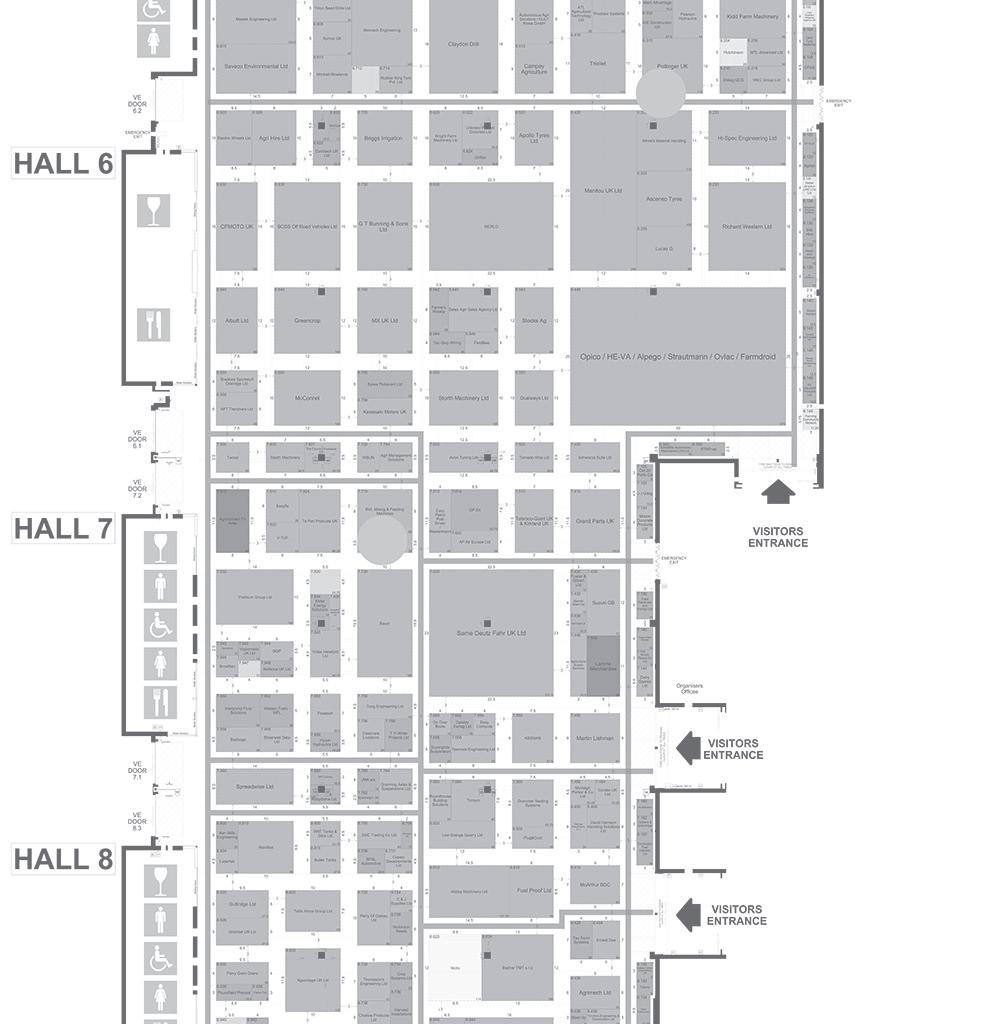

WELCOME to this edition of Machinery & Tractor Magazine. With the UK’s biggest machinery show LAMMA getting underway (January 15-16), we bring you the latest insights from across the market, as well as what to expect from machinery launches and updates from manufacturers.

Last year proved to be a challenging one for manufacturers and farmers, with unpredictable weather, volatile markets and changes to the political landscape. For some, with change comes opportunity, and as businesses navigate through the ongoing challenges they face, 2025 will be a time to look at new ventures to investigate or expand into.

The machinery and technology required to make some of these changes needs to be considered carefully, so time spent understanding the products and options available across the market is never a bad idea.

This year’s event is the largest ever staged and offers opportunities to look at new equipment and technology, alongside discussion from industry experts, plus an expanded Careers Zone following its success at the last event.

In addition to all of the new machinery and technology on show, you can also have a look at some of the used machinery in the bumper classified section.

A Gloucestershire farm remains the base and inspiration for machinery attachment manufacturer Albutt. Jane Carley reports.

At a time when many companies have diversified into a wide range of products to stay afloat, it is unusual to find a true specialist. Yet this has been the formula for success at Albutt, which has the tagline: ‘the attachment people’.

The business, which generated a turnover of £5.5 million in 2024, was founded 60 years ago at Great Washbourne, Gloucestershire, by farmer Robert Albutt.

Alongside his dairy, beef and sheep enterprise, he offered welding and fabrication services to local farmers. This expanded to making pit props for local company Dowty Mining and subcontract work for Douglas Equipment, building aircraft tugs.

A bucket made by Robert attracted the attention of local dealers looking for attachments, and it became clear that there was a demand for his work.

The farm workshop soon proved too small, and the first factory on the Great Washbourne site was opened in

1981. It was then expanded in 1996, 2009 and again in 2015.

The sense of tradition remains strong at Albutt.

