In the evolving landscape of global consciousness, the concept of carbon net-zero has transcended mere environmental policy; it has become a cultural imperative. As societies grapple with the urgency of climate change, embracing sustainability has shifted from a trend to a foundational aspect of our collective identity.

Executive Mat Service has taken a leadership role In this cultural movement. Carbon netzero is part of our core values and mindset. It represents a commitment to stewardship of our planet, a recognition of our interconnectedness with the environment, and a pledge to future generations.

Kim Caron Founder / President Executive Mat Group of Companies

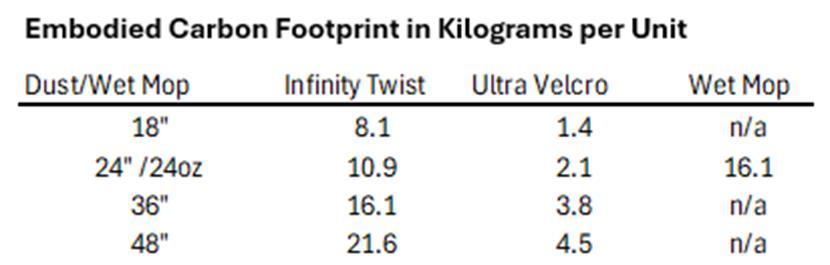

Kim Caron Founder / President Executive Mat Group of Companies

Executive Mat Service is at the forefront of achieving carbon neutrality, committed to mitigating environmental impacts and promoting a sustainable future. Our approach centers on extensive education, collaborative policy development, innovative solutions, and rigorous environmental stewardship.

Key Components of Our Strategy:

1. Scope 1 and 2 Carbon Accounting: We have established robust carbon accounting practices for Scope 1 and 2 emissions, significantly enhancing our ability to monitor and manage both direct and indirect carbon emissions.

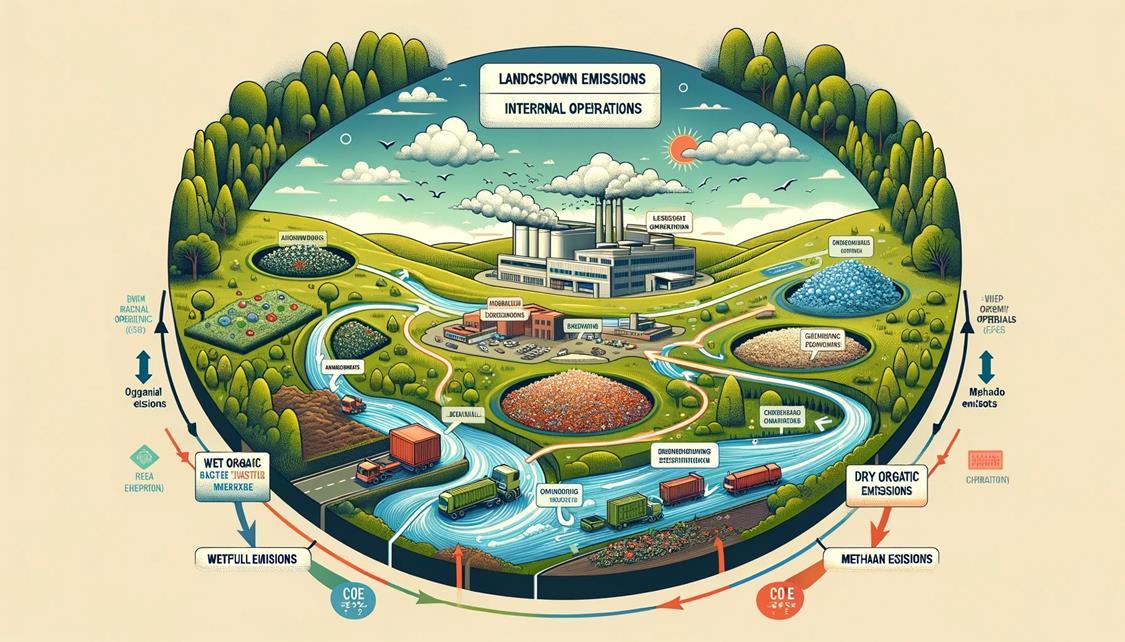

2. Innovating Scope 3 Challenges: Addressing the complexities of Scope 3 emissions, which constitute the largest portion of our carbon footprint, we have streamlined this category by focusing on "Internal Operations." This approach simplifies accounting and emphasizes that Scope 3 emissions can represent up to 80% of total emissions.

3. Emission Factor Development: By formulating specific emission factors, we've simplified the calculation and reporting of Scope 3 emissions, improving accuracy and manageability.

4. Carbon Net-Zero Education: Through targeted educational programs, we raise awareness and facilitate the transition to net-zero operations, ensuring all stakeholders grasp the essential concepts and actions required.

5. Collaboration on Policy Frameworks: In partnership with FRAS-Canada, we play a key role in creating streamlined frameworks for reporting Scope 3 emissions, enhancing both transparency and accountability.

6. Technology Innovation and Commercialization: Our associated enterprises, such as CDFSystems, Eco-Growth Environmental, Weather-Stopper, and Gravitas Energi, develop technologies that address specific environmental issues.

7. VER Marketplace Development: We have launched a marketplace for Verified Emission Reductions to encourage the adoption of technologies that reduce Scope 3 emissions and promote sustainability.

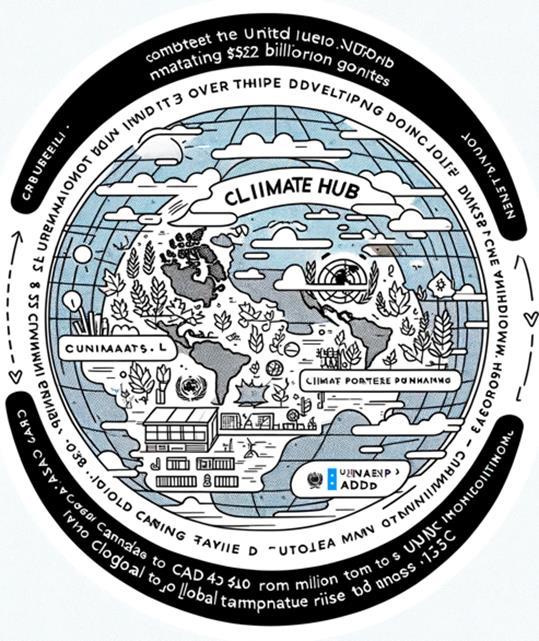

8. Advanced Methane Modeling: We utilize sophisticated mathematical models to better understand and reduce methane emissions from landfills, advancing our strategies for landfill avoidance.

9. Green Thumb Initiative: Focused on reducing landfill waste, this initiative plays a crucial role in our strategy to lower greenhouse gas emissions and foster a circular economy.

Executive Mat Service is dedicated not only to achieving carbon neutrality but also to setting an industry standard for environmental responsibility. Our integrated strategy provides a blueprint for others to emulate, demonstrating the feasibility and benefits of a comprehensive approach to carbon management.

The Green Wash Company is a fictitious entity created to highlight companies that claim a net-zero strategy set far in the future without taking genuine action. It is not intended to represent any actual company but serves to expose and critique such disingenuous practices

The Green Wash Company's purported commitment to environmental and net-zero goals appears more like a superficial effort rather than a genuine attempt to make meaningful changes. Here’s a critical assessment of their so-called sustainability initiatives:

• LED Lighting Transition: The Green Wash Company is nearing the completion of a multi-year project to switch to LED lighting across its facilities in the United States and Canada, aiming for Net Zero greenhouse gas (GHG) emissions by 2050. (Why 2050? This seems like a convenient way to defer responsibility to future generations rather than addressing the issue immediately.)

• Energy Reduction: By installing LED lights in older, more energy-intensive locations, The Green Wash Company has installed LED lighting in over 6 million square feet of space, expecting to reduce annual energy use by almost 23.3 million kilowatt-hours. (This is a mature technology that should have been implemented years ago. Boasting about it now shows a lack of genuine proactive measures.)

• CO2 Emissions Reduction: The switch to LED lighting is estimated to prevent more than 16,500 metric tons of CO2 emissions annually. (Again, this is something that should have been done years ago. It’s not a milestone to be proud of, but rather an overdue action.)

• Energy Consumption Intensity: From FY’21 to FY’22, The Green Wash Company reduced its energy consumption intensity by 7.9%, including the impact of the LED lighting transition project. (Once again, focusing on lighting. What about addressing Scope 1, 2, and 3 emissions comprehensively?)

• Beyond Lighting: The Green Wash Company is exploring other energy-efficient solutions, including testing solar technology. (What does "testing solar technology" mean? Is it a single solar panel in an obscure location? This feels disingenuous and lacks transparency.)

The Green Wash Company's approach to achieving their net-zero goal is touted as strategic and multifaceted, focusing primarily on lighting practices. (In reality, it is a joke and represents the worst form of greenwashing. They are far from making a genuine impact on sustainability.)

The world is facing an unprecedented climate emergency. Extreme weather events, rising sea levels, and catastrophic loss of biodiversity are no longer distant threats but present realities. As global temperatures soar, the urgency for climate action has never been clearer. This blog post explores how we arrived at this critical juncture and highlights how Executive Mat Service is not waiting for a distant net-zero future but is taking decisive, impactful action today.

The roots of the climate crisis lie in the Industrial Revolution, which marked the beginning of large-scale fossil fuel consumption and wide-spread use of landfills. Progress, however, came with a steep environmental cost.

1. Industrial Emissions: Factories and power plants began emitting vast quantities of carbon dioxide (CO2) and other greenhouse gases (GHGs) into the atmosphere. These emissions have trapped heat, leading to global warming.

2. Deforestation: Massive deforestation for agriculture and urban development has reduced the planet's capacity to absorb CO2, exacerbating the greenhouse effect.

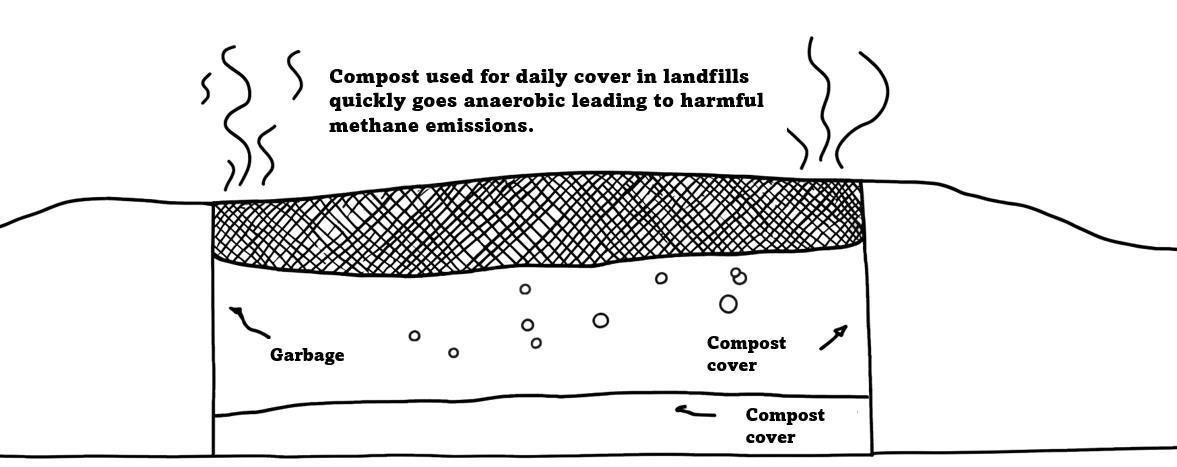

3. Waste Management: Inadequate waste management, particularly in landfills, has led to substantial methane emissions as organic waste decomposes anaerobically.

These activities have led to a dramatic increase in atmospheric GHG concentrations, resulting in the climate crisis we face today.

Executive Mat Service: Leading the Charge for Immediate Action

While many organizations are making long-term commitments to achieve net-zero emissions by 2050 or later, Executive Mat Service stands out by taking real, impactful action now. Here's how we are leading the way in climate action:

1. Carbon-Lowering Technology: We have developed the CDF low-carbon mat cleaning machine, a groundbreaking technology that significantly reduces carbon emissions within our processing facilities.

2. Landfill Waste Avoidance: Through our GREEN THUMB Initiative and the development of the Eco-Growth suite of technologies, we actively avoid landfill waste. This initiative ensures that organic waste is composted efficiently, preventing methane emissions from anaerobic decomposition in landfills.

