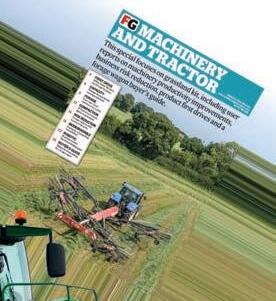

Don’t settle for second best

T

ENGINE 170 LIFT HEIGHT 8.8 LIFT CAPACITY 4.4

The Merlo Multifarmer is a unique machine equipped with a telescopic boom and a mechanical PTO to work in conjunction with the 3-point linkage at the rear of the frame. The MF44.9 is incredibly versatile and will support you in your every day work. Visit merlo.co.uk to find out more.

merlo.co.uk

‘You dreamt it, we built it’ is how Fendt describes the generation seven iteration of its 700 Vario Series, giving an indication – on paper at least – that it expects this model range to propel it to a wider position of market competition in the well-supplied 200-300hp sector. With a product which delivers for cultivations, haulage, crop applications, crop establishment, green harvest and the numerous other more specialist applications Fendt finds its products in, it has set a serious precedent to fulfil.

Developing the existing 700 Series, which includes Fendt’s most popular model – the 724 – by some significant margin, it was not a particularly unexpected choice. Its complete tractor offering covers about 46 different machines, so investing in the most popular product is not such a bad idea.

Currently, the Bavarian manufacturer has yet to announce any changes to the existing 700 Series range, so buyers currently have the option to order a 720, 722 or a 724 in either a Gen6 or Gen7. From an operator perspective, there is little difference between the two machines, with both utilising the FendtONE operation system.

Supplied across all models (except the 800 and both crawlers) the FendtONE operation system has scored well, with a wider range of machine adjustments and control configurations than most other manufacturers.

We tested this system in a 516 Vario tractor test in December 2022, with all

of our team finding it a well-built, adaptable place to work.

Changes to the cab for the Gen7 are modest and include Cat 4 filtration with a revised air circulation system, offering a claimed 30 per cent increase in cooling capacity, an upgraded heated/cooled massage seat with position memory, an offside window wash/wipe, and an optional refrigerator in the offside footwell.

The major changes from the six to the seven generations are mechanical. A new Agco Power 7.4-litre engine is unique to the Gen7 and replaces the 6.1-litre Deutz unit of the previous iteration. It is professed to offer improved

fuel consumption with the peak torque of 1,220Nm delivered at 1,300rpm.

Engine cooling has been revised and utilises a hydraulically-driven fan design lifted from the 1000 Series. The design is said to be 40 per cent more economical than a conventional assembly, but crucially the system requires a 560mm-diameter fan, creating a much narrower front end design with improved visibility of the front linkage.

The largest 728 model includes the brand’s dynamic performance system, which offers a 20hp power increase. Operating in a similar manner to a

boost, the system is designed to deliver an overall increase in available power for all tractor systems – driveline, hydraulics, pto and cooling – as it is demanded. The system is not dependent on a specific pto or transmission load before the increase is introduced.

In operation, the new engine did appear to run comfortably at a lower rpm, even when working with a six-metre power harrow on heavy, sloping land.

Working with the new engine, a revised version of the trademark Vario transmission now includes the manufacturer’s VarioDrive system, which is currently offered on the larger 900

Launched in mid-2022, the Gen7 700 Series promises to deliver the proven performance of the existing 700 Series range, but with greater power, manoeuvrability and payload. Toby Whatley had a first drive in the range-topping 728.Spanning 203-303hp, the Gen7 700 Series is a direct replacement for the brand’s current 700 Series. Cooling is now managed with a hydraulically-driven fan. Factory fit tyre inflation is offered with the firm’s VarioGrip system.

A revised driveline includes VarioDrive which powers the front axle independently from the rear.

THE 700 Series Gen 7 builds on what is an already highly accomplished and popular tractor range. Fendt says some customers, particularly vegetable growers, have built their fieldwork activities around the capabilities of the existing 724.

The new range appears to have maintained the features buyers liked while enhancing others; the addition of more top-end power, higher road speed and a factory-fit tyre inflation system.

and 1000 Series. The system effectively changes the tractor from four-wheel drive to all-wheel drive, where two swash-plate motors deliver drive to the front and rear axles independently, with oil supplied from a central hydraulic pump.

Apart from the obvious engineering complexity, the system allows for some clever drive divisions which allows the front axle to effectively pull the vehicle into a tighter turning circle, and also removes the two-range transmission and manual four-wheel drive engagement.

During the launch, Fendt proudly demonstrated the machine operating on a comparable turning circle to a

much smaller four cylinder 500 Series. In practice, the system is noticeably effective in changing the handling characteristics of the tractor, which was particularly recognisable when pulling away from a junction, where significantly less steering lock is required to align the machine onto the carriageway. For vegetable and root growers, this steering improvement could be a great advantage for bed and row-crop tasks.

Machines destined for high-hours carrying out haulage may benefit from the top speed increase to 60kph, delivered at a frugal 1,450rpm. For a machine of its size, the unit handled well at higher speeds, however its capability to travel at this speed should be matched with a suitable trailer,

The Agco Power engine delivers maximum torque at a lower rpm, resulting in reduced fuel consumption.

tyres and brakes, and also may not be legal on the public highway.

Despite a top-end power increase of nearly 70hp to 303hp, the overall machine wheel base has increased by 117mm to 2,900mm. This dimension matches its competitive stablemates well, including the 301hp John Deere 6250R, which shares an identical wheelbase dimension.

Options originally found on the larger models have been moved on to the Gen7, including VarioGrip central tyre inflation, which was a popular feature on the 800 Series.

This system allows varying tyre pressure between field and road and can take full advantage of VF tyres in reducing compaction and potentially improving on-road productivity.

The fact that the machine’s dimensions and maximum power now match a key competitor is not a coincidence – compact 300hp tractors are an increasing must-have for some contracting businesses.

Where the range sits within the wider Fendt offering is currently less apparent, as the Gen7 closely matches some of the specifications of the larger and heavier 800 Series, while the existing Gen 6 700 Series remains available to order.

With Agritechnica taking place in November, buyers can expect a realignment of the available models to potentially remove some of the range overlap.

Minor changes have been made to the cab, such as an optional large coolbox.

DON’T DELAY!

We’re freezing the price of a new combine for a limited time only. Order before June 30th and get your 2024 combine for the 2023 price*. Talk to your dealer today to get the best deal.

Front and rear mower combinations have done much to improve output for those who see butterfly-type triple mower combinations as too complex, costly and power hungry.

And for those who prefer to shed the conditioner, output moves up a gear from removing weight and lowering the power requirement compared to their nylon or steeltine counterparts.

With an increasing number of manufacturers offering wider working widths for the rear-mounted unit, there is now more scope than ever to boost mounted mowing performance, either in combination with a front mower or working solo.

For Dave Eardley, of D.W. Eardley, Almington, Shropshire, opting to take the plain disc rear mower

route has seen a 3.5-metre rear unit working in combination with a 3m front for the past few years, with the extra half-a-metre delivering a worthwhile increase in productivity.

“We have run a front and rear combination for years,” he explains. “It makes good use of tractor power and creates a decent outfit with good productivity. And at almost 6.5m, we have been cutting around 12 acres/hour quite easily with a 150hp tractor.”

The family-run dairy farm puts considerable effort into producing high quality silage to feed its 450cow herd. While local contractor J. and V. Seaton from Market Drayton carries out raking, foraging and clamp work, the Eardleys favour mowing and tedding to influence the dry matter values it requires for clamp silage.

“We went away from mower con-

ditioners many years ago, and removed the conditioner unit from the front mower – it is an element we do not miss,” he says.

“Plain disc mowers are simpler, easier to drive and a lot less complicated. And with a good-sized combination, we can knock down a decent area of grass, then ted as required to make the most of wilting.”

The farm aims to take five cuts of grass through the season, with each totalling around 81 hectares. It is a workload comfortably reached in two days, and does not require early starts to cut through the acreage, enabling the farm to make the most of rising sugars.

This year has seen mower performance leap forward again to make better use of natural drying.

In comes a Pottinger Novacat

442 from local dealer Robin Edwards Agri, complete with 4.3m working width to replace a 15-year old Novacat 350.

“Based on the performance and reliability of our old mower, there was no reason to look at other options,” he says.

“I wanted to go wider and the Novacat 442 delivers, bringing almost 0.9m of additional cutting width to the combination for little extra cost.

“Yes, I would have liked a triple just to help spread the weight across the back of the tractor, but the wide rear mower was less than half the price of buying a butterfly.

“And in reality, we are not that far behind the working width of a triple, and at a much lower cost.”

Used on the farm’s John Deere 6155R, Dave says early indications show an increased output of three acres/hour from the extra working width.

