Designing with Systems: Generative Geometry

Fabiana Aja

Fabiana Aja

Abstract

Creating a performative surface is not just creating a “fancy form”, as the name states it, their performance and the variation of its components will determine its shape thus giving it its structural integrity, capacity and strength. To develop a performative surface it is crucial to design a system that will create it; it is like the biological process of morphogenesis that we see in nature that causes an organism to attain its shape, seeing how a change or variation in one area is reflected on the others. In the following documentation it will be experimented and analyzed through the creation of physical models, grasshopper modeling and the use of two different materials, thick paper and veneer, the formulation of local components through the principles of associative geometry to achieve a performative surface; seeing how the geometrical design and intervention with one material may affect its shape and performance differently than it will in the other, reflecting in the shape of the component and consequently of the surface as a whole. The goal will be, not only to analyze and experiment the diverse approaches for each material, but to also achieve the best design of local and regional components that result in the geometrical and material intelligence needed to create a performative surface.

First Aproximation: Thick Paper

Paper Properties Analysis and Experimentation

During the experimentation process it was analyzed the performance of the paper, how it “works” before being intervined in any way; even though the paper in question is thicker than the common sheet, it shows how, when flat, it bends not being able to withstand its own weight let alone stand any external force or weight. During the experimentation, diverse forms of folding and/or twisting where performed, seeing how the thick paper would change its original properties.

In the first approach, as it can be seen in the images on the wright, the paper was cut into long strips that where later on twisted; by doing this the paperstarted to have the enough strength to hold itself up and to begin creating a surface, ebenthough the paper was able to carry itself it was not able to withstand any other weight.

In the second approach the paper was divided in a triangle pattern that allowed it to fold; this folding permited the paper to carry its own weight and to also form diverse surfaces as the division in the form of triangles lets it bend one way or curve to the other.

Local Component Formulation

Composition of local component seen unfolded: orange creases fold downward while pink creases fold upward, creating “mountains” and “valleys”.

Final local component once folded

View on Side A View on Side B 1 1 2 2 3 3 4 GlobalScale:FullAssembl y

Adding Local Components to Form a Whole

In these diagrams we can see two views/sides of the regional component being created by the adding of local components; the addition of the local component is done until creating a global or full assembly .

suruoT:ecafruSnoituloveR

Surface Creation Pseudo-Code Diagram

Surface Creation

Pseudo-Code Diagram

Analysing Flexibilty vs. Rigidity of the Surface

Conclusion

In this first approach utilizing thick paper as the material, it was seen how the material on its own does not have the strength to support its own weight let alone withstand external force. When twisting the paper it was seen how it slowly starts to acquire a shape and its capable of standing for itself and when adding depth in the form of folding the material not only is capable of standing by itself but it is also capable of creating different curvatures and thus surfaces; the folding triangle component allows a free and flexible shaping of the surface. The larger amount of folding divisions that were added in the V direction of the surface the more external weight it was able to withstand, nevertheless, the large amount of folding made the surface very flexible instead of providing it with the rigidity needed, also the foldings demand for a larger amount of material and some of the planes created could have been eliminated as they proved to not really be needed.

Second Aproximation: Veneer

Veneer Properties Analysis and Experimentation

During the experimentation process it was analyzed the performance of the veneer, how it “works” before being intervined in any way. The fibers forming the grain of the wood allow it to have a better capability of withstanding its own weight, but still not an external force or weight. Also when going with the direction of the wood grainsthe veneer obtains a more flexible property, however, when going against the direction of the wood grains the material becomes extremely rigid and in the risk of breakage when withstanding certain amount of force.

Local Component Formulation

Composition of geometry for local component seen from above; division of the triangles and of their offsets to form the grid.

Final local component seen from different sides.

Final local component seen from behind.