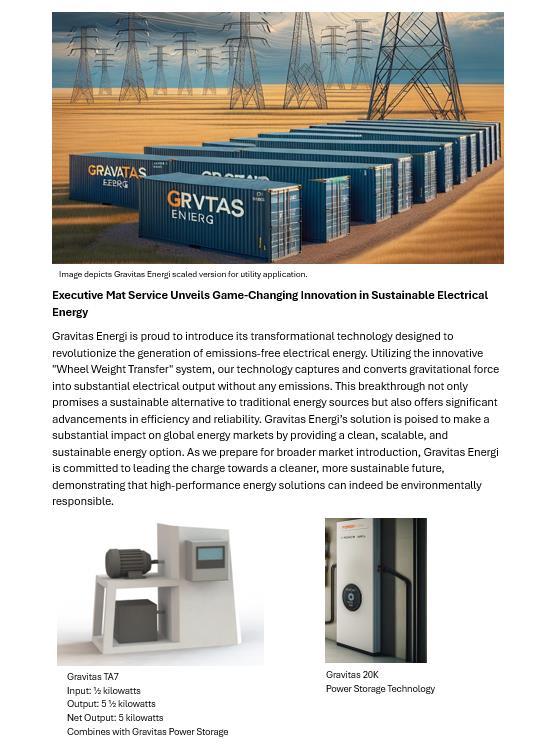

3. Gravitas Energi: This game-changing technology delivers low-cost, reliable electricity with zero carbon emissions. By harnessing innovative techniques, Gravitas Energi is set to revolutionize the energy sector and drastically cut down on greenhouse gas emissions.

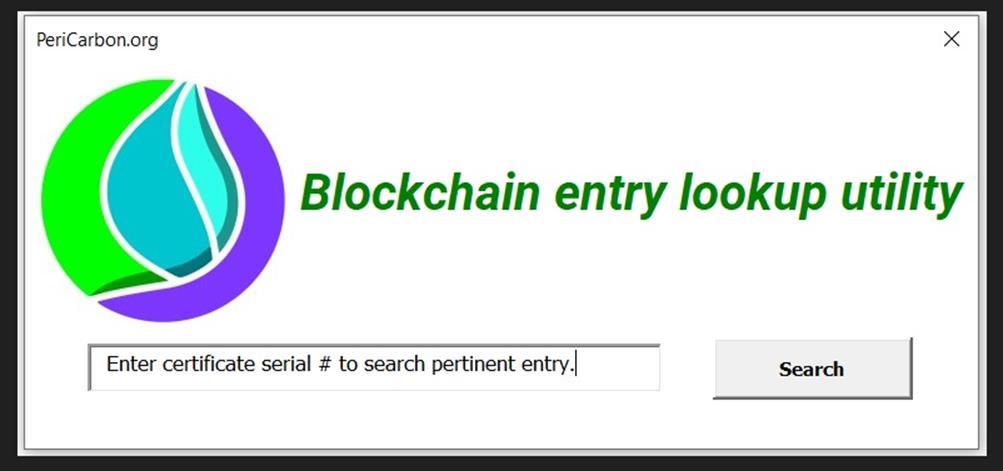

4. Carbon Offsetting: For the emissions we cannot eliminate, we use high-quality Verified Emission Reductions (VERs) from Pericarbon.org. These offsets ensure that our operations achieve true carbon neutrality today, rather than in some distant future.

The time for vague promises and distant goals is over. The climate crisis demands immediate and meaningful action. Executive Mat Service is committed to being a leader in this space, demonstrating that it is possible to operate a successful business while significantly reducing environmental impact.

Our approach is grounded in the belief that every action counts and that businesses have a critical role to play in mitigating climate change. By taking bold steps today, we are not only safeguarding our planet for future generations but also setting a standard for others to follow.

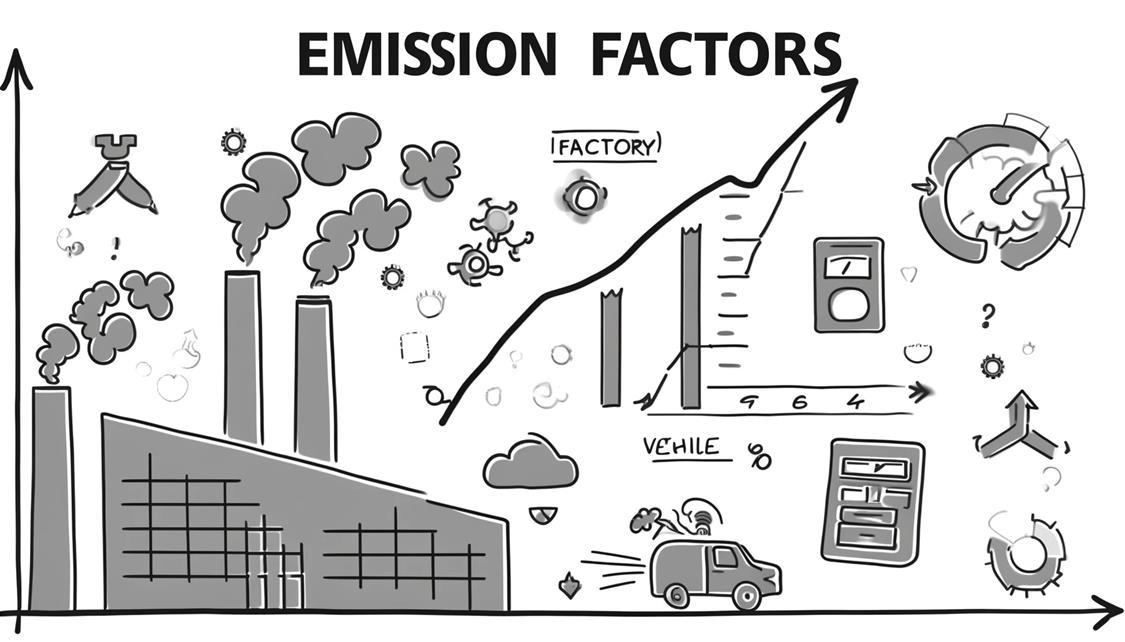

You can't manage what you can't measure –Understanding how to measure (carbon emission factors)

In light of upcoming Government-led mandatory carbon emission reporting over all scopes of carbon (including scope 3) there is an urgent need for simplistic and effective carbon accounting protocols. One powerful tool is the use of emission factors. Emission factors provide a straightforward and standardized approach to calculating greenhouse gas (GHG) emissions across various scopes.

• Definition: An emission factor is a coefficient that quantifies the emissions produced per unit of activity, such as kilograms of CO₂ per kilowatt-hour (kWh) of electricity consumed.

• Calculation Method:

• Determine Consumption: Identify the total quantity of the item being measured, for example kWh of electricity consumed within a specific period.

• Apply Emission Factor: Multiply the quantity being measured by the emission factor specific to the region or energy source.

• Example:

2. Benefits of Using Emission Factors

• Simplicity: Eliminates the need for complex data collection and analysis.

• Consistency: Ensures standardized and comparable emissions data to form baseline greenhouse gas emissions over all scopes of carbon emissions.

• Efficiency: Reduces the time and resources required for carbon accounting. Simplifies compliance with reporting standards and frameworks, such as the Greenhouse Gas Protocol and ISO 14064.

1. Adoption of Emission Factors

• Widespread Use: As emission factors become more widely adopted, organizations can achieve greater transparency and consistency in their carbon reporting and strategic plans to minimize carbon emissions.

2. Driving Innovation

• Continuous Improvement: Emission factors allow innovators to develop new technologies and processes to drive carbon emission reduction. Using current industry-standard baseline emission factors to measure meaningful reductions.

• Encouraging Participation: Simplified carbon accounting encourages more organizations to engage in carbon management and adoption of carbon lowering technologies and processes.

Getting Started: Net-Zero Analytics Inc. is a Canada-based firm specializing in assisting innovators calculate emission factors surrounding their new technology developments and processing solutions.

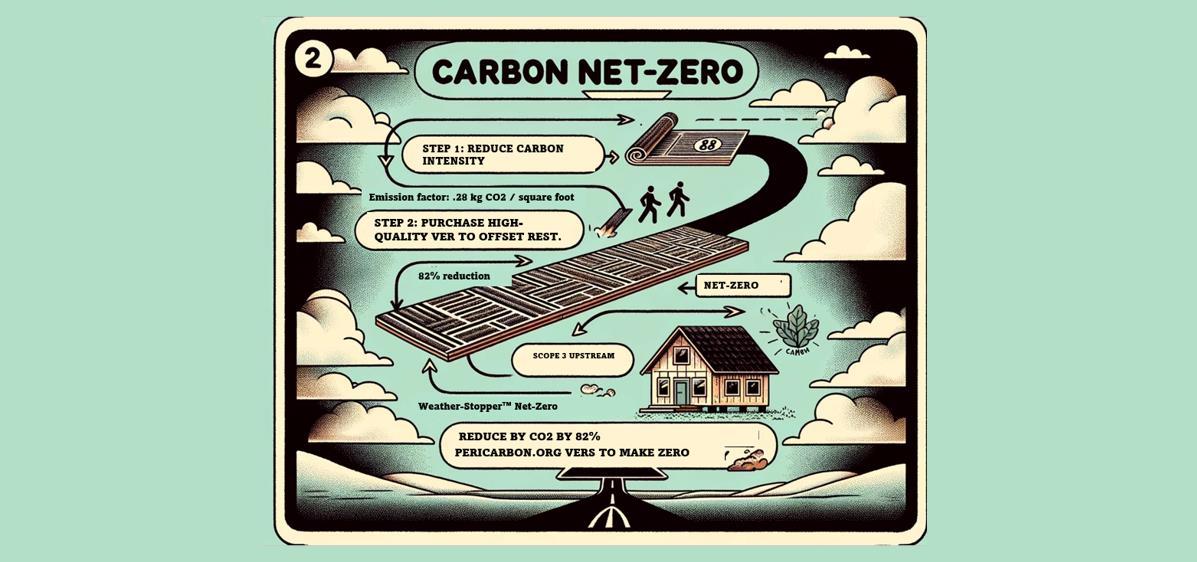

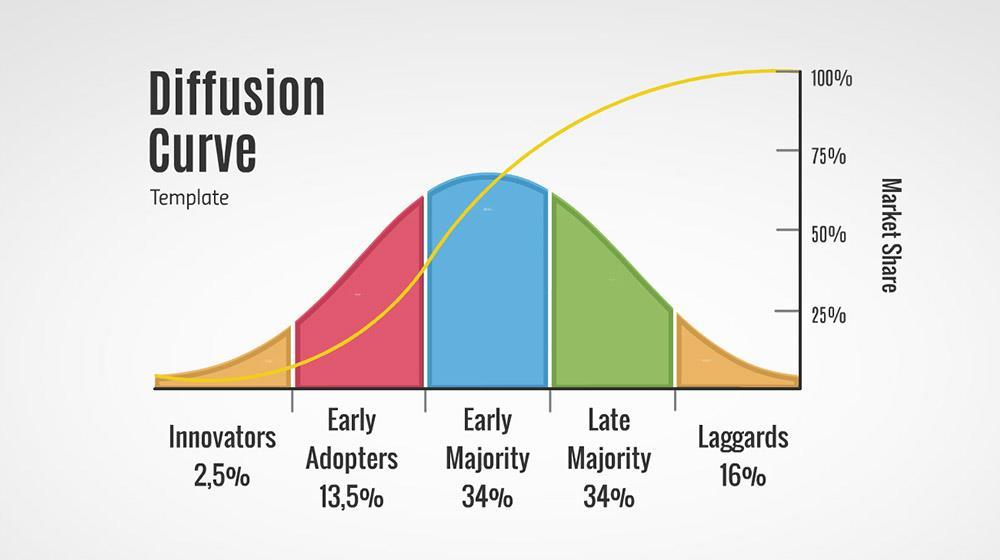

In the global effort to combat climate change, achieving carbon net-zero has emerged as a crucial target for businesses, governments, and individuals alike. 83 out of the Fortune 500 companies have committed to netzero, carbon-neutral, or related targets. Carbon net-zero refers to balancing the amount of carbon dioxide released into the atmosphere with the amount removed or offset. This typically involves following a 2-step process.

The initial and most impactful step towards achieving carbon net-zero is reducing your existing carbon footprint. This involves a series of strategic actions aimed at minimizing carbon emissions associated with your activities. This involves accounting for all Scopes of carbon, specifically Scope 3 “Internal Operations” emissions which can represent most of overall emissions.

Reduction strategies include seeking certified low-carbon goods and services within your supply chain. Eliminating landfill waste altogether is probably the most impactful strategy that signifies a commitment to operational changes that genuinely reduce the reliance on carbon-based resources.

Once you have reduced your carbon emissions as much as practically possible, the next step involves neutralizing the remaining emissions. This is done through the purchase of Verified Emission Reductions. VERs are carbon offsets that have been certified by third-party organizations to ensure they provide genuine, measurable environmental benefits. These offsets support projects that either avoid emissions (like landfill methane avoidance) or capture carbon directly from the atmosphere (such as reforestation i.e., treeplanting).

Achieving carbon net-zero is more than just an environmental responsibility; it’s a competitive edge for businesses, a marker of commitment to sustainability, and a significant step towards safeguarding our planet for future generations. As more entities commit to this goal, it catalyzes broader changes in policy, industry standards, and consumer expectations, leading to a more sustainable economy.