“The extra bed width has lifted our work rate from 12 to 15 acres/ hour,” he says. “And that means more wilting time for the fields that are cut later in the day. I am still mowing at the same speed, at up to 18kph depending on field conditions.”

The Novacat 442 is one of the widest tractor-mounted plain disc mowers on the market. It uses 10 discs, each carrying two blades, to achieve a 4.3m working width.

Pottinger says the 1,080kg mower needs 110hp to operate, and it

The AMAZONE FT front tank, you wouldn’t even know it was there

With the AMAZONE UF sprayer, its reputation goes before it. That well-proven formula of induction bowl performance, boom ride and nozzle control coupled with its exceptional build quality and reliability has made the UF what it is today.

When you are looking for increased work rates from a wraparound sprayer combination, there’s adding just extra capacity and then there’s adding AMAZONE convenience and comfort. All that connects the AMAZONE FT to the rear-mounted UF sprayer is just a cable and 2” feed and return pipes. After that technology takes over and you don’t even know a front tank is there.

Simplicity, performance, capacity, AMAZONE.

The Novacat 442 delivers, bringing almost 0.9 metres of additional cutting width to the combination for little extra cost

DAVID EARDLEY

leaves a 3.6m-wide swath when not equipped with swath discs. Using discs enables the swath to be pulled in, to either 2.6m or 3m.

The elephant in the room of course, is transport.

This model is unable to be carried vertically, so is carried horizontally, behind the tractor. It does feature a marker light on the end of the bed to warn motorists of the over-hanging length.

“My old mower could fold vertically, but it was not a problem to carry it horizontally behind the tractor,” he says. “Though this one is another 90cm longer.”

“And there is no denying the

442 model is lengthy when in transport, but it is no longer than a mounted plough,” he says. “Like most rear-mounted kit, you need to be aware of your surroundings.”

Getting from transport to working position is achieved hydraulically, and with ground pressure managed through an accumulator, compared to the previous model’s spring tensioners, Dave says the rear mower seems to glide much more easily across ground contours.

“Ground pressure is adjustable

EARDLEYfrom the cab, and is much more versatile given changing field conditions,” he says. “And from what I have cut already, I can see that the rear mower rides so much better than the front.”

After making three passes around the headland, Dave works from one side of the field to the other, turning back on himself to take the next cut.

“I mow using auto-steering, and I have needed to make a few tweaks to maintain an accurate guidance line particularly when working across slopes,” he says. “Though the two mowers have been very easy to match up with cutting heights, you cannot see a difference in stubble height.”

He also pays particular attention to blade sharpness. A new set goes on each season and, on the days he intends to mow, all are inspected and their leading edges sharpened to ensure a clean cut.

“Quick change blades make it very easy to take them off and run a flap disc across the leading edge before going mowing,” he says.

“A clean cut brings several benefits, including reduced fuel consumption, as a blunt set of blades will make the tractor work harder.

“A clean cut from sharp blades also promotes better regrowth and, with five cuts to make, we want our grass to recover quickly,” he adds.

A noticeable aspect of the rear mower’s wider cut is swath presentation. The 10-disc bed leaves a swath that is visibly wider than the front.

“When we go tedding, we are no longer dealing with closely matched swath widths, but they do ted-out just as easily as they did with the narrower mower,” he says.

“And during subsequent cuts –usually third and fourth – not having a conditioner does prevent the grass from drying out too fast, so it can buy you time in summer.

Overall, Dave says he is pleased with the decision to go wider with the rear mower, adding: “It is a cost-effective upgrade that has improved overall silage making efficiency along with the potential for a much more controlled wilt.”

A clean cut brings several benefits, including reduced fuel consumption

DAVECare is required for transport, as the rear-mounted 4.3-metre mower extends rearward behind the tractor. Prior to tedding, the differences in swath width are considerable.

For Ian Richardson, of Church Farm, Warmingham, Cheshire, being in control of silage-making is paying dividends with milk production.

The switch to producing their own high-quality forage started three years ago, when the Richardsons went all in with an 18-year-old Claas Jaguar 870. The family-run farm reasoned that taking a cut every five weeks, in pursuit of 28 per cent dry matter silage to provide higher quality forage, would help steer the

business towards putting more milk in the tank.

Ian Richardson says: “I have been pleasantly surprised to find that we have added an extra two to three litres just from improving forage quality. My cows have never milked as well on first cut silage as they have since we took full control and changed the way we work. It has proved that getting high-quality silage from first cut is essential.”

However, taking more frequent cuts required a rethink on the silage process. As a result, the Richardsons

have geared up with kit which allows them to take control of when and how silage is made. The self-propelled forager packs a modest 480hp from its Mercedes V8 engine, but gives the firepower needed to get the job done. Feeding the forager has seen the farm invest in a four-rotor Vicon rake to create a larger swath and, in turn, increase productivity.

Mr Richardson says: “2020 was our first season on our own running a self-propelled forager, and since

then we have never looked back. The key is to watch the forecast and try to get our timings just right – it is harder to do this when you are not in control of your kit.

“With increasingly tighter weather patterns, we have to be efficient. There may only be a short weather window, but we are geared up to be able to clear each cut in two days.”

He points out that nearly every forage contractor in the area operates a four-rotor rake and that the reasons for doing so are clear.

“You cannot guarantee settled

weather periods, and we might only get a two-day weather window,” he says. “So if I can get my silage made in two days, the weather is much less of a problem.”

This season, he has added a McHale triple mower to the fleet, supplied by G. Richardson Agri, Cheshire. This supports an existing Kuhn front/rear combination, and the combined capacity of five mowers gets the process off to a flying start.

“We can now drop 150 acres of grass in under six hours,” he says. “This makes the most of wilting, ahead of raking and chopping.”

To maximise forager performance, swaths are gathered using a four-rotor Vicon Andex 1304 Pro, which arrived three years ago to replace a twin-rotor machine. The pro-specification sees load-sensing hydraulics used, and this provides individual rotor lift, one-button fold and unfold, the ability to save a swath

width in the terminal, and apply different headland lift or lower delay.

The working width of the Andex 1304 Pro is adjustable from 10 metres to 12.5m, and this also allows hydraulic amendment of the swath width via rear rotor positioning.

In addition, electric rotor height control enables on-the-move adjustment of tine height, with the rotor head assemblies each carried on a triangular chassis, capable of ground contour following.

“We had a four-rotor rake on demo from Brookhouse Agricultural [Cheshire] and I soon realised that the time it saved us was phenomenal,” Mr Richardson says. “Taking more cuts now means our crops are not quite as heavy, and without the capability to pull more rows together, the forager was running around too fast; it just takes longer to fill trailers.”

The increased efficiency at Church Farm has come solely from swapping to a four-rotor rake, allowing the farm to put four rows into one.

Mr Richardson adds: “That bigger row has made a world of difference to our output. We had previously been putting three rows into one, but the rake operator was under pressure – really going far too fast –just to stay ahead of the forager.

“With a four-rotor rake, we can now prepare swaths at a much slower speed because we are covering the ground much more easily, and making better use of our equipment. In turn, the forager is loaded up more and working harder, rather than racing around.”

He says that because the whole team is better balanced, with fewer bottlenecks and improved flow, they

can operate with just three trailers instead of five.

“I am no longer waiting for trailers. We are so much more productive and each trailer now carries much more grass back to the clamp, simply because the forager is firing a constant stream of grass into the trailer, which packs in a better payload.”

“I never thought that putting one extra row into the swath could make such an improvement to the whole operation.”

With less rushing around, there is also more opportunity for the rake operator to fine-tune the rowing up process.

“We have electric rotor height adjustment that can be carried out from the cab using the rake’s joystick control,” Mr Richardson says.

“This helps us to further improve forage quality; we can keep the tines clear of the ground, reducing soil contamination, which is a huge benefit.”

He says that having the ability to constantly tweak the rake in response to field conditions lets them manage the quality all the way to the clamp.

“We are better off leaving a

few blades of grass on the floor, rather than scraping every last bit we can get and risking contamination. This gives us confidence to start mowing from the first week in May, to get the grass at its highest quality.

“From then on, we will keep taking the additional cuts we need every five weeks.”

Over the last couple of years, the farm has continued on a path of incremental growth, increasing cow numbers to 600 for its herd and taking on an additional 40.5 hectares to secure land for forage production. Next on the wish list is likely to be a larger forager.

“We have gradually geared up in recent years and as we continue to increase our overall efficiency, there will come a point where the forager has to provide that next level of output,” Mr Richardson says.

“High quality forage is really important to our business, because silage is our main driver for profit. If I do not make good silage, it becomes a lot harder to make profit.”

With a four-rotor rake, we can now prepare swaths at a much slower speed because we are covering the ground much more easily

IAN RICHARDSONThe ability to raise and lower rotors independently, along with electric rotor height adjustment, provides in-field flexibility. The four-rotor Vicon Andex 1304 Pro has increased efficiency and productivity at Church Farm, pulling four rows into one.

