Designers can speed time to market for their on-board charger application with key technologies from one supplier, including the control, gate drive and power stage

The market for Battery Electric Vehicles (BEVs) and Plug-in Hybrid Electric Vehicles (PHEVs) continues to grow as the push towards decarbonization requires sustainable solutions to reduce emissions. A critical application for EVs is the on-board charger, which converts AC power into DC power to recharge the vehicle’s high-voltage battery. Microchip Technology today announces an On-Board Charger (OBC) solution that uses a selection of its automotive-qualified digital, analog, connectivity and power devices, including the dsPIC33C Digital Signal Controller (DSC), the MCP14C1 isolated SiC gate driver and mSiC™ MOSFETs in an industry-standard D2PAK-7L XL package.

This solution is designed to increase an OBC system’s efficiency and reliability by leveraging the dsPIC33 DSC’s advanced control functions, the MCP14C1 gate driver’s highvoltage reinforced isolation with robust noise immunity and the mSiC MOSFETs’ reduced switching losses and improved thermal management capabilities. To further simplify the supply chain for customers, Microchip provides the key technologies that support the other functions of an OBC, including communication interfaces, security, sensors, memory and timing.

To accelerate system development and testing, Microchip offers a flexible programmable solution with ready-to-use software modules for Power Factor Correction (PFC),

DC-DC conversion, communication and diagnostic algorithms. The software modules in the dsPIC33 DSC are designed to optimize performance, efficiency and reliability, while offering flexibility for customization and adaptation to specific OEM requirements.

Here is an overview of the key components in this OBC solution:

• The dsPIC33C DSC is AEC-Q100 qualified and features a high-performance DSP core, high-resolution Pulse-Width Modulation (PWM) modules and highspeed Analog-to-Digital Converters (ADCs), making it optimal for power conversion applications. It is functional, safety ready and supports the AUTOSAR®

• The MCP14C1 isolated SiC gate driver is AEC-Q100 qualified and is offered in SOIC-8 wide-body package supporting reinforced isolation and SOIC-8 narrowbody supporting basic isolation. Compatible with the dsPIC33 DSC, the MCP14C1 is optimized to drive mSiC MOSFETs via Undervoltage Lockout (UVLO) for VGS = 18V gate drive split output terminals, which simplifies implementation and eliminates the need for an external diode. Galvanic isolation is achieved by leveraging capacitive isolation technology, which results in robust noise immunity and high CommonMode Transient Immunity (CMTI).

• The mSiC MOSFET in an AEC-Q101-qualified D2PAK-7L XL surface mount package includes five parallel source sense leads to reduce switching losses, increase current capability and decrease inductance. This device supports 400V and 800V battery voltages.

Microchip has published a white paper that provides more information about how this OBC solution can optimize a design’s performance and speed up its time to market. For more information about Microchip’s OBC solutions for EVs, visit Microchip’s website

The dsPIC33C DSC is an AUTOSAR-ready device and is supported by the MPLAB® development ecosystem including MPLAB PowerSmart™ Development Suite.

The main components for an OBC solution including the dsPIC33C DSC, the MCP14C1 isolated SiC gate driver and the mSiC MOSFET in a D2PAK-7L XL package are now available. For additional information and to purchase, contact a Microchip sales representative, authorized worldwide distributor or visit Microchip’s Purchasing and Client Services website, www.microchipdirect.com.

Microchip Technology www.microchip.com

3 | Microchip Makes it Easier to Design an On-Board Charger Solution

6 | Moxa New-gen x86 Industrial Computers Recognized by “Red Dot Award: Product Design 2024”

6 | Mouser Electronics, in Collaboration with STMicroelectronics, Explores Wireless Connectivity in New eBook

7 | Infineon introduces Power System Reliability Modeling to reduce power shortages and blackouts in data center systems

8 | Nexperia’s portfolio of 650V SiC diodes now addresses automotive and a wider range of industrial applications

8 | Newest Mouser Series Navigates Zonal Architectures for Software-Defined Vehicles

9 | Vector and QNX: Cooperation for Best-In-Class Solution of Safe Systems in SDVs

10 | Reference Book on Wireless Power Transmission Expanded

10 | Anglia adds new Environmental resource hub to speed compliance and introduces Beehives to its distribution centre site

11 | WeEn Semiconductors Unveils Latest Rugged, High-Performance IGBTs

eBooks 28 | Authorized Distributor Mouser Electronics Offers Wide Range of MEAN WELL Power Solutions

Management

Managing Director - I onela G anea

Editorial Director - Gabriel N eagu

Accounting - I oana P araschiv

Advertisement - Irina G anea

Web design - Eugen Vărzaru

Contributing editors

Cornel Pazara

PhD. Paul S vasta

PhD. N orocel C odreanu

PhD. Marian Blejan

PhD. B ogdan G rămescu

| TEN 30UIR & 40UIR / THN 10UIR series

Alphawave Semi Collaborates with Arm on High-Performance Compute Chiplet

| Testing O-RAN compatible devices

43 | Introducing the TimeProvider® XT Extension System for Migrating to a Modern Synchronization and Timing Systems Architecture

| New Power Supply Concepts Needed for Intelligent Edge Sensors

Azi” is a registered trademark at OSIM - Romania, Registered position:

Moxa Inc., a leader in industrial communications and networking, celebrated its new x86 industrial computers (IPCs) family—the BXP, DRP, and RKP Series reaching the pinnacle of design excellence with the Red Dot Winner 2024 recognition in the Industrial Design category. Designed to meet most industrial automation market needs, the rugged computers are equipped with exceptional reliability, adaptability, and longevity to address the increasing demands of data connectivity and real-time processing of large volumes of sensor and device data at the industrial edge.

The new x86 industrial computers emerged victorious at the Red Dot Award: Product Design 2024, thanks to its adaptable and user-oriented design with robust housing and remarkable I/O options for easy accessibility and edge connectivity to industrial applications. “With adaptability and user-oriented design, DRP, BXP, and RKP manage the complex requirements of industrial automation,” the prestigious Red Dot Award jury stated. Industrial computers play essential roles at the industrial edge, facilitating effective communication between industrial networks and various components of automation systems. They can enable both easy configuration and flexible integration while ensuring stable data connectivity for operations, making life easier for asset owners and system integrators. Notably, the DRP-C100 and BXP-C100 Series excel in performance, resilience, and endurance, making them ideal for Battery Energy Storage Systems (BESS). These systems require efficient data logging and robust data storage to manage thousands of data points generated every minute by monitoring systems, ensuring accurate data for maintenance and warranty claims. Engineered to maximize capabilities for industrial edge connectivity, the BXP, DRP, and RKP Series are each backed by a robust 3-year hardware warranty and 10-year longevity commitment (for product released in 2023 and after). These products reaffirm Moxa’s dedication to delivering exceptional product quality and ensuring stable, long-term support for our customers’ evolving business needs. Furthermore, the simplified configure-to-order service (CTOS) enables customers to identify the best fit for their applications in just a few steps.

■ MOXA | https://moxa.com

, Inc., the New Product Introduction (NPI) leader empowering innovation, today announces a new eBook in collaboration with STMicroelectronics, offering an in-depth look at wireless connectivity.

The plethora of new and pre-existing connected Internet of Things (IoT) and Industrial Internet of Things (IIoT) devices, gateways, and sensors require that wireless technology be dependable and compatible with many wireless protocols. This need will only grow as more technologies, such as connected vehicles, medical and wearable devices, and wireless charging fully mature. In Beyond the Wires: Exploring Bluetooth and LoRaWAN Connectivity, experts from STMicroelectronics discuss the evolution of the Bluetooth® Low Energy and LoRaWAN wireless standards and their benefits.

The eBook offers many use cases, from remote sensor networks to smart cities and homes, from agriculture to public entertainment. Special requirements for security, private networks, long-range and more are also discussed. The eBook also highlights relevant products from STMicroelectronics, including the company’s industry-leading RF system-on-chip (SoC) solutions, modules and development tools.

The STM32WBA5 multiprotocol wireless radio microcontroller (MCU), available from Mouser, features a powerful

Arm® Cortex®-M33 core and is certified for the Bluetooth Low Energy 5.4 protocol, Zigbee® R23 and OpenThread® 1.3. The STM32WBA5 offers an ultra-low-power platform and inherited digital/analogue peripherals, suitable for many applications, from industrial to smart home and consumer markets.

The STM32WLE5 wireless long-range microcontroller embeds a powerful and ultra-low-power LPWAN radio solution consisting of LoRa®, (G)FSK, (G)MSK, and BPSK. The Arm core of this MCU implements a full set of DSP instructions and an independent memory protection unit (MPU) that enhances application security.

The NUCLEO-WBA55CG Nucleo-64 board eases prototyping applications with the STM32WBA5 wireless microcontroller. Arduino Uno V3 connectivity support and ST morpho headers allow functionality expansion with a wide choice of specialised shields.

The STEVAL-ASTRA1B evaluation board includes LoRa, Bluetooth LE, and NFC, as well as a GNSS positioning module and MEMS sensors (including temperature and pressure sensors, an accelerometer, and a gyroscope), making it a complete proof-of-concept for asset tracking and monitoring.

The STEVAL-PROTEUS1 evaluation board includes Bluetooth LE, MEMS sensors and secure elements to target Industry 4.0 applications with condition-based maintenance and predictive maintenance, including the capability of anomaly detection thanks to AI capability.

The STM32WBA55G-DK1 Discovery kit is a complete demonstration and development platform for the STM32WBA55CGU7 MCU, enabling a wide diversity of applications by exploiting low-power communication, the Bluetooth SIG isochronous channel feature related to audio capability for Bluetooth Low Energy Audio, Matter as Border Router, and Zigbee.

To learn more about STMicroelectronics, visit: https://eu.mouser.com/manufacturer/stmicroelectronics.