Operations director Tom Worthington says: “All of the designs are done in-house, and technical director Mark Holder has been with the company for 42 years. While Robert handed over the running of the business to his son Alistair – who has also carried on farming – in 2008, he and his wife Judith retain a keen interest.”

Albutt uses the latest manufacturing techniques and has invested heavily in up-to-date equipment over the years.

Mr Worthington says: “We aim to lead the way on this. We invested in a new paint facility in 2015 and now use waterborne paint, which – as well as being highly durable – is far more environmentally friendly than two-pack paint.

“Albutt is also very committed to

Increases in machine capacity and workrate requirements have led to developments such as folding buckrakes up to 4.26 metres wide for wheeled loaders.

renewables, with a third of our electricity usage generated by solar panels on the roof.”

Albutt has full control over production, with several trusted subcontractors. The company also controls delivery by running its own transport fleet to ensure products of

the highest possible quality are made and delivered to exacting standards and timescales.

With 80% of its production sold in the UK, one way in which Albutt has diversified is into the waste, construction and forestry sectors.

“We have redeveloped products

Our new UNI-TOUCH® operating system makes agricultural tasks effortless with a customisable and intuitive 10.5 inch touchscreen console. Plus, with our programmable rocker switches, you can assign frequently used functions to specific buttons.

This means multi-stage implement operations can be easily personalised to work with just one click. Unimog has been evolving since 1945 and we are not about to stop.

Experience UNI-TOUCH® first at LAMMA Stand 18.130

Watch the video

AM Agri Ltd, Garthfield, Padanaram, Forfar, DD8 1PF, Tel 01307 462081, www.alanmackay.co.uk

Arthur Ibbett Ltd, River Lane, Great Paxton, Saint Neots, PE19 6RD, Tel 01480 473452, www.ibbetts-unimog.co.uk

Lloyd Ltd, Ponteland Road, Throckley, Newcastle Upon Tyne, NE15 9EP, Tel 01912 677555, www.lloyd.ltd.uk/mercedes-benz-unimog Rygor Commercials, 23 The Broadway, Westbury, BA13 4JX, Tel 01373 440122, www.rygor.co.uk/trucks/new-trucks/unimog South Cave Tractors Ltd, Common Lane, Brough, HU15 2RD, Tel 01430 424233, www.southcavetractors.com and Mercedes-Benz are trademarks of Mercedes-Benz Group AG.

for the tougher environment of the waste industry, where 24-hour working is highly demanding on implements,” says Mr Worthington.

The company is the market leader in several ranges including shear grabs, which saw a refreshed design in 2023, as well as buck rakes, folding forks and folding push-offs and buckets, along with many other product lines.

“We build to a quality, not to a price, which our customers appreciate. It goes right back to the very early days when Robert made a bucket and muck fork for the farm’s new Matbro Teleram in 1980,” says Mr Worthington.

While attachments are no longer bespoke, Mr Worthington says that Albutt is led by customer demand.

He adds: “As a small company, we can develop products to meet their

needs – an example of this is the Waste King range of buckets and forks which use higher yield steel. We can always add strength where required.”

To retain control, Albutt aligns itself with an extensive global dealer network, rather than manufacturers, ensuring that dealerships have access to the attachments they need for their handler franchise and to suit their customers’ expectations and applications.

“As handlers have got bigger, we have seen increased demand for larger attachments such as high tip buckets for grain stores and feed mills, and for higher specification equipment for wheeled loaders for contractors and on farms.

“We have gone from making forks for two-tonne telehandlers, to

buckets for 6t loaders and, moving into construction, fork positioners for 18t machines. We can be confident that we have the knowledge and experience to move with the market,” says Mr Worthington.

The company is also dominant in its export markets – some 80% of buck rakes and folding forks sold in New Zealand are thought to be Albutt.

In the United States, customer demand changed the nature of a product the company had been making for 28 years, with the development of 4.26 metres (14 feet) and 4.9m (16ft) wide buck rakes that were more suited to contractors’ requirements.

In Europe, as in the UK, moving between farms is now more of a challenge, with transport width restrictions adding another level of complication, so a high-capacity folding buck rake was introduced three years

ago and has been a hugely popular addition.

“We have always offered folding forks, but they offer less precision than a push-off buck rake and put more stresses on the loader and operator. We tested the prototype onfarm in Somerset and the contractor wanted to buy it immediately,” says Mr Worthington.

In recent years, the company has seen the usual challenges with steel, components, hydraulics and labour post-Covid-19 – ‘although, once recruited, staff tend to stay’, says Mr Worthington.

He says: “Products are built on jigs for uniformity, and we are rigorous about using all possible resources to improve safety, with cranes in all sections and rotators used when welding. Increasing the size of attachments has meant that we have had to

Albutt specialises in attachments for all types of handling machines across the range of industry sectors.

expand the factory to ensure we have the space for safe manufacturing.”

Quality is always the driving force.

“We fit HB500 bucket lips, the hardest available to last longer,” says Mr Worthington.