Bigger swaths make better use of forager power, with fewer trailers bringing better loads back to the clamp.

While soil health, grass varieties and the number of cuts are always important decisions, the machinery used to harvest grass is sometimes not given enough attention.

Tractors working with mowers, tedders, rakes, balers and trailers result in multiple field passes to harvest and collect the crop.

However to protect the sward for regrowth, tractor and forage harvester tyres need to be carefully considered.

The only part of the tractor in contact with the ground is the tyre and this is where benefits to silage production can be had, says Tom Godwin of Continental Agricultural Tyres.

“Tyre choice can protect the sward, reduce soil compaction and improve operational efficiencies, such as fuel consumption and task productivity.

“Wheel slip can cause sward

damage which will affect subsequent cuts and overall yield.

“Operators who fail to choose the correct pressure for load, or use inefficient tyres, will also use more fuel and take longer to cover the same acreage.”

To avoid negatively impacting silage quality, stunting grass regrowth, or damaging machinery, operators should undertake daily checks to ensure correct set-up.

“Tyre checks are essential before working on grassland. Calibrating tyre pressure to the load of the implement, and any tractor ballast needed, will help enable equipment to travel at the optimum speed and height.

“By choosing lower operating pressures, tractors can also maximise forage quality and quantity, while minimising sward damage,” says Mr Godwin.

“Tyre choice can be baffling, with radial, increased flexion [IF] and very increased or very high flexion [VF] options, along with varying tread patterns and the gulf of difference in cost.

“For contractors looking to provide a top-class service, VF tyres can help save time, reduce fuel consumption and improve silage quality over multiple cuts.”

VF tyres have the potential to carry 40 per cent more load at the same pressure as a standard radial.

Alternatively, a VF tyre is capable

of running at 40 per cent less pressure under the same load as a standard tyre.

This advantage can offset the greater cost of VF technology.

However, Mr Godwin is keen to stress that VF is not for everyone.

“Developments in radial tyres to increase flexibility, reducing the risk of cracking, and new lug patterns with smoother cleats, have narrowed the gap between standard and VF or IF.

“For dairy farms or contractors looking to replace tyres on existing tractors and harvesters, VF could be an expensive option if the machine is not expected to be with the owner for the lifetime of the tyres.”

Further developments in tyres for farm machinery have led to hybrid tyre options becoming available.

A VF hybrid tyre has a block pattern tread to make it more fuel efficient on the road, and with VF load-carrying capability it

can also be run at lower pressures in the field.

The continual flow of traffic through gates to transport crops from fields can lead to soil contamination. The hybrid tread is claimed to hold less material than a conventional tyre, which reduces the likelihood of contaminants from other areas on the land.

A tractor with triple mowers will often be stationed in the field for most of the silage-making season.

A high-horsepower tractor with the added weight of three mowers can weigh in excess of 10,000kg.

On soft ground this can cause compaction and sward damage which can lead to decreased yields for further cuts.

Adjusting and monitoring the pressure of a standard radial tyre can mitigate this without the need for IF or VF tyre technology, however tractors moving between road and field work regularly providing haulage may benefit from VF

The need for quality grass silage to reduce a reliance on bought-in fertiliser and feed has put greater emphasis on how to get the most from crops. Developments in tyre technology could boost productivity. Farmers Guardian reports.Tom Godwin of Continental.

hybrid technology as the tyre pressure can be varied depending on the surface.

The price increase of machines is leading to operators keeping them longer, in which case the tyre choice

will play a gradually increasing role. Changing tyres to optimise both field and road hours could reduce fuel consumption, sward damage and compaction. Whether operating a tractor with 10,000 hours or a

• Hydraulic and mechanical hitches to suit most tractors

• In-cab release mechanism for quick, easy implement changes

• Safe, secure, patented latching and locking system

• Hydraulic push-back design gives maximum ground clearance

• Ball and Spoon eliminates rattling and shunting noises

• Reduces wear and hitch damage by up to 90%

MORE WAYS TO ADD MORE PRODUCTIVITY FRONT

For further details about any products in the

brand-new forage harvester, the potential for tyres to make a significant difference to forage quality should be consistent.

Replacing tyres on ageing machinery can offer greater operation-

al efficiencies without the need for high levels of investment, while specifying the best tyres for the job on a new machine can offer greater flexibility and economy of operation, plus potentially improved used values.

Meeting the needs of a variety of farms in a strong livestock area takes flexibility, and that is what J. Hamlett Contracting aims to offer by chopping silage with a forage wagon.

“Losing some of our grazing led us in the direction of contracting, and then we saw a gap in our farming year between planting and baling,” explains John Hamlett, who runs the business with his son, Rob.

“We did not want to go down the self-propelled forager route because of the need for a team of men with tractors and trailers, plus there’s a lot of competition locally.”

The forage wagon, they saw, could be operated as a self-contained unit without tying up other machinery.

“We also believed it would suit our way of contracting – not every

customer wants exactly the same service and we like to tailor it to their needs.”

In 2015, the first Pottinger Torro Combiline 5510 arrived on the farm, initially to be shared with a neighbour and to test the water.

“We actually had a trailed forager to begin with, but that was

replaced with a second wagon two years later as it was not quick enough,” says Rob.

With a team of eight on hand in the season, foraging is offered as a complete service, from mowing to buckraking, with John taking care of the raking where possible to help get the best out of the wagon.

John says: “For example, if I see a wet spot with the rake, I can advise Rob where it is so that he can go there with an empty, rather than full, wagon. I can set the field up to suit us.”

The ability to pick and choose where to start a field for the best results is a distinct benefit over a forager, they point out.

“We can easily change fields too, if a farmer has both grass and lucerne or wants to mix in some clover in the pit. It is a different way

of making silage, we feel the quality of the silage that the wagon creates has been a benefit to our farm and our customers,” he adds.

Some customers will mow and rake their own grass; the pair comment that some farms which have moved away from using trailed foragers often now engage them to chop and ensile their crop.

“We also work alongside farmers that have their own forage box — we are happy to fit in,” says John.

A frequent request is for multicut crops, with the lighter sward making a quick job — John points out that this makes their system of charging by the hour considerably more favourable for the customer than paying by the acre over four to five cuts.

“It is an honest system — you pay for what you get.”

To make an improved swath on

With self-propelled foragers getting larger and more sophisticated every year, where does the forage box fit in? Jane Carley speaks to one contractor who is a convert.

We also work alongside farmers that have their own forage box — we are happy to fit in JOHN HAMLETTJ. Hamlett Contracting runs a pair of Pottinger Combiline forage wagons.

the lighter crops, the business has recently invested in a second hand, four-rotor rake — a Claas Liner 3500.

“We thought we would try one out before buying new. It puts four rows into one which helps get the job done. We take the inside swath out with the wagon to avoid contamination, when silaging in the same field as the rake, even if it means swapping fields.

“Making four to five cuts a season can be more difficult in a dry season, but it is an ideal niche for the wagon,” he suggests.

Taking care of buckraking, using tractors and forks rather than a loading shovel, improves pit quality and helps with the management of the operation, Rob suggests.

“If the buckrake driver is getting snowed-under, we can communicate and chop in fields that are further away. Without pressure on the pit team, you make better silage.”

Customer service has extended even to picking up half loads in January for an organic farm that had run out of silage and had taken a bit

off their fields to tide them over. Output is naturally impacted by road miles, but they reckon on 2028 hectares (50-70 acres) per day per wagon.

The rolling banks around the business’s base at Ruyton-XITowns, Shropshire, are also less hairy in a forage wagon than a large self-propelled machine, they say.

“It was one of the factors that particularly favoured Pottinger, too, as the wagons have a lower centre of gravity than some on the market,” says Rob.

Mowers from the Austrian company were already in the fleet, along with an 842C twin-rotor rake.

John also took the opportunity to see the forage wagons on the production line during a factory tour.

“We upgraded to the 60cu.m 6010 Combiline models in 2018 and 2019; that is as big as we can go due to the banks and smaller fields,” he explains.

John says that with the load, plus the weight of the crop being compacted, they do need plenty of

horsepower on hills; New Holland T7.210 and T7.245 models are used throughout the business to provide the muscle.

Rob adds that the operation is relatively frugal on fuel, however, at around 25 litres/hour.

The two-metre pick-up is connected to the custom-designed additive applicators to switch on and off at the headland and is fitted with a crop roller to avoid digging in, saving tines and avoiding contamination.

“Although it is a relatively simple machine, the automation is there that you need, from two speed discharge, a control panel from inside and outside the cab, and the knives can be easily swung out to sharpen and change,” Rob explains.

“I did not specify Autocut automatic knife sharpening — for the extra it costs, I thought I would rather have another set of knives and swap them, so we can sharpen after every job.

“Having sharp knives makes a real difference to diesel consumption.”

John adds that stones are the biggest problem on farms where the fields are not rolled and can break, as well as blunt, knives.