1 2 3

Adding Local Components to Form a Whole 1 2 3

ssem b l y

GlobalScale:FullA

Surface Creation Pseudo-Code Diagram

Surface Creation

Pseudo-Code Diagram

Surface Creation

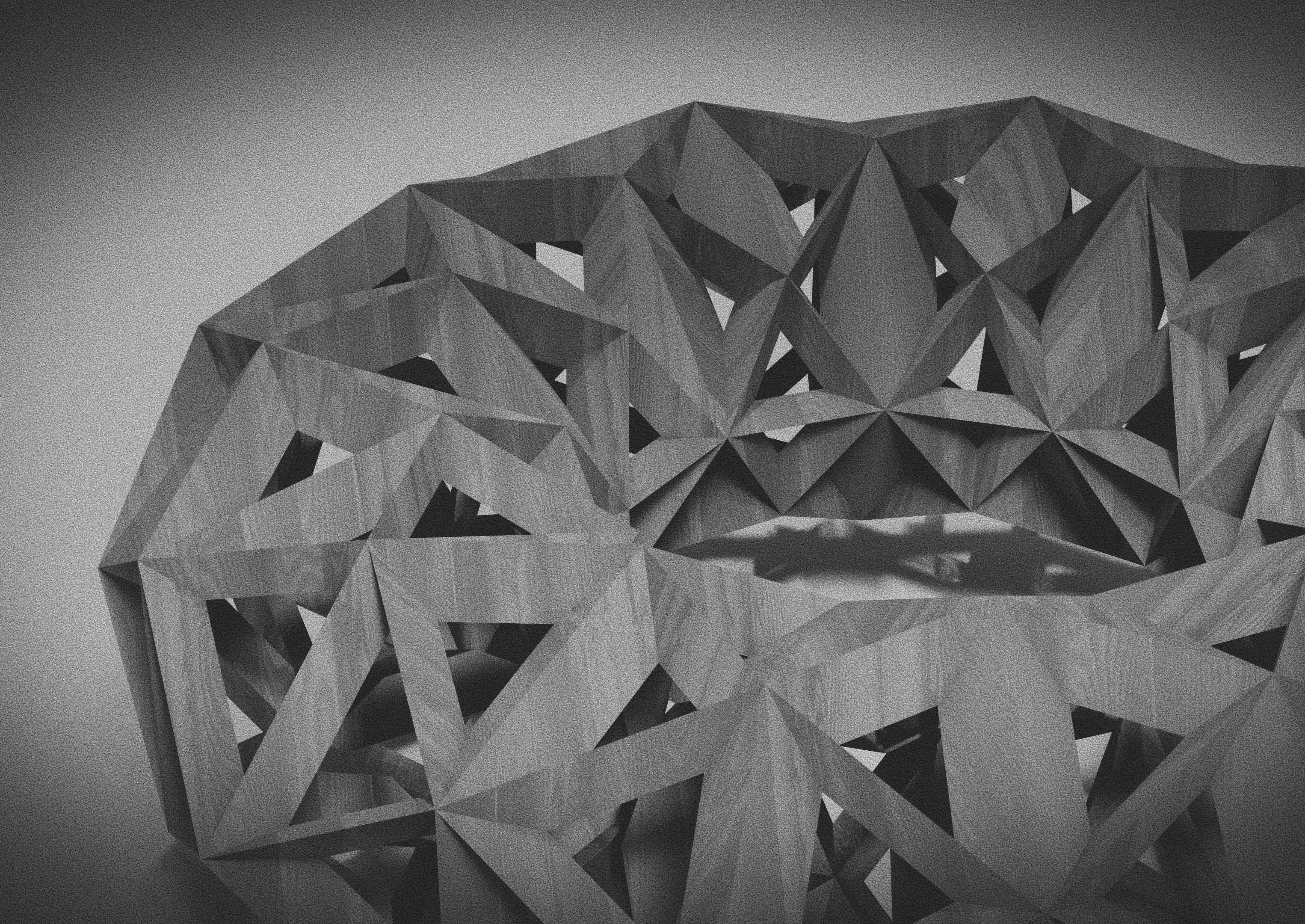

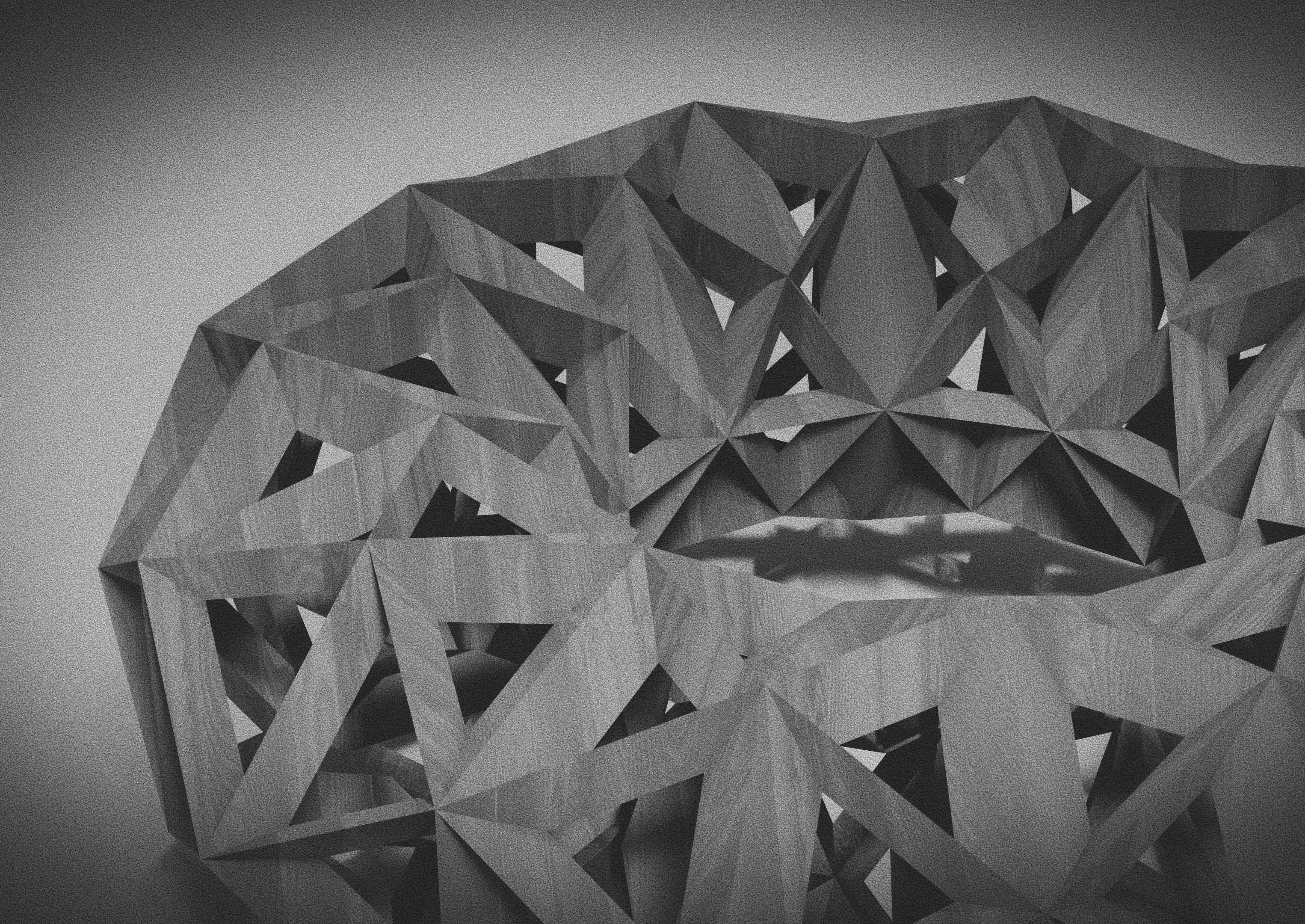

Rendered Visuals

Physical Component Assembly

Conclusion

In this second and final approach the material in question, veneer, demonstrated different properties from the thick paper used in the first attempt; the venner, coming from wood, its grain/fibers allow it to have a better capability of withstanding its own weight, but still not an external weight. Also when going with the direction of the wood grains it is seen how the material obtains a more flexible property, however, when going against the direction of the wood grains the material becomes extremely rigid and breakable when withstanding a certain amount of force. In this attempt the component also follows a triangular pattern that eventually forms a type of diagrid that allows the surface to curve, resulting in its form. By adding an offset of said triangles and allowing the material to fold inward, a depth was achieved, permitting the structure of the surface to become more rigid and stable. The connection or joint of each component was attained by adding an “external” component, for the future of this it would prove fitter to allow the components to join by modifying the flaps so that they may lock into one another, sort of like a weaving pattern, without the need of an external component, consequently achieving a higher associative geometry and performative surface as a whole.

Fabiana Aja

Fabiana Aja