ERIN DOERING | SELECTED WORKS

2

edoeringarch@gmail.com

(843) 422-9445

EDUCATION

Clemson University | Master of Architecture II

Clemson Architecture Center in Charleston

Immersed in an off-campus program that is a community service oriented program structured to bridge academia and practice by teaching in a hybrid environment in the historic and urban setting of Charleston, South Carolina.

Clemson University | Bachelor of Arts in Architecture | Social Sciences Minor

Charles E. Daniel Center for Building Research and Urban Studies in Genoa

Immersed in an off-campus program that balances the studio experience with the study of Italian architectural history, contemporary design, urban practices, culture, and field sketching. Included an extensive guided travel to a number of historically and architecturally prominent cities throughout Italy.

EXPERIENCE

2022 Student Intern| SMHa

Assisted in a BAR submittal for MUSC’s College of Health Sciences. Assisted in conceptual design for Charleston Yacht Club and Sander’s House at Point Hope renovation projects. Produced construction documents for Charleston ENT & Allergy.

Summer Intern| Batson Associates Inc.

Assisted in design and construction documents for Saint Joseph’s Candler Raydient Urgent Care and Medical Office, Piedmont Athens Regional Hybrid Operating Room, and the Lewis Candler Research Pavillion Renovation.

Graduate Assistant | Clemson University School of Architecture

Maintains School of Architecture departmental website. Writes, edits, and curates web content and graphics such as student work, event announcements, and resources.

Architectural Associate | Rule, Joy, Trammel + Rubio, LLC

Produced presentation and construction documents during all design phases of Canterbury Court Senior Living and Memory Care Campus expansion of Atlanta, The Works Apartment Building of Atlanta, and Woodward Mill Apartment Complex in Sugar Hill, Georgia.

Summer Intern | Pearce Scott Architects

Performed redline changes and revisions, prepared client conceptual presentations, researched and analyzing project sites, and refined construction details for single family homes of the lowcountry. Spearheaded a print marketing plan showcasing past projects to reach future clients.

Writer | CRIT Architectural Journal

Undergraduate Mentor | Clemson University School of Architecture

Member | Clemson University Habitat for Humanity Conference Panelist | AIA/ACSA Intersections Research Conference

3

ACTIVITIES & ACHIEVEMENTS ERIN DOERING

@ edoeringarch 2019 2018 2023 2023 2021 2018 2021 CURRENT CURRENT CURRENT 2019 2021 2017

2022

2022

AutoCAD REVIT SketchUp Photoshop Bluebeam Modelling Illustrator InDesign Sketching SCAN FOR PORTFOLIO NCARB HOURS Practice Management 49% 39% 100% 100% 100% 54% Project Management Programming & Analysis Project Planning & Design Project Development & Documentation Construction & Evaluation HOBBIES Hiking Reading Photography Traveling Sketching Mountain Biking

SKILLS

4 05 06 03 02 01 04 07 08 09 10 10 11 12

5 URBAN CONTEXT 01 SYMBIOSIS 02 CREATE, CONSERVE, COLLABORATE 03 PORTAL OF THE PIAZZA DESIGN & FABRICATION 04 FRIERSON ELEMENTARY GARDEN PAVILION 05 THE W’ALL 06 ARCHITECTURE F(OLLIES) 07 AN ANALYSIS OF VILLA MALAPARTE 08 WHERE SKY MEETS EARTH FIELD STUDIES 09 ARCHITECTURE THROUGH THE LENS 10 TRAVEL SKETCHES IN THE PROFESSION 11 URBAN SENIOR LIVING CAMPUS 12 GARDEN-STYLE APARTMENT COMPLEX

SYMBIOSIS

Partner: Yarely Martinez Smith

This project, a submission for the COTE Top 10 Student Competition, aims to offer affordable and dependent co-housing for the young professionals and transitioning homeless of the Seattle population through co-housing along Lake Union. This is accomplished through shared living spaces, community gardens and water collection as means of selfsustainment and affordability.

The current typologies of houseboats along Lake Union are organized in a linear fashion along a single boardwalk. They are connected to municipal utilities like water and sewer, causing them to be expensive

31% 79% to own and not self-sustaining.affordable units that are self-sustaining through water and gardening. Building on multiple levels

INCREASE IN POPULATION DENSITY

INCREASE IN PUBLIC SPACE

7

TYPICAL LAKE UNION HOUSEBOAT LAYOUT

DESIGN PROPOSAL

LAKE UNION DOWNTOWN SEATTLE UNIVERSITY OF WASHINGTON SITE

PROJECT SITE

YOUNG PROFESSIONALS

DISPLACED INDIVIDUALS

USER GROUPS

8 LIVE WORK PLAY PRODUCE PUBLIC HOUSING SOUP KITCHEN CO-WORKING SPACE RECREATION HOUSING MULTI-PURPOSE

LAUNDRY & SHARED KITCHEN

COVERED GREENHOUSE

CO-WORKING SPACE

LEVEL 3

DISPLACED INDIVIDUALS UNIT

GYM

SOUP KITCHEN

LEVEL 2

DISPLACED INDIVIDUALS UNIT

DISPLACED INDIVIDUALS UNIT

BIKE STORAGE

KAYAK STORAGE

DISPLACED INDIVIDUALS UNIT

LEVEL 1

40” AVERAGE ANNUAL PRECIPITATION 64% AVERAGE CLOUDY DAYS 73.3% AVERAGE HUMIDITY EVAPORATIVE COOLING THROUGH LAKE WATER GARDEN ROOFS ACT AS A NATURAL INSULATION FOR UNITS 15.57 WALL R-VALUE 38 ROOF R-VALUE 14.3 FLOOR R-VALUE GROW KEEP SELL OF PRODUCE GROWN A YEAR IN COMMUNITY SAVED PER UNIT +/- 113,880 LBS. $8,286.96 41% SOLD AT THE MARKET

LIME CONCRETE STRUCTURAL BARGES WINTER SOLSTICE 19° SUMMER SOLSTICE 66° THERMALLY TREATED WOOD OPEN WEB WOOD JOIST STRUCTURE - DOUGLAS FIR CLADDING - WESTERN RED CEDAR SITE 1MILE 3 MILERADIUS 2 MILE RADIUS 6MILERADIUS 4 MILERADIUS 5 MILERADIUS RADIUS LOCALLY SOURCED AND SUSTAINABLE MATERIALS REQUIRES LESS ENERGY TO PRODUCE EMITS LESS CARBON DIOXIDE THAN NORMAL CONCRETE MOISTURE CONTROLLED RESISTS WEATHERING EFFECTS COOKED IN OXYGEN-FREE OVENS AT 400 DEGREES NATURAL LIGHTWEIGHT CORROSION RESISTANT 400