“To get the best chop quality we make sure we move grass off the swath, placing it into the next row,” he says.

Chop length is 35mm, one

downside compared to a forager, although there have been no complaints about quality or intakes.

However, Rob admits: “The availability on the market of a wagon with a shorter chop length would make me consider upgrading our machines.”

The pair suggest that spares and repair costs are minimal – bed chain links are swapped once a year and chains and pick-up cams every other year; a new set of knives is generally fitted.

“Build quality including paint has been excellent and we get very good back-up from the local dealer - HJR Agri - and Pottinger itself,” says John.

“Our operators are a multi-skilled team and we start the year on-farm in January with lambing

and then calving before we start drilling,” he says.

Using a forage wagon has given us a useful service which has proven to be successful for our business and our customers are pleased with the silage that the wagon produces. It is a machine that has helped our business to evolve.”

The flexibility of the wagons allows smaller areas to be collected, in addition to mixing different crops for a more diverse forage in the clamp.

Using a forage wagon has given us a useful service which helps keep everyone employed year-round

ROB HAMLETT

With the drive to reduce single-use plastics currently a key focus for many industries, the spotlight is inevitably turning to agriculture. Plastics are widely used in crop production and preservation; research shows about 12.5 million tonnes were used in 2019. Yet, recycling rates are comparatively low and the viability of deploying recycled materials in its manufacture depends on the end use.

Extensive study into silage preservation has been carried out at the Institute of Biological, Environmental and Rural Sciences (Ibers) in Aberystwyth. Agricultural researcher Rhun Fychan says: “Silage plastics are designed to offer top quality

preservation of silage and are made using high quality polymers. Considering ways to make it more sustainable is a complex issue – bale wrap is a high-tech product made of 25 micron film and designed to be applied in five to seven layers, so it is a difficult product to develop from biodegradable materials.

“Biodegradable films are subject to stringent controls and can currently only be used indoors –they could potentially only last for a few months before silage quality is affected and many farms will want to keep them considerably longer than that.”

Lloyd Dawson, commercial sales director at Berry BPI Agriculture, points out that bale wrap has been developed to last for a defined period.

He says: “If the wrap breaks down before that period, not only is the silage itself lost, but there is also the cost of the machinery involved in producing silage to consider.

“Biodegradable films break down on contact with the soil, and it is not always easy to say how long silage bales will be stored for. In 2022, the dry summer meant that fewer bales were made, so farmers are likely to make more this time. Even maize covers will sometimes disappear too soon or sometimes not at all. The use of biodegradable wrap is not feasible or scalable at the moment.”

In its current format, silage stretch film is 100 per cent recyclable and

thus can be considered as a process rather than as packaging, Mr Dawson says.

“Netwrap and twine are packaging; net, in particular, is difficult to recycle as it can be contaminated with fodder and is hard to shred into smaller pieces for processing.”

Producing the film from recycled plastic does not offer an immediate solution either.

“Using recycled content would make 25 micron film heavier and actually put more plastic into the market,” Mr Dawson says.

He also points out that new product developments focus on making wrap longer, lighter and stronger than the original product.

“With Silotite Pro1800, rolls that were 1,500 metres long are now 1,800m, giving 20 per cent more per

Industry developments are looking at ways to make forage conservation more sustainable, but do not expect to see biodegradable wrap any time soon. Jane Carley reports.

Biodegradable films could potentially only last for a few months before silage quality is affected RHUN FYCHANBerry BPI has made updates to its Silotite product, making longer rolls from a thinner film. Cardboard packaging has also been eliminated at Berry BPI, and has been replaced with recyclable plastic.

reel. We have reduced the weight of the plastic but not the strength.

“This cuts transport, handling and packaging by 20 per cent, reducing the number of boxes, packets and cores needed per season. Operators can also be more productive as they are not having to change rolls as often.”

Another update is to eliminate the

use of cardboard boxes in packaging.

With plastic use under public scrutiny, the question is whether farm plastics can be manufactured in a way that makes them more sustainable. farmers have to pay for the service at the same rates as other waste – in my view, there should be a financial incentive to recycle farm plastics.”

Mr Dawson says: “We use a plastic sleeve which is 10 times lighter and can be recycled with the bale wrap, so for every 10 rolls we are getting rid of 45kg of packaging.”

Baler developments have also made a contribution, he says, with film-on-film systems replacing

netwrap with a wide width film, which can be recycled with the bale wrap and, moreover, improve silage quality.

Mr Fychan says used bale wrap is of high value for recycling, but needs to be kept clean and dry.

“Recycling sites are available at a number of locations in the UK, but

Bale wrap recycling schemes in the UK have not been successful, agrees Mr Dawson.

He says: “Just 25 per cent of plastic used is returned by farmers. There have been three attempts at voluntary schemes, and while accreditation protocols such as Red Tractor require farmers to recycle, they will only do what is needed to comply.”

Recycled wrap can be used to make up to 30 per cent of the constituents of new silage sheets, Mr Dawson says.

“It could go higher – up to 60 per cent – to make a product that is not as strong but still functions. At the end of that life, the sheets can be recycled and made into products such as plastic furniture.”

Mr Dawson says: “Farmers must take responsibility; Ireland has a legislated scheme where farmers pay €240 [£211] per tonne, but this compares well with what supermarkets have to pay under extended producer responsibility.

“It is not something you can put a voluntary levy on as some distributors will not apply it, so

any companies who do want to contribute to sustainability are at a commercial disadvantage.”

He suggests that ‘collection centres’ might be a workable alternative to farm collections, with smaller farms being able to put two years’ worth of plastic in a load.

Where covers for silage clamps are concerned, traditional silage films are constructed from a mix of raw materials of varying quality, explains Will Wilson of Silostop.

He says: “The latest development is high oxygen barrier film, which is made from mainly virgin materials as a food grade stable product. It is designed to reduce dry matter (DM) losses in the upper layer of the silo, eliminate waste on the surface and shoulders, and increase aerobic stability at feed out.

“Results using high oxygen barrier silage films show under 5 per cent surface silage losses – Silostop Agri is looking into the use of more recycled material in manufacture, but only if the technical properties of the sheets can be retained.”

In addition to the 80-micron 11-layer Silostop Max, the company offers 45-micron nine-layer Silostop Orange, which uses less plastic and is ideal for single-cut crops; achieving the same results.

Mr Wilson says: “It is not UVstable, so it needs an anti-UV cover, which is reusable for up to 10 years and is 100 per cent recyclable, helping farmers cut plastic use by 60 per cent.”

While it is possible to reuse plastic covers, and many farmers will redeploy last year’s sheets as

an extra layer against the clamp walls, the practicalities of packing away and storing sheets, plus the risk of contamination of the following crop, make it difficult, he points out. The covers are, however, 100 per cent recyclable.

Just as with silage stretch film, the challenge with developing biodegradable covers is defining the period in which they will start to break down.

Mr Wilson says: “Concerns about plastic may be one factor which continues a move away from baled to clamped or large bagged silage that we are seeing. For many farms, the silage quality is key and it is a convenient way to feed out.”

Mr Fychan says: “Clamp coverings offer more immediate potential for using biodegradable materials, so I would expect developments to be seen first in that area.”

Ibers is studying the use of plant material to produce plastic and has applied for funding to look at biodegradable wrap in the future.

RESEARCHERS at the University of Turin – Ernesto Tabacco, Francesco Ferrero and Giorgio Borreani – carried out a study into the feasibility of utilising biodegradable plastic film to cover corn silage under farm conditions in 2020.

The study evaluated the shelf life of Italian-made Mater-Bi biodegradable plastic film under outdoor conditions, analysing its effects on the fermentative characteristics, microbial counts and aerobic stability of maize silage. It was compared with commercially available polyethylene and high oxygen barrier films.

The maize was ensiled in 30 drive-over piles covered with either Mater-Bi, polyethylene or oxygen barrier films. Each pile was opened after 21, 85, 133, 195

and 230 days of conservation, and the effect of the film was assessed in silage samples that were both close to and far from the film.

The positive effect of the oxygen barrier film was found to last throughout the whole conservation period, while conventional polyethylene film showed a good conservation effect for 133 days.

Mater-Bi, the first completely biodegradable and compostable bio-based polymer, showed similar characteristics to oxygen barrier film for three months of conservation, after which it began to biodegrade, demonstrating its limitations for long-term silage preservation.

MORE INFORMATION

To read the report, go to mdpi. com/2076-3417/10/8/2803

High oxygen barrier film [...] is designed to reduce dry matter losses in the upper layer of the silo

WILL WILSONCovered with a UV-resistant layer, Silostop Orange has a 10-year life and is fully recyclable.

Developers of autonomous machines are now considering how they will market their prod that will be formed with implement suppliers. AgXeed is making good progress, discovers

Founded in 2018, Netherlands-based AgXeed has made the transition from drawing board to robot production in a short space of time. The company now has 30 of its AgBots with customers across Europe, with the first models due in the UK this summer.