To read the new eBook, visit: https://resources.mouser.com/manufacturer-ebooks/stbeyond-the-wires-bluetooth-lorawan-connectivity.

■ Mouser Electronics | www.mouser.com

Infineon Technologies AG introduces Power System Reliability Modeling, an innovative solution addressing the increasing challenges faced by data centers and telecom infrastructures due to power supply failures in the system. With 39 percent of downtimes attributed to power outages and an average cost of $687,700 per downtime, the need for seamless operations and mitigation of financial impact is urgent. By integrating Infineon’s power monitoring solution, organizations can enhance operational resilience, reduce their carbon-footprint and achieve substantial cost savings. The offering consists of an algorithm running on a digital power controller, thus integrating software and hardware. This is in line with Infineon’s strategic approach to provide customers with comprehensive system solutions that include both semiconductor devices and matching software tools. Target applications of the solution include DCDC converters, ACDC rectifiers and IBC modules utilized in data centers, AI servers, GPUs, and telecom networks. Power System Reliability Modeling acts as a bridge between component and system reliability. It enables real-time power supply health monitoring of the system and lifetime estimation based on dynamic system operating parameters, a power supply system model, and a reliability prediction procedure in digital power controllers by Infineon. This solution ensures improved device utilization and data-driven maintenance recommendations, translating into enhanced profitability and reduced Total Cost of Ownership (TCO). Customers benefit from real-time system diagnostics for their power supply as well as powerful system reliability-based decisions and quality assurance. The solution is easy to use and integrate into existing designs.

Further information about the solution is available at www.infineon.com/reliabilitymodeling.

■ Infineon Technologies | www.infineon.com

Nexperia’s portfolio of 650V SiC diodes now addresses automotive and a wider range of industrial applications

Nexperia announced that its class-leading 650 V, 10 A silicon carbide (SiC) Schottky diode is now automotive qualified (PSC1065H-Q) and available in real-two-pin (R2P) DPAK (TO252-2) packaging, making it suitable for various applications in electric vehicles and other automobiles. Additionally, in a further extension to its portfolio of SiC diodes, Nexperia is now also offering industrial-grade devices with current ratings of 6 A, 16 A, and 20 A in TO-220-2, TO-247-2, and D2PAK-2 packaging to facilitate greater design flexibility. These diodes address the challenges of demanding high voltage and high current applications including switched-mode power supplies, AC-DC and DC-DC converters, battery-charging infrastructure, motor drives, uninterruptible power supplies as well as photovoltaic inverters for sustainable energy production.

The merged PiN Schottky (MPS) structure of these devices provides additional advantages over similar competing SiC diodes, including outstanding robustness against surge currents. This eliminates the need for additional protection circuitry, thereby significantly reducing system complexity and enabling hardware designers to achieve higher efficiency with smaller form factors in rugged high-power applications. Nexperia’s consistent quality across various semiconductor technologies provides designers with confidence in the reliability of these diodes.

In addition, Nexperia’s ‘thin SiC’ technology delivers a thinner substrate (one-third of its original thickness) which dramatically reduces the thermal resistance from the junction to the back-side metal. This results in lower operating temperature, higher reliability and device lifetime, higher surge current capability, and lower forward voltage drop.

To learn more about Nexperia’s extended range of 650 V SiC Schottky diodes for automotive and industrial applications, visit www.nexperia.com/sic diodes.

■ Nexperia | www.nexperia.com

As automotive technology ratches up in electronics, designers have turned to zonal architecture — to maximize efficiency within individual subsystems while allowing for easier management of the hardware and software stacks for the whole car.

Mouser Electronics, Inc., the authorized global distributor with the newest electronic components and industrial automation products, today announced the newest installment of its Empowering Innovation Together (EIT) technology series, which examines the benefits of zonal architectures and the enhanced connectivity features it provides software-defined vehicles (SDV). This installment of the EIT technical content series explores design concepts, virtualization, and future use cases enabled by zonal architectures, driving future automotive innovations.

As the automotive industry shifts towards electric vehicles and advanced driver assistance systems, these modern designs require significant hardware and software upgrades.

Vehicle performance is optimized by creating distinct zones within the vehicle that cater to specific functionalities and implementing vehicle compute platforms. This approach offers improved reliability, increased performance, and longer lifespans for cars, ultimately transforming them into immersive experiences. Mouser explores how these new features can open up a plethora of possibilities for automotive design and engineering.

Join The Tech Between Us podcast, where Mouser Director of Technical Content Raymond Yin and Christian Uebber, Chief Technology Officer from ETAS, discuss the complex nature of advanced architectures. Together, they explore the necessary software and hardware changes to transition to new compute platforms, with emphasis on the importance of codesign considerations.

“In our latest spotlight, we explore the transformative possibilities of zonal architecture,” said Yin . “This forward-looking approach is revolutionizing spatial design, and we delve into its variety of applications through insightful discussions with leading experts in the field.”

This series includes technical articles, an infographic, a video and more, introducing the SDV movement and how zonal architectures enhance safety, efficiency, and personalization. These resources offer guidance to automotive engineers who are considering the benefits of this new network architecture.

Established in 2015, Mouser’s Empowering Innovation Together program is one of the industry’s most recognized electronic component programs.

To learn more, visit https://www.mouser.com/empoweringinnovation and follow Mouser on Facebook, LinkedIn, X and YouTube

■ Mouser Electronics | www.mouser.com

Vector announces a collaboration with QNX, a business unit of BlackBerry Limited, that will pave the way to Automotive Safety Integrity Level (ASIL) D for SoftwareDefined Vehicles (SDV).

Within the collaboration, Vector provides a QNX® operating system (OS) integration, the corresponding interface and a safety case. OEMs and Tier-1s can now easily develop AUTOSAR-based applications with MICROSAR Adaptive Safe on QNX® OS for Safety while benefiting from pre-aligned and industry-certified safety concepts to create safe, highperformance systems for SDVs.

“This collaboration is an important step towards realizing the Software-Defined Vehicle,” says Grant Courville, Vice President of Product and Strategy at BlackBerry QNX. “We are working closely with Vector to deliver a pre-integrated offering that realizes the benefits of the QNX OS for Safety combined with MICROSAR Adaptive Safe for our mutual customers.”

While integrating AUTOSAR Adaptive to the QNX OS, performance is always a key requirement at Vector. Therefore, to address these performance needs, a specific QNX OS abstraction layer was developed that makes use of native QNX API system calls.

“Partnering with innovators such as QNX enables our customers to develop faster and more efficiently,” says Matthias Traub, Director Embedded Software and Systems at Vector. “We accelerate the development of SDVs with pre-integrated and coordinated and industry-certified safety concepts”.

For more information on Vector’s SDV solutions, visit: www.vector.com/sdv

■ Vector | www.vector.com

Reference book “Trilogy of Wireless Power Transfer”: Expertise for wireless power transmission Image source: Würth Elektronik

The reference book “Trilogy of Wireless Power Transfer” by Würth Elektronik is now available in a revised second edition. The manufacturer with the largest selection of wireless power coils on the market shares its expertise in wireless power transmission. The practice-oriented reference book consists of three parts: Basic Principles of Wireless Power Transmission, Wireless Power Transfer Systems and Applications. It costs 19 euros and is available from Würth Elektronik and in bookstores.

The first part of the reference book has been completely revised and explains the physical principles of the various methods of contactless power transmission. The key standards and developments of the technology are also discussed. The second part describes the wireless power transfer systems and the different topologies of wireless power transmission. In the same chapter, the correct selection of the required transmitter and receiver coils to increase efficiency, and also the available transistors, are discussed.

The practice-oriented third part is supplemented with an innovative application: NFC communication together with wireless power transmission. An overview of EMI-related topics rounds off the compilation of application examples in the practice section. The authors of the “Trilogy of Wireless Power Transfer” are Cem Som, Vice President Europe at Wurth Electronics Midcom Inc. and Dr. Michael de Rooij, Vice President Applications Engineering at Efficient Power Conversion Corporation, Inc.

■ Würth Elektronik eiSos | www.we-online.com

hub to speed compliance and introduces Beehives to its distribution centre site

Anglia Components announced a new environmental resource hub on its UK and European eCommerce platform, www.anglia-live.com, which aims to provide environmental information on each of its supply partners in one place. This will reduce the time buyers and compliance engineers are required to spend on compliance documentation when analysing supply chains to determine their own corporate environmental impact and ethical status. For each of Anglia’s authorised supply partners the hub provides links to various environmental and ethical statements, such as the manufacturer’s environmental policy, its position on conflict materials, REACH, Modern Slavery and EU sanctions against Russia.

Environmental Policies; Conflict Materials; REACH; Modern Slavery; EU Sanctions vs Russia

Anglia is highly committed to improving the environment and reducing its carbon footprint. A raft of measures have been introduced over the past 18 months, including:

• New packaging which reduces waste and is both reusable and recyclable

• Reduced air miles for components

• Smart building practices

• Environmentally friendly company transport policies

And most recently to align with its other sustainable practices and to support elements of their ISO14001 accreditation, Anglia also integrated 5 beehives into its 2 acre landscaped distribution centre site. The introduction of bees helps in maintaining a healthy balance within the local ecosystem by pollinating plants, ensuring their reproduction, and aiding in the overall sustainability of the surrounding environment.

Visit www.anglia-live.com to view the new environmental resource hub and find out more about how Anglia are demonstrating their commitment to sustainability and the environment.

■ Anglia Components PLC | www.anglia-live.com

WeEn Semiconductors Unveils Latest Rugged, High-Performance IGBTs

WeEn Semiconductors, specialists in developing and manufacturing advanced bipolar power semiconductor products, has announced an expansion to its range of high-performance and rugged IGBTs at this year’s PCIM Europe exhibition and conference. Offering voltage ratings of 650V and 1200V, the new devices incorporate a fast recovery anti-parallel diode and boast extremely low leakage currents and exceptional conduction and switching characteristics at both high and low junction temperatures.