BEDROOM SHARED CLOSET

BATHROOM SHOWER

SHARED SINKS

SHARED KITCHEN & DINING

COVERED BALCONY

12

UNIT

UNIT LAYOUT UNIT COMMONS UNIT BEDROOM

BALCONY

DIRTY WATER PULLED FROM LAKE UNION TO BE CLEANED AND USED IN SYSTEM GRAY WATER AND BLACK WATER COLLECTED INTO POLY TANKS FOR CLEANING

BLACK WATER RUN THOUGH ANAEROBIC DIGESTER TANK

GRAY WATER RUN THROUGH HYDRALOOP FOR CLEANING

CLEAN WATER PUMPED TO COMMUNITY POOL AND DEPOSITED BACK INTO THE LAKE

FILTERED WATER PUMPED TO GARDENS FOR WATERING

POLY TANKS FOR WATER CONTAINMENT ANAEROBIC DIGESTER TANK

The water system is designed to pull dirty water from the existing Lake Union surrounding the site and cleaning it to be able to use it for the basic water needs of the complex and using the waste as a renewable source of energy.

WATER SYSTEM DIAGRAM

13

1 2 3 4 5 6

REED PLANT FILTRATION SYSTEM

HYDRALOOP

1 2 3 4 5 6

14

15

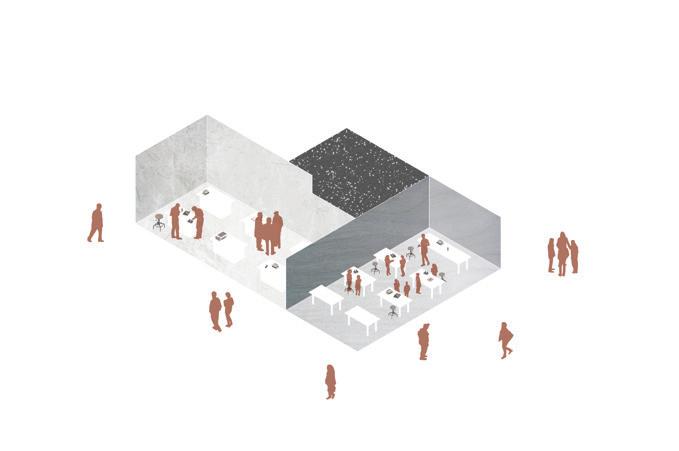

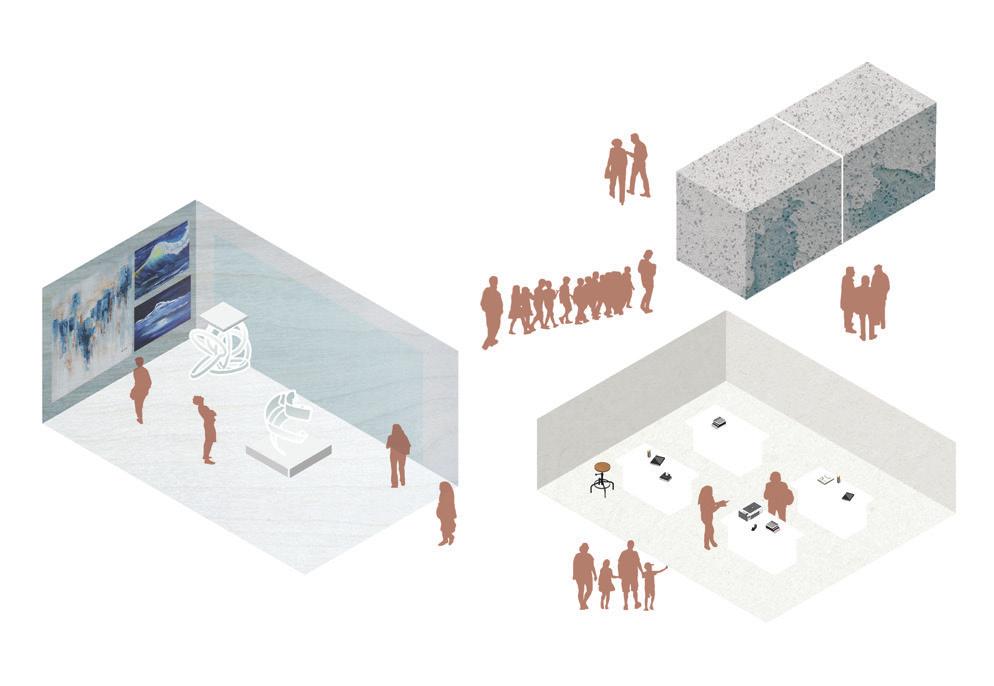

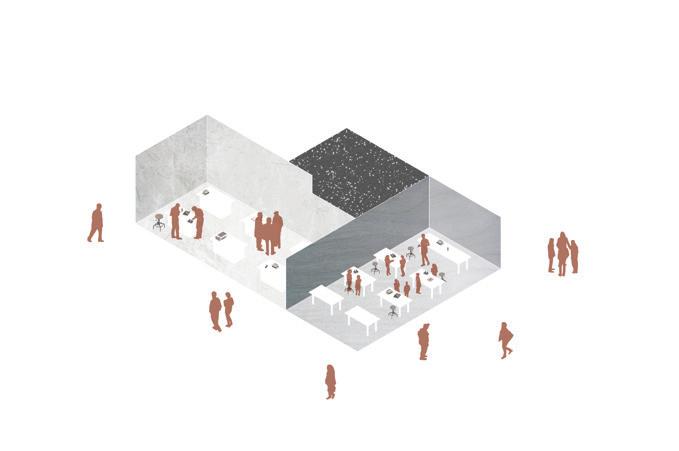

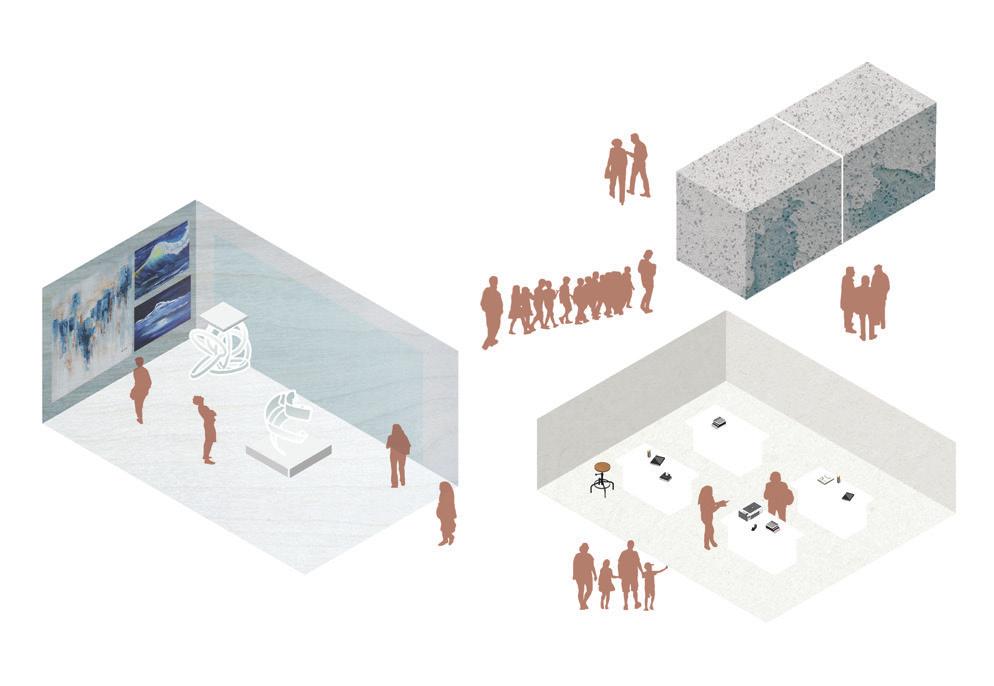

CREATE, CONSERVE, COLLABORATE

Team: Lydia Gandy, Ashley Seiderman, & Hayden Bryson

The Detroit Water Education Center embraces the process of collaboration between researchers, students, artists, and other patrons. This is achieved by merging diverse programs into large, interdisciplinary spaces situated on the site of the former Broadhead Naval Armory. Our design grew around three central focuses of water, art, and users. Spaces that serve as fixed points that contain specific research, educational, or policy-making programs. The area between specified programs provide opportunities for more open collaboration and temporary uses such as events or exhibit spaces. Rooms are designed to be transparent so that all patrons are involved in the collaboration environment.

16

PROGRAMMING

MULTI-PURPOSE

Transparent spaces that serve as fixed points that contain specific research, educational, or policy-making programs. Open space collaborationpromotes and more temporary uses.

17

RESEARCH

WATER FACADE

ADAPTIVE REUSE

18 1 2 3 3 4 4 4 1 AUDITORIUM 2 ENTRANCE 3 LIBRARY 4 LAB 5 CONFERENCE ROOMS 6 CLASSROOMS 7 FABRICATION LAB 8 RESTROOMS 9 STORAGE 10 OFFICE 11 EXHIBIT 12 CAFE 4 4 4 5 6 6 7 7 8 8 8 9 1 2 2 10 10 11 11 10 12