Founder and chief executive Joris Hiddema has a long history in engineering with roles at John Deere and Agco’s Grubbervorst technology centre. He established AgXeed with three similarly-experienced partners, their goal being to offer an autonomous solution to some of farming’s challenges.

The company rolled out its first prototype in 2019 and began commercial production in 2022, setting up an international distribution network. It has also attracted invest-

ment from some key partners in the machinery trade, notably Claas, which distributes AgXeed products through selected dealers in Germany and Switzerland, including via a rental model. Amazone also came on board in 2022 and has adapted implements from its existing range to work with the AgBots.

In the UK, AgXeed is represented by technology specialists SoilEssentials and AS Communications (ASC).

Graham Ralston, hardware director of SoilEssentials, outlines the issues facing farm mechanisation in the 21st century which could be addressed with the use of robots.

“To increase the scale of their businesses, farmers have invested in large, heavy equipment, which ties up working capital, in order to com-

plete the work in the timescales available. Tractor prices are increased by increasing levels of ‘cab comforts’ which seem to be needed to attract a dwindling workforce.”

The effect of this, he maintains, is soil compaction and a consequent cycle of remediation. Meanwhile, customers are increasingly looking for traceability – likely to be mandatory eventually – and time management has become an issue. This is particularly the case for smaller businesses who may have diversified enterprises from which time spent in the tractor seat can be a distraction.

Farmer and director of ASC, Will Mumford, echoes the labour challenge, plus the increasingly unpredictable climate exacerbating the issues caused by heavy machinery.

He says: “We need to remove weight but we now do not have the option of

20-30 people operating smaller machines, so automation will be the key.”

According to Joris Hiddema, the first customers are already seeing the benefits of deploying AgBots with increasing hours in the field carried out autonomously.

“The farmer can plan ahead and optimise as he goes, using precision farming to increase yield while gathering data for business decisions,” he says.

For example, on a 200-hectare farm near Mannheim in Germany’s key vegetable region, grower Volker Hack has carried out 350 hours’ work in two months, with the AgBot working day and night.

SoilEssentials was attracted to the product by its quality design and engineering, while the standard three-point linkage fitted means that

customers can use existing implements with the AgBot, says Mr Ralston.

Both ASC and SoilEssentials are working to develop their skills with the products, but already have experience with generating the accurate maps of field boundaries needed to operate them.

The maps are created on foot and then loaded up into the AgXeed online portal, allowing the operator to manage and pre-plan work.

“Purchasers need to consider the location of land parcels and logistics, and how the operator is going to integrate with the machine, setting up alerts for refills of fuel, seed and fertiliser,” says Mr Mumford.

“Having studied the autonomous machines on the market, I believe AgXeed’s AgBots are the right choice, comparable with a ‘conventional tractor’. As a farmer, I also

wanted to be confident that this would be the right choice for me.”

Mr Ralston outlines the considerations for farmers before investing in an autonomous machine.

“Think about which tasks it can perform on your farm, where it will work and how you will manage the logistics.

Also who will need to integrate with it, so who needs to ‘buy into’ the system –and how they will be trained.”

Continues over the page.

THE AgXeed range includes three models to suit different applications, with wheeled or tracked chassis. All feature hybrid drive from a diesel engine and optional electric pto.

The AgBot 5.115T2 is fitted with rubber crawler tracks, adjustable for track widths from 1.9 to 3.2 metres and is powered by a 156hp Stage V Deutz engine. With cat 2/3 linkages front and rear, it offers three tonnes and 8t lift capacity respectively and up to four double acting spool valves.

Designed for light soil applications and maintenance, the four-wheeled AgBot 2.055W4 has a 75hp Stage V Deutz engine and lift capacity of 1.5t and 4t front and rear and up to three spool valves. Track width is adjustable from 1.5-3m and there is a choice of wheel/tyre configurations including 710mm wide flotations.

Three-wheel layout on the 2.055W3 is designed to offer a light, even tread and this model is targeted at orchards and similar applications. It shares the 75hp Deutz power unit with its fourwheel brother and has a cat 2 three-point linkage with 2.5t lift

capacity plus three spool valves. Wide tyres up to 710mm minimise ground impact.

“The lack of a cab enables autonomous machines to be omnidirectional,” says Mr Hiddema. “You can hitch a front mower or a rear mulcher on either linkage and work in either direction to suit your requirements.”

Mr Ralston says he can see applications in the UK for repetitive tasks such as grass mowing or to free up an operator for other jobs during drilling.

“The AgBot could take care of a 3m drill while the operator gets on with rolling; but he is then also

already in the field when it needs refilling with seed.”

Communication is via RTK GNSS for guidance and positioning; AgBots are connected to the AgXeed portal which allows management by farm, field and part-fields, using a ‘digital shed’ where AgBots are combined with implements ahead of being assigned a specific routing for the task in question.

This considers the mounting position, size and settings of the implement, with the routing algorithm incorporating data on the desired turning radius, number of headlands, routing mode and overlap.

All tasks can be stored for later execution or sent to the chosen combination for immediate action.

A remote control is used to attach implements and navigate AgBots to the field, where operation is autonomous.

Work can be monitored remotely via a camera on the machine and the AgXeed portal allows remote access for servicing. IsoBus integration of implements means that machine failures such as a clogged seed tube on a planter

are communicated as an error code on the phone app version of the portal – AgXeed is working with its implement partners on standard IsoBus error codes for this.

“Remote access is available to AgXeed and its distributors,” says Mr Hiddema. “This means that many issues can be quickly fixed remotely.”

The operations and analysis section of the portal gives a full overview: fields and part fields, orchards, planned, running and executed tasks, as well as live telemetry information from running combinations. A complete history of the information gathered while the combinations were working is available, including time and efficiency analysis, fuel consumption data and application quantities, and is stored with a time stamp.

While the AgXeed team concede that purchase prices for autonomous equipment will always be higher than their manned equivalent, they stress that lower lifetime costs can be achieved with the lower service, labour and fuel costs on offer.

The lack of a cab enables autonomous machines to be omnidirectional JORIS HIDDEMAThe three-wheel AgBot layout is designed to minimise its impact on soil and is aimed at orchard or similar applications.

Originally offered as an alternative to a trailed forage harvester, forage wagons fell out of favour with some businesses as larger, higher-capacity self-propelled precision chop foragers became widely available. However, with increased fuel costs, a shortage of operators, greater consideration of sward compaction and higher horsepower tractors, the forage wagon is becoming more attractive for businesses looking to take greater control of their winter forage production by completing the whole process in-house.

FOLLOWING the purchase of Lely’s forage business in 2017, Agco has invested heavily in this product sector, including the Tigo forage wagons.

Sold as an exclusive Fendt product, the range covers 19 models in six ranges, with capacities ranging from 26 to 54cu.m. The manufacturer advises the larger XR, VR and PR 31-54cu.m capacity models are more popular in the UK market, and feature knife sets of between 40 and 45, divided into two groups, giving cut lengths of 37-74mm.

The twin-gang design offers a claimed faster change of cut length by introducing or removing gangs of knives. Depending on the capacity, the units are supplied with 60km/h rated double or triple-axle layouts working in conjunction with a hydropneumatic selflevelling suspension. The system works to keep the body of the trailer vertical when working on slopes or cornering during transport.

Tractor implement control (TIM) and IsoBus allow for automatic adjustment of the forward speed depending on the swath size and load on the pickup reel.

AUSTRIAN manufacturer Pottinger claims to offer the largest model range in the UK market, with 58 variations designed for both farmers and contracting businesses.

Split over four product groups, the range is manufactured in capacities from 24 to 54 cu.m, fitted with 31 to 65 knives depending on

the model. The larger knife assembly provides a shorter chop length of 25mm, however, this does increase the machine power requirement.

To address this and allow for greater up-front input, the manufacturer’s flagship Jumo range is rated for a maximum input of 500hp, claiming a higher throughput

than a self-propelled harvester. The UK market entry-level Faro range may be more suited to dairies producing regular, smaller cuts, with capacities of up to 33cu.m and a power requirement of 90-150hp. All models are available with IsoBus control, with larger units including onboard weighing and an automatic blade sharpening system.

Continues over the page.

Increased costs and tractor power may bring the forage wagon back to the attention of livestock enterprises looking to cut and clamp their own grass without utilising a contractor and self-propelled chopper. Toby Whatley looks at the market options.

SPANNING four model ranges with capacities from 28 to 43cu.m, Krone’s forage wagon includes cam-less pickup reels operating up to 2.12 metres wide.

Following the pickup, all models use a Hardox steel feed rotor.

Assembled in a ‘W’ pattern, the rotor

is claimed to give a scissor-cutting effect on the material as it passes across the knife cassette.