“We have certainly faced competition from cheaper products, but when customers go elsewhere, they generally come back. A £100,000 handler is no good without the right attachments.”

This commitment to quality extends to the selection of materials, with Hardox for the manufacture of tines being imported directly from SSAB’s mills in Sweden, and Strenx steel being widely used across the entire range.

It is a philosophy that should fare the company well as farmers seek to get more out of their machines in the years to come.

This innovative new front loader from STOLL fully integrates the loader’s controls with the tractor system via the tractor’s onboard joystick and ISOBUS terminal. With up to 12 additional functions selectable from the tractor’s display unit, the ProfiLine ISOBUS Connected takes front loader performance and productivity to a different level.

Looking to progress in your career in agriculture or interested in apprenticeship opportunities? We take a look at the programme at this year’s LAMMA Careers Zone.

Now in its third year and bigger than ever, the Careers Zone is aimed at inspiring and attracting the next generation of agricultural innovators.

Linked with some of the industry’s most progressive businesses, anyone looking for career or industry progression will have the opportunity to speak to several organisations.

This zone can help you build connections and offers a chance for those starting on the career ladder to find out more about the industry.

Participants in the zone will not only be some of the show’s leading exhibitors, including Agco, but will also look beyond the manufacturing industry, with G’s Fresh among others also looking for the next generation of talent to join them.

Visitors can expect to see stands offering helpful advice to build connections and several live sessions with questions and answers from some of the sector’s industry experts.

Anyone looking for careers or industry progression will have the opportunity to speak to several organisations at the Careers Zone.

10.30am-11am Fields of opportunity: Mary Hext, Join the Country Trust, a charity dedicated to providing food and farm education for children facing Why farm education Country Trust disadvantage. Hear inspiring stories about how their hands-on, real-world programmes impact the lives is vital of children, farmers and teachers. This interactive talk will deepen your understanding of why food and farm education is essential for the future of farming and wider communities, and how you can be involved in helping to create lasting change.

11.30am-12pm Farming and technology: UK Agri-Tech Centre UK Agri-Tech Centre is bringing the conversation about farming technology to LAMMA. Join the seminar to Your perspective explore findings from research, take part in a panel Q&A and share your thoughts on agri-tech in an interactive workshop. This is your chance to learn how other farmers want to use technology to address challenges and seize new opportunities, speak directly to the UK Agri-Tech Centre and fellow farmers to shape the future of farming tools and technologies, and take part in open discussions about what is working, what is not and what needs to change. Whether you are curious about new ideas or want to help develop practical solutions, this is a great opportunity to make your voice heard.

12.30pm-1pm Exciting futures in the Sharon Kirby and Helen An exploration of the variety of career opportunities in the land-based sector, including traditional, digital land-based sector Martin, Bishop Burton and research.

1.30pm-2pm Climbing the career Ollie Brisbourne, Lantra This presentation will focus on Ollie Brisbourne’s experience in aiming for the career path he sought and ladder on a basis that the options available to do so, but working out a way which worked for him to achieve the best outcomes suits you best for himself and his career.

3pm-3.30pm LAMMA Young Engineer Toby Whatley, The LAMMA Young Engineer Award showcases engineers who have created or made changes to a piece Award Agriconnect of agricultural machinery, equipment or technology and, by doing so, improved efficiency, profitability or sustainability on-farm. Join us to crown the winner of 2025’s Young Engineer Award.

10.30am-11am Q&A session: A day in G’s Fresh grower Join us for a candid conversation with one of the G’s Fresh growing team on how they sustainably deliver the life of a G’s Fresh fresh produce from seed to shelf. Understand more about growing methods, approach to sustainability grower and what a day in the life of a G’s Fresh grower looks like.

11.30am-12pm The economic impact Charlie Rollason, Agco At a time when many businesses within the industry are carefully monitoring their spending, training is usually of quality training one of the first areas to be reduced. However, Agco’s aftersales training manager for UK and Ireland, Charlie Rollason, will explain why quality training can have a positive impact on both efficiency and revenue.

12.30pm-1pm City and Guilds Jackie Hough City and Guilds will be showcasing its commitment to supporting agricultural and land-based industries by highlighting its T-Levels, a new technical route for 16-19 year olds, as well updates on further qualifications it is developing.

The new 6R with in-base Sport Package achieves a car-like level of acceleration agility, steering precision and line-holding control – along with the proven 6R field performance, fluid efficiency and residual value.

Take it for a ride by contacting your local John Deere dealer today! Explore a next-level 6R road experience!

Traditional yet modern, manufacturer Alvan Blanch is carrying on the family heritage. Jane Carley reports.

As a family-owned and run business operating in the village of Chelworth near Malmesbury, Wiltshire, Alvan Blanch has a true insight into the challenges facing its customers.

The experience it has gained over the past 72 years designing and developing crop drying and processing equipment for farms across the world means the company is ideally placed to help them meet these challenges.

Arable farmer and contractor Alvan Blanch designed his first grain dryer in 1946 and, after a pe-

riod making a range of agricultural machinery including a novel hedgecutter, focused on post-harvest products.