INTERACTIVE EXHIBIT

DISCOVERY LAB

OFFICES

WATER EDUCATION CLASSROOM

WATER CONSERVATORY LAB

INTERDISCIPLINARY EDUCATION SPACE

LIBRARY

19

FACADE DESIGN PROCESS

FACADE DESIGN PROCESS

22

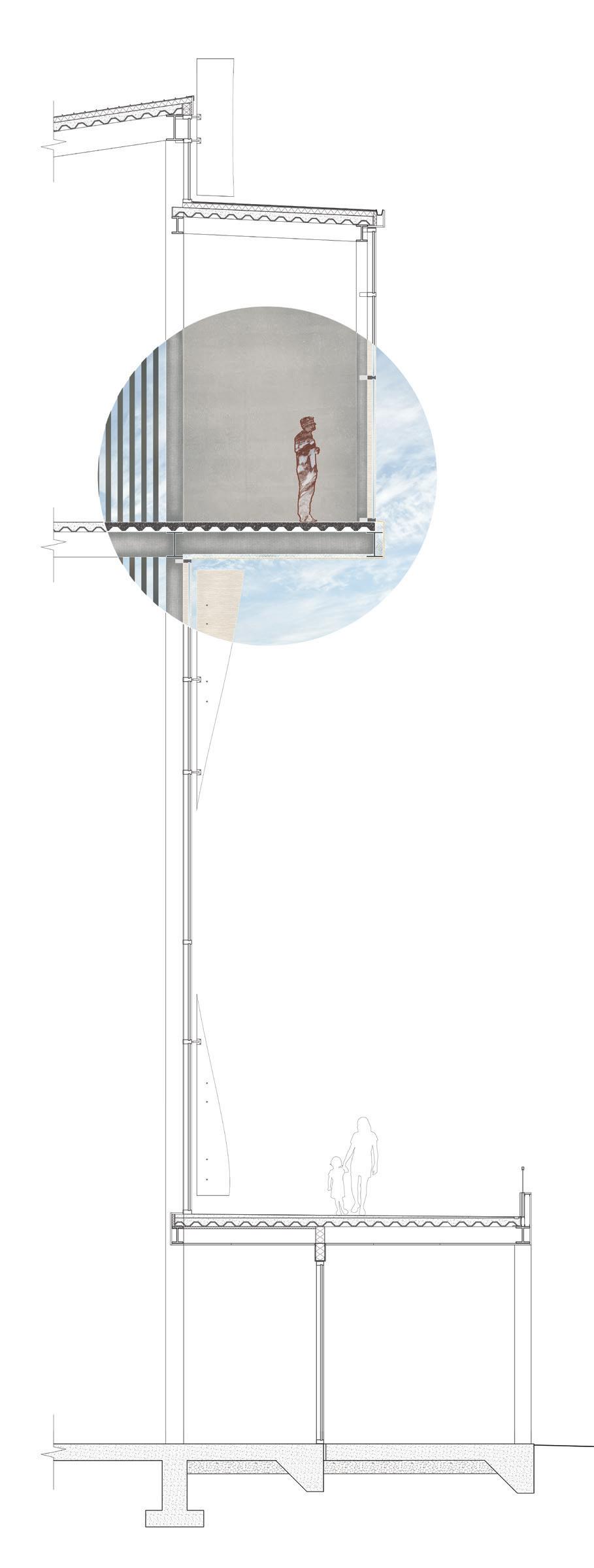

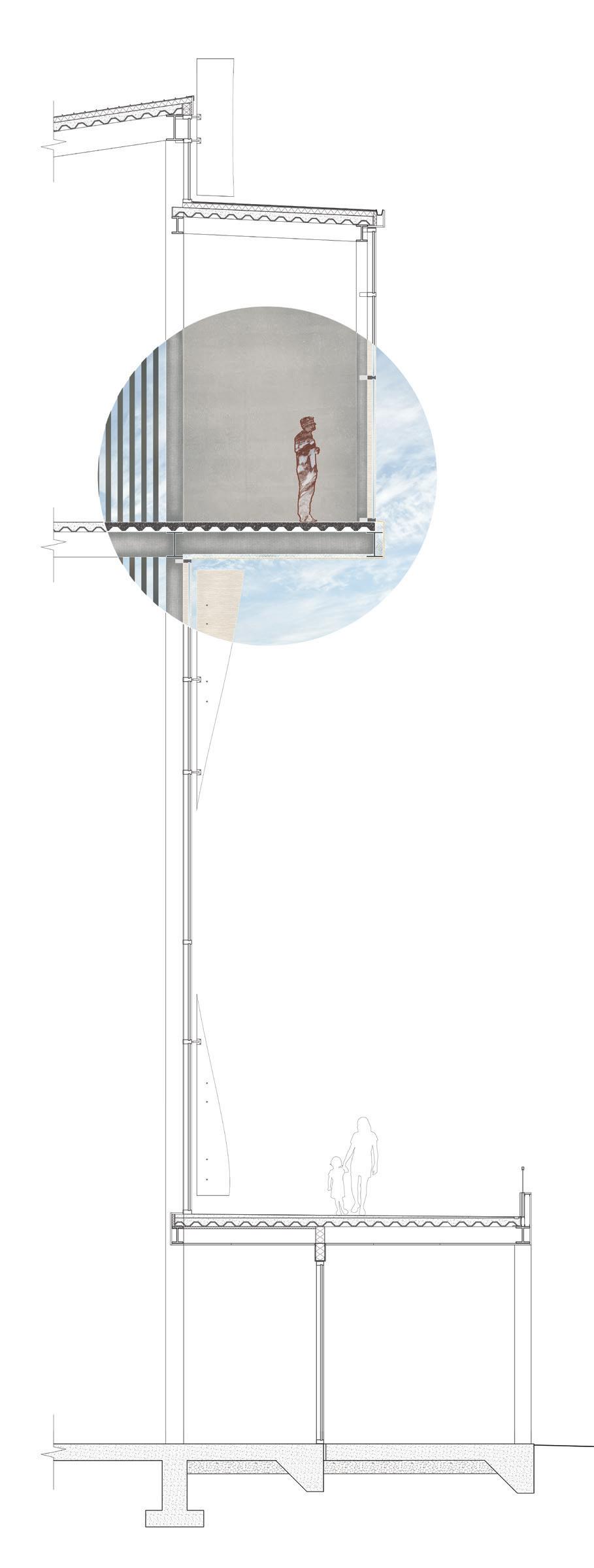

WALL SECTION MODEL

SITE MODEL

COLUMN

HIGH DENSITY SPRAY FOAM INSULATION

ALUMINUM LOUVER SYSTEM

CURTAIN WALL SYSTEM

STANDING SEEM METAL ROOFING PANELS

CONCRETE FOOTING

CONTINUOUS VAPOR BARRIER

RIGID INSULATION

STANDING SEEM METAL ROOFING PANELS CONTINUOUS VAPOR BARRIER RIGID INSULATION

6” CONCRETE ON METAL DECK

6” CONCRETE ON METAL DECK

LIMESTONE PANEL FACE

COLUMN BEYOND

CURTAIN WALL SYSTEM

LIMESTONE PANEL FACE

6” CONCRETE ON METAL DECK

6” CONCRETE ON METAL DECK

HIGH DENSITY SPRAY FOAM INSULATION LIMESTONE PANEL FACE ALUMINUM LOUVER SYSTEM

HIGH DENSITY SPRAY FOAM INSULATION

LOUVER SYSTEM ANCHOR CURTAIN WALL SYSTEM

HORIZONTAL LOUVER SUPPORT SYSTEM

6” CONCRETE ON METAL DECK

6” CONCRETE ON METAL DECK

HIGH DENSITY SPRAY FOAM INSULATION

