion over the next two years,” said COO Rudi Badenhorst.

All of this investment is, of course, about longevity and sustainability in Zambia, and that comes with a respect for the environment. Reducing emissions, increasing efficiencies, and supporting the wider energy transition

with the products that are mined successfully make FQM and Kansanshi an example to follow for many.

“We are committed to sustainable and responsible mining practices. We focus on innovation, efficiency and environmental factors which enable us to meet the growing demand for copper while minimising the impact on the planet,” the company states.

As one of the world’s top 10 copper producers, the company will retain and grow its position by sticking to its core offering of providing a tangible benefit from everything we do for investors, employees and the many communities that host operations.

PRODUCTION: Chris Bolderstone

Through the tough times, the biggest and best change and adapt to remain relevant. ArcelorMittal SA is truly one of the largest, and it is busy exploring all opportunities to revitalise business after a tough period. New industry sectors, new focuses on quality and environmental projects, and a unwavering commitment to return of profitability are helping to make this giant sustainable once again.

//Steel remains the backbone of the global economy, underpinning infrastructure from north to south and east to west. Despite environmental concerns in manufacturing, steel is an enabler of life. According to EUROFER, the European Steel Industry, ‘modern society would be impossible without steel’.

As part of the global energy transition, and with investors calling for an acceleration of ESG strategies, steel has found it difficult to cope. Around the world, the sector has been shocked, especially in traditional markets. Now, China and India lead the way by a strong margin when it comes to production. Coincidently(?), these are two of the top three carbon dioxide emitting nations globally.

In South Africa, one of the world’s largest steel makers, ArcelorMittal, has been active since 1928. Through various iterations, the company has grown and merged to become the largest steel company in the country. But, like in other regions, a flagging local economy combined with changing market dynamics and increasing prices have decimated local steel making, and many are turning to imports from Brazil, Indonesia, Vietnam or the other big producers.

For ArcelorMittal in South Africa this is a problem. The company runs a significant operation and contributes to the national economy. The mining industry in particular is both a supplier and a consumer of SA steel. Local manufacturers are desperate for fast turnaround times from a local

supplier. And the government is keen to see more sustainable jobs created in a sector with so much potential.

So what is being done to unlock opportunities? CEO Kobus Verster has long said that renewable energy is a major source of potential for the company. He has also highlighted transport infrastructure and construction as industry sectors where ArcelorMittal can remain a strong player. The key is to drive down the cost of production while highlighting the benefits of buying local.

The first area to look at is energy. The company has been critical of the country’s well-known energy issues. Loadshedding has been damaging for steel makers who require significant

amount of energy to produce. In South Africa, the company has already made its intentions clear. In 2020, ArcelorMittal SA said it was looking for Power Purchase Agreements (PPAs) with Independent Power Producers (IPP) for its sites in Vanderbijlpark, Newcastle, Vereeniging, Pretoria, Thabazimbi and Saldanha. In 2022, it was announced that two renewable energy plants had been planned for Gauteng and the Western Cape with the group hoping to demonstrate what is possible with renewable energy, and providing a long-term future for its thousands of local employees. 100MW total capacity would be the goal for the two plants, which ArcelorMittal hopes to see operating by the end of 2025. For this heavy manufacturing firm, the introduction of meaningful

//

OUR FIRST-HALF RESULTS REFLECT THE RESILIENCE OF OUR BUSINESS MODEL AND THE EFFECTIVENESS OF OUR MANAGEMENT STRATEGIES IN NAVIGATING A COMPLEX OPERATING ENVIRONMENT //

renewable energy cannot come quick enough. Eskom and Transnet challenges are unabating, and while loadshedding has been light in recent months, most expect the issue to return. Transnet faces longer-term overhaul as it implements a major turnaround strategy that impacts the ability of all of South Africa’s exporters. But positivity remains inside the company as it edges closer to the start of construction for its first solar PV

plant. In May, it was announced that Vanderbijlpark will host the project, currently out for tender. ArcelorMittal is awaiting the receipt of approval from Eskom around the grid connection, and when this is confirmed construction can progress quickly. Projections suggest that the project will supply 43% of the facilities energy demand and 23% of the South African operations

Continues on page 52

Director

Timing is everything, Jenny says. But when it comes to investing in your future, the truth is, there's never a bad time to start. The sooner you start, the greater the rewards. At just 16, Jenny started her career in the Construction Industry by working part time after school at her father’s business. After finishing school Jenny became part of the Delta team full time and started enrolling in Accounting, Safety and HR courses. Soon she took on her first national role in Finances and HR– a position she set her sight on and chased down. “I had strong male and female role models and so I grew up being pretty determined.” -says Jenny . Putting herself out there paid off and soon she was working her way up in the organization to become part of the Management Team.