In 1965, Alvan began to explore overseas markets and the company now exports to more than 100 countries worldwide.

When Alvan died in 1991, his son Andrew took over as managing director and the company is still very much a family concern, with the third generation now part of the management team – Christabel Blanch is Africa sales manager and her brother Charlie Blanch is business improvement manager.

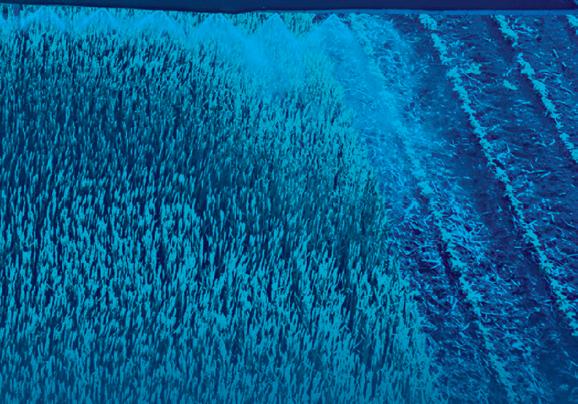

The business now encompasses a vast range of products for crop drying, handling and processing, but at its heart is the continuous dryer, which can be adapted for multiple crops and other products too.

As Christabel Blanch says: “We guarantee that if you can combine it, we can dry it, even in extreme conditions, which has been key to our success globally.

“Customers tend to keep an Alvan Blanch dryer for 30 years or more, so it is important to consider what their needs will be in 30 years’

time when specifying their system.

“Every dryer is built to order, to suit the customer’s crop, system and throughput.”

Industrial products manager Simon Shaw expands on this: “In Ice-

land for example, barley harvested at 47% moisture was dried down to 15% in one pass.

“The dryer is unique. Other designs use vertical columns and a mixed flow which relies on the movement of the grain to work.

“The continuous dryer uses a chain and slat mechanism to pull the grain along so it can dry wetter or irregular crops, while its louvred bed with overlapping plates gives a consistent airflow and can be easily adjusted for different products.”

The consistency of the drying process and low temperature system safeguards grain quality which finds favour with maltsters, Christabel points out.

To meet the requirements of modern farms, a choice of heat sources can be used and control has been automated, with smart moisture control and app monitoring now integrated.

The interest in renewable energy

sources has led to the development of heat recovery systems, using waste heat from the cooling process, which can offer up to 35% fuel savings.

Fuel is also especially relevant for developing markets such as Africa, she says, where not only costs are a concern, but also the reliability of the electricity supply.

With many farms diversifying into new activities, the conveyor dryer has the advantage that it can also be used for materials such as woodchip, paper pellets and various waste products such as digestate, Simon points out, giving yearround use for the investment and reducing the overall cost per tonne.

“We have our own test facility where we can dry materials and ensure the precise specification and settings for the customer’s dryer, while guaranteeing capacity,” Christabel says.

Adaptability extends to meeting

the needs of emerging techniques such as intercropping, and the business has used its farming links to develop in this area.

“Our uncle and cousins farm next door to the factory and are taking part in Soil Association intercropping trials, so we can relate to the opportunities that farms are exploring,” says Christabel.

“They will want to use their existing dryer, and only simple modifications to the hardware and electronics are needed to handle the small tonnages for specialist crops.”

Simon points to maize drying as another emerging application.

He says: “On-floor systems are not suitable in isolation as the moisture condenses above the crop before falling back down onto it, creating a cap. A continuous flow dryer can be used in conjunction with the floor.”

Grain drying capacity has been a talking point in recent years as farmers juggle harvest throughputs and weather windows.

Simon says: “Where a larger combine has come onto the farm, the question of needing a bigger dryer arises, but an automated system means you can run 24 hours a day to give the required

drying capacity, with less labour and lower costs.

“In the eastern counties, where drying floors are widely used, automation avoids overloading the drying floor and increases efficien-

cy, which may in itself mean that a larger combine is not needed.”

Other key sectors for the company include mill and mix equipment, which has always ticked over, but is now seeing a resurgence.

Christabel says: “Again, the longevity of this equipment is a key selling point and there is strong second-hand demand.”

Grain handling equipment is supplied by Danish manufacturer Soby, chosen for its heavy-duty, cost-effective solutions.

Significant investment has been made into the production faculties, with Charlie Blanch joining the company from the renewable energy industry to manage the upgrades.

“We are looking to automate production for increased efficiency, but also because skilled manufacturing labour is difficult to find,” he says.

Updates have included restructuring an assembly hall with a new roof, and new robotic folding and welding systems.

“The dryers were built piece by piece, but now we will use subassemblies which are welded by robot, craned into place and bolted together,” he explains.

“We have also updated the paint shop to take the largest dryer and we are revising our parts storage to make better use of the space.”

A build which has previously tak-

■ Investment of more than £3 million over the past three years

■ Production facility now approximately 9,000sq.m

■ Total production area

17,000sq.m (1.7 hectares or four acres)

■ Machinery is produced from raw materials such as sheet steel, with bearings starting from steel rods

■ 100-200 dryers of varying sizes and capacities are produced each year

■ Alvan Blanch produces approximately 36% of its own electricity from solar panels on the factory roof, with more panels to be added to the offices in 2025

en three to four weeks will now be completed in a week due to slicker assembly processes offered by automation, he says.