Based on an advanced fine trench gate field-stop (FS) technology, the new IGBTs provide a more uniform electric field within the chip, support higher breakdown voltages and offer improved dynamic control. By offering the optimum trade-off between conduction and switching losses, as well as an enhanced EMI design, the devices will maximize efficiency in a wide variety of mid- to high-switching-frequency power conversion designs.

The new IGBTs offer ratings of 650V/75A, 1200V/40A and 1200V/75A and are supplied in TO247 or TO247-4L packages depending on the selected device. All of the devices will operate with a maximum junction temperature (Tj) of 175 °C and have undergone high-voltage H3TRB (high-humidity, high-temperature and high-voltage reverse bias) and 100%biased HTRB (high-temperature reverse bias) tests up to this maximum.

Target applications for the new WeEn IGBTs include solar inverters, motor control systems, uninterruptible power supplies (UPS) and welding. A positive temperature coefficient simplifies parallel operation in applications where higher performance is required, while options for bare die, discrete and module product variants provide flexibility for a wide variety of target designs.

For more information, please explore WeEn Semiconductors’ product portfolio here.

■ WeEn Semiconductors | www.ween-semi.com/en

Authors:

Pramit Nandy and Vijay Bapu Microchip Technology Inc

Authors:

Pramit Nandy and Vijay Bapu Microchip Technology Inc

The manufacturing industry has been evolving for over 200 years now. Industry 4.0 is the fourth industrial revolution concentrating on interconnectivity, automation, machine learning, and real-time data processing. As various manufacturing industries are marching towards Industry 4.0, to stay competitive and reduce manufacturing costs, manufacturers are putting more equipment and less people in factories. Manufacturers are investing heavily in advanced mobile robotics in their factories (i.e., Amazon delivery warehouses, assembly lines) and warehouses for doing the lion’s share of the building, assembling and transporting of material. However, these mobile robots must be charged regularly which is an increasing challenge for industrial factories. There have now been some improvements in the wireless charging space that are making these robots more flexible, which has boosted the manufacturing capacity and efficiency of factories.

With the right combination of component selection, coil design and board layout, wireless charging is becoming a game changer for the manufacturing industry and is impacting the whole economy.

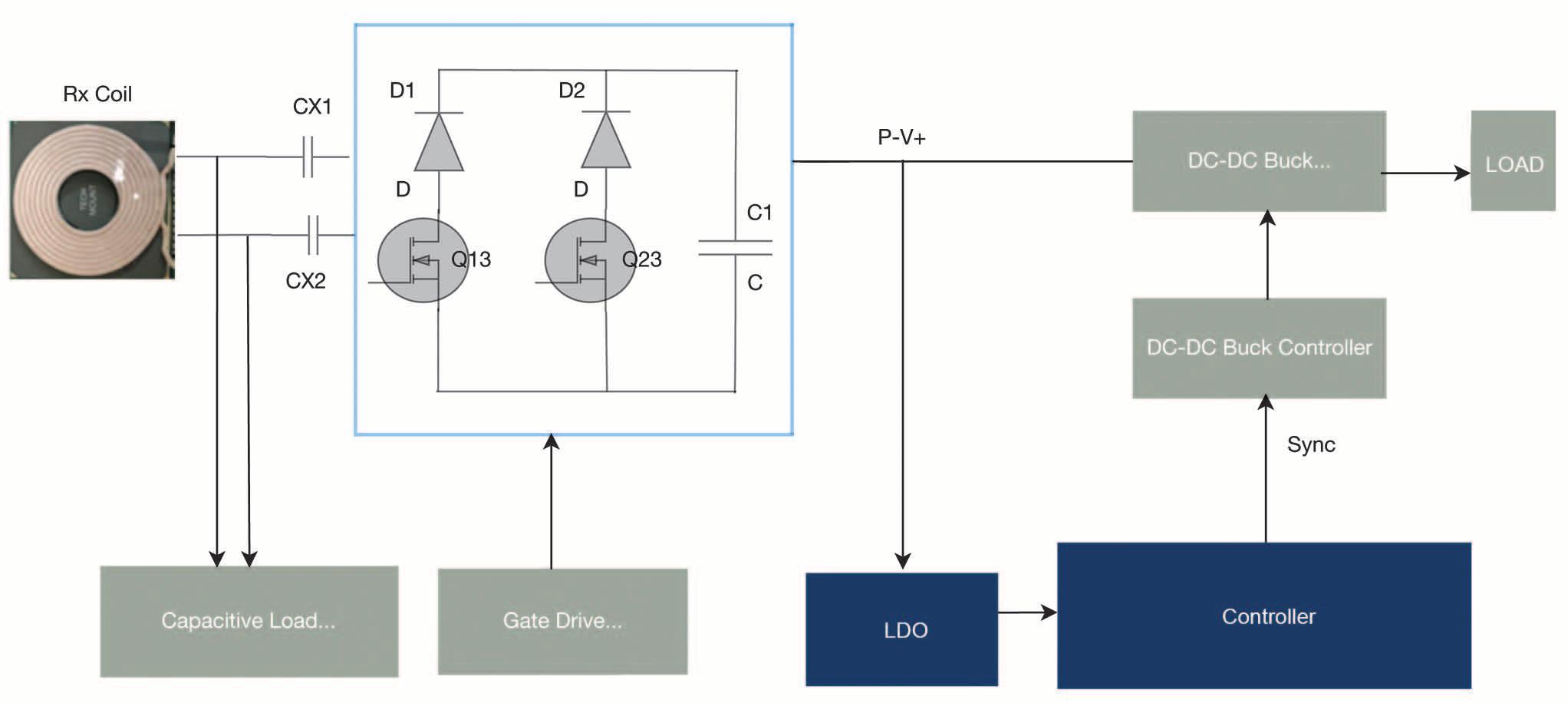

The latest wireless charging solutions use techniques based on the principle of electromagnetic induction. When an alternating current is passed through an induction coil on the transmitter side, an oscillating magnetic field is created. When this oscillating magnetic field couples with an induction coil on the receiver side, an alternating electric current is produced in the receiver side coil (see Figure 2).

Wireless charging systems require a number of components including the transmitter coil, tuning capacitors, a coil drive and a receiver coil. Other components include diode rectifiers, a DC-DC converter, transmitter and receiver control circuitry and algorithms, and a battery charging circuit.

In the example shown below, electromagnetic induction enables the wireless charging systems to transfer energy from a charging source pad installed on the factory floor to a receiving pad installed on the mobile robot.

Modern wireless charging systems with increased efficiency and cost-optimized components have proven to be a game changer in a factory setup for a number of reasons. First, they improve productivity and reduce manufacturing costs in a variety of ways. They enable continuous operation with opportunity charging (i.e., using idle time to charge), and reduce investment since robots can be multipurposed for different operations. They also reduce human intervention because the charging process can be automated, as well as maintenance costs since connector and cables, etc., can be eliminated resulting in a completely contactless solution.

Second, these charging systems increase safety and security. They remove the risk of sparks caused by connectors and short circuits due to contamination or moisture inside them. Other safety benefits include these solutions’ reliable detection of metal debris and other foreign objects between the transmitter and receiver coil.

Additionally, it is easy to implement secure authentication between charger and robot to avoid unauthorized access, and data transfer during charging can be used for predictive maintenance to prevent downtime. Other benefits include how much easier

wireless charging systems are to maintain and clean on the factory floor when compared to wired charging systems. This is an important contributor to the completely automated factory, minimizing human intervention and helping to create a safer environment by preventing worker-toworker spread of communicable diseases such as COVID-19).

Keeping its advantages in mind, wireless charging technology on a factory setup has the potential to take the manufacturing industry to the next level and solve difficult production challenges. However, there are some challenges with wireless charging, too. These challenges include the need for a relatively high investment to implement the wireless charging infrastructure when compared to traditional wired charging, and comparatively lower efficiency, EMI concerns. There are also safety issues related to overheating if there is a foreign object between the transmitter and receiver coil. BOM cost management and component selection are particularly important.

In the wireless power transmitter, the critical loop for the switching currents in a high-power wireless power system includes the power switches, the resonant capacitors and the coil.

This loop involves high voltages, high currents, and high switching frequencies. PCB Layout, component placement and routing in this high-power wireless power transfer system affects efficiency, EMI performance, and thermal dissipation which in turn affect system performance and reliability. There are also challenges with coil parameter variation due to manufacturing variabilities in the coil. Coil to coil variation can result in variations across products resulting in inconsistent behavior and unreliable performance in the field.

While general-purpose devices can be used to build a wireless charging solution, they cannot perform at the same level as fixed-function alternatives. Solutions can also vary in cost and efficiency depending on component selection and board layout decisions. There are many ways to optimize today’s wireless charging solutions.

Fixed-function devices are used to optimize a wireless charging solution so it can address the challenges of implementing safe, reliable, efficient wireless power at high power levels. An important step is to optimize the solution’s transmitter and receiver circuitry

that runs highly specialized algorithms for communications, power control and Foreign Object Detection (FOD). These algorithms are based on extensive R&D and multiple granted patents.

Ideally, the communication in the wireless charging solution should be in-band, eliminating the added system cost of out-ofband communications schemes. Look for power transfer frequency in the range of about 100KHz. Power control should be performed using variable frequency and variable duty cycle control of the PWM driving the full bridge inverter in the transmitter. At high power levels, FOD becomes critical. In this method, power transfer is briefly stopped for a few microseconds and the coil voltage is measured using the solution’s high peripherals and core. The presence (or not) of a foreign object can be detected by calculating the slope of the coil voltage when the output FETs are off. All components of the solution, including the controller, FETs, regulators, and coils, must be chosen such that their cost fits within the total system budget, which may need to include high-end metal contacts for reliability in an environment with moisture or dust. The efficiency of the solution depends on both the power control scheme and an optimal coil design. An

example is Microchip’s WP300 solution, whose design delivers greater than 90 percent efficiency at loads above 100 Watts. This efficiency is measured from the DC input to the transmitter to the regulated DC output of the receiver. The solution can operate at an input voltage of 12-36V DC and can regulate to a similar voltage range on the receiver side.