SPRAY

LIMESTONE PANEL FACE

CURTAIN WALL SYSTEM

CURTAIN WALL SYSTEM COLUMN BEYOND 8” CONCRETE SLAB WITH GRAVEL BELOW CONCRETE FOOTING

COLUMN BEYOND

8” CONCRETE SLAB WITH GRAVEL BELOW

SOUTH FACADE WALL SECTION

23

LIMESTONE

PANEL FACE LIMESTONE PANEL FACE LIMESTONE PANEL FACE ALUMINUM LOUVER SYSTEM LOUVER SYSTEM ANCHOR CURTAIN WALL SYSTEM

BEAM

GYPSUM

BEAM BEYOND

COLUMN BEYOND

ALUMINUM

CURTAIN

HORIZONTAL LOUVER SUPPORT SYSTEM CURTAIN WALL SYSTEM HIGH DENSITY

FOAM INSULATION LIMESTONE PANEL FACE COLUMN BEYOND

BEYOND

WALL BOARD HIGH DENSITY SPRAY FOAM INSULATION

I-BEAM

COLUMN BEYOND

LOUVER SYSTEM

WALL SYSTEM I-BEAM I-BEAM

I-BEAM I-BEAM

BEYOND I-BEAM BEAM BEYOND

BOARD

I-BEAM BEAM BEYOND

COLUMN BEYOND

24

25

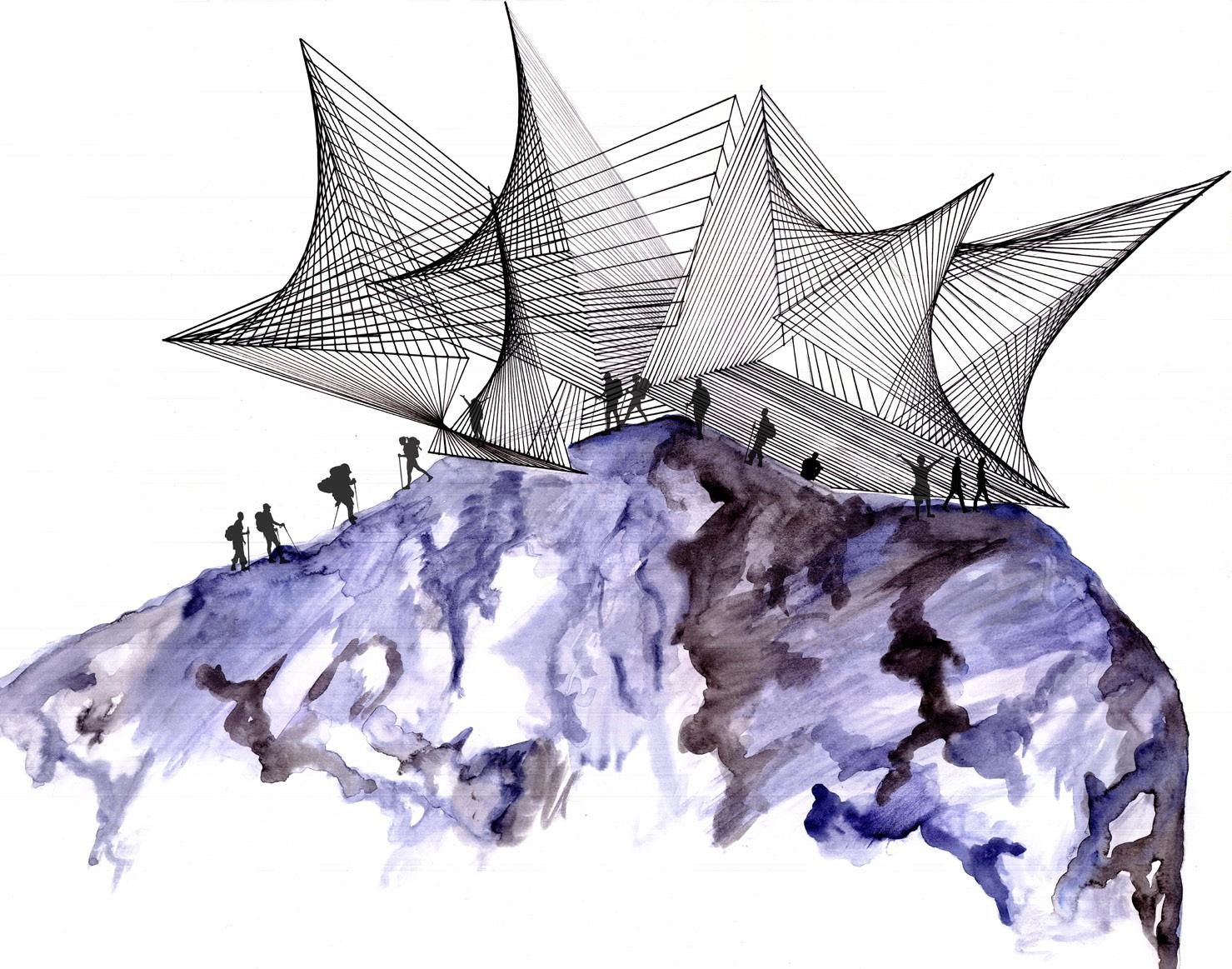

PORTAL OF THE PIAZZA

Partner: Joseph Scherer

While studying abroad in Genoa, Italy; I was fully immersed into the rich history the city had to offer, including it being the birthplace of explorer, Christopher Columbus. The