3 minute read

REGENERATIVE FARMING

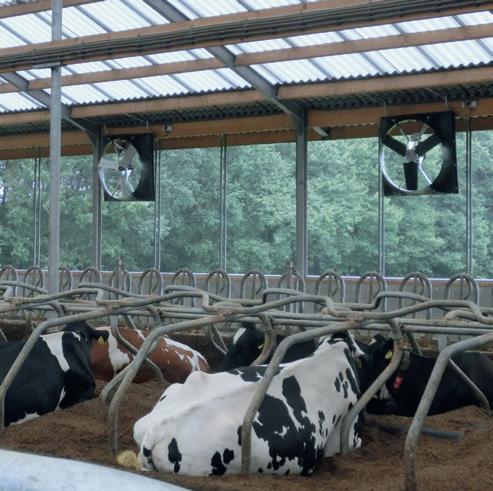

HEATSTRESS?

The climate in the barn is the key!

NEW! THE SOLUTION:

ABBIFAN 140-XXP-2

The latest motor technology now applied on our fans! Direct drive.

DC-permanent magnetic motor 40-70% energy savings No frequency control needed No motor protection switch needed No special wiring needed No maintenance Mains: 230/400V 50Hz

Simpler installation Less electric wiring No obstacles inside No restlessness when doing maintenance Shorter suspension of the fans Lower total investment Airflow in length of cubicles

We are noticing a range of different plants growing in our swards

JONNY CRICKMORE

Quality not quantity was the recipe for success for one regenerative cheese producer speaking at Groundswell, Hertfordshire. Chloe Palmer reports.

Regen dairy farming for cheesemakers

NEW! CROSS VENTILATION

blows fresh outside air in your barn!

www.abbi-aerotech.com www.rumitechs.co.uk Ph: 07714 846987 Moving away from the ‘treadmill of production’ towards producing an artisan, more nutritious product with a strong story is the way forward, according to several high pro le regenerative cheese producers and retailers speaking at this year’s Groundswell event.

Jonny Crickmore, of Fen Farm

Dairy, Su olk, admi ed he ‘sleepwalked into pushing for a high yielding cow’ before he decided he wanted to do ‘something di erent’. A er looking at other business models, he realised ‘the value was in the tank’.

He said: “We considered what else we could do with our milk and set out on a mission to make our cheese. A er nine years, we are using most of the milk we produce from our Montebeliarde cows to produce our cheese, which is entirely consistent and sells across the UK.

“While developing our product we visited cheesemakers across the UK and France and realised the farmers who make good cheese allow animals to graze on pastures which are diverse.

“ ey do not encourage cows to produce too much milk and we could see the way we farm in uences the quality of the cheese we make.

“For us, growing good quality grass silage and cu ing grass more frequently has allowed us to save £40,000 in concentrate costs and prevented our cows from becoming too fat.

Plantains

“We are now direct sowing plantains and clovers into our grass leys and growing almost everything we feed. We are using less fertiliser and are now noticing a range of di erent plants growing in our swards.”

He added that he used spreadsheets to record data on everything he was doing, which showed although milk yield reduced, the quality of milk increased.

Mr Crickmore said: “We have taken control of our business and we are in a very strong position.

“I do not really need my milk buyer anymore.”

Clare Hill, regenerative agriculture director at FAI Farms and consultant supporting farms adopting regenerative agricultural methods, said the dominance of ‘yield-based models’ in dairying ran contrary to a regenerative approach.

She said: “Some milk processors are o ering 1ppl for regenerative practices, but this still incentivises production. Milk contracts and borrowing are based on high yields, so everything needs to support this, meaning inputs have to increase.

“If we are looking to scale up regenerative agriculture, it cannot be done top down as it is a bottom up approach. Regenerative agriculture is difficult to standardise and categorise, because it is a grass roots movement, so no-one can control it.”

James Ru er, of Paxton and Whit eld Cheesemongers, agreed and suggested regenerative cheesemaking should not be about a brand or a sticker, rather it should be a ‘process, a force for good’.