Knife options range from 32 to 48 units, with automatic half-set removal giving chop lengths of between 37 and 70mm. The three largest ranges include the manufacturer’s

Speedsharp system as standard which pivots the knife cassette from under the unit and sharpens all blades simultaneously using a bank of hydraulically-driven abrasive wheels.

When used to transport maize or grass alongside a forager, a cover can be fitted to prevent material

from falling into the cutter unit. All models can be supplied with IsoBus control alongside weigh cells for load traceability on the larger models. For those operating a zero-grazing system, an additional cross-conveyor at the rear of the unit can be fitted to models up to 40cu.m.

POTENTIALLY better known for its muck spreaders and chaser bins, Bergmann’s forage wagon range is split over two ranges with four models in each.

The smaller tandem axle Carex is supplied in capacities from 37 to 43cu.m, with a 2.05-metre wide pickup delivering material through a 41-knife cutting unit. The larger Shuttle range offers capacities from 45-51cu.m, with a wider 2.27m pickup and 53-knife cassette and a combination of single and triple axles offered.

Cut length for both machines is fixed at 34mm, with access and tool-free knife removal achieved by hydraulically lowering the cassette and raising the drawbar.

All models have hydraulic suspension with an independent 300mm of travel per axle, which can be combined with electronic or hydraulic forced axle steering. Control of all models is achieved

through a range of control boxes or an IsoBus connection.

DISTRIBUTED by Bourne-based Opico, the Strautmann range of forage wagons claims to offer a market-leading consistency in chop length using its Continuous Flow System. The system spreads the intake crop across the entire cutting area of between 32 and 48 double knives which fills the body of the trailer at a reduced angle. Both features are said to reduce fuel requirement and knife wear.

The six-model range offers capacities of 23 to 52cu.m and can be fitted with the recently introduced Flex-Load pickup. The design uses plastic tines replacing traditional spring steel which,

Strautmann says, adapts better to field surface undulations and reduces soil and stone contamination to the cutting unit and subsequent forage.

Control is achieved through an in-cab control box or full IsoBus connection.

Added to the range for this year, the manufacturer has introduced the Magnon 8 forage wagon to the UK market. Positioned as the smaller model to the largest Magnon 10 Series, the Magnon 8 is claimed to offer reduced external dimensions compared to competitive machines of similar capacities.

225 Sniper, hydraulic side shift

270 Sniper, hydraulic side shift

250

280

230 HD

hydraulic

, Variable Offset Parallel

&

All prices plus vat.

Hi-Power

BUNNING 18T GRAIN

TRAILER. Hyd door. Sprung draw bar. Roll over sheet. Air/ hyd brakes. On 650/50 R22.5 wheels. Rear steer . Ym 2001. Only done grain.

Price: £13,500

LARTINGTON MAJESTIC 18T GRAIN SILAGE TRAILER. Hyd door . Sprung draw bar. Commercial axles. Air /hyd brakes. On 560 /60 R 22.5 wheels. Front window.

Price: £14,750

BAILEY 15T LOWLOADER TRAILER. 20’6” on the flat .5’ beaver tail. Sprung draw bar. Air/hyd brakes. Extra wide ramps. Ym 2017.

Price: £12,500

BLUE BALE TRAILER ON 435

WHEELS. Commercial axle . Tidy order.

Price: £3250

BAILEY 10T GRAIN/SILAGE

TRAILER. Hyd door. Super singles. Sprung axles.

Price: £8000

PORTEQUIP 21’ BALE

TRAILER. Head board. Rear bale rail. On 400 flotation wheels. Ym 2010. Tidy order.

Price: £5000

ABBEY 1600 SLURRY TANK. On big flotation wheels.

Tidy tank .

Price: £5000

KRONE EASY CUT R 280 CV MOUNTED MOWER CONDITIONER c/w spreader hood. Ym 2015. Better pictures to follow.

Price: £7500

MCHALE PROGLIDE R3100 mounted mower conditioner. Ym 2017.

Price: £8750

MCHALE PROGLIDE F3100 FRONT MOUNTED MOWER CONDITIONER. Ym 2017 .

Price: £8750

KRONE EC R 320 PLAIN MOWER. Ym 2019. 1 farmer from new. (Dont come any cleaner)

Price: £8000

POTTINGER NOVACAT 442. Plain mower. 4.42 cutting width. Ym 2015.

Price: £7000

KRONE EASY CUT 2800 CV TRAILED MOWER CONDITIONER. Ym 2015 1 farmer from new and a credit to him!!!

Price: £14,500

KRONE 3201 CV TRAILED MOWER CONDITIONER. Swivel head stock. 1 farmer from new. Tidy order.

Price: £9250

POTTINGER NOVACAT 442 MOUNTED PLAIN DISC MOWER. Ym 2013.

Price: £6250

KRONE AM 283 PLAIN MOUNTED MOWER. Ym 2014

Price: £4600

MALONE PROCUT 900 PLAIN MOWER. Ym 2019

Price: £4750

KVERNELAND 336 8’ TRAILED MOWER CONDITIONER. Ym 1995.

Price: £2500

KUHN 75 01 TWIN ROTOR RAKE. Hyd in / out ym 2019. Very good order.

Price: £14500

KUHN GA 7501+ TWIN RAKE. Hyd in/out . Ym 2019. 1 farmer from new. Nice rake (better pictures to follow)

Price: £14500

KUHN GF 502 4 ROTOR TEDDER. Digi drive. Ym 2015. 1 farmer from new. Immaculate!!

Price: £4850

AGCO FENDT TWISTER 6606 DN 6 ROTOR TEDDER 2019. Very good order

Price: £7000

FUSION 3 PLUS. Ym 2021 20000 bales owner driver from new. Very well minded machine. Proper job!!!!!

Price: POA

MCHALE FUSION 3. PLUS. Camless pick up. 35000 bales. Ym 2020. Good order.

Price: POA

MCHALE F5500 ROUND BALER. Drop floor. 25 knife chopper. Big wheels. Braked axle. Ym 2017. 18746 bales.

Price: £23000

MCHALE F550 ROUND BALER 23 KNIFE CHOPPER. Ym 2010. 49453 bales done. 1 farmer from new.

Price: £13500

MCHALE F5500 ROUND BALER. Drop floor. 15 knife chopper. Electric cont rols. Crop roller. 12056 bales. Ym 2017. Very good order.

Price: £23000

MCHALE 991LBER MOUNTED BALER WRAPPER. Radio receiver. Tidy order.

Price: £6200

TANCO E100 ECO WRAP. Cable control. Only done 1339 bales. Ym 2019. In ex demo condition.

Price: £6950

KUHN HR 3004 POWER HARROW. C/W packer roller. Ym 2014. (Big gear box) very tidy order.

Price: £8500

Claas Rollant 375RC

auto lube, crop roller, 30000 bales

for work.

11,608 Bales, Rotor Cutter, Tandem Axle 600/55R26.5, Monitor and harness, Camera, LED Service Light Pack, Bale Weight, Moisture, Intelicruise and Data Logging Phil Maw 07966 067 240

electric controls c/w remote 2008

SN: 21049267 £32,000 year 2019, system disc and stand drawbar, 350 Acres Approx.

Hardi Master

Range Command Sidewinder, 50kph, year 2019, 3700 hours, Auto Guidance Ready, front linkage and PTO, 3 speed PTO, electric mirrors, exhaust brake, air conditioning, air brakes, front hydraulic services, 540/65R28 & 650/65R38 tyres.

Andy Loxton 07977 480 920

£67,500

SN: 11049010 £17,250

year 2011, Amazone KE3000 Super Power Harrow, c/w Leveling Board, Rubber Packer, Single Disc, Following Harrow, Pre-emergance & Bout Markers Steps 1 Tonne Hopper (P1000 extension). Graham Milner 07885 243 761

Hardi Navigator 4000

SN: 21049379 £9,950

20 Metre Mounted sprayer, year 2015, 20M boom, 1800 Litre tank, c/w HC5500 Spray Controller.

Nev Kirby 07970 805 369

Ifor Williams TA510G3

year 2007, Engine hours 2292, Threshing hours

1978, Self Leveling Sieves, Straw Chopper, Chaff Blowers, 800/65R32 & 500/85R24 c/w 20FT

Varifeed Header and Trailer. header trailer

David Hirst

t: 07792 927 432

Ifor Williams GX106

SN: 11049008

£POA

Ifor Williams TA510G-12

SN: 31046295 £45,000

30m tri fold booms, 500ltr rinse tank, dynamic fluid4, 464H pump, boom prime, auto slant boom height, axle suspension, fast filler with hose & filter, Intellitrack, Dave Bradley 07977 480 920

Richard Western SF14

SN: C1049092 £5,995

4FT Tri Axle Cattle Trailer c/w Partition and Spare Wheel, year 2014.