concept of our Columbian Exchange Galleria was the creation of a very public space that links the progression from one elevation to another. Our goal was to create a keeping the space in our galleria open, public, and inviting.

DESIGN CONCEPT

27

GLUED LAMINATED TIMBER BEAM

ALUMINUM SECONDARY STRUCTURE

STEEL CONNECTION

STEEL I-BEAM

WOOD PANEL FACADE

GLASS FACADE ALUMINUM STRUCTURE

MOISTURE PROTECTION SEAL

CONCRETE FOUNDATION

ASSEMBLY DIAGRAM

28

29

LONGITUDINAL SECTION

TRANSVERSE SECTION

30

31 DETAILED SECTION

32 LEVEL 23 PLAN LEVEL 30 PLAN 1 - Cafe 2 - Exhibit Space 1 - Cafe 2 - Bathrooms 3 - Storage 4 - Office

33

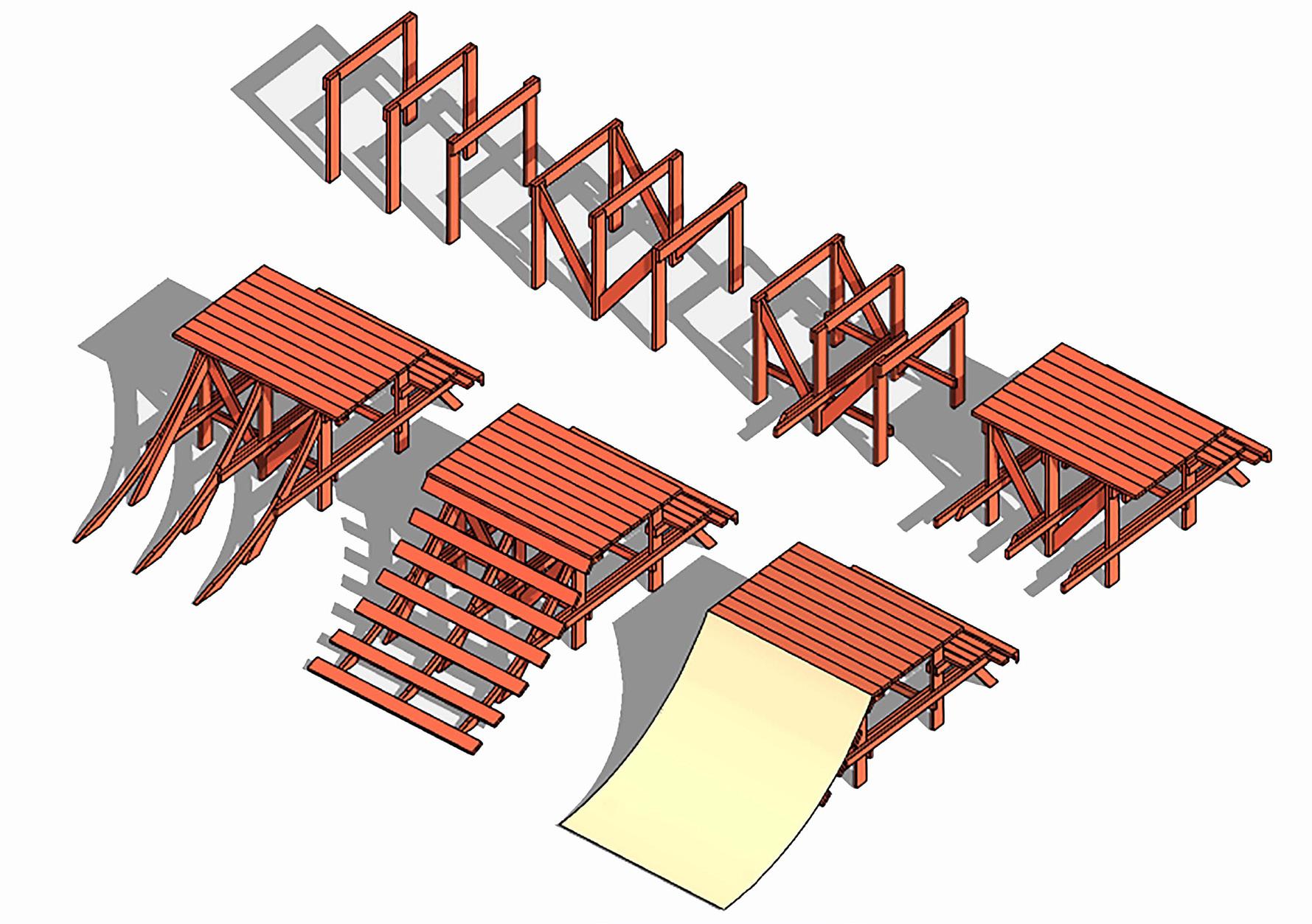

FRIERSON ELEMENTARY GARDEN PAVILION

Part outdoor classroom and part gardening center, the project combines two covered pavilion areas that join at the corners. The covered pavilions are arranged to be able to accommodate separate activities, but they are also arranged toward a shared focal point, giving the space versatility for multiple uses.