In the era of increasing environmental awareness, organizations are under growing pressure to not only track but also manage their carbon emissions. Understanding the full extent of one's carbon footprint involves delving into the "scopes" of emissions defined by the Greenhouse Gas (GHG) Protocol, which categorizes them into three parts: Scope 1, Scope 2, and Scope 3. This comprehensive approach helps organizations identify effective strategies to reduce their carbon impact, especially considering that Scope 3 emissions can constitute as much as 80% of a total carbon footprint for many companies.

Scope 1 emissions are direct emissions from owned or controlled sources. This includes fuel combustion on-site such as gas boilers or company-owned vehicles. Mitigation strategies here are often focused on switching to renewable energy sources or improving energy efficiency.

Scope 2 emissions cover indirect emissions from the generation of purchased electricity consumed by the reporting company. Companies can reduce these emissions by opting for electricity from renewable sources, such as wind, solar or gravity (Gravitas Energi), and by increasing the energy efficiency of their buildings and processes.

Scope 3 emissions, also known as value chain emissions, however, are the most elusive as they include all other indirect emissions that occur in a company’s value chain. This encompasses emissions related to business travel, procurement, and waste disposal. Scope 3 can often account for the majority of an organization’s carbon footprint up to 80% or more. This makes it a critical target for those aiming to make a significant impact on their overall emissions.

Image depicts a building whose management have committed to carbon net-zero.

In an era where sustainability shapes market landscapes and investor priorities, the International Financial Reporting Standards (IFRS) Foundation has introduced pivotal changes aimed at enhancing how companies report on sustainability and climate-related matters. These changes are encapsulated in two new standards, IFRS S1 and IFRS S2, which seek to refine and expand the scope of corporate disclosures concerning sustainability-related risks and climate impacts. Here’s a closer look at these new standards and what they mean for businesses globally.

IFRS S1 marks a significant shift in how companies communicate sustainability issues to investors. The standard mandates a comprehensive set of disclosure requirements, enabling companies to articulate the sustainability-related risks and opportunities they face over the short, medium, and long term. This includes any information that might reasonably impact the company's cash flows, access to finance, or cost of capital. By focusing on ‘sustainability-related risks and opportunities that could reasonably be expected to affect the entity’s prospects’, IFRS S1 aims to integrate sustainability into the core financial disclosure framework, making it a pivotal factor in investment decisions.

While IFRS S1 sets the stage for broad sustainability reporting, IFRS S2 drills down into the specifics of climate-related issues. This standard requires companies to disclose information regarding how they are managing the potential negative effects of climate change. This encompasses physical risks such as extreme weather events, transition risks including policy and regulatory changes, and opportunities that

may arise from the global shift towards a greener economy. IFRS S2 is designed to work in tandem with IFRS S1, ensuring that climate-related disclosures are both comprehensive and contextual.

With these standards, the IFRS Foundation encourages organizations not just to passively await legal mandates but to adopt a proactive approach in addressing climate change. Companies are urged to begin by assessing and implementing action plans to reduce Scope 3 "Internal Operations" emissions. Scope 3 emissions, which are not directly produced by the company but are a consequence of their internal and external activities, often represent the bulk of an organization’s carbon footprint. By focusing on these emissions, companies can significantly influence their overall environmental impact.

Organizations that move swiftly to align their reporting with IFRS S1 and S2 standards will likely gain a competitive edge. Early adoption can enhance a company's reputation, improve investor confidence, and facilitate access to green financing options. More importantly, it prepares businesses to be resilient and adaptable in a future where sustainability and climate resilience are not just regulatory requirements but also critical business imperatives.

Image is from Canadian Sustainability Standards Board Exposure. Drafts CSDS 1 and CSDS 2. Executive Mat Service Ltd. Has provided input into developing Scope 3 “Internal Operations” Emissions standard.

In the evolving landscape of environmental accountability, accurate and efficient carbon emissions reporting is paramount for companies committed to sustainability. Executive Mat Service Ltd., in collaboration with "Financial Reporting and Assurance Standards Canada," is pioneering a groundbreaking framework for Scope 3 carbon emissions reporting. This initiative introduces the concept of "Internal Operations - IO" emissions, aimed at simplifying the reporting process through a structured, two-step approach

Scope 3 emissions encompass all indirect emissions that occur in a company’s value chain. These include emissions associated with both upstream and downstream activities which traditionally are complex to track and report. The difficulty lies in the diverse range of activities and interactions that contribute to these emissions, making them challenging to quantify and manage.

Executive Mat Service has developed a strategic method to simplify this complexity through the categorization of emissions into two distinct types: Upstream IO and Downstream IO emissions.

1. Upstream IO Emissions:

• Definition: These are emissions associated with inputs to an organization that are consumed onsite.

Details: This category records the carbon intensity of goods and services procured by the company. By focusing on the direct inputs and their immediate impacts, this

• method allows for a more manageable approach to capturing data and encourages suppliers to adopt greener practices.

• Definition: Emissions that occur from the disposal of a company’s waste generated onsite within the organization.

• Details: Particularly, this approach uses the gold-standard Scholl-Canyon landfill methane model with “Caron-Refinements” to measure emissions from landfill waste. This model provides a detailed and refined assessment of the methane emissions resulting from waste disposal, offering a clear view of the downstream impact.

The introduction of the IO emissions reporting structure by Executive Mat Service is set to transform how companies report their carbon footprints. This method not only simplifies the complex nature of Scope 3 emissions but also enhances transparency and accuracy in environmental reporting. By categorizing emissions into upstream and downstream activities, companies can more effectively identify hotspots for carbon reduction and engage in more targeted sustainability strategies.

Additionally, this structured approach fosters a better understanding among stakeholders about where emissions are generated and how they can be mitigated. It empowers businesses to take concrete steps toward sustainability by focusing on specific areas within their control and influence.

As Executive Mat Service Ltd. continues to lead in sustainability initiatives, their work with "Financial Reporting and Assurance Standards Canada" on simplifying Scope 3 carbon emissions reporting is a testament to their commitment to environmental stewardship. This innovative approach not only aids in fulfilling regulatory requirements more efficiently but also aligns with global efforts to combat climate change through better business practices.

The adoption of the IO emissions framework could serve as a model for other companies striving to enhance their environmental reporting and impact. As more organizations adopt these practices, the collective impact on reducing global carbon emissions could be substantial, marking a significant step forward in corporate environmental responsibility.

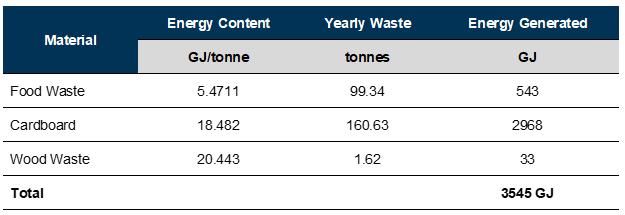

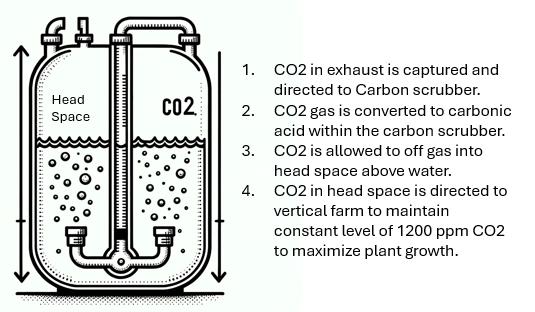

As industries and organizations strive to reduce their carbon footprint, Scope 1 emissions, which encompass direct emissions from owned or controlled sources, are a critical focus. One innovative approach to mitigating these emissions is through energy recovery, specifically by utilizing biomass energy devices. This method not only reduces dependence on fossil fuels but also aligns with global climate goals.

When biomass is used as a feedstock, it is considered carbon neutral under the Paris Agreement on Climate Change. This designation stems from the fact that the carbon dioxide released during the energy recovery process is offset by the carbon dioxide absorbed by the plants during their growth. As a result, biomass energy systems do not contribute to a net increase in atmospheric CO2 levels, making them a sustainable alternative to fossil fuels.

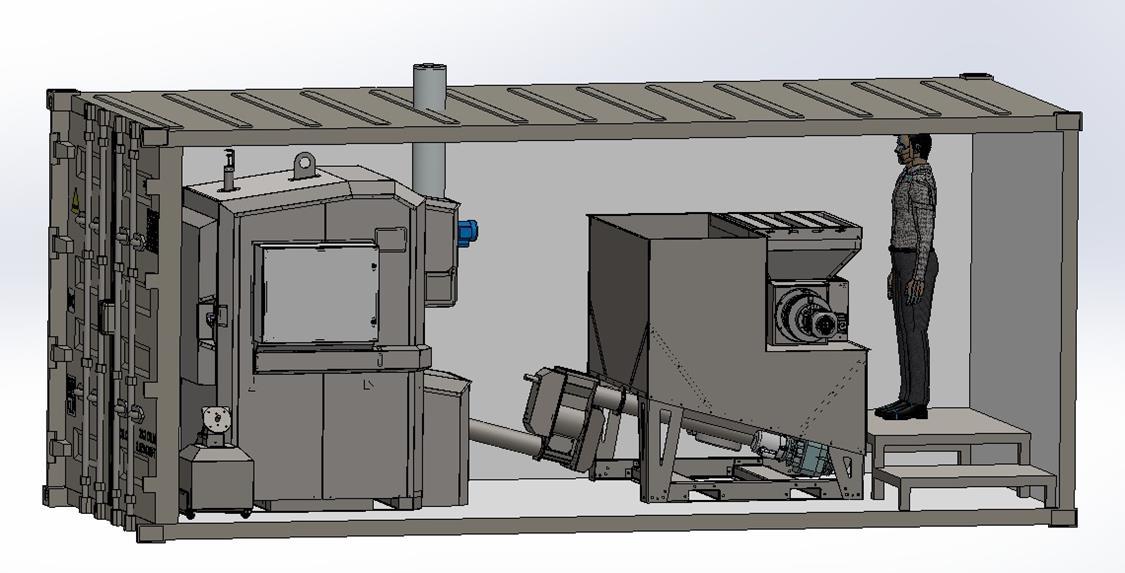

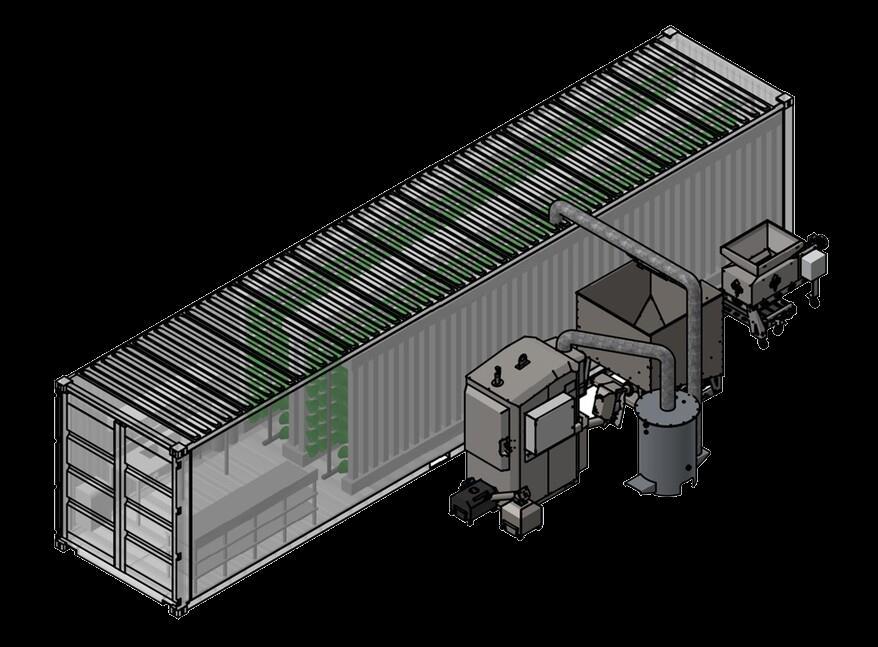

One notable example of a biomass energy device is the Eco-Growth Environmental ER500 system. With a maximum output of 500,000 BTU (145 kilowatts), the ER500 efficiently converts dry organic waste into valuable thermal energy. This high-output system is capable of handling various types of biomass feedstocks, making it versatile for different industrial and commercial applications.

The thermal energy generated by the ER500 system can replace the direct use of fossil fuels for space heating or process water heating. By doing so, organizations can significantly reduce their Scope 1 emissions. The adoption of biomass energy devices like the ER500 not only helps in cutting down greenhouse gas emissions but also promotes the use of renewable energy sources.

1. Emission Reduction: Utilizing biomass for energy recovery directly reduces emissions from fossil fuels, lowering the overall carbon footprint.

2. Sustainability: Biomass energy is renewable and abundant, providing a sustainable energy source that supports waste management and recycling efforts.