The PCB Layout, component placement and PCB stack-up in the WP300 based reference solution have been optimized for best performance. The PCB is designed such that the digital section, the analog and the power sections are isolated, so the noise coupling is minimized.

EMI is also mitigated using appropriate control methods in the transmitter and optimal use of decoupling capacitors to reduce switching noise, in addition to reduction in the switching frequency. Decoupling capacitors reduce the switching noise coupling but increases loss which results in increased thermal dissipation and loss in efficiency. These tradeoffs are crucial to evaluate to optimize the design. The coil parameters can be calibrated during assembly on the production line. The benefit of the solution is that coil calibration data is written to the WP300TX IC during product test.

This results in consistent operation across product and reliable performance. Finally, to create 1:1 pairing between the transmitter and receiver, secure communications can be included in-band to make sure only receiver devices that are authenticated by the transmitter are powered. Figure 4 includes block diagrams of a 300W transmitter controller and 300W receiver controller that have been optimized to deliver these capabilities.

System developers should work with a supplier that provides detailed guidelines for using their wireless charging solutions including component selection, coil design and board layout.

Suppliers should also provide step-by-step guidance to ensure seamless execution of the final product. With this approach, developers can save time, mitigate risk, and simplify their wireless charger designs

so that they deliver on the full promise of electromagnetic induction technology, while also improving their productivity, reducing manufacturing cost and improving safety and security.

■ Microchip Technology www.microchip.com

World-leading performance over temperature enables cool-running, fast-switching 650 V and 1,200 V SiC MOSFETs to support up to 3x more powerful AI data centers and faster charging EVs

Navitas Semiconductor, the industry leader in next-generation GaNFast™ gallium nitride (GaN) and GeneSiC™ silicon carbide (SiC) power semiconductors, announces their new portfolio of Gen-3 ‘Fast’ (G3F) 650 V and 1,200 V SiC MOSFETs optimized for fastest switching speed, highest efficiency, and increased power density for applications such as AI data center power supplies, on-board chargers (OBCs), fast EV roadside super-chargers, and solar / energy-storage systems (ESS). The broad portfolio range covers industrystandard packages from D2PAK-7 to TO247-4, designed for demanding, highpower, high-reliability applications.

The G3F family is optimized for highspeed switching performance, resulting in 40% improvement to hard-switching figures-of-merits (FOMs) compared to competition in CCM TPPFC systems. This will enable increasing the wattage of nextgeneration AI power supply units (PSUs) up to 10 kW, and power per rack increase from 30 kW to 100-120 kW.

The G3F GeneSiC MOSFETs are developed using a proprietary ‘trench-assisted planar’

technology. and offer better-than-trench MOSFET performance, while also providing superior robustness, manufacturability and cost than competition. G3F MOSFETs deliver high-efficiency with high-speed performance, enabling up to 25°C lower case temperature, and up to 3x longer life than SiC products from other vendors.

The ‘trench-assisted planar’ technology enables an extremely low R DS(ON) increase versus temperature, which results in the lowest power losses across the complete operating range and offers up to 20% lower RDS(ON) under real-life operation at high temperatures compared to competition.

Additionally, all GeneSiC MOSFETs have the highest-published 100%-tested avalanche capability, 30% longer short-circuit withstand time, and tight threshold voltage distributions for easy paralleling, GeneSiC MOSFETs are ideal for highpower, fast-time-to-market applications.

Navitas’ latest 4.5 kW high-power density AI Server PSU reference design in CRPS185 form-factor, showcases the 650

V-rated, 40mOhms G3F FETs for an Interleaved CCM TP PFC topology. Alongside the GaNSafe™ Power ICs in the LLC stage, a power density of 138 W/inch3 and peak efficiency above 97% is realized, which comfortably achieves ‘Titanium Plus’ efficiency standards, now mandatory in Europe.

For the EV market, 1,200 V/34 mOhm (G3F34MT12K) G3F FETs enable Navitas’ new 22 kW, 800V Bi-Directional OBC and 3KW DC-DC converter to achieve a superior power density of 3,5 kW/L and a peak efficiency of 95.5%.

“G3F sets a new standard for efficient, coolrunning SiC performance, coupled with high reliability and robustness for highpower, high-stress systems,” noted Dr. Sid Sundaresan, Senior Vice President of SiC Technology and Operations. “We’re pushing the boundaries of SiC, with up to 600 kHz switching speeds, and hard-switching figures-of-merit up to 40% better than competition.”

Navitas Semiconductor www.navitassemi.com

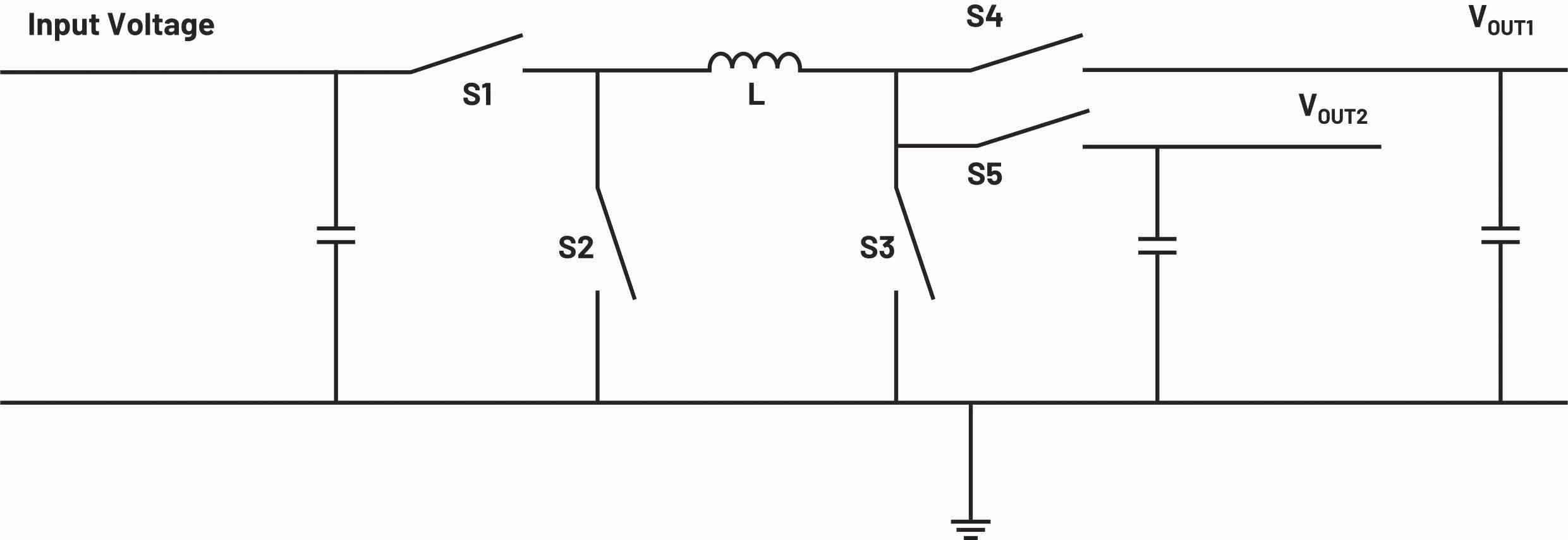

This article focuses on the Analog Devices MAX15258, which is designed to accommodate up to two MOSFET drivers and four external MOSFETs in single-phase or dual-phase boost/inverting-buck-boost configurations. It is possible to combine two devices for triple-phase or quad-phase operation, achieving higher output power and efficiency levels.

Author: Rolf HornInginer de aplicații

DigiKey

The telecommunications sector has become an important element of modern society and instantaneous global communication. Whether for a phone call, text message, or web command, telecom equipment ensures reliable connections. The power supply operating behind the scenes is an essential component that is rarely acknowledged.

MEETING THE NEED OF INCREASED POWER DEMAND

The power demand within the telecommunications industry has grown over time, driven by developments in technology,