The structure is a study in the effective use of angles. Both of the pavilions are t rapezoidal, slanted 15 degrees. The “floating” roofs of each pavilion are also arranged at irregular angles to maximize shade and manage water runoff.

TRELLIS INSTALL

GABLE FABRICATION

GABLE RAISE

PERLIN INSTALL

HORIZONTAL BRACING

DIAGONAL BRACING

ROOFING INSTALL

STORAGE

WALLS

STORAGE PANELS

35 SITE PREPARATION DIGGING CONCRETE POUR SEPTEMBER

OCTOBER

NOVEMBER DECEMBER

DECEMBER

36 #4 REBAR, CONT. @ 16" O.C. 5" CONCRETE SLAB ABU ZMAX GALVANIZED ADJUSTABLE STANDOFF POST BASE FOR 6X6 NOMINAL LUMBER 1/2" DIA. HDG BOLTS 6x8 PRESSURE TREATED BEVELED POST 1' 4" 1' - 4" 5" 5/8" THREADED ROD 6" LONG, SECURED W/ ANCHORING EPOXY 1 1/2" CLEAR EL = 0'-0" 16" DIAMETER CONCRETE FOOTING 6x8 PRESSURE TREATED BEVELED POST 2" SURFACE PATH 2" 4 1/4" 7 1/2" 4 1/4" 3" 3' 0" FIRST FLOOR 0' - 0" 4" 4" 8" REINFORCED CONCRETE CURB 2" GRAVEL 3 1/4" 5 1/2" 3 1/4" 2" #4 REBAR VERTICAL @ 16' O.C. 2" GRAVEL 2" 3 3/4" 1' - 4 1/2" 3 3/4" 2" 4" 8" ELEVATION = 0'-4" 1'4" 2 - #4 REBAR HORIZONTAL AT TOP OF CURB 12' X 24" CONCRETE FOUNDATION W/ 4 PIECES OF #4 REBAR FIRST FLOOR 0' - 0" TOP OF FOOTER -1' - 0" 9A A B T4 T2 14" 14" 14" 14" 14" 14" 6 7/8" 3" TYP. 3 A0.02 TYP. T3 Project Number: Date: Drawn By: 12345678910 12345678910 4/7/2022 8:46:21 PM A0.02 FOUNDATIONPLAN 001 CONSTRUCTION DOCUMENTS 04/03/2022 STUDIOV Edith L. Frierson Elementary Garden Pavilion 6133 MAYBANK HWY WADMALAW, SC 29487 1 1/2" = 1'-0" A0.02 2 TYPICAL SLAB TURNDOWN 1 1/2" = 1'-0" A0.02 3 FLAGPOLE POST FOOTER 1 1/2" = 1'-0" A0.02 4 STEM WALL FOOTING DETAIL NORTH #DESCRIPTIONDATE FOUNDATION POUR 16" DIAMETER CONCRETE FOOTING 6x8 PRESSURE TREATED BEVELED POST 2" SURFACE PATH 2" 4 1/4" 7 1/2" 4 1/4" 3" 3'0" FIRST FLOOR 0' - 0" 4" 4" 8" REINFORCED CONCRETE CURB 3 1/4" 5 1/2" 3 1/4" 2" #4 REBAR VERTICAL @ 16' O.C. 2" GRAVEL 2" 3 3/4" 1' - 4 1/2" 3 3/4" 2" 4" 8" 1' 4" 2 - #4 REBAR HORIZONTAL AT TOP OF CURB 12' X 24" CONCRETE FOUNDATION W/ 4 PIECES OF #4 REBAR TOP OF FOOTER -1' - 0" 8A 7A 9A B T4 T2 14" 14" 14 14 14" 6 7/8 3" 2 A0.02 TYP. 3 A0.02 TYP. 4 A0.02 TYP. REBAR #4 T3 POSTS SHOWN -0" X 2'-0" Project Number: Date: Drawn By: 12345678910 4/7/2022 8:46:21 PM A0.02 FOUNDATIONPLAN 001 CONSTRUCTION DOCUMENTS 04/03/2022 STUDIO V Edith L. Frierson Elementary Garden Pavilion 6133 MAYBANK HWY WADMALAW, SC 29487 1 1/2" = 1'-0" A0.02 1 1/2" = 1'-0" A0.02 3 FLAGPOLE POST FOOTER 1 1/2" = 1'-0" A0.02 4 STEM WALL FOOTING DETAIL NORTH #DESCRIPTIONDATE 1/2” DIA. HDG BOLTS 5/8” THREADED ROD 6” LONG, SECURED W/ ANCHORING EPOXY #4 REBAR, CONT. @ 16” O.C. 6x8 PRESSURE TREATED BEVELED POST ABU ZMAX GALVENIZED ADJUSTABLE STANDOFF POST BASE FOR 6x6 NOMINAL LUMBER 5” CONCRETE SLAB 1’ - 4” EL = 0’-0” 1’4” 8” REINFORCED CONCRETE CURB 2 - #4 REBAR HORIZONTAL AT TOP OF CURB #4 REBAR VERTICAL @ 16” O.C. 12’ x 24” CONCRETE FOUNDATION W/ 4 PIECES OF #4 REBAR 2” GRAVEL 2” 3 1/4” 4” 4” 2” 1’-4” 1’ - 4 1/2” 3” 3” 8”