SN: 9104748 £3,250

Plant Trailer, 10’x6’ Internal Size, 2021 Year, Tandem Axle, Closed in Sides, Ramp Tail Gate Half Mesh

SN: C1048413 £3,650

12FT Cattle Trailer with Folding Sheep Decks, Dividing Gates and Spare Wheel.

Tom Fawcett 07779 793 039

Eddie Greaves 07976 464028

SN: 11049259 £15,000 year 2011, hydraulic rear door, hydraulic brakes, sprung drawbar, grain chute, 10 stud axle, front ladder & window. Graham milner 07885 243 761

Eddie Greaves 07976 464028 russells.uk.com

Main Road, Brompton-By-Sawdon,

Main Road, Brompton-By-Sawdon, Scarborough, North Yorkshire YO13 9DP

Scarborough, North Yorkshire YO13 9DP

Tel: +44 (0)1723 859785 / 859698

T

el: +44 (0)1723 859785 / 859698

Sales: Eric-07836 630558/ Martyn-07946 335030

Sales: Alistair-07498 884351 / Eric-07836 630558

Thomas-07538 390091

www Hardwickagricultural.co uk

www.hardwickagricultural.co.uk

New Deutz Fahr 6135C

4-cylinder, 137hp, 50kph, RV shi 20/18, Stop/Go feature In stock and ready for delivery

New Deutz Fahr 5115 PS

4 Cylinder, 115hp, 40kph, Stoll loader, 40/40 Powershi In stock and ready for delivery

New Kubota M4-073

4 cylinder, 74hp, 40kph F18/ R18 transmission, electro hydraulic shu le

Used Vicon RV2160 Op feed year 2010, bale count 33000, ISOBUS , bale kicker, self-oiling system, 0.8m to 1.6m bale diameter

New Merlo 35.7 – 145 CS

Cab & boom suspension, 40k-2 speed hydrosta c drive, reverse fan, pick up hitch, DEMO

Range of New Kuhn Mowers

FC3115D, FC314D,FC284 ,FC244D, GMD280, GMD310F In stock and ready for delivery

New Kubota M6-132 4-cylinder, 133hp/ 153hp boosted 32/32 powershi 40kph In stock and ready for delivery

Used Deutz Fahr 6180 C-Shi C-Shi transmission, (24F/24R), Creep gear, 50K, APS, 4wd and di lock, Year 2016, 3103 hours

Ex- Demo Deutz Fahr 7250TTV 250hp, 60kph, 5.5 ton front li , 10 ton rear li , auto-steer, 540/650 tyres. Year 2022, 310h

Used Deutz Fahr 6205 RC-Shi RC-Shi transmission (54F/27R), creep gear, 50K, APS, 4wd and di lock Year 2019 3,926 hours

New Kubota M7-153 Premium 24-cylinder, 150hp (170 boosted), 50kph, 30/15 powershi In stock and ready for delivery

New Kubota M5-112 4-cylinder, 115hp, 40kph transmission, 36/36 powershi In stock and ready for delivery

Kubota G23 twin cut Year 2009, 570 hours, 4wd and di lock, power steering, hand thro le, low li grass box

Used Kuhn VB2160 year 2014, bale count 36,783, hydraulic drop floor, 0.8m to 1.6m bales, 2.1m pickup

Used Vicon RV2160 year 2008, bale count 39,071 Variable chamber round baler, ISOBUS, 2.2m pickup reel, bale kicker, self-oiling system

New Merlo 33.7 – 115

Boom suspension, 40k-2 speed hydrosta c drive, reverse fan, pick up hitch, DAB radio

New Merlo P27.6 Plus

Boom levelling, 40kph hydrosta c drive, inching pedal, 5.9m li height, DAB radio

Used Shelbourne HD5.5 Hedge cu er 5.5m reach, 1.2m head, joys ck Year 2011

New Kuhn VB 3160

5 belt, terminal pressure adjustment, 0.80m –1.60m diameter bales, 2.1m pick up reel

New Kuhn VB 3165 5 belts, terminal pressure adjustment, 0.80m – 1.60m diameter bales, 2.3m pick up reel, 14 knife chopper

5 belt, terminal pressure adjustment, 0.80m –1.60m diameter bales, 2.1m pick up reel

Used Shelbourne HD60T Hedge cu er 6m reach, 1.2m head, joys ck Year 2010

Used Lely Splendimo 280MC Year 2013, 2.8m,, nylon condi oner nes, ver cal fold

Used Kuhn FC3161 TLD Year 2020, 3.1m wide, metal condi oner , 7-disc, fast fit blades

Used Amazone ZA-M Profis 3001 Year 2014, 3100L, So ballis c system, weigher, border deflector

Used Amazone 3200 Year 2020, 3200 L capacity, hydraulic shut o , manual rates

New Kuhn RW1110C E-Twin In stock and ready for delivery

New Kuhn GF7802 Tedder In stock and ready for delivery New Kuhn

GA4121GM RAKE In stock and ready for delivery

4 belts, weigher, I-dense system, 0.80m-1.85m diameter bales, 2.3m pick up reel with 14 knifes

Used Kuhn EP5557 PAL hedge cu er 5.50m reach, 1.2m headth width, 240° head rota on, Year 2012

Used Kuhn MDS 395 Year 2005, manual rates, M820 side extensions, blob marker

New Kuhn GA9531 Rake In stock and ready for delivery

2015 Kuhn GA13131 13m 4 rotor rake. Reduced price ...................................................£24,000 + VAT

2016 New holland RB150 super feed round baler. 13500 bales .......................................£17,950 + VAT

2010 Kverneland 2540MH 4m plain mower. Very tidy ........................................................ £4950 + VAT

2011 Lely 320MC mounted mower conditioner ....... ............................................................... £3950 + VAT

2020 Kverneland TL1500 Geospread fertiliser spreader ............................................£13,450 + VAT

2009 Strautmann Vertimix 900 diet feeder. Good order ..................................................... £5250 + VAT

USED TRACTORS

2020 Case IH Puma 150 CVX. Front linkage and PTO. 2100 hours ............................ £82,500 + VAT

2021 Case IH Maxxum 115. Very tidy 1716 hours ...

......................................................... £55,000 + VAT

NEW KVERNELAND GRASSLAND EQUIPMENT IN STOCK

Telephone: (015242) 61353

George Newhouse: 07764 221054 Gary Robinson - 07709 640133 www.paxtons.co.uk

New Kramer KL30.8T

40 kph, Load Stabiliser, Telescopic Boom Dirt Scraper, Mitas 375/70 R20, Pallet Forks, Security 36 (3000h), warranty.

Due in late June 2023

Please call our sales team Andy Lomas on 07912 085991

FULL RANGE OF MALONE TEDDERS AND MOWERS IN STOCK, 0% FINANCE AVAILABLE

RANGE OF MACHINERY TO INCLUDE BALERS, MOWERS, WRAPPERS, RAKES IN STOCK, 2 YEARS 0% FINANCE

New Kramer KL35.8T

40kph, Load Stabiliser, Telescopic Boom Dirt Scraper, Air Con & Rear Window Heating, Mitas 425/75 R20, Pallet Forks, Security 36 (3000h), warranty.

Due in July 2023

New Kramer KT557, Ecospeed PRO 40kph, Smart Driving, Load Stabiliser, Tilt Ram Lock, Auto Hitch Trailer Coupling, Reversing Camera, Hyd Trailer Brake Valve, Air Sus Comfort Seat, Air Con, Ag Tyres Michelin 500/70 R24 159A8 XMCL, JCB Headstock, Security 36 (3000h) warranty.

Due in late June 2023.

23 MF 7S 190, DYNA/ VT, full guidance, 500 hrs, f/links & PTO, as new .£POA

23 MF 7S 180, DYNA 6, 50k, full guidance, 470 hrs, f/links & PTO, as new £POA

21 MF 7719, DYNA VT, f/links & PTO, full spec, 3400 hrs, v tidy

21 MF 7718S, DYNA 6 50k Air, FL & PTO, full guidance

70 MF 7718S front/cab sus, 50k air, 4 spools, 2,500 hours ..............

MF 5475 FWD, f/links, f/sus, v tidy, 4800 hrs, excellent tractor

MF 6485 tier 3, 50K, full sus, probably the best available in the UK

NH CR9080 YR 10

CLAAS 310 MEDION YR 07

NH TX66 YR 03

CASE MAXXUM YR 19

MERCEDES UNIMOG U4000 YR 10

JCB 535-95 TELESCOPIC YR 16

JCB 540-140 TELESCOPIC LATE 16

JCB 416 HT 09 LOADING SHOVEL CHOICE OF 6

JCB 520-40 TELESCOPIC

JCB 550-80 WASTEMASTER YR 14

HYDEMA 912D 4X4 ARTICULATED DUMPER CHOICE

KUHN 6 ROTA TEDDER

RICHARD WESTERN 12T SILAGE/GRAIN TRAILER

WEST SILAGE/GRAIN TRAILER

TEAGLE TELEHAWK STRAW CHOPPER YR 18

KRONE 890 BIG PACK YR 21

STORTH 700 heavy duty slurry stirrer, done very little

Rand, 7/71 single axel compressor, low hrs, tidy .£7750

1 pair WATSON 10f flat rollers, very tidy.............................................. £POA