3. Cost Efficiency: Converting waste to energy can reduce waste disposal costs and provide a cost-effective energy solution.

4. Energy Independence: Biomass energy systems can enhance energy security by reducing reliance on imported fossil fuels.

Emission Factor – Energy Recovery

Greenhouse Gas Quantification Assessment Report CE0163185

Based on calculations made by Emissions Reduction Alberta there is 182.9 mt available biomass feedstock with a net reduction in Scope 1 CO2 emissions of 197 mt. Energy Recovery Emission factor = 1 mt dry feedstock = 1.08 mt CO2 reduction.

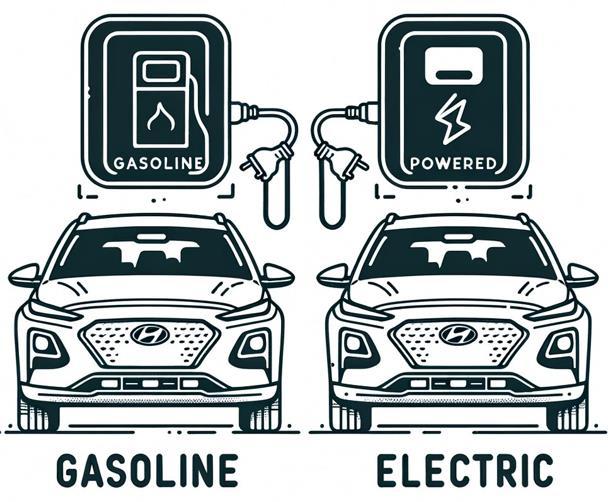

Kona EV vs. Gasoline: Carbon Footprint Comparison in British Columbia and Alberta

As electric vehicles (EVs) gain popularity, understanding their environmental benefits compared to traditional gasoline vehicles is crucial. Executive Mat Service management in British Columbia and Alberta adopted Kona all-electric vehicles for management travel. The following details the Scope 1 carbon footprint reduction achieved by the Hyundai Kona EV compared to a gasoline powered Kona in the two Canadian provinces. The focus is on the emission factor reductions per 100 km driven.

Before diving into the comparison, it’s essential to understand the emission factors for electricity generation in BC and Alberta:

• British Columbia: Known for its clean energy mix, primarily hydroelectric power, BC has a low carbon intensity of electricity at 15 grams CO2 per kWh.

• Alberta: Predominantly reliant on fossil fuels, particularly coal and natural gas, Alberta’s electricity generation has a higher carbon intensity at 540 grams CO2 per kWh.

Kona EV vs. Gasoline Vehicle: Emission Factor Reductions

To compare the carbon footprints, we’ll examine the emission factor reductions achieved by the Kona EV compared to a gasoline vehicle, which consumes 8.6 liters of gasoline per 100 km.

• British Columbia:

• Electricity Emission Factor: 15 grams CO2 per kWh (0.015 kg CO2 per kWh).

• Kona EV Carbon Footprint:

• Electricity Consumption: 15.8 kWh per 100 km.

• Calculation: 15.8 kWh × 0.015 kg CO2/kWh = 0.237 kg CO2 per 100 km.

• Gasoline Vehicle Carbon Footprint: 19.87 kg CO2 per 100 km.

• Emission Factor Reduction:

• Calculation: 19.87 kg CO2 (Gasoline) - 0.237 kg CO2 (Kona EV) = 19.633 kg CO2 reduced per 100 km.

• Alberta:

• Electricity Emission Factor: 540 grams CO2 per kWh (0.54 kg CO2 per kWh).

• Kona EV Carbon Footprint:

• Electricity Consumption: 15.8 kWh per 100 km.

• Calculation: 15.8 kWh × 0.54 kg CO2/kWh = 8.532 kg CO2 per 100 km.

• Gasoline Vehicle Carbon Footprint: 19.87 kg CO2 per 100 km.

• Emission Factor Reduction:

• Calculation:

• Table shows Gasoline versus EV emission standards comparison by Canadian Province. 1 Source Canada – Environment Climate Change.

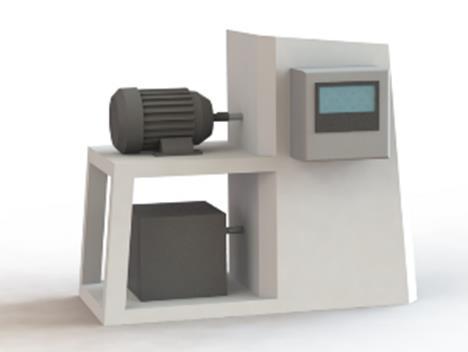

The Gravitas Energi TA150 system is a groundbreaking technology poised to transform the landscape of electricity generation. With its ability to produce electricity 24 hours a day, 365 days a year, the TA150 system is not just a game-changer: it's a beacon of hope for a greener future.

1. Unmatched Efficiency: The Gravitas Energi TA150 system boasts unparalleled efficiency, capable of generating a net 150 kilowatts of continuous output resulting in a staggering 1,314,000 kilowatt hours of electricity per year.

2. Environmental Benefits: One of the most compelling aspects of the TA150 system is its minimal environmental footprint. By harnessing the power of gravity, the system achieves remarkable results in emissions reduction. In Alberta with an emissions factor of 540 grams CO2/kWh x 1,314,000 kWh the annual Scope 2 emission reduction is 709.56 mt.

3. Cost Savings: Beyond its environmental benefits, the Gravitas Energi TA150 system also delivers tangible economic advantages. By generating electricity efficiently and reliably, the system helps save money on energy production and distribution. Additionally, the reduced reliance on fossil fuels translates into long-term cost savings, as volatile fuel prices become less of a concern.

4. Scope 2 Emissions Reduction: The adoption of the TA150 system contributes to the reduction of Scope 2 emissions, which encompass indirect emissions associated with the generation of purchased electricity

Bathroom/Restroom Consumables

Hand soaps and sanitizers

Paper towels and tissues

Toilet paper

Cleaning chemicals

Floor Matting Services

Entrance mats -fatigue mats

Specialty mats (anti-static, scraper, etc.)

Services

Regular cleaning and disinfection

Deep cleaning services

Window cleaning

Services

Landscape maintenance • Plant care and tree services • Snow removal and winter services • Pest control

/ Mechanical / Plumbing Services • System maintenance and repairs

Duct cleaning and inspection

Maintenance • Regular maintenance supplies

Paints and finishes

Executive Mat Service's two-stage approach to reducing Scope 3 indirect emissions for our Floor Mat Service includes:

Embodied Carbon Reduction: Utilizing sustainable and recycled materials for mat production to lower the carbon footprint.

Service Provision Efficiency: Streamlining delivery routes and employing energy-efficient cleaning technologies to reduce carbon intensity during servicing.

Scope 3: Internal Operations/ Floor

Embodied carbon in floor mats refers to the total amount of carbon dioxide emissions (CO2) associated with the production and transportation of floor mats. This encompasses all greenhouse gas emissions released from the extraction of raw materials used in its manufacture to the point where the matting is ready for installation.

The concept of embodied carbon is critical for understanding the environmental impact of products like floor mats in a comprehensive manner. It helps businesses and consumers make more informed decisions regarding their product choices, aiming to select options that minimize environmental footprints and support sustainability goals. For Executive Mat Service, reducing embodied carbon is a significant part of our environmental strategy.

Assessing the embodied carbon of three different floor matting options to determine level of alignment towards environmental objectives. Here is an overview based on the emission factors provided:

1. Nylon/Nitrile Rubber Carpet-Top Matting:

• Materials: Nylon and synthetic rubber (nitrile).

• Analysis: This matting type, with a high nylon content, results in a higher carbon footprint due to the significant emission factor of nylon. The overall embodied carbon footprint is offset through use of smaller volume of nitrile rubber. It is less favorable due to its relatively high embodied carbon.

2. PET/Nitrile Bi-Level Matting:

• Materials: Polyethylene terephthalate (PET) and synthetic rubber (nitrile).

• Analysis: The PET component brings down the overall carbon footprint compared to pure synthetic (nylon) options; the matting incorporates significantly more nitrile rubber making it the most carbon intense of the 3 matting types..

3. PET/Natural Rubber (Weather-Stopper Matting):

• Materials: Polyethylene terephthalate (PET) and natural rubber.

• Analysis: This type of matting exhibits the lowest embodied carbon of the three options. The inclusion of natural rubber, which has a significantly lower emission factor, alongside PET, results in a more environmentally friendly solution ideal for sustainability-driven specifications like those of the LCBO.

Executive Mat Service is at the forefront of environmental sustainability. As part of the journey towards achieving carbon net-zero, Executive Mat Service has implemented a two-step strategy that effectively combines technological advancements with strategic environmental initiatives.

1. Reduction of Carbon Intensity: The first step in our approach has been to significantly reduce the carbon intensity of our products. By developing the Weather-Stopper matting, Executive Mat Service has utilized materials such as PET and natural rubber, which have much lower embodied carbon compared to traditional materials.

2. Purchase of High-Quality VERs (Carbon Offsets): To address any remaining emissions and achieve a net-zero carbon footprint, Executive Mat Service has committed to purchasing high-quality Verified Emission Reductions (VERs). The company has successfully purchased and retired a substantial amount of VERs through the Pericarbon.org Carbon Registry. The transparency of these transactions are bolstered by their visibility on the Pericarbon.org blockchain, providing clear and accessible proof of the company's environmental commitments.

Factors

Floor Mat Material Input

on: 4x6

Table 3 shows embodied carbon footprint in kg. for a 4’x6’ by matting type. Carbon footprint was divided by mat trade size to achieve kg. CO2 per square foot (ft2). Carbon footprint associated with transporting each mat type from factory to Brantford Ontario was added to report total embodied carbon footprint.

4:

Embodied Carbon Footprint KG,/CO2 by size

Table 4 shows embodied carbon footprint in kg. for a range of sizes. Currently sizes: 4’x8’, 6’x6’ and 6’x10’ are not available in the Weather-Stopper format.

1. Weather-Stopper lowest embodied carbon footprint floor mat on the market.

2. Emission Factor - Industry baseline for carpet-top on nitrile rubber is 1.61 kg CO2 per square foot.

3. Emission Factor – Weather-Stopper is .28 kg CO2 per square foot.

4. 100% of all Weather-Stopper floor mats have been certified net-zero through purchase and retirement of VERs at a rate of .28 kg CO2 per square foot.

Emission factors expressed as kilograms CO2 per square foot of floor matting delivered. Includes carbon intensity of cleaning & sanitizing, delivery and overheads.

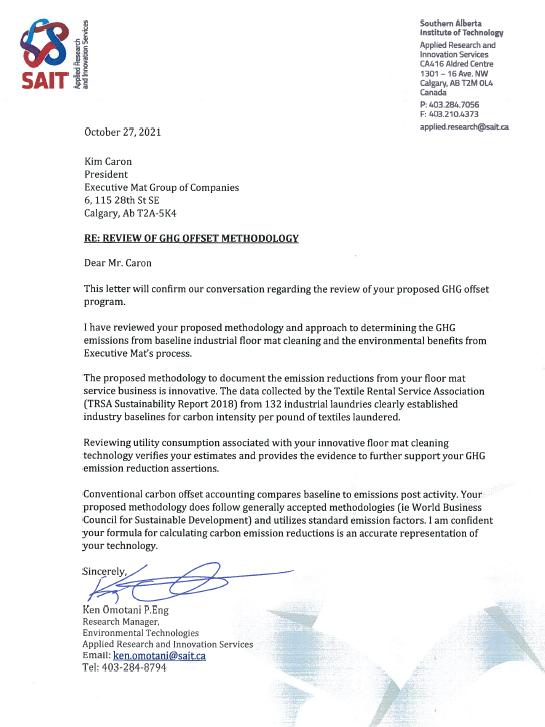

Calculating carbon reductions is a vital process in assessing the environmental impact of product or service innovations. It begins with establishing an industry baseline, which serves as a reference point for measuring carbon emissions. By comparing emissions before and after implementing innovations, organizations can quantify the reduction in carbon emissions achieved. This method enables businesses to track progress towards sustainability goals and evaluate the effectiveness of their initiatives in reducing environmental impact.

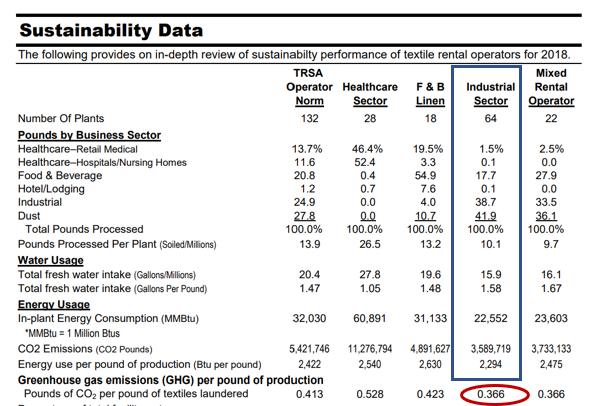

Floor mat rental baseline carbon intensity has been established in a sustainability report prepared for Textile Rental Institute of America.