STEEL FABRICATION

37 6x8 PRESSURE TREATED COLUMN 4x6 PRESSURE TREATED BEAM L 2-1/2 x 2-1/2 x 3/16 STEEL ANGLE 4x7 STEEL ANGLE 6x6 PRESSURE TREATED BEAM 1/2x2 LAG SCREW CONCRETE FOOTING (SEE 2/S101) 6x8 PRESSURE TREATED COLUMN 4x6 PRESSURE TREATED BEAM L 2-1/2 x 2-1/2 x 3/16 STEEL ANGLE 6x6 PRESSURE TREATED BEAM 1/2x2 LAG SCREW CONCRETE FOOTING (SEE 2/S101) 1/4" STEEL PLATE L 2-1/2 x 2-1/2 x 3/16 STEEL ANGLE FIRST FLOOR 0' - 0" B.O. BELT COURSE 7' - 2 1/2" 3" 36" 8" 5' - 6" 6x8 PRESSURE TREATED POST L 2-1/2 x 2-1/2 x 3/16 STEEL ANGLE 4x7 STEEL ANGLE 6x6 PRESSURE TREATED BEAM CONCRETE PAD 4x6 PRESSURE TREATED PINE 4x6 PRESSURE TREATED BEAM L 2-1/2 x 2-1/2 x 3/16 STEEL ANGLE 6x6 PRESSURE TREATED BEAM 1/2x2 LAG SCREW CONCRETE FOOTING (SEE 2/S101) 1/2x2 LAG SCREW 1/4" STEEL PLATE 1/2 THREADED ROD 1/4" STEEL PLATE 16" 16" L 2-1/2 x 2-1/2 x 3/16 STEEL ANGLE FIRST FLOOR 0' - 0" B.O. BELT COURSE 7' - 2 1/2" 6x8 PRESSURE TREATED BEVELED POST 4x6 PRESSURE TREATED BEAM L 2-1/2 x 2-1/2 x 3/16 STEEL ANGLE 6x6 PRESSURE TREATED BEAM 1/2x2 LAG SCREWS REINFORCED CONRETE PAD (SEE 9/A3.06) 1/2 THREADED ROD 6-1/2 x 6-1/2 STEEL ANGLE 1/2 x 2 LAG SCREWS 1/4" STEEL PLATE 1/4" STEEL PLATE L 2-1/2 x 2-1/2 x 3/16 STEEL ANGLE FIRST FLOOR 0' - 0" B.O. BELT COURSE 7' - 2 1/2" 6x8 PRESSURE TREATED POST 4x6 PRESSURE TREATED BEAM L 2-1/2 x 2-1/2 x 3/16 STEEL ANGLE 6x6 PRESSURE TREATED BEAM 1/2x2 LAG SCREWS CONRETE FOOTING (SEE S/501) 1/2x2 LAG SCREWS 1/2 THREADED ROD 6-1/2x6-1/2 STEEL ANGLE 1/4" STEEL PLATE 1/4" STEEL PLATE 16" FIRST FLOOR 0' - 0" B.O. BELT COURSE 7' - 2 1/2" 123456789 123456789 1/2" = 1'-0" A3.04 4 WEST MEMBRANE DETAIL 1/2" = 1'-0" A3.04 2 EAST MEMBRANE DETAIL

5’ - 6” 1/4” STEEL PLATE 1/2 THREADED ROD 1/2x2 LAG SCREW 4x6 PRESSURE TREATED PINE 4x7 STEEL ANGLE 3/16 STEEL ANGLE 6x8 PRESSURE TREATED POST 6x6 PRESSURE TREATED BEAM CONCRETE PAD 36” 8” 3” 16”

38 FIRST FLOOR PLAN 0' - 0" A3.05 1 A3.05 2 B.O. BELT COURSE 7' - 2 1/2" T.O. ROOF 16' - 6" A0.02 2 TYP. 14'- 27/16" 6' - 4 13/16" 7'11 1/16" 12'3 1/16" 12' - 9 1/2" 13' - 11" TYP. A3.05 4 A3.05 3 7 ' -1" 10' - 5 5/16" T.O. ROOF 16' - 6" 10'- 49/16" A3.05 1 TYP. 14 ' -107/16" 123456789 1/4" = 1'-0" A3.01 1 SECTION GABLE 1B 1/4" = 1'-0" A3.01 3 SECTION GABLE 3B GABLE FABRICATION T.O. ROOF 16’ - 6” 7’ 6 1/2” 0’ - 0” B.O. BELT COURSE FIRST FLOOR 12’ - 9 1/2” 14’-27/16” 12’3 1/16” 6’ - 4 13/16” 7’11” TYP. TYP. 3 A3.05 2 A0.02 4 A3.05 2 13’ - 11” 7’-1”

39 STORAGE ASSEMBLY

7' - 5 1/8" 1 1/2" 7'0" 2'9" 1" 4'3" 1/2" P5 P6 1/2" 6680° 6680° 6' - 3" 7'1" 3' - 0 3/4" 3' - 0 3/4" 1/2" 6' - 2" 3' - 0 3/4" 3' - 0 3/4" 1/2" 5/8" 7/16" 3’ - 3/4” 3’ - 3/4” 3’ - 3/4” 3’ - 3/4” 1/2” 1/2” 1/2”

PLAN

40

41

W’ALL

Team: Michael Urueta, Lydia Gandy, Abby Anderson, Malik Sanders, Lily Morris, Mikayla Mannera, Jacob Zeeveld, and Brooklyn Walrod

Can architecture make the invisible visible? The W’ALL seeks to remind us of the many neglected social inequalities in the built environment that are still invisible. The exhibit is interactive and immersive, using 4 senses: sight, sound, smell, and touch. The interior and exterior reveal the content through virtual and physical displays. It is built to epitomize the recent research projects in Clemson University’s “Call My Name” and “Design Justice” Creative Inquiry.

WEAVING DRAPING QUILTING

The content of the exhibit lent itself to be discussed spatially. An immersive experience would place the viewer between the presented stories and challenge them to ask where their existence is within them. There needed to be an effort to uncover the information revealed invisibly, accepting the truth that there is always more to learn. The truth will be challenging at times, but it will help us heal collectively.

Three pods correlate with the three themes of content. The pods are embedded in the wall; the wall is the visible entity that must be addressed to understand the invisible barriers that it creates. Weaving, draping, and quilting served as representatives of the narratives shared.