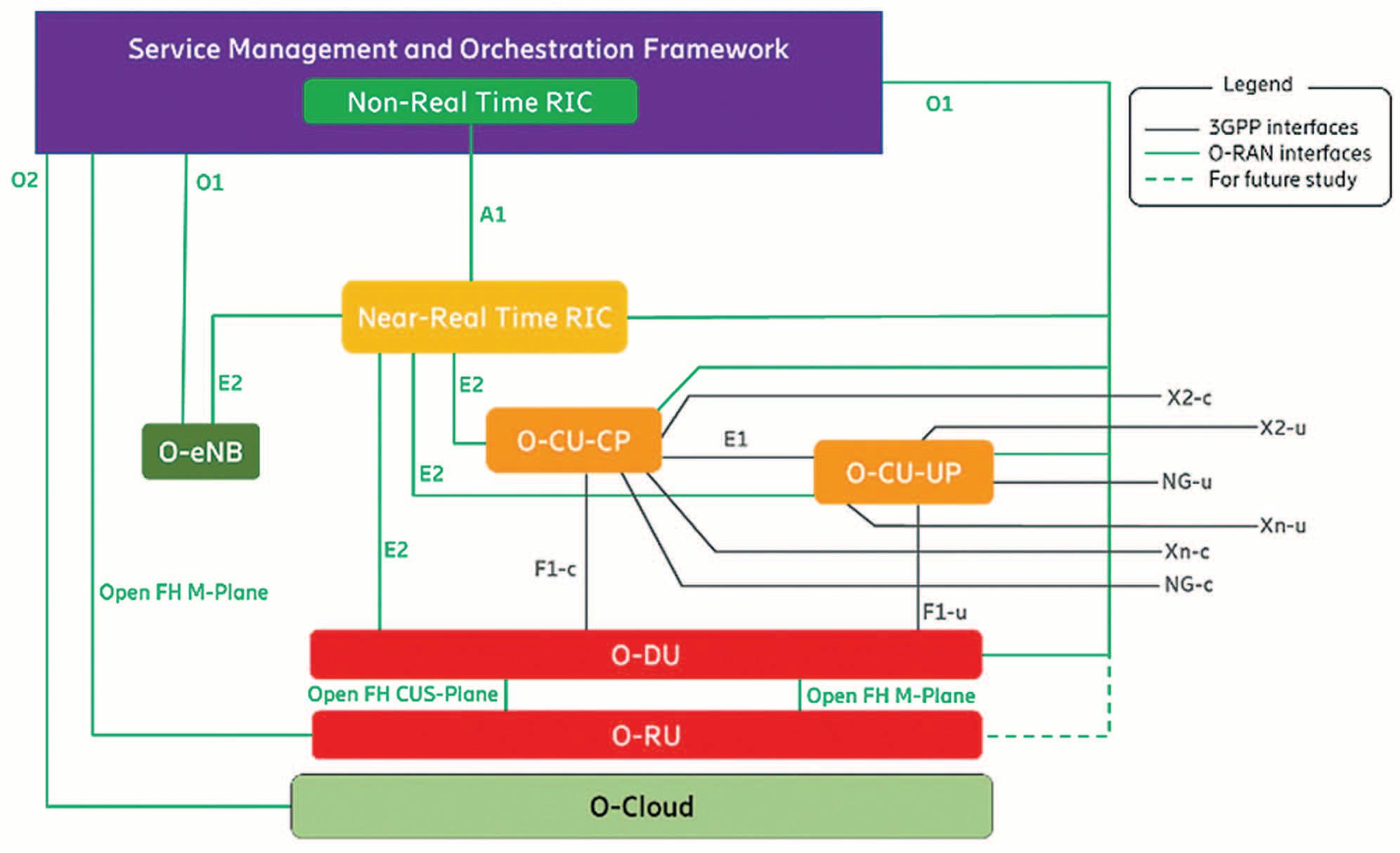

heightened network traffic, and the expansion of telecommunications infrastructure. The transition from third generation (3G) to fourth generation (4G) and fifth generation (5G) networks has led to advanced and high power equipment. The deployment of 5G technology has had a significant impact on the power requirements of base stations and cell towers. Base stations, particularly those in urban areas, require higher power levels to support the increased number of antennas and radio units needed for massive MIMO (Multiple Input, Multiple Output) configurations and beamforming.

Redundancy is another crucial factor. Power supplies must be designed with redundancy in mind, often including backup power sources like batteries or generators to ensure uninterrupted operation in case of power outages.

Compared to previous generations of wireless networks, the deployment of 5G mobile technology introduces several changes to power device requirements. For 5G to deliver on its promise of reliable, high speed, and low latency communication, some criteria must be addressed.

POWER AMPLIFIER REQUIREMENTS

• Support a broad spectrum of frequency bands, including sub-6 GHz and mmWave (millimeter wave) frequencies, which present unique challenges for signal propagation.

• Accommodate wider signal bandwidths and higher power levels, as well as providing linear amplification to prevent distortion of high-data-rate signals.

• Operate efficiently to minimize power consumption and heat generation, especially for battery-powered devices and remote small cells.

• Include a lightweight, compact form factor that can fit into small enclosures, such as small cell sites and user equipment.

• Incorporate advanced materials and technologies such as semiconductor devices made of Gallium Nitride (GaN) and Silicon Carbide (SiC) to provide increased power density, enhanced performance, and increased operating frequencies.

For historical, practical, and technical reasons, telecom systems typically utilize a48VDC power supply. In the event of a grid malfunction or other emergency, telecommunications networks require dependable backup power sources.

Commonly used for reserve power, leadacid batteries can also operate at -48VDC Using the same voltage for both primary and backup power makes it easier to design and maintain backup systems. Additionally, lower voltages such as -48VDC are safer for personnel working with telecom equipment, reducing the risk of electrical shock and injury. Power supplies for telecommunications equipment must meet specific operational requirements to ensure reliability and efficiency.

Here are some important specifications:

• Input voltage range: The power supply should be designed to tolerate a broad input voltage range.

• Voltage regulation: The power supply must provide a stable and regulated output voltage per the requirements of the telecom equipment.

• High efficiency: Power supplies should be highly efficient to reduce power loss and energy consumption. Efficiencies of at least 90% are typical.

• Redundancy: To ensure uninterrupted operation, power supplies frequently include redundancy features such as N+1 where an additional power supply is used. If one fails, the other can assume the burden.

• Hot-swappable: In mission-critical installations, power supplies should be hot-swappable, assuring minimal downtime during replacement or maintenance.

• High reliability: The power supply should be equipped with protection mechanisms to avert damage caused by adverse operating conditions, such as overcurrent, overvoltage, and short-circuits.

The active-clamp forward converter (ACFC) is a DC/DC converter configuration common in power supply systems, and it is primarily utilized for converting48V DC to positive voltage levels. The ACFC is a voltage conversion circuit that integrates characteristics from the forward converter and the active-clamp circuit to enhance efficiency.

This technology is prevalent in power supply systems for telecommunications and data center apparatus. The central element of the ACFC is a transformer (Figure 1).

Block diagram of a power supply stage for 5G applications.

The main winding of the transformer receives the input voltage, resulting in the induction of a voltage in the secondary winding. The output voltage of the transformer is determined by its turn ratio.

The active-clamp circuit, which incorporates supplementary semiconductor switches and a capacitor, regulates and governs the energy contained inside the leakage inductance of the transformer. When the primary switch is off, the energy stored in the leakage inductance is redirected to the clamp capacitor, thereby preventing voltage spikes. This practice mitigates the strain on the primary switch and enhances operational effectiveness. The voltage from the transformer’s secondary winding is rectified by a diode, and the output voltage is smoothed by an output filter capacitor. Finally, ACFC operates with soft switching, meaning that switching transitions are smoother and produce less noise. This results in reduced electromagnetic interference (EMI) and lower switching losses.

The ACFC circuit reduces voltage spikes and stress on components, leading to improved efficiency, especially at high input-to-output voltage ratios. Moreover, it can handle a wide range of input voltages, making it suitable for telecom and data center applications with varying input voltages.

Disadvantages of the active clamp circuit include the following:

• If not constrained to a maximum value, an increased duty cycle can result in transformer saturation or additional voltage stress on the main switch, necessitating the precise sizing of the clamp capacitor.

• ACFC is a single-stage DC-to-DC converter. As the power level rises, the advantages of a multiphase design for power intensive applications such as telecom will increase.

• An active clamp forward design cannot be scaled to higher output power and maintain similar performance.

© ADI

Analog Devices’ MAX15258 is a highvoltage multi-phase boost controller with an I2C digital interface designed for telecom and industrial applications. The device features a wide input voltage range of 8V to 76V for boost configuration and -8V to -76V for inverting buck/boost configuration. The output voltage range, from 3.3V to 60V, covers the requirements of various applications, including telecom devices.

A typical application of this versatile IC is the power supply for a 5G macrocell or femtocell shown in Figure 2.

The hot-swap feature is ensured by a negative voltage hot-swap controller, such as ADI’s ADM1073, powered by -48VDC. The same voltage supplies the MAX15258 buck/boost converter, which is capable of providing up to 800W of output power.

The MAX15258 is designed to support up to two MOSFET drivers and four external MOSFETs in boost/inverting-buck-boost single-phase or dual-phase configurations. It also combines two devices for triple-phase or quad-phase operation. It has an internal high-voltage FB level shifter for differentially sensing the output voltage when configured as an invertingbuck-boost converter. Through a dedicated reference input pin or via an I2C digital interface, the output voltage can be set dynamically.

An external resistor can be used to adjust the internal oscillator, or the regulator can be synchronized with an external clock to maintain a constant switching frequency. Switching frequencies from 120 kHz to 1 MHz are supported. The controller is also protected against overcurrent, output overvoltage, input undervoltage, and thermal shutdown.

The resistor at the OVP pin designates the number of phases to the controller. This identification is used to determine how the controller responds to the primary phase's multiphase clock signal.

In a quad-phase converter, the two phases of the MAX15258 controller or the target are interleaved by 180°, whereas the phase shift between the controller and target is 90° (Figure 3).

In multiphase operations, the MAX15258 monitors the low-side MOSFET current for active phase current balancing. As feedback, the current imbalance is applied to the cycle-by-cycle current sensing circuitry to help regulate the load current. Doing so ensures equitable distribution between the two phases. Unlike forward converter designs, designers do not need to account for a possible 15% to 20% phase imbalance during the design calculation stages when using this IC.

In triple-phase or quad-phase operation, the average per-chip current is transmitted between the controller and target via dedicated differential connections. The current-mode controller and target devices regulate their respective currents so that all phases equitably share the load current.

The quad-phase interleaved inverting buck-boost power supply shown in Figure 4 is suitable for applications requiring large amounts of power. The CSIO+ and CSIO– signals connect the two controllers, and the SYNC pins are connected to assure clock synchronization for the phase interleaving scheme with coordinated phases.

The MAX15258 is a low-frequency boost converter. This reduces the converters' primary source of power loss - switching losses. Because each converter operates in its low-loss area at low frequency, this offers high output power at a high equivalent total frequency. This makes it the go-to device for converting -48VDC Operating with a stable duty cycle, it obtains a high output power with extremely high efficiency. Figure 5 shows the efficiency curves of a coupled inductor-based MAX15258 800W reference design for various combinations of VIN and VOUT. As a result of reduced conduction losses, the plots plainly display efficiency figures more than 98%.