Table 5: Reported Baseline Carbon Intensity

Table 5 shows the average carbon footprint associated with cleaning floor mats in an industrial processing facility. Average carbon intensity was reported as .366 pounds CO2/pound processed or .166 kilograms CO2 per pound processed.

Table 6: Reported Baseline Carbon Intensity by Square Foot. (Carpet-Top is 30% lighter and 10% smaller)

Table 6 shows the average carbon footprint associated with cleaning floor mats by ft2.Standard 4’x6’ floor mat was used in the comparison. Carpet-top matting shows lowest carbon intensity per square foot due to light weight and smaller size. A 4’x’6 carpet-top measures 10% smaller than 4’x6’ Weather-Stopper mat.

• Delivery CO2 calculation: .0263 kg. CO2 / ft2. Derived from ISO14001 audit conducted across 5 Canadian floor mat locations over 12-months.

• Overheads estimation .0009 kg. CO2 / ft2 sourced from ISO14001 audit findings.

May 2024

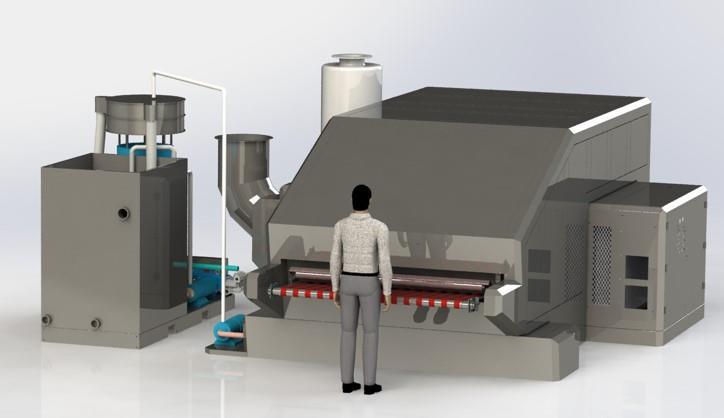

In the commercial cleaning industry, the traditional methods of washing and drying nylon floor mats have been a significant source of carbon emissions. According to a TRSA report, approximately 0.366 pounds of CO2 pollution is emitted for every pound of floor matting cleaned. However, a groundbreaking advancement in this field has been introduced by CDF-Systems, which promises to drastically reduce these emissions and contribute positively to environmental conservation.

CDF-Systems has developed a revolutionary dry technology that cuts down the carbon intensity of washing and drying nylon floor mats by more than 90%. Considering the billions of pounds of floor matting cleaned annually the potential carbon savings from this technology are staggering. This innovation not only helps businesses who consume mat services reduce their Scope 3 "Internal Operations" emissions significantly but also aligns with global carbon reduction goals.

In addition to its carbon-saving benefits, the CDF-Systems technology addresses another critical environmental issue: water scarcity. The system is designed to virtually recycle 100% of the water used in the cleaning process, making it an invaluable asset in drought-prone areas. This feature not only helps conserve water but also reduces the overall environmental footprint of the cleaning process.

From an operational perspective, the CDF-Systems cleaning technology offers simplicity and efficiency. It is a one-touch process where soiled matting is fed into the machine face up and exits clean, dry, and sanitized ready for immediate reuse. This process significantly cuts down on labor and utility costs compared to traditional cleaning methods. Moreover, the technology can handle a broader range of matting types, including advanced bi-level systems like Weather-Stopper technology, which outperforms conventional nylon matting in controlling tracked in dirt, debris and moisture.

In today's market, where consumers and businesses alike are increasingly conscious of their environmental impact, goods and services that are certified as low-carbon or carbon net-zero are more appealing. CDF technology not only meets these standards but has also been third-party certified as low carbon. Operators using this system can generate Verified Emission Reductions (VERs), which are tradable on the Pericarbon.org Carbon Registry blockchain. These VERs serve as carbon offsets, allowing other entities who purchase them to balance their emissions, thereby fostering a broader commitment to climate action.

The CDF-Systems mat cleaning technology represents a triple win: for consumers, it ensures safer and cleaner floors with significantly reduced carbon footprints; for operators, it lowers operating costs and provides a competitive edge; and for society, it offers substantial reductions in greenhouse gas emissions. As businesses and consumers increasingly prioritize sustainability, technologies like those developed by CDF-Systems are not just beneficial but essential for a sustainable future.

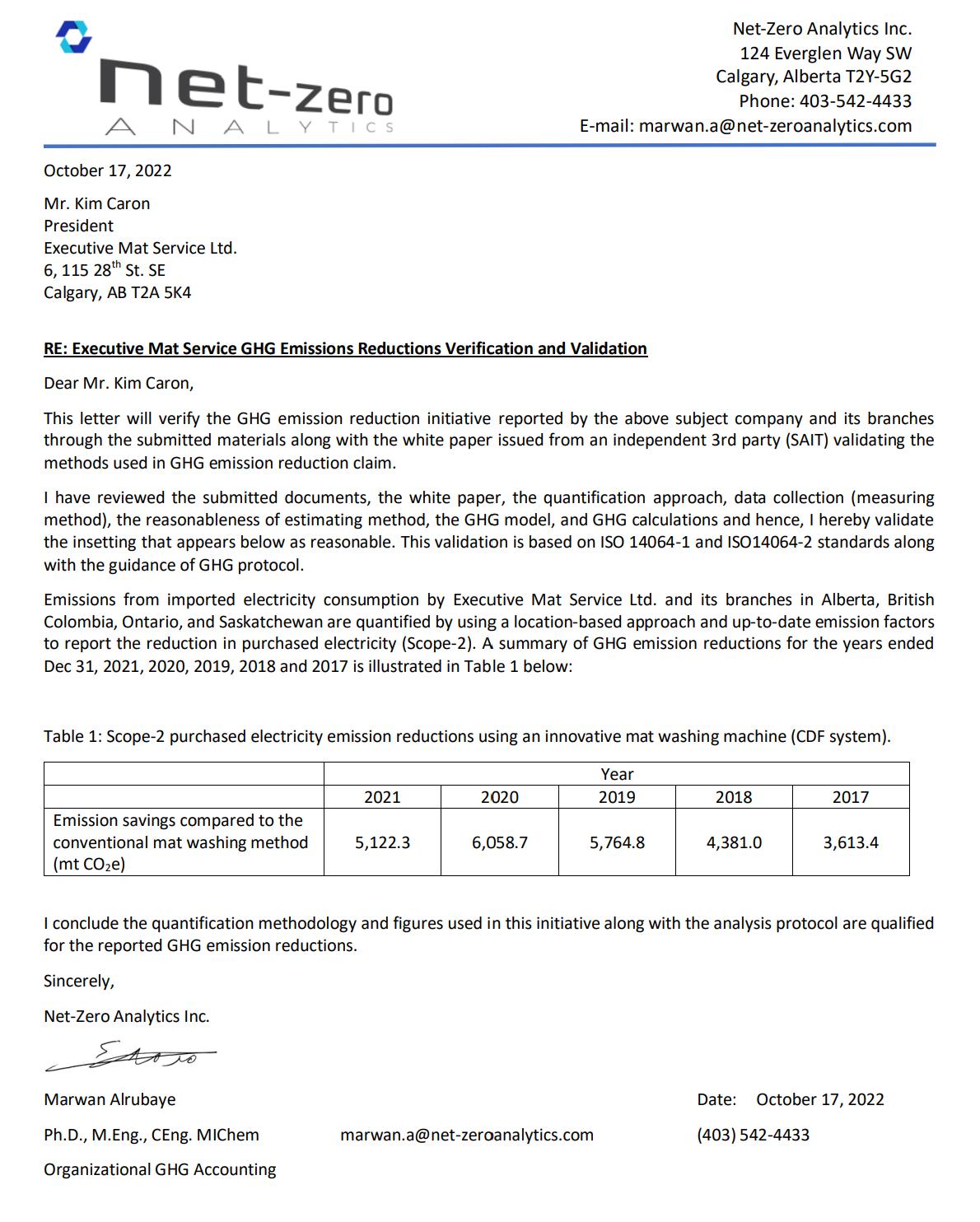

Executive Mat Service, a Canadian National floor mat service provider, has positioned itself at the forefront of environmental sustainability by being an early adopter of the innovative CDF cleaning technology. With mat cleaning facilities located in Vancouver, Calgary, Edmonton, Regina, and Toronto, Executive Mat Service has collectively reduced their carbon emissions by an impressive 30,000 metric tonnes compared to industry baselines since 2017.

Here’s why EMS’s adoption of CDF-Cleaning Technology is a game-changer:

Efficient Processing of High-Performance Matting: With CDF-Cleaning Technology in place, EMS can streamline the processing of top-tier matting solutions like the WeatherStopper. This advanced technology ensures that even the most durable and specialized mats receive thorough cleaning and maintenance, extending their lifespan and performance.

Dramatic Reduction in Carbon Footprint: By implementing CDF-Cleaning Technology across all its operations, EMS is making a tangible commitment to sustainability. This innovative approach significantly minimizes the carbon footprint associated with traditional mat cleaning methods. From reduced water usage to optimized energy consumption, every aspect of the cleaning process is engineered to be eco-friendly.

Table 7: Emission Factor for electricity across Canada

Table 7 CDF technology uses displacement drying process that uses electricity instead of natural gas. Based on an average production rate of 4,000 ft2 processed per hour and electricity consumption of 120 kW/h. Virtually 100% of water is recycled using electricity therefore is considered a factor contributing to reported CO2.

• Delivery CO2 calculation: .0263 kg. CO2 / ft2. Derived from ISO14001 audit conducted across 5 Canadian floor mat locations over 12-months.

• Overheads estimation .0009 kg. CO2 / ft2 sourced from ISO14001 audit findings.

Weather-Stopper floor matting surpasses carpet-top style matting in performance, necessitating fewer service intervals.

1. Studies reveal that Weather-Stopper matting, serviced every 4 weeks, excels in floor safety and cleanliness compared to weekly serviced carpet-top matting.

2. CDF cleaning technology sanitizes and cleans floor matting with significantly lower carbon intensity, marking a notable advancement in environmental sustainability.

Table 8: Scope 3 Internal Operations / Floor Mat Service Comparison

Table 8 shows the carbon footprint reduction associated with converting an Ontario client with 28 locations from weekly carpet-top service using a supplier utilizing industry baseline cleaning systems. Weather-Stopper matting was introduced on an every-4-week service program and mats were processed in a CDF equipped facility

1 TRSA includes reported production CO2 intensity of .166 kg CO2/ Square Foot processed plus .0272 kg for Delivery and Overhead. CDF production numbers are based on 4,000 ft2 processed per hour using 125 kWh (no natural gas). The same .0272 was applied for Delivery and Overhead. EmissionComparisonPerService

Magnifying Carbon Reductions: To illustrate the tangible environmental benefits of Executive Mat Service's approach, consider a typical scenario in Ontario. Traditionally, businesses in the region might require weekly matting service in winter and bi-weekly service in summer, totaling 39 deliveries annually. Assuming an average organization requires 200 square feet of floor matting for safety, this equates to a significant carbon footprint of 1,507 kg CO2 per year (39 x 200 ft2 x emission factor of .1932 kg CO2/ft2).

In contrast, by adopting Executive Mat Service's OPTIMIZED solutions, the carbon emissions associated with matting services can be dramatically reduced. With only 13 deliveries per year, the same 200 ft2 x emission factor of .0281 kg CO2/ft2 the carbon footprint plummets to just 73 kg CO2 annually, representing a staggering 95% reduction compared to traditional practices.

Scope 3 Upstream Reductions are not just a theoretical concept; they are a practical and impactful strategy for businesses looking to enhance their sustainability efforts. Through the adoption of cutting-edge technologies like CDF and high-performance products like Weather-Stopper mats, Executive Mat Service is leading the charge towards a greener, more sustainable future.

In today’s fast-paced, delivery-dependent world, the efficiency of service routing isn’t just a logistical concern it's also a critical environmental one. Companies across the globe are under increasing pressure not only to cut costs but also to reduce their carbon footprints. Interestingly, while fuel emissions from delivery vehicles are typically accounted for under a service provider's Scope 1 emissions, they also considerably impact the Scope 3 emissions of the end client. By optimizing delivery routes, companies can significantly enhance cost efficiencies and lower carbon emissions, creating a ripple effect of benefits.

At its core, the principle of routing efficiency is about doing more with less. For delivery companies, this means maximizing the number of stops they can make in a single journey without extending the delivery day beyond workable hours. Advanced routing algorithms can now calculate the quickest and shortest routes between multiple delivery points, allowing drivers to cover more ground in less time. This reduction in drive time and distance directly correlates with decreased fuel consumption, which not only lowers operational costs but also reduces wear and tear on delivery vehicles, thereby saving on maintenance costs and extending the lifecycle of a delivery fleet.