Christabel says that in export markets, which account for 85% of Alvan Blanch’s production, large dryers are increasing in popularity.

This is an area which has seen some challenges in recent years, with Covid-19 followed by global conflict, and Russia being the company’s single biggest market for grain dryers. Liquidity is also an issue for some African countries.

“The median age on the African continent is 18-19 years, so there is huge population growth to come.

“It is lacking in infrastructure and there are issues with power supply, but there is huge potential which has been overlooked by Europe, while India and China have developed strong trade relationships.

“We have got lots of experience

An assembled dryer ready for painting.

in the region and will continue to invest.”

In the UK, Inheritance Tax and National Insurance costs are a looming challenge, not just for Alvan Blanch’s customers, but for the family firm itself.

Between 100 and 200 dryers are built each year.

“So any cost savings we can offer for customers are even more important going forward,” says Simon.

“We see a lot of opportunities in the south of England for drying a variety of crops alongside on-floor systems, while there is also growing interest in mill and mix from farmers looking for cost-effective rations

for cattle. Farm-saved seed is another area with great potential and we already have the products in the range for all of these applications.”

Christabel adds: “Small-scale and traditional farming products that we developed 70 years ago –such as threshers – which have

stayed in our range for overseas customers, are now in demand in the UK.

“Conversely, our African markets are looking to expand and scale up their grain processing equipment, so we need to be able to continue to meet both needs.”

Flexible, reliable and easy to maintain:

As a pioneer in agricultural technology, Vogelsang leads the way in environmental friendly spreading equipment. The dribble bar systems combined with the ExaCut distributor give the highest application of liquid manure nutrients.

Dribble bars are available in working widths of 7.5m right up to 36m and are retrofit-friendly.

VOGELSANG – LEADING IN TECHNOLOGY

Contact us at: 01270 216 600 | sales.uk@vogelsang.info vogelsang.co.uk

LAMMA 2025 stand 12:230

Trimble Agriculture, the brand you know and trust, is partnering with one of the largest machinery manufacturers in the market, AGCO, to become PTx Trimble With this, PTx Trimble joins AGCO’s successful brand portfolio, which includes household names such as Fendt, Massey Ferguson and Valtra.

Together, we are creating the most effective precision agriculture network for British and Irish farmers, making the biggest impact ever seen in the industry.

PTx Trimble: At the Heart of Farmers’ Needs

At PTx Trimble, we place farmers and their needs at the centre of our mission. “PTx Trimble precision agriculture solutions are designed to adapt to all brands and models of machinery on farms,” explains Mick McCarthy, channel sales representative. “By focusing on farmers, we design our products to meet the daily challenges of our clients with technology that works across their entire fleet.”

Simple and Smart Solutions for Precision Agriculture

PTx Trimble solutions enable farmers to work quickly and efficiently with high precision.

“Our goal is to provide technology that improves the accuracy and efficiency of agricultural operations, allowing farmers to save valuable time and inputs while maximising yields,” emphasises Mick McCarthy. “Our brand - independent solutions give farmers the ability to connect any equipment across their entire operation.”

Our connected consoles allow real-time data sharing from the office to the field and vice versa, on all devices. “Thanks to our software, the farm office is now on your phone without any hassle,” adds Mick McCarthy.

Our dealer’s network provides farmers with personalised expertise and professional support all year round. They also act as the only authorised repair centers to provide support, regardless of where the products were purchased from.

PTx Trimble: A New Name, the Same Excellence

While our name is changing, our high - performance products and the expertise of our distribution network remain the same. PTx Trimble continues to provide reliable, intuitive, and easy -to - use technology, always centred on your needs.

With this new alliance, we are more determined than ever to provide farmers with the tools they need to succeed.

Welcome to a new era of precision agriculture with PTx Trimble.

PTx Trimble offers precision agriculture solutions suitable for every season. Born from a joint venture between AGCO and Trimble, PTx Trimble continues to revolutionise the future of agriculture by developing intuitive solutions compatible with all brands of equipment, specifically designed to meet the needs of farmers.

Ready to cultivate your future? Scan here to learn more. Contact us today or learn

Scan the QR code to unlock the full potential of Manitou's agricultural telehandlers – your perfect partner for every farming task

Scan the QR code to unlock the full potential of Manitou's agricultural telehandlers – your perfect partner for every farming task.

THE new AF10 combine has been redesigned from the ground up, with major advances in the new machine including a 775hp engine, an active dynamic cleaning system, 20,000-litre grain tank, 210-litre/ second unloading rate and headers of up to 15 metres wide.

The AFXL rotor of the AF10 is 40% longer than the 260 series and provides increased throughput, with the combine equipped with a comprehensive suite of precision technologies, including dual Pro 1200 displays and Harvest Command combine automation.