Power supplies play an important role in the telecommunications industry. Due to their ability to attain high efficiency and minimize power losses, active clamp forward converters (ACFCs) are favored in telecom power supply designs. However, inherent limitations can hinder their efficacy in specific circumstances. To overcome the limitations of active clamp forward converters, a new generation of power supply technologies has emerged, offering enhanced efficiency, increased power density, and simplified control mechanisms. In the telecom industry, these novel solutions pave the way for more advanced and optimized power supplies.

Despre autor

Rolf Horn, applications engineer at DigiKey, has been in the European Technical Support group since 2014 with primary responsibility for answering any development and engineering related questions from customers in EMEA, as well as writing and proof-reading German articles and blogs on DigiKey’s TechForum and maker.io platforms. Prior to DigiKey, he worked at several manufacturers in the semiconductor area with focus on embedded FPGA, microcontroller and processor systems for industrial and automotive applications. Rolf holds a degree in electrical and electronics engineering from the University of Applied Sciences in Munich, Bavaria and he started his professional career at a local electronics products distributor as system-solutions architect to share his steadily growing knowledge and expertise as trusted advisor.

DigiKey www.digikey.ro

Author: Shingo Kojima

Sr Principal Engineer of Embedded Processing Renesas Electronics

Author: Shingo Kojima

Sr Principal Engineer of Embedded Processing Renesas Electronics

Overview

As the working population decreases due to falling birthrates and a growing proportion of the population being elderly, advanced artificial intelligence (AI) processing, such as recognition of the surrounding environment, decision of actions, and motion control, will be required in various aspects of society, including factories, logistics, medical care, service robots operating in the city, and security cameras. Systems will need to handle advanced artificial intelligence (AI) processing in real time in various types of programs. In particular, the system must be embedded within the device to enable a quick response to its constantly changing environment.

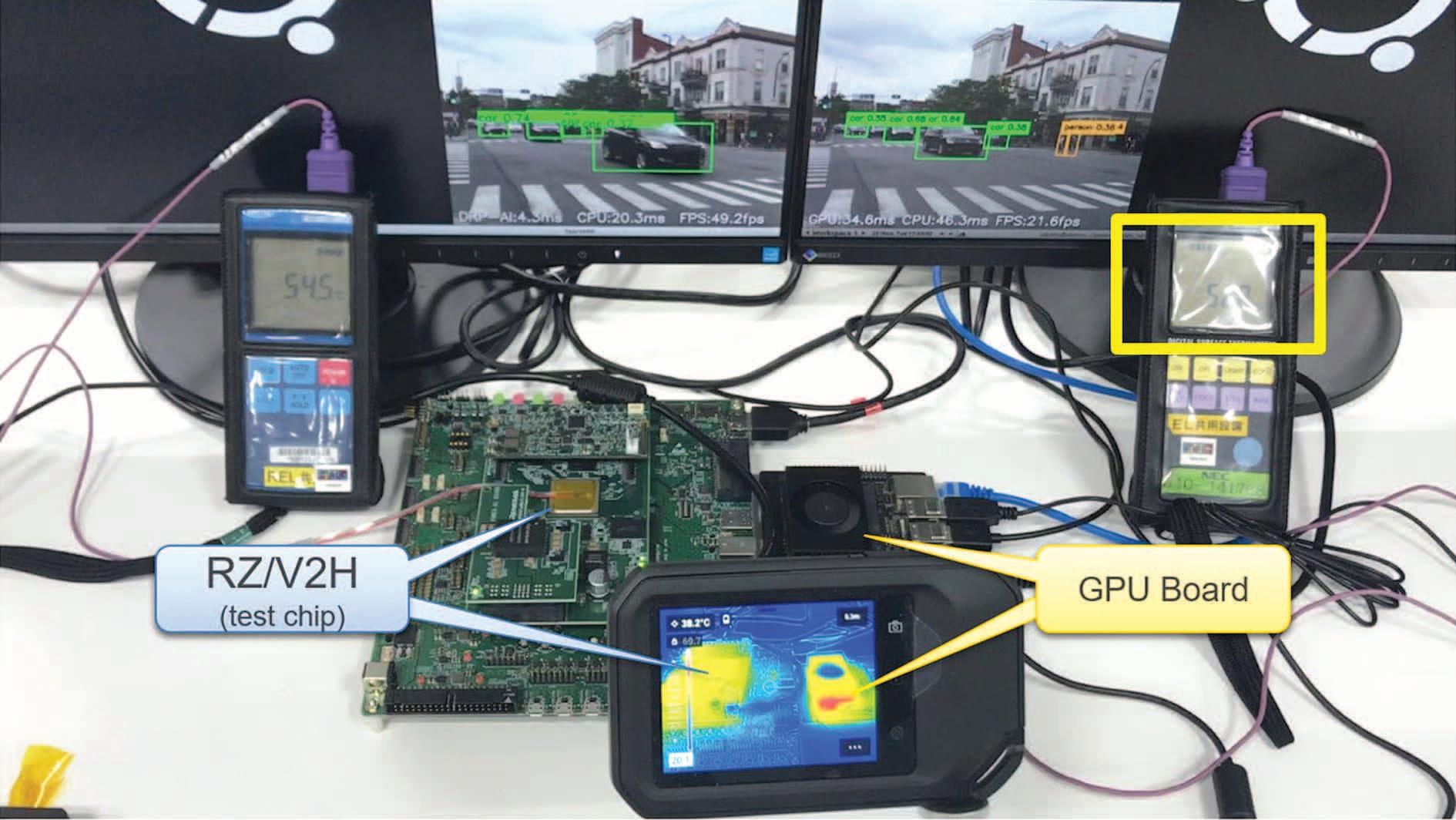

This article introduces the RZ/V2H MPU which enables both vision AI and real-time control capabilities. The RZ/V2H is able to respond to the further evolution of AI and the sophisticated requirements of these applications This article introduces how the RZ/V2H solves heat generation challenges, enables high real-time processing speed, and realizes higher performance and lower power consumption for AI-equipped products.

However, AI chips. At the same time consuming less power while performing advanced AI processing in embedded devices with strict limitations on heat generation. To meet these market needs, Renesas developed DRP-AI3 (Dynamically Reconfigurable Processor for AI3) as an AI accelerator for high-speed AI inference processing combining low power and flexibility required by the edge devices. This reconfigurable AI accelerator processor technology, cultivated over many years, is embedded in the RZ/V series of MPUs targeted at AI applications.

RZ/V2H is a new high-end product of the RZ/V series, achieving power efficiency approximately 10 times higher than that of the previous products.

The RZ/V2H is able to respond to the further evolution of AI and the sophisticated requirements of applications such as robots. This article introduces how the RZ/V2H solves heat generation challenges, enables high real-time processing speed, and realizes higher performance and lower power consumption for AI-equipped products.

DRP-AI3

As a typical technology for improving AI processing efficiency, pruning is available to omit calculations that do not significantly affect recognition accuracy. However, it is common that calculations that do not affect recognition accuracy randomly exist in AI models.

This causes a difference between the parallelism of hardware processing and the randomness of pruning, which makes processing inefficient.

To solve this issue, Renesas optimized its unique DRP-based AI accelerator (DRP-AI) for pruning. By analyzing how pruning pattern characteristics and a pruning method are related to recognition accuracy in typical image recognition AI models

(CNN models), we identified the hardware structure of an AI accelerator that can achieve both high recognition accuracy and an efficient pruning rate, and applied it to the DRP-AI3 design. In addition, software was developed to reduce the weight of AI models optimized for this DRP-AI3.

This software converts the random pruning model configuration into highly efficient parallel computing, resulting in higher-speed AI processing. In particular, Renesas' highly flexible pruning support technology (flexible N:M pruning technology), which can dynamically change the number of cycles in response to changes in the local pruning rate in AI models, allows for fine control of the pruning rate according to the power consumption, operating speed, and recognition accuracy required by users.

Heterogeneous Architecture Features in which DRP-AI3, DRP, and CPUs Operate Cooperatively

• Multi-threaded and pipelined processing with AI accelerator(DRP-AI3), DRP, and CPUs

• Low jitter and high speed robot applications with DRP (dynamically reconfigurable wired logic hardware)

Service robots, for example, require advanced AI processing to recognize the surrounding environment. On the other hand, algorithm-based processing that does not use AI is also required for deciding and controlling the robot's behavior. However, current embedded processors (CPUs) lack sufficient resources to perform these various types of processing in real time.

Renesas solved this problem by developing a heterogeneous architecture technology that enables the dynamically reconfigurable processor (DRP), AI accelerator (DRP-AI3), and CPU to work together.

As shown in Figure 1, the dynamically reconfigurable processor (DRP) can execute applications while dynamically switching the circuit connection configuration of the arithmetic units on the chip at each operating clock according to the content to be processed. Since only the necessary arithmetic circuits are used, the DRP consumes less power than with CPU processing and can achieve higher speed. Furthermore, compared to CPUs, where frequent external memory accesses due to cache misses and other causes will degrade performance, the DRP can build the necessary data paths in hardware ahead of time, resulting in less performance degradation and less variation in operating speed (jitter) due to memory accesses.

The DRP also has a dynamic reconfigurable function that switches the circuit connection information each time the algorithm changes, enabling processing with limited hardware resources, even in robotic applications that require processing of multiple algorithms.

The DRP is particularly effective in processing streaming data such as image recognition, where parallelization and pipelining directly improve performance. On the other hand, programs such as robot behavior decision and control require processing while changing conditions and processing details in response to changes in the surrounding environment. CPU software processing may be more suitable for this than hardware processing such as in the DRP.