From an environmental perspective, the benefits of optimized delivery routes are even more compelling. Transportation is a major contributor to global CO2 emissions, and reducing the distance traveled by delivery vehicles directly lowers their carbon outputs. By decreasing the

number of trips required to deliver goods and services, companies not only adhere to their Scope 1 responsibilities but also positively influence the Scope 3 emissions of their clients. This is particularly important for businesses committed to achieving net-zero emissions, as Scope 3 encompasses all indirect emissions that occur in a company's value chain, including those associated with procured goods and services.

Efficient delivery routing also extends beyond just the roads traveled; it encompasses minimizing the time spent at each delivery location as well. By streamlining on-site processes, service representatives can achieve greater in-and-out efficiencies, allowing for more deliveries to be completed within the same working day. This not only maximizes productivity but also substantially decreases the carbon emissions per delivery. Technologies such as FotoFinish streamline the onsite delivery process, reducing waiting times, further enhancing the efficiency of the delivery process. As each minute saved per stop accumulates, the overall environmental impact is significantly reduced, demonstrating how operational efficiencies can directly contribute to sustainability goals.

Executive Mat Service has implemented a three-step approach to enhance delivery efficiency and environmental sustainability:

1. Development of the Weather-Stopper Floor Mat: This high-performance mat features a bi-level construction that outperforms traditional carpet-top mats, reducing the need for frequent service visits and thus lowering associated carbon emissions.

2. Adoption of Advanced Route Scheduling Software: By optimizing delivery sequences, this software ensures the most efficient travel paths are used, decreasing travel time and fuel consumption.

3. Integration of FotoFinish Technology: This tool automates quality assurance and proof of delivery processes, saving time at each stop and increasing service reliability, further enhancing overall operational efficiency.

In conclusion, Executive Mat Service is deeply committed to carbon efficiency across all facets of our operations. We understand that true environmental responsibility extends beyond the cleaning and sanitizing of our products to include every step of our delivery process. By innovating with highperformance products like the Weather-Stopper floor mat, utilizing advanced route scheduling software, and integrating FotoFinish technology, we are not only enhancing our service quality but also significantly reducing our carbon footprint.

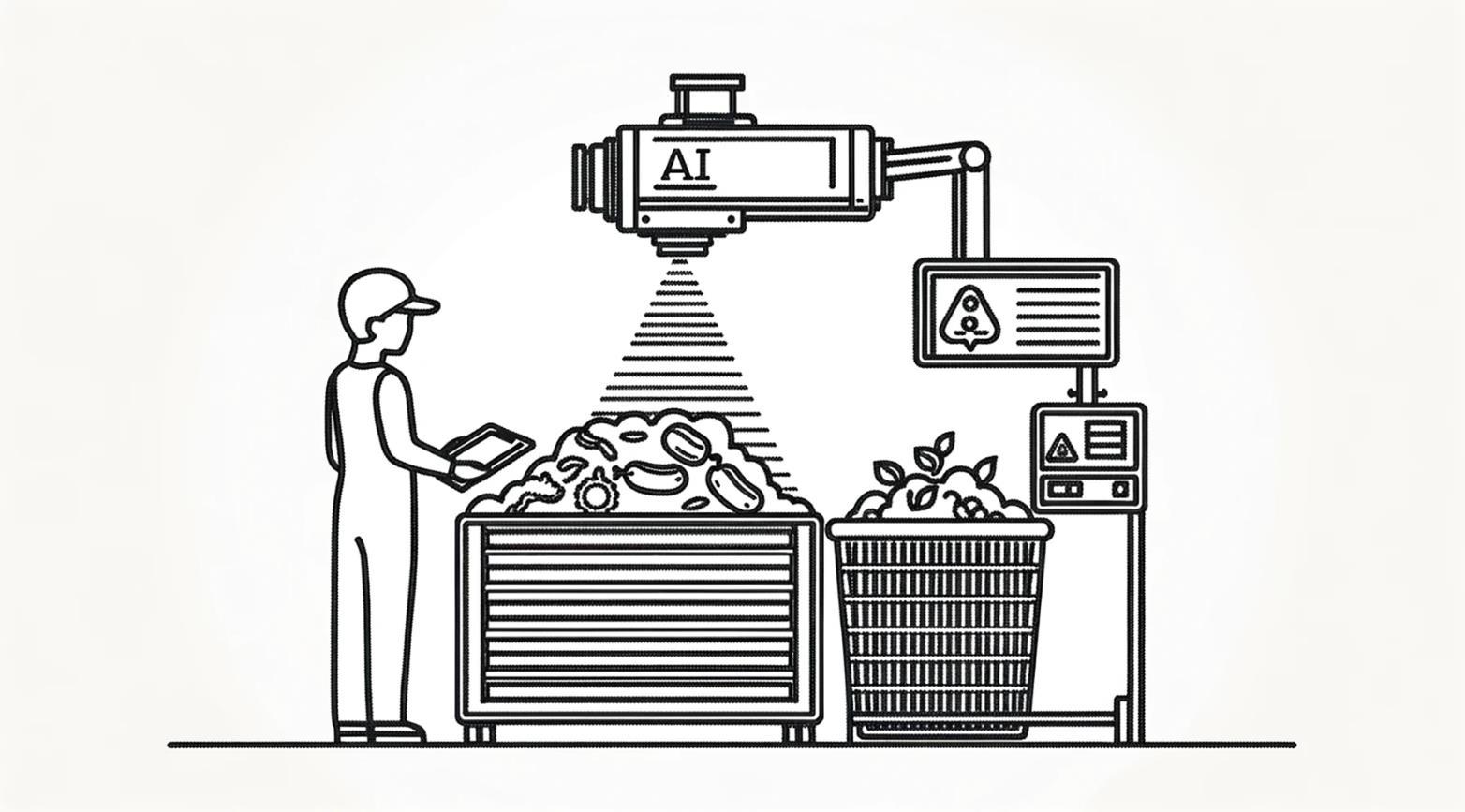

In the competitive world of floor mat services, efficiency and quality assurance are paramount. Companies need to ensure that each stop on their delivery routes, typically averaging 30-40 stops per day, is optimized to avoid delays that can throw off an entire day’s schedule. Drawing a parallel to urban garbage collection, where trucks make 500-800 stops daily, even minor delays can significantly extend working hours. This principle is exactly where artificial intelligence (AI) comes into play, transforming operational efficiency and service quality in surprising ways.

Introducing FotoFinish: AI-powered Quality Assurance and Efficiency

FotoFinish, a remarkable application of Large Language Model AI technology, is at the forefront of this transformation in the floor mat service industry. Designed to streamline operations and enhance quality control, FotoFinish simplifies the process of service delivery verification with a quick snap and upload of a photo.

Upon delivery, service technicians are required only to take a photo of the placed mat(s) and upload it via their smart device. From there, AI takes over with the following checks:

• Quality Standards: The AI assesses if the mat meets or exceeds predefined quality benchmarks.

• Proper Placement: It checks whether the mat is positioned in the designated area, ensuring optimal usage and safety.

• Cleanliness: The AI evaluates the cleanliness of the mat, crucial for maintaining a professional and hygienic appearance.

If any issues are detected that don’t meet the company’s high standards, an automated alert is sent to the quality assurance director to initiate corrective measures promptly.

FotoFinish also serves as an automated "Proof of Delivery" system. Each uploaded picture is time-stamped and securely stored on a cloud server, providing irrefutable evidence of service delivery. This feature is especially useful for:

• Customized Reporting: Stakeholders can receive tailored reports or review individual delivery details, enhancing transparency and accountability.

• Integration with Third-party Software: FotoFinish can seamlessly integrate with other software solutions, facilitating automated reconciliations and streamlining backend processes.

In an era where litigation over floor safety is a rising concern, FotoFinish offers more than just operational efficiency. It provides concrete proof of due care and attention to floor safety, significantly mitigating legal risks associated with slip-and-fall accidents and other liabilities.

The application of AI into Executive Mat Service’s floor matting program is a game-changer. By automating quality assurance and proof of delivery, Executive Mat not only ensures topnotch service quality but also optimizes operational efficiency, saving precious time and resources which translates to lower pricing for clients.

This image was captured using the AI-powered FotoFinish tool, which scans for product quality and placement deficiencies. If any issues are detected, the tool automatically generates a notification to the quality assurance director, ensuring prompt remedial action to maintain the highest standards of service quality and customer satisfaction.

Life is full of surprises, and sometimes those surprises come in the form of unforeseen circumstances that can disrupt the smooth operation of a business. One such unexpected event is the soiling of floor mats, which can create health and safety concerns and impact the cleanliness and appearance of a facility. Recognizing the need for a reliable solution, Executive Mat Service has introduced a comprehensive program designed to act like an insurance policy for your floor mats, ensuring your business remains prepared and compliant.

The Unforeseen Circumstances Program is a proactive service offering that helps businesses effectively manage unexpected floor mat soiling events. Here’s how it works:

• Custom Inventory Planning: We collaborate closely with your custodial team to assess your facility’s specific needs and determine the additional mat inventory required. This ensures that enough replacement mats are available on-site for immediate use.

Isolation Protocols: To address health and safety concerns, we supply bags labeled "Danger Biological Soiling" for the custodial staff. These bags are

• used to isolate contaminated mats, preventing the spread of contaminants, and ensuring compliance with safety protocols.

• Training & Support: We provide training and support to your custodial staff on the proper handling and isolation of soiled mats, enhancing their readiness to manage such situations.

2. Notification – Communication is Key

• Notification: In the event of a biological soiling incident, the customer simply notifies Executive Mat Service Customer Service.

• Reserved Mat Replacement: Our service team, on the next scheduled service day, retrieves the contaminated mat and replaces it with a freshly laundered mat to be held in reserve, minimizing disruption to your operations and maintaining a clean and safe environment.

• Special Handling Procedures: We initiate special handling procedures to manage the contaminated mat. This includes high-temperature cleaning and sanitization, ensuring the mat is safe for future use.

1. Enhanced Preparedness: By maintaining a reserve inventory of mats, your facility is always ready to handle unexpected soiling events without delay.

2. Health & Safety Assurance: The program’s focus on isolation and proper handling of contaminated mats ensures compliance with health and safety standards.

3. Operational Continuity: With immediate mat replacement, your business can continue operating smoothly, even during unforeseen circumstances.

4. Cost-Effective Solution: The program acts as an insurance policy, mitigating the potential costs and disruptions associated with emergency mat replacement.

Executive Mat Service is committed to providing innovative and reliable solutions that enhance the safety and efficiency of your facility. Our Unforeseen Circumstances Program reflects our dedication to customer satisfaction and our proactive approach to facility management.

Floor mats are common in commercial settings, but when they become wavy or buckled, they can present significant risks. Understanding the implications of these hazards is crucial for maintaining safety and compliance.

1. Why It Matters: Wavy floor mats can lead to trips and falls, posing serious injury risks to customers and employees alike. Ensuring mats lie flat and secure minimizes the likelihood of accidents, protecting individuals and safeguarding businesses against potential liability.

2. Who is Responsible: Property owners and managers are primarily responsible for maintaining safe premises. This includes regular inspections of floor mats and immediate action to correct any issues. Failing to manage these risks can lead to negligence claims if accidents occur.

3. Accounting for Risk: Identifying trip hazards from wavy floor mats is an essential part of risk management. Businesses must proactively address these issues, using proper matting solutions and adhering to safety standards to prevent accidents and ensure a safe environment for all visitors.

By recognizing the dangers of wavy floor mats and taking steps to mitigate these risks, businesses can uphold their duty of care and promote a safer community. WeatherStopper™ floor matting is the solution.

Floor mats are tested for friction coefficient when new. Our competitors state this mat is floor safety certified?

The floor mat service industry is currently grappling with a significant challenge: the emergence of rippled or buckled floor mats. This issue has become prevalent due to several critical factors in the manufacturing and maintenance of these mats:

• Removal of DEHP: DEHP, or Di(2-ethylhexyl) phthalate, a key plasticizer previously used in the production of nitrile rubber, has been phased out. Nitrile rubber, a blend of the monomers acrylonitrile (CH₂=CH-CN) and butadiene (CH₂=CH-CH=CH₂), is a crucial component in the construction of nylon carpet-top floor matting. The absence of DEHP, without a viable alternative, has affected the mat's durability and flatness.

• Incompatible Substrate: The substrate, which is the fabric to which the nylon is mechanically attached to create the mat's carpet-top, tends to shrink during the laundering process. This shrinkage occurs at a different rate than the nylon fibers and the rubber backing, leading to distortions in the mat as it goes through repeated wash cycles.

• Modern Washing Equipment: The use of newer washer-extractors, which are primarily designed for cleaning everyday clothing items like pants and shirts, has introduced higher levels of extraction force to the mats. Typically handling 450 pounds of mats per load, these machines can apply up to 400 G-force during the extraction cycle. This intense force causes the mats to stretch and often results in permanent rippling or buckling.