FOLLOWING its 2023 preview, the now European-manufactured Seed Hawk 600-900C is a versatile no-till seed drill available in working widths from six to nine metres and operates with tine coulters to open a slot and place both seed and fertiliser on undisturbed soil.

Built around the Canadian developed Seed Hawk knife coulter system, the 600-900C uses Vaderstad’s established Fenix III metering system, which operates through the manufacturer’s tablet-based Vaderstad E-Control system.

CREATED to occupy a position in the manufacturer’s TM range between the smaller TM220 and larger TM320 models, the TM280 and TM280S have

been introduced to provide a 2.75-tonne lift capacity and a 4.8-metre lift height, with an overall machine height of 2.6m.

THE GF13003 is claimed to be the world’s first 13-metre fully mounted tedder. Operating with 12 rotors, the

unit folds to a transport width of less than 3m using a patented design of frame mechanics.

POTTINGER JUMBO 5390

PROVIDED as part of a new midrange series of loader wagons, the Jumbo 5000 is available in six new models, with capacities ranging between 32 and 54cu.m. They can be specified with a 1,890mm, six-row pickup or the seven-row pickup with

a width of 2,350mm. The 1,580mmwide and 800mm-diameter loading rotor have been designed to actively feed the forage smoothly through the chopping system.

A 45-knife bank provides a minimum chop length of 34mm.

BVL will be unveiling a version of its V-MIX Drive Maximus Plus selfpropelled diet feeder, which includes a number of updated features. The BvL loading head operates with tines instead of knives, which are designed

to comb the silage from the clamp face and claim to preserve the plant structure. The automatic mixing system can be activated with settings for the auger speed and mixing time.

THE all-new tractor range uses a unique-to-Fendt AgcoPower five-litre, four-cylinder engine and is the second introduction into the manufacturer’s CORE range.

A new TA150 transmission has been developed specifically for the 600 Series and uses a complete stepless drive to a maximum of 50km/h, with split drive to the front and rear axles.

SET to replace the current F5000 range, the new F5 line-up will comprise four models: the non-chopper F5-540 variant; the semi-automatic F5-550, with 15-knife chopper unit; and two 25-knife chopper variants, the F5-560 and F5-560 Plus, which are both fully automatic balers, with the latter flagship model capable of film binding.

F5 balers are fitted with a 540rpm gearbox as standard, but prospective buyers can also choose the optional fitment of a 1,000rpm gearbox. Bale density adjustment can be controlled

9 VOGELSANG

through McHale’s i-Control-5 terminal.

Operators can select from 10 settings to determine bale density and shape depending on crop conditions.

VOGELSANG’S smaller, more affordable X-Split Compact has been developed for smaller farms looking to improve slurry management. It operates with similar technology as the full-sized model and can separate material with up to 40% dry matter suited to farms with up to 100 cows.

COVERING a power range of 95-145hp, Massey Ferguson’s new 5M series has been introduced to replace its existing entry-level 5700M tractor range. Assembled at the manufacturer’s plant in Beauvais, France, all six models are fitted with an AgcoPower 4.4-litre, four-cylinder engine with the firm’s Dyna-4 transmission.

Externally, the range has been

updated with new styling, which MF highlights brings the range inline with its wider tractor offering. New LED lighting packages are included in the visual changes, alongside a redesign of the exhaust system, which MF says has been moved under the cab to provide greater visibility from the 1.3-metre-wide cab with flat floor. Cab suspension can also now be added as an option on all models.