It is important to distribute processing to the right places and to operate in a coordinated manner. Renesas’ a heterogeneous architecture technology allows the DRP and CPU to work together.

to a maximum of 80 TOPS when compared to models before pruning. This is about 80 times higher than the processing performance of the previous RZ/V products, a significant performance improvement that

In AI-MPUs, a portion of the image processing program is offloaded to the DRP, thereby contributing to the improvement of the overall system processing time. (Figure 4)

An overview of the MPU and AI accelerator (DRP-AI3) architecture is shown in Figure 2. Robotic applications use a sophisticated combination of AI-based image recognition and non-AI decision and control algorithms. Therefore, a configuration with a DRP for AI processing (DRP-AI3) and a DRP for non-AI algorithms will significantly increase the throughput of the robotic application.

RZ/V2H equipped with this technology has achieved a maximum of 8 TOPS (8 trillion sum-of-products operations per second) for the processing performance of the AI accelerator. Furthermore, for AI models that have been pruned, the number of operation cycles can be reduced in proportion to the amount of pruning, thus achieving AI model processing performance equivalent

can sufficiently keep pace with the rapid evolution of AI (Figure 3).

On the one hand, as AI processing speeds up, the processing time for algorithmbased image processing without AI, such as pre- and post-AI processing is becoming a relative bottleneck.

In terms of power efficiency, the performance evaluation of the AI accelerator demonstrated the world's top level power efficiency (approximately 10 TOPS per watt) when running major AI models. (Figure 5)

We also showed that the same AI realtime processing could be performed on an evaluation board equipped with the RZ/V2H, without a fan at temperatures comparable to competitor products equipped with fans. (Figure 6)

For example, SLAM (Simultaneously Localization And Mapping), one of the typical robot applications, has a complex configuration that requires multiple program processes for robot position recognition in parallel with environment recognition by AI processing. The Renesas DRP enables the robot to switch programs instantaneously, and parallel operation

with an AI accelerator and CPU has proven to be about 17 times faster than CPU operation alone, and to reduce power consumption to 1/12 the level of CPU operation alone.

Conclusion

Renesas developed RZ/V2H, a unique AI processor that combines the low power and flexibility required by endpoints, with processing capabilities for pruning

AI models, and 10 times more power efficient (10 TOPS/W) than the previous products.

Renesas will release products in a timely manner responding to the AI evolution,

Architecture Speeds Up Image Recognition Processing (Measured by Test Chip).

which is expected to become increasingly sophisticated, and will contribute to deploy systems that respond to end-point products in a smart and real-time manner.

Related Information

• RZ/V2H: https://www.renesas.com/rzv2h

• DRP-AI: Renesas' proprietary AI accelerator that combines high AI inference performance with low power consumption

■ Renesas www.renesas.com

Mouser Electronics, Inc., the New Product Introduction (NPI) leader empowering innovation, has recently released several new eBooks in collaboration with valued manufacturing partner Analog Devices, Inc. (ADI). The eBooks focus on a wide range of topics, such as how production facilities can achieve greater productivity through a flexible manufacturing approach, the technologies being used to support sustainable manufacturing practices, embedded security concepts, and the technological advances in digital factories.

In 10 Experts on Flexible Manufacturing, subject matter experts from ADI and other technology companies discuss how today's sensors, robotic subsystems, and AI-enabled compute units allow factories to adapt fabrication and production with more flexibility. This enables production facilities to achieve greater throughput, product quality and costefficiency than ever before. At the same time, improved processes and control can help facilitate a more sustainable manufacturing process that wastes less energy and materials. The eBook also highlights many of ADI's products that help bring flexible manufacturing to life.

In Engineering a More Sustainable Future: Redefining Industrial Efficiency in the Digital Age, experts from Mouser and ADI explore a wide range of topics related to industrial efficiency. The eBook features more than 10 articles, including a detailed analysis of motor encoders, a single-pair Ethernet condition monitoring vibration sensing solution, and the redesign of an RTD-based temperature sensor for the smart factory age. Several chapters include helpful infographics, as well as links to relevant products from ADI.

Today's embedded devices are expected to measure, store, and communicate data and upgrade firmware securely, but each function represents a system vulnerability point. In Embedded Security: Keeping Edge Data Safe, experts from ADI and other companies take a deep look at embedded security concepts and their importance. ADI has a long history in the field of embedded security and offers customers a broad portfolio of solutions, many of which are highlighted in the eBook.

To learn more about ADI, visit: https://www.mouser.com/manufacturer/analog-devices.

To view more eBooks created by Mouser and ADI, visit: https://analog.mouser.com/adi-ebooks

To browse Mouser's entire manufacturer eBook library, visit: https://resources.mouser.com/manufacturer-ebooks.

■ Mouser Electronics | www.mouser.com

Electronics, Inc., the authorized global distributor with the newest electronic components and industrial automation products, is an authorized global distributor of solutions from MEAN WELL, a leading global standard power supply manufacturer. Mouser offers a comprehensive portfolio of MEAN WELL’s power solutions, with over 4,500 parts in stock and over 35,000 parts available to order.

The MEAN WELL LOP-200 and LOP-300 PCB-type power supplies, available from Mouser, feature a low profile, a comprehensive 12 to 54V voltage range, and power of up to 200 or 300 watts, respectively. The LOP-400, LOP-500, and LOP-600 offer the same voltage range and power of 600, 750 or 900 watts. These power supplies provide compliance with OVCIII and simultaneous adherence to various safety standards such as 62368-1/60601-1/615581/60335-1. These certifications make them suitable for a broad range of applications, including factory automation, medical devices, telecommunications equipment, household devices, and more.

The NGE series are wall-mounted interchangeable AC adapters with global certifications. These green adapters are available with a fixed US plug, a fixed EU plug, or with interchangeable plugs. The NGE series adapters offer power ratings of 12W, 18W, 30W, 45W, 65W, and 90W and are available

with five types of interchangeable AC plugs (European, USA, UK, Australian, and Chinese), making them ideal for travel use. Multiple protections are featured in these adapters, including short circuit, overload, and overvoltage, and all these adapters are approved for ITE, medical, household, and industrial appliance safety regulations.

DDRH-120 and DDRH-240 DIN-rail DC/DC converters offer superior EMC performance, high altitude 5000M operation, and compliance with the IEC/EN 62109-1 PV safety standard. Both converters come with complete protection, including undervoltage and reverse polarity (no damage) for the DC input, as well as short circuit, overload, overvoltage, and overtemperature for the output. These DC-DC converters are suitable for photovoltaic power generation, energy storage, charging stations, industrial control systems, and other applications with high- and low-voltage DC conversion requirements.

The MEAN WELL XLN and XLC series LED power supplies, designed for general indoor lighting and commercial luminaires, feature a rugged plastic housing. These LED power supplies are available in 25W, 40W, and 60W power ratings. The XLN LED power supplies include an independent wiring output design, fully encapsulated to meet IP67 waterproof function. The output and dimming circuits are isolated and comply with double-isolation and safety voltage (SELV) design to ensure user safety. The entire series has complete international certification and full-range voltage input (UIL8750 class 2/class P).

Mouser Electronics has been an authorized distributor of MEAN WELL power solutions since 2007. Mouser received the US Distributor of the Year Award from MEAN WELL for 2023 and a Sustainability Award from the MEAN WELL Sustainable Development Group for 2022.

To learn more about MEAN WELL products available from Mouser, visit www.mouser.com/manufacturer/meanwell

■ Mouser Electronics | www.mouser.com

Compact 10, 30 and 40 Watt railway DC/DC converters with ultra-wide 12:1 input voltage range

The THN 10UIR, TEN 30UIR and TEN 40UIR are railway approved series of high performance DC/DC converters with ultra-wide 12:1 input voltage range and output power of 10, 30 and 40 Watts respectively. The compact, fully encapsulated converters provide an increased resistance against shock/vibration, and thermal shock. A high efficiency of up to 90% give the converters an effective temperature range of –40°C up to +70°C (with heatsink up to 80°C) without derating. Thanks to the dedicated holdup capacitor connection, they meet extended holdup-time requirements without the need for bulky input capacitors. The approvals according to standards EN 50155 and EN 61373 qualify them for railway and transportation systems. Additional qualification for the fire behavior of components according to EN 45545-2 and the safety approval according to IEC/EN/UL 62368-1 support a potential compliance test of the application. All models offer an I/O-isolation voltage of 3’000 VDC and feature an active under voltage lockout function, remote on/off and adjustable outputs to ensure that these converters fit in any ruggedized applications.

• Compact 1″×1″ (THN 10UIR) and 2″×1″ package (TEN 30UIR and TEN 40UIR)

• Ultra-wide input voltage range 9–75, 14–160 VDC

• EN 50155 and EN 61373

• Qualification for fire behavior according to EN 45545-2

• I/O-isolation 3‘000 VDC

• High efficiency up to 90%

• Under voltage lock out circuit

• Adjustable output voltage and Remote On/Off

URL Landingpage: https://www.tracopower.com/thn10uir-ten30uir-ten40uir

URL Video:

https://youtu.be/MnSrBg1LW6Y?si=dc_3w9eb9G140pMT

■ Traco Power | www.tracopower.com

Arm Neoverse CSS-based CPU chiplet with ultrahigh-speed interfaces and advanced packaging delivers scalable performance for AI, HPC and networking infrastructure

Alphawave Semi, a global leader in high-speed connectivity and compute silicon for the world’s technology infrastructure, has collaborated with Arm on the development of an advanced compute chiplet built on Arm® Neoverse™ Compute Subsystems (CSS) for artificial intelligence/machine learning (AI/ML), high-performance compute (HPC), data centre and 5G/6G networking infrastructure applications. The development follows last year’s announcement that Alphawave Semi joined Arm Total Design, an ecosystem building custom silicon solutions based on Arm Neoverse CSS.