These issues collectively contribute to the "wavy mat epidemic," affecting not just the aesthetic appeal of the mats but also their functionality and safety. As the industry scrambles to address these challenges, the need for innovations in both material composition and care processes is becoming ever more apparent.

The mat service industry is witnessing a revolutionary change with the introduction of Weather-Stopper Technology, which promises to solve the persistent issue of wavy floor mats. This innovative approach utilizes several key developments:

1. Natural Rubber Base: Unlike synthetic rubbers such as nitrile, natural rubber does not require the use of plasticizers like DEHP. This shift not only enhances the environmental appeal of the mats but also improves their durability and stability.

2. Needle-Punch PET Fabric: By using recycled PET (polyethylene terephthalate) from plastic water bottles, Weather-Stopper mats eliminate the need for a separate substrate. The needle-punch process mechanically entangles fibers to create a robust, non-woven fabric that maintains its form without the usual shrinkage issues seen in traditional mats.

3. CDF-Systems Mat Washing Technology: This cutting-edge technology cleans and sanitizes mats while keeping them flat, eliminating the need for high G-force centrifugal extraction. This process prevents the stretching that typically causes ripples and buckles, maintaining the mats' integrity and safety.

Weather-Stopper Technology represents a significant leap forward in addressing the functional and aesthetic challenges faced by the mat service industry, promising a new era of durable, reliable, and eco-friendly floor mats.

Scope 3 Internal Operation/Dust Mop

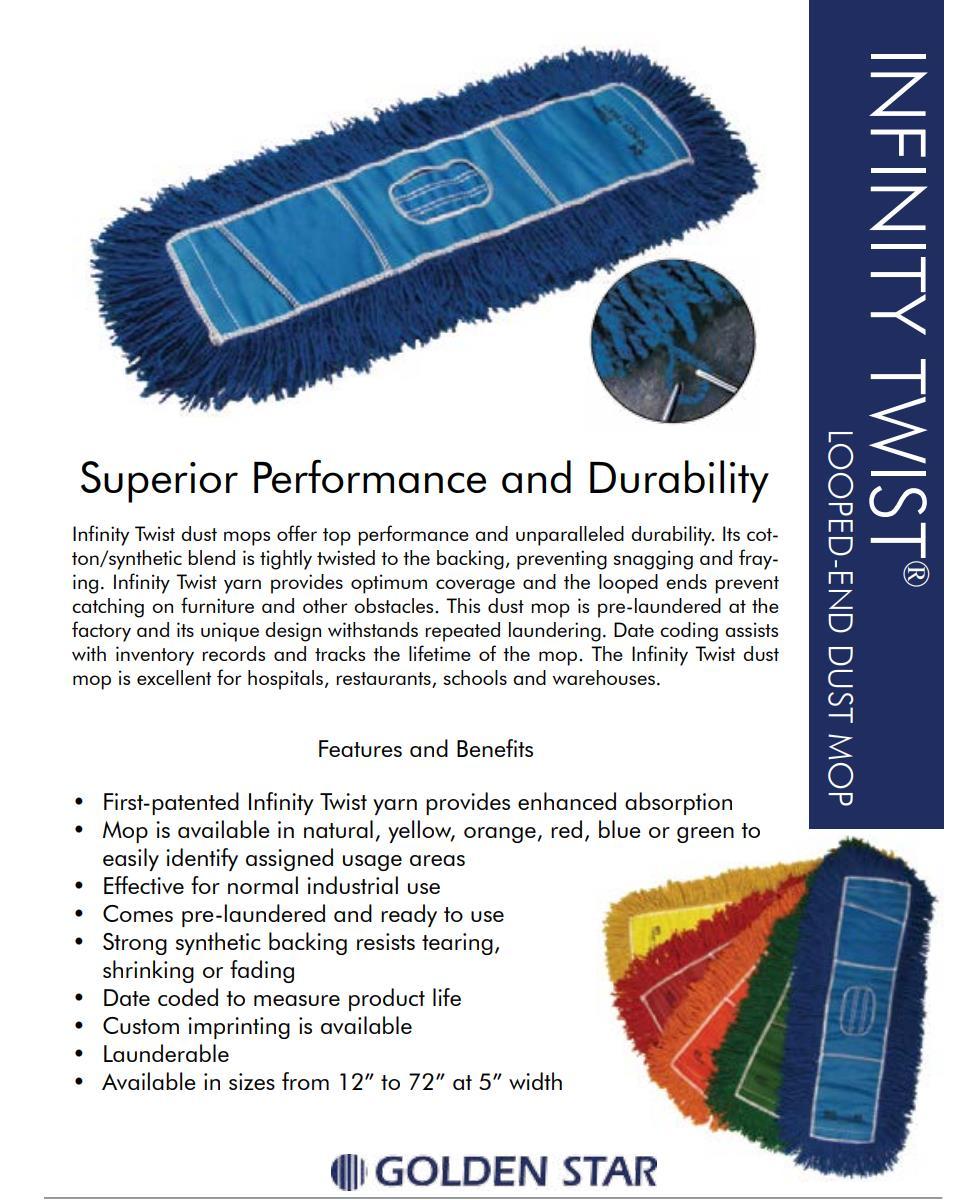

In the world of cleaning, dust mops play an essential role in maintaining pristine environments in both retail and commercial spaces. Traditional dust mop programs have long relied on cotton mop heads, often 6 inches wide, fitted to metal frames for easy handle attachment. This setup is typically treated with a heavy oil coating, enhancing the mop's ability to trap dust and dirt. However, while effective, this traditional method presents several sustainability challenges that are increasingly hard to ignore in our environmentally conscious world.

1. Cotton Mop Heads: Cotton, while a natural fiber, requires extensive water and energy to produce and maintain. In the context of dust mops, oil-treated cotton is particularly burdensome for laundry processes, requiring lengthy drying times and thus consuming considerable energy.

2. Oil Coatings: The application of oil is designed to enhance dust capture but introduces environmental issues during the cleaning phase. As the oil is washed from the mop, it enters the sanitary sewer system, complicating water treatment processes and posing risks to water quality.

In response to these sustainability concerns, advancements in material science have led to the development of dust mops that utilize a unique blend of synthetic fibers. These modern dust mops are not only more effective but also significantly reduce environmental impact.

1. Unlike the traditional oil-coated cotton, these advanced synthetic fibers work on the principle of static electricity. As the mop moves across the floor, it generates a static charge. This static charge creates an attractive force between the negatively charged dust mop fibers and the positively charged dust particles on the floor.

2. This electrostatic attraction ensures that dust, dirt, and debris cling to the mop rather than resettling on the floor surfaces, providing a superior cleaning effect without the need for chemical enhancers.

1. The synthetic fibers used in modern dust mops have a quick-drying nature, which significantly reduces the time and energy required for drying after washes.

2. These fibers are lighter and less dense than traditional cotton, which allows them to dry rapidly, decreasing the energy consumption and carbon footprint associated with their maintenance.

The switch to synthetic fiber dust mops offers substantial environmental benefits:

1. Reduced Water and Energy Usage: The quick-drying nature of synthetic fibers lowers energy consumption in laundry processes, aligning with sustainability goals.

2. Decreased Chemical Discharge: By eliminating the need for oil coatings, these mops reduce the risk of chemical pollutants entering wastewater systems, easing the burden on public water treatment facilities.

Conclusion

We are committed to developing ways to minimize our ecological footprint by embracing technologies that offer both performance and sustainability The evolution of our dust mop program from traditional cotton and oil to synthetic fiber technology is another example of our steadfast commitment to science-based improvements in our product offering and processing systems.

When it comes to maintaining a clean and safe environment, choosing the right dust mop technology is not as straightforward as one might think. The evolution from traditional oiltreated cotton dust mops to synthetic static-based systems marks a significant technological breakthrough, offering improved efficiency and cleanliness. However, the method of replacing dust mop heads plays a crucial role in determining overall productivity and hygiene.

A typical dust mop program using synthetic mop heads involves sliding a metal frame in and out of the mop head to replace a dirty mop with a freshly laundered one. This process, while seemingly simple, can be deceptively time-consuming and messy.

In-the-field studies have shown that it can take between 7-10 minutes for an untrained operator to perform a mop head exchange. This process often results in the transfer of soil from the soiled mop head to the operator, leading to further cleaning needs and potential frustration.

Understanding that time is money, Executive Mat Service has pioneered their "Concierge Dust Mop Program," designed to streamline and simplify the mop replacement process.

1. Pre-installed Mop Heads: Freshly laundered mop heads are delivered with the frame already installed in a reusable nylon bag. This eliminates the need for operators to handle dirty mop heads directly.

2. Quick and Easy Replacement: The operator simply unclicks the handle from the soiled mop frame and connects it to the clean mop head, a process that takes less than 10 seconds. This is a significant reduction from the 7-10 minutes required for traditional mop head exchanges.

3. Efficient Disposal: The soiled dust mop is placed into the same reusable nylon bag that housed the clean mop and is stored for removal on the next scheduled service day. This not only ensures a cleaner and more efficient process but also reduces the environmental impact by reusing the nylon bags.

Conclusion

Choosing the right dust mop technology and replacement method can significantly impact the efficiency and cleanliness of your facility. Executive Mat Service’s Concierge Dust Mop Program exemplifies how innovative solutions can save time, reduce mess, and enhance overall productivity. The cost savings in time and the reduction in frustration far exceed any additional costs associated with the Concierge Dust Mop Program. In the world of floor maintenance, it's clear that time truly is money. By adopting more efficient and cleaner dust mop systems, businesses can ensure their operations run smoothly, ultimately benefiting their bottom line.

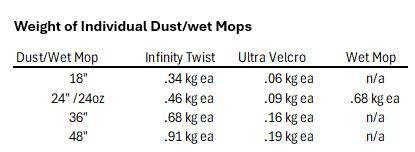

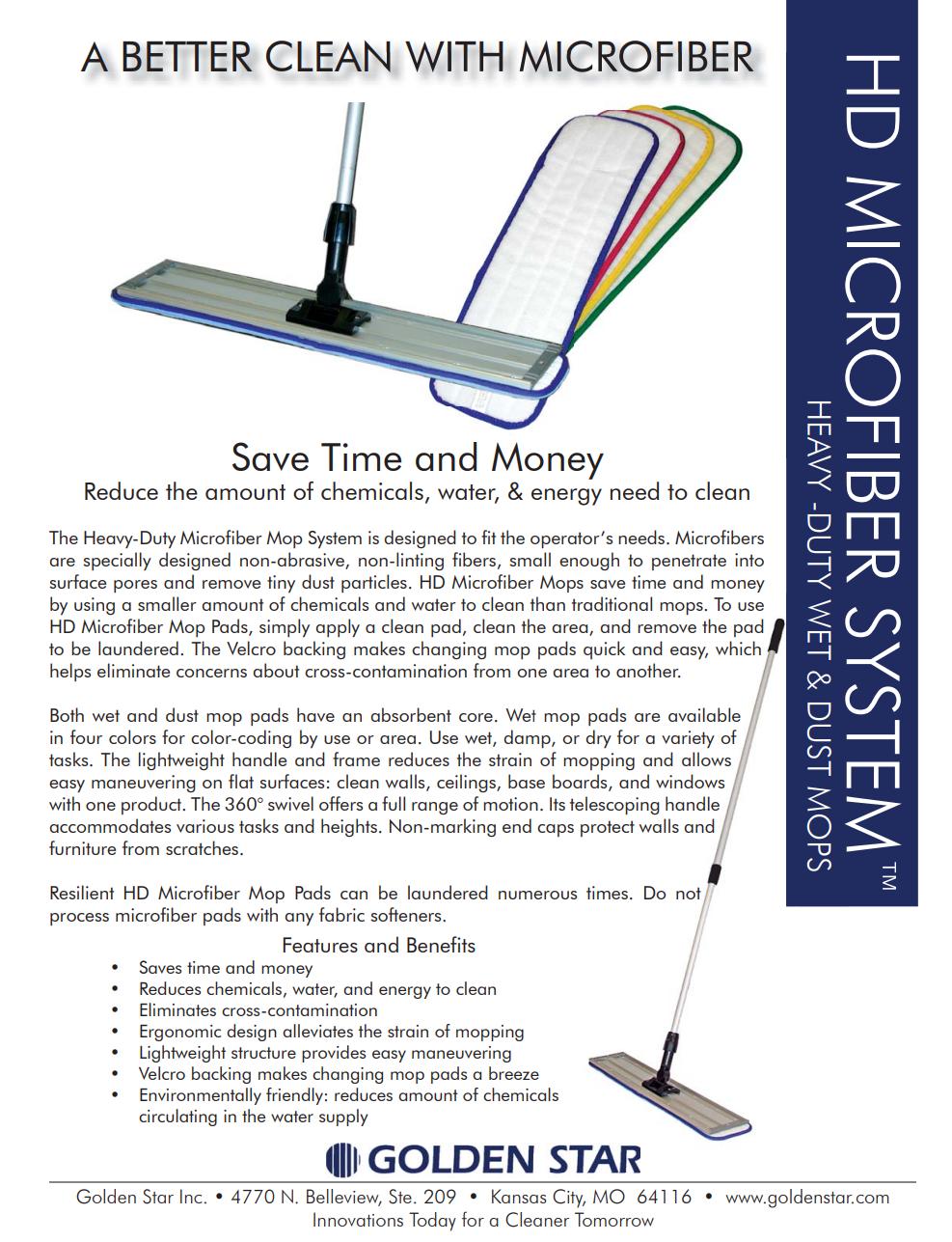

The floor cleaning industry has seen numerous advancements over the years, yet the fundamental design of dust mops has remained relatively unchanged. Traditional synthetic dust mops, while effective, come with their own set of challenges. These challenges include unnecessary weight and carbon intensity, as well as time-consuming mop head exchanges. However, a new innovation using Velcro technology is poised to revolutionize dust mop design and functionality.