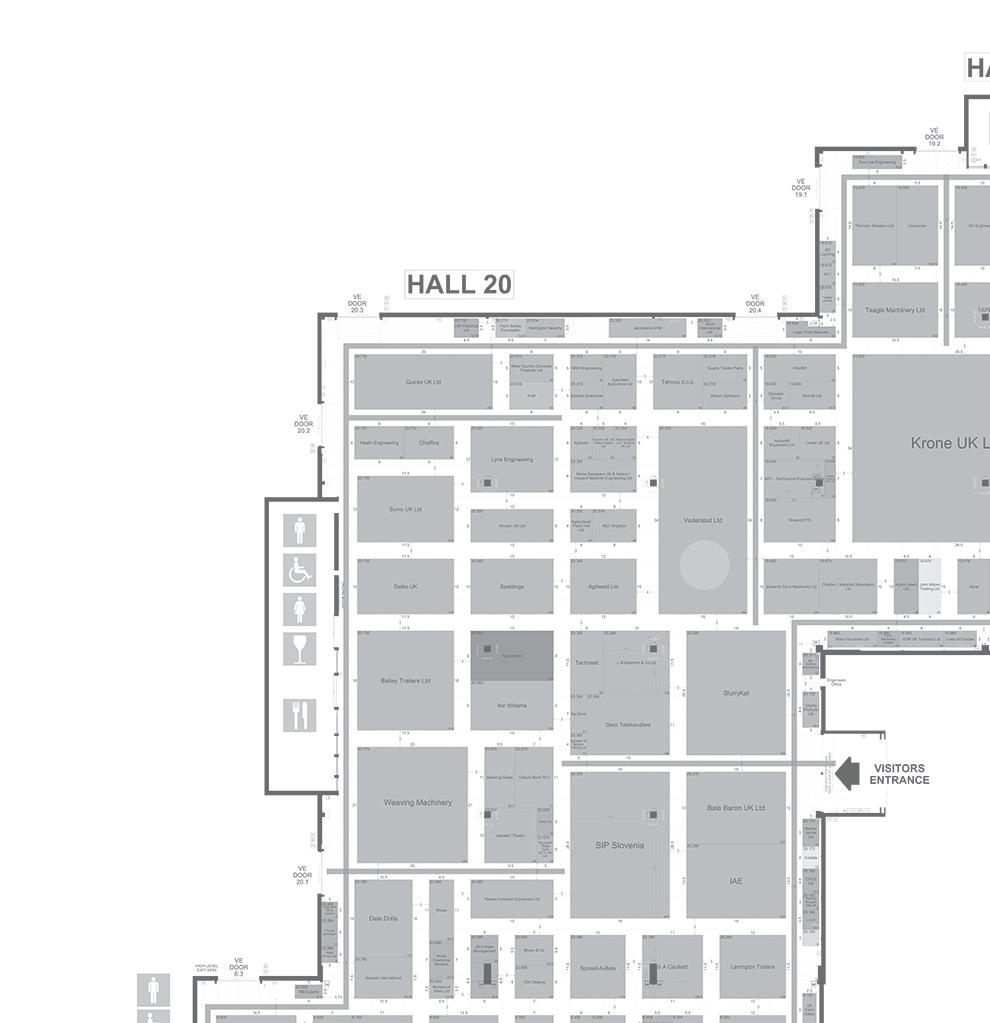

LAMMA 2025 hosts more than 600 exhibitors, offering the widest range of machinery and equipment of any UK show. There are numerous launches and plenty of updated machines to see. Jane Carley picks out some of the main attractions.

MASSEY Ferguson will show examples from its new MF 5M Series, which includes six tractors from 95hp up to the new 145hp top model replacing the MF 5700 M. All models feature the proven AgcoPower four-cylinder, 4.4-litre engine, delivering the necessary power for demanding tasks, driving through the established Dyna-4 transmission with optional braketo-neutral, adding convenience for repetitive handling tasks.

There is a choice of an 58 litre/ minute or optional 100 litre/minute hydraulic pump, and cab suspension is available across the range. There is a wide choice of factory-fitted MF loaders.

New Smart Farming options, including MF Guide, MF Section Control and MF Rate Control, are also available for this range, saving time, effort, inputs and money.

KUBOTA will launch its M7004 tractor series to mark a decade of the M7 tractor line-up.

Powered by a proven 6.1-litre, four-cylinder Kubota engine, producing 130-175hp, the three-model M7004 series offers a choice of two transmissions: powershift or Kubota Variable Transmission, with the latter gaining updated pre-set droop settings for customisable transmission sensitivity and optimum fuel efficiency.

Key updates include a newly repositioned cooling pack at the front of the engine, improving access to key components, while simplifying maintenance, plus repositioned fuel

and DEF tanks, along with cab steps which create easier access and egress from the tractor.

A new automatic assisted parking brake is integrated within the tractor shuttle in order to stop and park safely. In addition, the K-Monitor benefits from a new quad-core processor which delivers expanded functionality and faster processing speeds.

The launch of the new M7004 series also coincides with Kubota celebrating its 50th anniversary in Europe. To mark the occasion, 50 anniversary edition M7004 tractors will be produced, each featuring a striking orange and black wrap.

We manufacture, supply & build...

LAMMA will mark the first appearance of the new-look Case IH Farmall C. As well as a refreshed design, the versatile front loader tractor now boasts significantly enhanced performance, the option of full precision farming technology and a range of new features to aid loader work.

These include a six-post cab and repositioned exhaust, as well as increased hydraulic pump capacity for faster loader cycle times, and a newly introduced ActiveClutch, which allows the tractor to be held on the brake pedal without requiring the clutch.

The Farmall C also offers headland management solutions, optional factory-fitted telematics and modernised digital instrumentation and adaptive lighting.

An increased gross vehicle weight of 7,000kg and an upgraded rear lift capacity means heavier implements can be utilised, providing greater versatility.

It will also be the first UK appearance of an AF10 combine harvester with a grain tank capacity of 20,000 litres and a new 762mm-diameter AFXL rotor, the longest in the industry at 3.67 metres.

NEW Holland’s new T5 Dual Command range will also be shown in the UK for the first time at LAMMA. It features five models ranging from 80 to 117hp, powered by the efficient FPT F36 3.6-litre, four-cylinder engine with the T5 Dual Command transmission to handle a wide range of farm tasks.

The T5 offers a 4,700kg rear lift capacity, a 7% increase from previous models, and an optional wet clutch front pto for expanded

compatibility with various attachments.

It also brings digital technologies such as telematics, autoguidance and IsoBus Class 2 connectivity to smaller farms for the first time.

Operator comfort has been enhanced with mechanical Comfort Ride cab suspension, improved visibility and ergonomic controls, including the IntelliView 12-inch touchscreen.