43

44 printed patch. panel B26-side B2-front-weaving B3-front-weaving B4-front B5-frontdraping B6-front-draping B7-front-draping B9-frontquilt B10-front-quilt B11-front-quilt B1-side B12-side B13-side B15-back-quilt B16-back-quilt B17-back drape B23-back-weaving B24-back-weaving B18-backdrape B19-back-draping B20-back-draping B21/B20 B5/B6 B3/B4 B23/B22 B24/B25 B5/B6 C3-front-weaving C5-front C7-front-draping C10-front-quilting C11-front-quilting C13-side C15-back-quilting C16-back-quilting C17-back C22-back C23-back-weaving C24-back-weaving C25-back C26-side C29-inside C31-inside C32-inside C30-inside C28-inside E24-back-weaving E25-back E26-side E3-front-weaving E4-front E6-front-draping E7-front-draping E8-front E10-front-quilting E11-front-quilting E12-front E14-back E15-back-quilting E16-back-quilting E18-back E19-back-draping E20-back-draping E22-back E23-back-weaving E27-inside E29-inside E31-inside E32-inside E30-inside E28-inside G25-backG12-front G14-back G16-back-quilting G17-back G21-back G35-top G37-top G29-inside G31-inside G32-inside G30-inside A5/6 A7/8 A8 A9 A10 A11 A9/10 A15/14a A12a A13a A14a A15 A21/20 A17/16 A11/12a A19 A20 A21 A22 A23 A24 D3-front-weaving D6-front-draping D7-front-draping frontquilt D10-front-quilt D15-back-quilt D16-back-quilt D18D19-back-draping D23-back-weaving D24-back-weaving D13-side B17/B16 B9/B10 B19/B18 B7/B8 B3/B4 B23/B22 F3-front-weaving F6-front-draping F7-front-draping F9q F10-front-quilt B21/B20 B5/B6 F24/F25 F1/F2 F25-side F15-back-quilt F16-back-quilt F17-back bF19-back-draping F20-back-draping F21-back F23-back-weaving F24-back-weaving B9-frontquilt B10-front-quilt B11-front-quilt B12-side B13-side B15-back-quilt B16-back-quilt B17-back B18-backdrape B19-back-draping B17/B16 B9/B10 B19/B18 B7/B8 B21/B20 B5/B6 B3/B4 B23/B22 B24/B25 B5/B6 B11/B12 B14/B15 C3-front-weaving C4-front C6-front-draping C7-front-draping C10-front-quilting C9-front C11-front-quilting C13-side C15-back-quilting C1-front C2-front-weaving D6-front-draping D7-front-draping frontquilt D10-front-quilt D11-front-quilt D15-back-quilt D16-back-quilt draping D19-back-draping D20-back-draping weaving D23-back-weaving D24-back-weaving D12-side D13-side D1-side D26-side D25-side B19/B18 B7/B8 B21/B20 B5/B6 B3/B4 B23/B22 B11/B12 B14/B15 E1-front E2-front-weaving E3-front-weaving E4-front E6-front-draping E7-front-draping E8-front E10-front-quilting E11-front-quilting E12-front E14-back E15-back-quilting E16-back-quilting B11/B12 F14-side F1-side F19-back-draping F20-back-draping F22F23-back-weaving F24-back-weaving G4-front G12-front G14-back ROW 1 ROW 2 ROW 3 ROW 5 ROW 6 weaving D13-side B17/B16 B9/B10 B19/B18 B7/B8 B3/B4 B23/B22 B24/B25 B5/B6 ROW 4

ROW 7

SEWN ELEMENTS

45

46

47

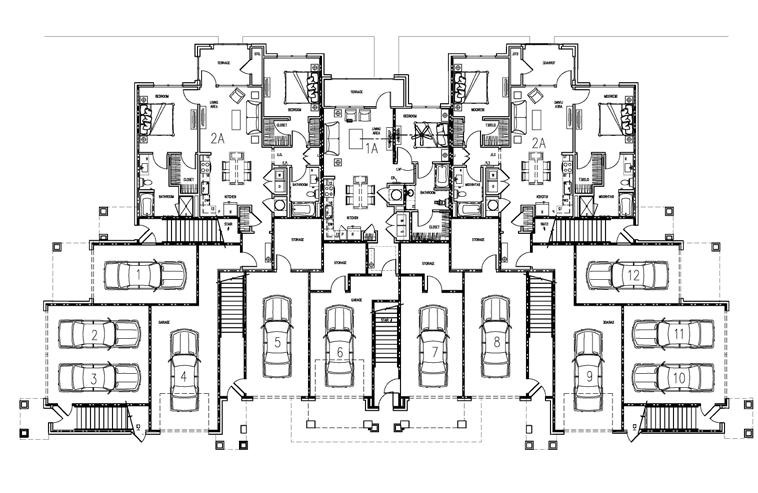

URBAN SENIOR LIVING CAMPUS

Atlanta, Georgia | June 2019 - July 2020 | Rule, Joy, Trammel, + Rubio, LLC

This project, located in Atlanta, GA, is an expansion of a current senior living facility and totals 14.13 acres. The project consisted of three major components: a healthcare building, an independent living building, and renovation of the current existing common spaces. All new construction (and interior renovation) was Type 1A non-combustible construction. Drawings and renderings are all produced in collaboration by a five-person team.

63 HEALTHCARE BUILDING 4 LEVELS EXISTING FACILITIES 10 LEVELS INDEPENDENT LIVING BUILDING 10 LEVELS

MEMORY GARDEN AMENITY DECK PEACHTREE ROAD PROJECT SITE

The Independent Living (IL) tower is all new construction. The building is ten stories over most of its height with a step down to four stories at the eastern and to suit zoning over three levels of parking (296 spaces). The building has 102 units from 1 Bedroom to 3 Bedroom units and also hosts a bar and restaurant on level 2 with break out space onto a large amenity deck.

64

INDEPENDENT LIVING LEVEL 5 PLAN

INDEPENDENT LIVING LEVELS 6-10 PLAN

INDEPENDENT LIVING LEVELS 2-4 PLAN

INDEPENDENT LIVING LEVEL 1 PLAN

The healthcare building is all new construction on newly acquired land on the north end of the site. The building has three levels over parking consisting of 40 Assisted Care units; 40 Skilled Nursing units; 21 Memory Care units and all of the common and support spaces, including a memory garden on the second level.

65

HEALTHCARE LEVEL 1 PLAN

HEALTHCARE LEVEL 2 PLAN

HEALTHCARE LEVEL 3 PLAN

HEALTHCARE LEVEL 4 PLAN

PARAPET WALL BEYOND

PRE-FINISHED ALUMINUM

TWO 39’ - 0”

ROOF FULLY ADHERED TPO ROOFING W/ COVER BOARD AND R-20 RIGID INSULATION

PARKING AL CORRIDOR AL CORRIDOR

12” STEP BALCONIES

8” P.T. SLAB TYP. DRAINABLE EIFS ON METAL STUDS W/ SHEATHING W/ WEATHER BARRIER & BATT

SCHEDULED TRANSOM

SCHEDULED

BALCONY

SCHEDULED SWING 1/2” STEP AT BALCONIES

EIFS CORNICE PER

9” P.T. SLAB @ ROOF 1 1/2” EIFS SOFFIT

BALCONY GUARDRAIL ATTACHMENT

TURN UP TPO ROOFING ON ALL 27’ -

DROPHEAD

8” P.T. SLAB

DRIP EDGE

1 1/2” EIFS SOFFIT, DROP FOR EXHAUST

PIECE ALUM. REGLET & 41’ - 6” 7’2”

PRE-FINISHED ALUMINUM GUARDRAIL

WALL

PRECAST WALL 1 1/2” EIFS

OVERHEAD

DRAINABLE EIFS ON 6” METAL R-13 INSULATION

AIR TIGHT TILED GRID PLENIUM

PLASTER OVERHEAD COILING GRILLE

5” CONCRETE

NOTCH FOR

DRIVEWAY

DRIVEWAY

CONCRETE SPREAD FOOTING @ COLUMN BEYOND

66

10’5” 9’2 1/8” 2’4” 13’6” 2’6” 1’ -10”

VERTICAL CLEARANCE BAR SUSPENDED BY PDECK

TYPICAL WALL SECTION AT DECK ENTRY

BALCONY

67

FACADE DESIGN PROCESS

FACADE DESIGN PROCESS