Traditional synthetic dust mops are designed with a metal frame that slides into the mop head, accommodating the addition of a pole. This design requires extra fabric to house the frame, which serves no purpose in the actual dusting process. This extra fabric adds unnecessary weight to the mop, increasing the carbon footprint associated with its production, transportation, and use.

Moreover, the process of changing mop heads can be cumbersome and time-consuming. In-the-field studies show that it can take between 7-10 minutes for an untrained operator to perform a mop head exchange. This often involves handling dirty mop heads, which can lead to further frustration and inefficiency.

1. Reducing Carbon Footprint and Weight: The innovative use of Velcro technology in dust mops addresses the issue of excess weight and unnecessary fabric. By eliminating the need for extra fabric to accommodate a metal frame, Velcro microfiber dust mops are

significantly lighter. This reduction in weight translates to a smaller carbon footprint, making these mops a more environmentally friendly option.

The Velcro system maintains the same high-performance characteristics as traditional dust mops, effectively capturing dust and dirt without the added bulk. This innovation not only enhances the sustainability of the product but also improves its overall usability.

2. Simplifying Mop Head Exchanges: One of the most significant advantages of Velcro microfiber dust mops is the ease of changing mop heads. With the Velcro system, operators can simply pull the mop head away from the Velcro frame in one easy movement. This process is quick, clean, and efficient, taking mere seconds compared to the lengthy and messy traditional method.

This streamlined process reduces downtime and increases productivity, allowing cleaning staff to focus more on maintaining cleanliness rather than struggling with equipment. The "no fuss, no muss" approach of Velcro microfiber dust mops significantly enhances the user experience, making them a preferred choice for modern cleaning operations.

Conclusion

Executive Mat Service has integrated Velcro technology into our microfiber dust mops, marking a significant improvement in floor cleaning technology. By addressing the issues of excess weight, carbon intensity, and time-consuming mop head exchanges, Velcro microfiber dust mops offer a sustainable and efficient alternative to traditional dust mops.

Weights are based on product specifications detailed at GoldenStar.com

Source:greenly.earth/carbonaccounting for embodied carbon of raw materials and manufacturing processes 21.5 kg CO2e/kg fiber. Add additional 10% carbon intensity was added for logistics.

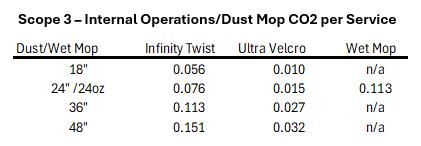

Based on TRSA published average carbon footprint of .366 lbs. CO2 per lb processed converted to metric. No carbon intensity was considered for delivery as mops are delivered the same time as floor mats and carbon intensity of delivery is included in with the floor mats.

48% of the mop’s content is PostConsumer Content (PCC)

Executive Mat Service synthetic dust mops work by creating a static charge that attracts and holds dirt particles. Here’s how the process works:

1. Charging the Fibers: When you push the mop across the floor the synthetic fibers of the dust mop become charged with static electricity. This causes the fibers to stand on end and become negatively charged.

2. Attraction of Dust: Dust particles are naturally positively charged. Because opposites attract, the negatively charged fibers of the dust mop will pull in the positively charged dust particles.

3. Capturing the Dirt: Once the dust particles encounter the charged fibers, they are held in place by the static cling. This effectively captures the dirt and prevents it from being redistributed around the room.

4. Cleaning the Mop: The industrial laundering process releases the static charge and dislodges the captured dirt.

Executive Mat Service dust mop service is an efficient way to clean floor surfaces without spreading dust particles into the air.

Executive Mat Service synthetic dust mops work by creating a static charge that attracts and holds dirt particles. Here’s how the process works:

1. Charging the Fibers: When you push the mop across the floor the synthetic fibers of the dust mop become charged with static electricity. This causes the fibers to stand on end and become negatively charged.

2. Attraction of Dust: Dust particles are naturally positively charged. Because opposites attract, the negatively charged fibers of the dust mop will pull in the positively charged dust particles.

3. Capturing the Dirt: Once the dust particles encounter the charged fibers, they are held in place by the static cling. This effectively captures the dirt and prevents it from being redistributed around the room.

4. Cleaning the Mop: The industrial laundering process releases the static charge and dislodges the captured dirt.

Executive Mat Service dust mop service is an efficient way to clean floor surfaces without spreading dust particles into the air. Safeguarding Steps,

Opting for a wet mop rental service over limited-life disposable wet mops offers numerous benefits, both economically and environmentally. Our wet mop rental services provide high-quality, durable mops that are professionally laundered and maintained, ensuring optimal cleanliness and longevity. Our wet mop program minimizes waste while reducing the environmental footprint, lowers operational costs, and maintain a higher standard of cleanliness.

Scope 3 emissions encompass the indirect greenhouse gas (GHG) emissions that occur in a company’s value chain, both upstream and downstream. A significant aspect of downstream emissions is the release of methane from organic waste decomposition in landfills. Methane, a potent greenhouse gas with a global warming potential (GWP) 87x greater than CO2 over a 20-year period.

To accurately estimate methane emissions from landfills, scientists use methane propensity models such as the Scholl-Canyon model. This model helps calculate the carbon dioxide equivalent (CO₂e) emissions resulting from the anaerobic decomposition of organic waste. The Scholl-Canyon model considers various factors, including the type and moisture content of the waste, to predict methane generation over time.

Key Components of the Scholl-Canyon Model:

1. Waste Composition: Differentiates between wet and dry organic waste.

2. Decomposition Rate: Estimates the rate at which organic waste breaks down anaerobically.

3. Methane Correction Factor: Adjusts for the proportion of methane in the landfill gas.

4. Methane Capture Efficiency: Accounts for the efficiency of landfill gas collection systems.

K value represents how quickly a waste will decay and considers the relative moisture content. For example: organic food waste has a lower K value due to high moisture content (80%) and corresponding lower level of carbon.

Applying this model using methane’s 87x GWP and the non-linear rate of decay in landfill (40% of 40-year methane generation occurs in the first 5-years), we can determine Emission Factors (Efactor) of individual waste streams. Applying Efactors to individual waste streams being disposed of in landfill provides a quick and easy methodology to determine the 5-year impact of wastes on atmospheric carbon dioxide levels.

companies can better understand the methane emissions associated with their products' end-oflife disposal and develop strategies to mitigate these emissions.

Following FOD modeling generated by Brightspot Climate and Emissions Reduction Alberta the following Efactors were determined for 2-broad categories of organic waste1 The Efactors were restated using methane’s 87x global warming potential and a 5-year window instead of the 40-year total expressed in the FOD model.

Emission Factors:

1. Wet Organic Waste Emission Factor: 43.5 kg CO₂e per kg of waste.

2. Dry Organic Waste Emission Factor: 126.8 kg CO₂e per kg of waste.

• Data Collection: Companies need to identify organic waste going to landfill by wet and dry and collect annual weight data. on the type and amount of organic waste generated downstream.

• Emission Calculation: Multiply the quantity of waste in each classification by the corresponding emission factor to estimate the CO₂e emissions.

• Reporting: Include these emissions in the company’s Scope 3 downstream emissions inventory.

Mitigation Strategies

To reduce Scope 3 downstream emissions related to methane, companies can now look to adopt strategies to prevent organic wastes from entering a state of anaerobic decay.

1: ERA Greenhouse Gas Quantification Assessment Report CE0163185 Hotel Blackfoot

1: ERA Greenhouse Gas Quantification Assessment Report CE0163185 Hotel Blackfoot

At Executive Mat Service, we recognize the urgent need to address the environmental impact of our single-use disposable culture. As convenience increasingly dictates lifestyle choices, it has led to an exponential rise in waste that ends up in our landfills, contributing significantly to greenhouse gas (GHG) emissions and, consequently, climate change. In response, we have launched the Green Thumb Initiative, a comprehensive program aimed at drastically reducing landfill contributions by upcycling waste materials into valuable resources.

Landfills are not just dumping grounds; they are active environmental hazards. As organic and inorganic waste decomposes, it releases methane and other GHGs, which are up to 87 times more potent than carbon dioxide over a 20-year period. This makes landfills one of the most significant contributors to global warming and underscores the need for sustainable waste management solutions.

The Green Thumb Initiative

The Green Thumb Initiative represents a bold step towards sustainability. It is designed to intercept and upcycle various waste streams that are conventionally destined for landfills. By leveraging our existing delivery logistics, these materials are collected and brought back to our processing plant, minimizing additional carbon emissions that would have been generated through separate collection processes.

At the heart of the Green Thumb Initiative is our innovative approach to upcycling waste. Much of the collected waste is transformed into biomass feedstock, which is then utilized in our Eco-Growth Energy

Recovery boiler system. This system plays a crucial role in our operations by heating laundry water an essential resource in our business. Utilizing biomass feedstock not only diverts waste from landfills but also replaces the need for fossil fuels, creating a double environmental benefit.

Heating laundry water with waste-derived biomass is not just an environmentally sound practice; it's also economically advantageous. By repurposing what would otherwise be landfill waste, we significantly reduce our energy costs and allows us the opportunity to reinvest in other carbon-lowering technologies

Our dedication to reducing environmental impact is not just about innovative solutions but also about being accountable and transparent in our practices. Executive Mat Service has been ISO14001 certified since 2010, a testament to our commitment to effective environmental management systems. We engage annually with ISO consultants to explore new ways to reduce our carbon intensity. These efforts contribute not only to lowering our own carbon footprint but also to assisting our customers in reducing their Scope 3 emissions related to "Internal Operations."

The Green Thumb Initiative by Executive Mat Service is more than just a program—it's a part of our mission to lead the industry towards a sustainable future. By turning waste into energy, we showcase how businesses can operate both economically and sustainably, setting a benchmark for others in the industry. As we continue to innovate and expand our sustainable practices, we invite our partners and customers to join us in making a meaningful impact on the planet, one step at a time.

the

"Tackling

Synopsis: In today's convenience-driven world, the environmental toll of single-use coffee pods has become alarmingly evident. With the disposal of 62 billion pods annually in the US and Europe alone, approximately 1.55 billion kilograms of organic waste end up in landfills each year.

The Impact of Methane Emissions: This massive waste volume leads to significant landfill methane emissions, a potent greenhouse gas. Using established models, it's estimated that these pods could contribute to 6.665 billion tonnes of greenhouse gas pollution annually, equivalent to 1 kilogram of pollution per pod.

Local Example: Calgary's Contribution: In Calgary, with a population of 1.4 million, the annual landfill contribution from single-use pods reaches 2,205 tonnes, resulting in 95,256 tonnes of CO2 equivalent emissions.

The Urgency of Action: The reliance on single-use pods highlights a broader issue of disposable culture, posing unsustainable consequences for the planet. Urgent action is needed to address this global crisis.

A Sustainable Solution: Executive Mat Service, based in Calgary, is leading the charge with its GREEN THUMB INITIATIVE. Through a single-serve pod recycling program, in partnership with Eco-Growth Environmental, millions of pods are upcycled into emissions-neutral energy and dimensional lumber. This initiative showcases a practical approach to combatting single-use waste and invites broader participation.

Image depicts

problem with single-service coffee pods ending up in landfill turning into landfill methane.

Image depicts

problem with single-service coffee pods ending up in landfill turning into landfill methane.

Eco-Growth Environmental represents a pioneering venture in the realm of sustainable waste management and energy production, initially incubated within Executive Mat Service. This innovative initiative was born out of the need to convert "GREEN THUMB WASTE operations into clean thermal energy, specifically to heat process water for laundry operations.

Transition to a Standalone Business Entity: Capitalizing on its early successes and the growing demand for sustainable waste management solutions, Eco-Growth Environmental soon expanded into a separate business unit. The company has since positioned itself as a global leader in the development of landfill avoidance technologies, including Rapid Dehydrators and micro waste-to-energy systems. These technologies are designed not only to reduce waste but to transform it into valuable energy resources, minimizing environmental impact while maximizing efficiency.