It is not the size of the corporation that determines it’s greatness, it is the sheer dedication, heart, sweat and loyalty in each of it’s employees.

Continued from page 49

overall requirement. This, said Verster, would drastically reduces costs and improve environmental credentials.

In Saldanha, experiments are underway to revive the once magnificent site – a former hive of activity – by introducing hydrogen production. South Africa has long been hailed as a country with huge hydrogen production potential because of its abundant natural resources. Green hydrogen is the premier form of hydrogen production – using renewable energy to power electrolysers and leaving only water as a byproduct.

ArcelorMittal SA has signed a MoU with an international developer of renewable energy to investigate potential for production

of green hydrogen directly reduced iron (gHDRI). The hydrogen could be exported or used locally as the company looks to decarbonise its operations around the country.

Despite the opportunities that are presenting themselves frequently, the company has been forced to restrategise as it prepares for a future that is uncertain and requires large investment into greening operations. Part of this rightsizing was announced in November 2023 when ArcelorMittal SA said it would wind down its longs operation from its Newcastle and Vereeniging Works. Highlighting various economic factors out of its control, the company stated that, even following a period of aggressive cost cutting and raw material pricing

reductions, it had to be realistic about long-term sustainability.

“The ArcelorMittal South Africa Board and Management have reached this point after having exhausted all possible options,” said CEO Kobus Verster. “As difficult as these circumstances are, we have a duty to ensure that the business remains sustainable in the long term, in the interests of the company and its stakeholders. The remaining business, after the wind down, will be on a more sustainable financial footing and able to invest the appropriate capital in product development and available growth prospects.”

However, after a consultation period, the closure was pushed out as ArcelorMittal SA looks to develop a viable business plan for the operation with government

and trade unions looking to retain 3500 jobs while securing supply of longs for construction, mining, and more industry sectors.

This show of resilience was mirrored in the company’s financial results, released on 1 August 24, where the company cited challenging market conditions but still posted a headline loss of R1,110 million, representing an improvement from the R1,442 million loss in the preceding six months.

“The company has made significant strides in environmental management, achieving 100% ISO 14001 certification for all operations,” the company said. “Notable improvements include significant progress in reducing emissions. Particulate emissions reduced by 34%, with Vanderbijlpark having achieved a 67% reduction since 2008. ArcelorMittal SA also continues to invest in community development, particularly in education

and skills training, impacting over 27,000 learners and creating job opportunities for unemployed youth.”

Verster highlighted the strength of the business. “Our first-half results reflect the resilience of our business model and the effectiveness of our management strategies in navigating a complex operating environment. While challenges persist, we are confident in our ability to capitalise on emerging opportunities and drive sustainable growth for the benefit of all our stakeholders.”

Looking forward, considering the company’s investments into sustainability projects and highpayback projects, combined with slightly improved market conditions, the company is expecting to return to profitability.

“While global and local steel markets remain challenging, ArcelorMittal SA sees potential for

gradual recovery in the second half of 2024. The company expects to return to profitability, supported by operational improvements, increased production volumes, and potential positive shifts in market dynamics,” it says.

So much history, such strength, unrivalled expertise, and facilities that others could only imagine, ArcelorMittal SA remains an industry leader. Not a company to shy away during tough times, this business has been through social, environmental, economic, and financial challenges before. If there is one business that can truly say it has the experience to push on to stronger times, it is this hardy South African steelmaker.

PRODUCTION: Sam Hendricks

A number of growth strategies have helped Jotun Paints South Africa to expand across the sub-Saharan region with new products and continued investment in people and resources. MD Martin Ibsen and Logistics, Warehouse and CSD Manager, Enba Govender talk to Enterprise Africa about the company’s ongoing development.

//At the end of 2021, Jotun Paints South Africa was in a strong place, bouncing back from the Covid slowdown thanks to bright and long-lasting relationships with customers in niche industry sectors. The company told Enterprise Africa of a record year amidst challenging conditions.