NEW BROUGHAN 20, 16t Silage trailers, full spec, choice from £25,750

PAUL 07713 128783 DAN 07791 527935

www.woodacreparkfarms.co.uk

NH BB1290 PLUS YR 17

NH BB1290 YR 16

JOHN DEERE 1434P SQUARE BALER YR 14

KRONE 1290HDP BIG PACK YR 13 CHOICE

NH BB 9090 YR 09

NH BB 9080 YR 09

NH BB 980 YR 08

K 2 DUO MK5 1100 REAR DISCHARGE SPREADER YR 14

KUHN MULTIMASTER 121 4F AUTO RESET

OCE FOLDING BUCKRAKE

COUSINS V4 CULTIVATOR

FLINGK 10 LEG CHISEL PLOUGH WITH CRUMBLER 50 ACRES ONLY

LINKAGE AND FRONT WEIGHTS

TYRES BUCKETS

BREAKING NH TX66 COMBINE

BREAKING NH +MF SQUARE BALERS

We are currently aware of a number of fraudulent advertisers attempting to sell items within the classified section. Whilst we endeavour to protect our readers and pull these adverts before going to press, sometimes they may unfortunately appear in print.

Please be mindful before entering into any deals you PROCEED WITH CAUTION with the seller and do not part with money until goods are received.

Farmers Guardian are NOT responsible for any part of the transaction that takes place with the seller and the buyer.

INTERNATIONAL 584

5700 Hours tidy tractor in good usable condition Had new Clutch and TA Splitter has been done. Good tyres £5000 NO VAT ono Handy little tractor for sale on behalf of a customer.

Large range of other machinery in stock PX & delivery taken • Tel 01889 500 572 - 07860715642

New Bailey 25` trailer, Super Singles, strap box, £8950.

Cherry 12t trailer, Super Singles, linkage back door, tidy, £5450.

2012 Claas Disco 3100 plain disc mower, 3m cut, good order, £3950.

2017 Fransgard RV390 tedder/rake, 3.9m, VGC, £2950.

2018 Bunning 105C rear discharge spreader, slurry door, very tidy, £22500

2019 Claas Liner 2900 twin rotor rake, excellent order, due in, £17500

2015 West 2800 gallon dual spreader, very good order, £13950

2014 Claas Liner 2800 twin rotor rake, tidy, due in, £13500

2018 HiSpec 2600g slurry tanker, c/w rain gun, 30.5 tyres, due in, £14950

2008 Pottinger 4.2m single rotor rake, very good condition, £3695

2010 Major 2000 gallon slurry tanker, 30.5 x 32 tyres, very clean, £9750

2009 Claas 355 rotor cut round baler, net/wrap, £9250

1999 Kuhn Fc302G trailed mower conditioner, gyro headstock, tidy, £3950

2018 Portoquip 13 ton 26` bale trailer, Super Singles, £8250

2014 Richard Western 10 ton grain trailer, as new, £7450

2016 Kuhn 10` mounted mower conditioner, very tidy, £6995

2006 Claas Liner 680 twin rotor rake, tidy, £6995

2017 Krone KW770 tedder, 6 rotor, hydraulic folding, tidy, £5750

2016 Krone Swadro 46 single rotor rake, excellent, £4995

2012 Kuhn FC283G2 mounted mower conditioner, £4995

2021 MF 9` mounted disc mower, done very little, £4950

2018 Vicon 3200 mounted plain disc mower, centre pivot, tidy, £4400

2010 Claas Liner 430 & 470 single rotor rakes, From £4250

Foster D2P rear mounted diggers, good order, choice of two, From £895

Claas 46 round baler, net/wrap, standard pickup, very good order, £3450

2002 Reco 3200 Profi round baler, wide pickup, good condition, £3450

2011 Marshall MS90 rotor spreader, good order, £2995

2009 Browns 6m hyd. folding spring tined harrows, good condition, £2695

2012 Major 9` topper, very good order, £1250

2010 Techoma 12m, 600 litre, sprayer, tidy, £995

2015 Claas Volto 800 & 1100 mounted tedders, due in, £POA

2019 Bailey 12 ton silage trailer, full spec, due in, £POA

Dragon 10 ton grain trailers, very tidy, choice of two, due in, £POA

2023 NEW Bailey 25` bale trailers, Super Singles, £8950

2023 NEW Beaco 14` & 16` mounted grass harrows, £POA

Tel Brian Robinson on 07740 683113

More pictures on website www.middlefarm4x4s.co.uk

?

Be careful anytime you are asked for personal information. Keep your information secure. Never provide anyone with personal bank information without confirming that they are legitimate.

Farmers Guardian only ever asks for your banking information if you are purchasing a product from us and will always call from 01772 799 500 or 01772 799 400.

EVENING SALE OF TRACTORS, FARM MACHINERY & SMALLHOLDERS EQUIPMENT

6.00 P.M. WEDNESDAY 24TH MAY 2023 AT

GOLDSTRAW FARM, NESS, LITTLE NESTON, WIRRAL, CH64 4AR

To include:- 1961 MF35 c/w Loader (on farm from new) Deutz D8006 2wd tractor (on farm from new) 8, 10 and 12 T grain trailers, mtd chain harrows post knocker, 4 wheel horse carriage, Quantock 400 lt sprayer, McConnel PA34 hedge cutter, Sitrex HM300 hay bob, Kvernland 165 drum mower, Major grass topper, workshop tools, fencing materials, galvanized and glazed feed troughs etc etc

SATURDAY 3RD JUNE 10.30 AM

THE OAKS FARM, HAWARDEN, FLINTSHIRE CH5 3LU

An immaculately maintained range of tractors, loaders, trailers and mainly arable equipment from a small arable unit together with 80 acres of growing Winter Wheat and Barley

To include:- 1976 John Dere 2130 tractor. International McCormick B250 tractor, Matbro TS260 loader, JCB 926 forklift, Daewoo DH170 17T tracked excavator. 2019 Barford 19T low loader, 2012 NC14T dump trailer, 2016 NC12T grain trailer, 2 x West 12T grain trailers, 2016 Dowdeswell 5F reversable plough, Amazone cultivatordrill 3 metre combination unit. Quivogne SA 3.8m trailed discs (2004). Rabe PKE 400 power harrow, Lely Cultiterra spring time cultivator, Galucho 3.5m trailed cultivator, 3m & 1m furrow press, front mtd snow plough, Mecmar 12T batch grain drier, drain jetter/power washer 300 galv tank, Amazone ZAM twin disc fertilizer spreader. Bamlett hydro tip cement mixer, flat and Cambridge rolls, 4 bag (0.5T) lifter. Various muck forks, grain buckets, ditching buckets etc. Spare tyres and wheels, Workshop equipment, implement spares, security fencing, Eccles Jade 4 berth caravan etc etc. Also to include 80 acres of growing Winter Wheat and Barley crop to be sold in 6 Lots (see separate Catalogue and Plans)

Photographs on our Facebook page

Further details and catalogues from J. Bradburne Price & Co

Email debbie@jbradburneprice.com www.jbradburne price.com

Telephone: 01352 753873

hyd quick hitch slewing front arm, heated cab, rubber track, 3 buckets, 3 cylinder Kubota engine, piped for hammer excellent value and in stock ready to go, finance available £13,995 + VAT

Cheapest in the country, one off price, Yanmar engines, full spec, supplied with 3 buckets finance available subject to status Yanmar engine £15,995+vat Kubota £14,995+vat

810 TH KUBOTA ENGINED TELESCOPIC 1 TON LIFT MINI LOADERS

Euro head stock, 2420 kg unladen weight tow easy on a 3.5 ton trailer, Euro five kubota 4 cylinder diesel, Two speed transmission Multi function joy stick, Hyd third service

metre lift height £18,995

FORK LIFTS with side shift 3 m mast two ton lift ,two speed transmission , silent clean running 8 hours constant work time on a single charge 48v/360ah heavy duty batteries quick charge supplied .One year parts warranty smart nippy little things, in stock ready to go £9995+vat

HZM 810B Articulated mini shovel 1.1 tonne lift, twin hydraulic auxiliary lines to the front, single rear auxiliary hyd, a 4 cylinder engine with a torque converter trans, a reverse camera and hydraulic quick hitch! These machines measure to be 4.6m long, 1.55m wide and 2.390m high. They are in stock now, and are ready to go for only £13,995 + VAT

HZM 816T TELESCOPIC ARTICULATED LOADER

BACK IN STOCK full range of attachments, comes with pallet forks and buckets as standard £21,995 + VAT