Alphawave Semi’s chiplet-based custom silicon design platform adds a differentiator in our portfolio that includes IO extension chiplets, memory chiplets, and compute chiplets, as well as Alphawave Semi’s ultra-high-speed connectivity IP and advanced packaging capabilities. This compute chiplet lineup features an Arm Neoverse N3 CPU core cluster and the Arm Coherent Mesh Network (CMN) ensuring efficient, scalable performance. Available on industry-leading process nodes, the technology allows customers to accelerate development and reduce the time-to-market (TTM) of a new generation of custom system-on-chip (SoC) technologies. These advanced SoCs support the rapid deployment of high-performance digital infrastructure, enabling the creation of custom silicon solutions tailored to specific needs.

In collaboration with Arm, Alphawave Semi enhances this setup with their advanced packaging techniques and a leading-edge portfolio of connectivity technologies, including PCIe Gen 6.0 and 7.0, Universal Chiplet Express (UCIe), 112/224G Ethernet and HBM subsystems. This strategic integration ensures that the Arm-based compute chiplet delivers robust performance and flexibility, catering to next-generation HPC, data center, AI/ML, and 5G/6G infrastructure needs while accelerating time-to-market for customers.

■ Alphawave Semi | https://awavesemi.com

Power Integrations, the leader in high-voltage integrated circuits for energy-efficient power conversion, today enhanced its hardware-software bundle for brushless DC motors (BLDC) with BridgeSwitch™-2, a new high-voltage integrated half-bridge (IHB) motor-driver IC family targeting applications up to 1 HP (746 W). The new ICs, which feature high- and low-side drivers and advanced FREDFETs with integrated lossless current sensing, deliver inverter efficiency of up to 99 percent. The IHB architecture eliminates hot spots, which increases design flexibility and reliability, slashes component count and saves PCB area. BridgeSwitch-2 is supported by Power Integrations’ MotorXpert™ software suite which includes single-phase trapezoidal control and three-phase sensor-less Field Oriented Control (FOC) modules, speeding inverter development.

BridgeSwitch-2 ICs handle operational exceptions in hardware, which permits the use of IEC 60730 Class A safety software, reducing certification time by months. Quiescent BLDC inverters can be ordered into sleep-mode, reducing driver power consumption to less than 10 mW; this leaves more power available under regulated standby power limits to be allocated for loads such as network access and monitoring.

Cristian Ionescu-Catrina, product marketing manager at Power Integrations, said: “The low standby consumption of BridgeSwitch-2-based motor drives enables designers to meet new and emerging EU ERP regulations. BridgeSwitch-2 ICs are also far more efficient than IGBT based IPMs across the entire load range.” He continued: “From startup to perform-

BLDC motor hardware-software combo slashes inverter sleep-mode consumption to less than 10 mW, expands output power to 1 HP

ance optimization, the GUI-based tool, terminal emulator and MISRA C-compliant code library of MotorXpert greatly simplifies the design process, allowing the motor architecture to be optimized in real-time without repeated firmware updates.

BridgeSwitch-2 is microprocessor agnostic, easing its adoption into existing systems – this is important as engineers update designs to meet more stringent standby regulations.”

BridgeSwitch-2 ICs address a power range of 30 to 746 W (1 HP), encompassing a broad range of applications including heat exchanger fans, refrigerator compressors, fluid and circulation pumps, gas boiler combustion fans, washing machine drums and kitchen blenders and mixers. The IHB architecture reduces component count by 50 percent and PCB space by 30 percent over discrete designs by eliminating shunt resistors and associated signal conditioning circuits. Shunt losses are also eliminated, improving efficiency. Precise motor control is achieved with the built-in real-time reporting of phase current (IPH) information. Accurate turn-on/off gate drive and a soft-body diode result in a typical EMI profile 10 dB lower than existing drivers, so a smaller EMI filter can be selected.

BridgeSwitch-2 ICs feature built-in DC overvoltage protection and current limits that protect the inverter and the system without relying on system software. The choice of error-flag or comprehensive fault bus reporting supports a range of system requirements. Emerging use-cases like failure prediction are now possible with the high accuracy of the built-in IPH information and comprehensive reporting via the fault bus.

BridgeSwitch-2 motor drives use built-in, hardware-based lowand high-side over-current protection to meet IEC 60335-1 Class A requirements. BridgeSwitch-2 also works without an auxiliary power supply, further reducing PCB area and component count.

■ Power Integrations | www.power.com

Packages with enhanced thermal performance improve power density and reliability, while power modules with a wide range of topology options simplify and accelerate high-performance design.

WeEn Semiconductors, has unveiled new families of silicon carbide (SiC) MOSFETs and Schottky Barrier Diodes (SBDs) in TSPAK packaging at this year’s PCIM Europe exhibition and conference.

WeEn Semiconductor’s new TSPAK MOSFET and SBD devices address the demand for high-performance, compact and reliable power management in applications ranging from automotive charging and on-board charger applications to photovoltaic (PV) inverters and high-power-density power supplies (PSUs).

Offering a variety of configuration options for maximum design flexibility, the company’s new SiC modules are ideal for applications such as EV charging, energy storage systems, PV inverters, motor drives, industrial PSUs and test instrumentation.

Originally developed for automotive applications, TSPAK devices combine innovative top-side cooling capability with low thermal impedance to deliver enhanced thermal performance. By removing the PCB thermal resistance from the thermal dissipating path, the Junction-Ambient thermal resistance improves by 16-19%. This supports high reliability by enabling a greater number of power cycles than conventional packaging as well as providing the increased power densities demanded by compact system designs. Low circuit inductance and low EMC noise help to improve performance and reduce filtering requirements. The WeEn Semiconductors family of TSPAK MOSFETs features 650V, 750V, and 1200V options with resistances ranging from 12mΩ to 150mΩ. TSPAK SBDs are available with current ratings of 10 to 40A in 650V, 750V, and 1200V variants.

For more information, please explore WeEn Semiconductors’ product portfolio here.

■ WeEn Semiconductors | www.ween-semi.com/en

Author: Edgar Schäfer, Field Application Engineer Automotive Business Unit (ABU) Rutronik

Author: Edgar Schäfer, Field Application Engineer Automotive Business Unit (ABU) Rutronik

Among the biggest challenges facing electric vehicle users are battery life and range. One way to increase both is to improve the efficiency of the entire vehicle. However, there are major consumers in the car standing in the way. One of them is the air conditioning system. The electric powertrain has less power loss than an internal combustion engine and therefore has less waste heat that can be used to heat the interior. This means that in electric vehicles, additional electric heating is required to achieve or maintain the desired temperature.

Ways to create an efficient air conditioning system

One way to increase the efficiency of the air conditioning system is to reuse the air in the interior (recirculation). In the winter, heated air is reheated, while in the summer, conditioned air is recooled and fed back into the interior. Since only a smaller temperature difference needs to be bridged, less energy is required.

How CO2 sensors in electric vehicles help maintain healthy air quality inside the vehicle while extending battery life and range.

A major disadvantage of this method is that no fresh air is supplied to the interior. If the used air is not renewed, CO2 levels increase and the air quality inside

the vehicle gradually deteriorates. This may result in headaches, fatigue, and a less-than-ideal driving experience.

This represents a potential source of danger in road traffic, as ventilation measures are necessary above CO2 levels of 1000 ppm.

One solution is to use CO2 sensors for control purposes. When integrated into the vehicle’s air conditioning system, they monitor the air quality inside the vehicle. If CO2 values are too high, a warning can be output or fresh air can be added directly to maintain healthy air quality.

Choosing the appropriate sensor for electric vehicle applications depends on several factors. These include the size of the vehicle, the desired measurement range, and the type of measurement.

Furthermore, the dimensions, performance, and cost of the sensors are crucial.

Small and precise CO2 sensor

A CO2 sensor with a particularly small form factor (14 mm × 13.8 mm × 7.5 mm) is the Xensiv PAS from Infineon (Figure 1). It reduces the space requirement by more than 75 percent compared to commercially available CO2 sensors.

At the same time, it offers precise CO2 measurements based on MEMS technology. For example, on a printed circuit board the Xensiv PAS CO2 sensor integrates a photoacoustic converter, including a detector, an infrared source and an optical

filter, a microcontroller for signal processing and algorithms, and a MOSFET chip to drive the infrared source. The integrated microcontroller performs ppm calculations as well as advanced compensation and configuration algorithms. The result is the true CO2 content and not just a correlation. In addition, various configuration options (e.g. measurement frequency, baseline calibration) and interfaces (UART, I2C, PWM interface) are available. The spectrum for the CO2 measurement covers a range from 0 ppm to 32,000 ppm. The accuracy is ±30 ppm ±3 percent of the read measured value. The supplier guarantees it for the measurement range of 400 to 5000 ppm, which is perfectly adequate for this range of applications. This is because a typical atmosphere has a CO2 content of 400 ppm; the value inside the vehicle is typically higher.

Further advantages for customers are to be found in the production process. Infineon claims to offer the first SMD-capable CO2 sensor (SMD package, available on tape & reel) to comply with the international JEDEC standard for lead-free surface-mount reflow – for easy assembly as well as system integration even at high production volumes. The Xensiv PAS CO2 sensor also offers a high degree of flexibility thanks to a wide range of configuration options, enabling a fast time to market.

The PAS method is based on the photoacoustic effect: Gas molecules absorb light of a certain wavelength, causing them to expand. In the case of carbon dioxide, it is the 4.2 μm wavelength.

Light pulses are emitted in rapid succession by an infrared source. Only light with a 4.2 μm wavelength enters the sensor chamber via an optical filter that is specially adapted to CO2 molecules. The CO2 molecules in the sensor chamber absorb the energy.

Rapid heating and cooling causes thermal expansion and contraction. This produces a change in pressure, which is detected by the highly sensitive