Continues over the page

VISITORS will get the first showing of the new Fendt 600 Vario series. The top model Fendt 620 Profi+ offers 209hp from its four-cylinder, five-litre AgcoPower CORE50 engine, which also features a Dynamic Performance system that can provide an additional 15hp regardless of forward speed.

All-rounder

Designed to span a gap in traditional tractor ranges, the Fendt 600 Vario is pitched as a compact all-rounder which can be used for towing heavy loads, carrying front tanks or operating heavy mounted implements. Top speed is 50km/h at 1,250rpm and it offers 950Nm from 1,200-1,600rpm. Its turning circle is just 10.2 metres.

Best known for its high capacity Ideal combine, Fendt’s 306hp

C-series machines may appeal to smaller farms.

The 5275C model at LAMMA features ParaLevel, which stabilises

the combine on undulating and hilly land. Based on a parallelogram, it can compensate for slopes of up to 20%. This means the combine

POLARIS will show the 2025 versions of its Ranger and Sportsman models.

Designated the ‘Ranger full size’ ranges, the updated UTV models have a wider chassis to offer three or six seats and more powerful engines in both diesel and petrol variants.

Updates include a new frontend design with a beefier grille and bumper, while brighter LEDs are also fitted to the Diesel and the top-spec XP 1000 EPS Nordic Pro models.

Tractor homologated Ranger XP 1000 models get a boost in power to 999cc from the ProStar 1000 engine, along with a choice of drive modes.

An upgraded Gen 2 continuously variable transmission is said to reduce shifting effort by up to 50% to enable easier and smoother shifting, achieved by removing a collar gear.

The XP Kinetic offers a similar spec, but powered by Lithium-ion batteries. Its ‘Ultimate’ trim version adds a 7-inch touchscreen which offers configurable gauges to monitor ride activity, including battery status, front and rear camera and navigation capability.

Polaris has refined its Sportsman 570 ‘two up’ ranges. The X2, Touring and 6X6 all have LED headlights, new styling and compatibility with some 90 accessories, including snow ploughs, removable windshields, cargo boxes and bumpers.

The company has also doubled the service intervals for all its 2025 models to 2,000 miles or 200 hours for reduced running costs.

BOSS ORV

BOSS ORV is now the UK and Ireland distributor for AODES off-road vehicles, which will make their debut at LAMMA.

Established more than 30 years ago and headquartered in Shandong, China, AODES is a multinational brand sold in over 100 countries. The Pathcross

can operate at maximum output while the threshing unit, separating and cleaning systems remain horizontal.

ATV range features V-Twin engines in 525cc, 650cc and 1,000cc displacements.

The new range will be shown alongside Corvus UTV, Powerland electric ATV and Faunamaster maintenance products also distributed by Boss ORV.

A RANGE of Merlo’s latest machines will be on show. This includes the ultra compact TF27.6 with a width of only 1.86 metres and a height of 1.96m, and the eWorker 25.5 zero-emission, fourwheel drive electric telehandler, which offers a 2.5-tonne lift capacity, a 5m lift height and eight-hour battery life.

The range extends to the TF65.9 HF-CVTRONIC with a FPT 170hp engine, 6.5t lift capacity, 9m boom height and Merlo’s ASCS system, for superior performance with real-time

load monitoring and attachment recognition for enhanced safety and efficiency.

Merlo will also be rolling out its MerloMobility telematics system across its agricultural fleet starting in Q2. This system offers proactive maintenance capabilities and enhanced security through realtime data, accessible via desktop or smartphone apps, allowing operators to monitor performance and maximise uptime.

A RANGE of materials handling updates will be unveiled by JCB.

New to the Loadall telehandler lineup are top-spec AGRI Pro versions of the 538-60 and 560-80, the former bringing the 50km/h DualTech VT hydro-mechanical transmission to the six-metre class for the first time.

AGRI Pro spec also features an uprated driveline with heavier-duty axles, wider tyres and a dual-axle power braking system to further raise the productivity potential of these machines.

For high-lift operations –particularly stacking and retrieving bales – the new JCB Loadall 542-100 combines a 4.2-tonne lift capacity and

9.8-metre lift height with the 40km/h or 50km/h DualTech VT transmission.

Wheeled loader innovations include the 403E Full Cab, a battery-electric ultra-compact machine, while the latest JCB 435S heavy-duty silage and muck loader gains more power and torque.

There are two new mid-range telescopic wheeled loaders: the TM280, with 109hp and hydrostatic drive; and the compact TM280S, with 130hp and DualTech VT hydro-mechanical drive, using a new chassis design which houses the powertrain as low as possible while still delivering a 2.75t lift capacity and 4.8m lift height.

VISITORS to the Lynx Engineering stand will be able to see the new Stoll ProfiLine IsoBus front loader fully installed and working on a tractor.

The hydraulically controlled Stoll ISOBUSConnected loader system requires no specific loader or midmount valves on the tractor. Instead, it delivers full integration of the front loader controls with the tractor system via the tractor’s onboard joystick and IsoBus terminal.

This means that fitting the loader and connecting it with the tractor’s existing IsoBus control platform will take substantially less time in the workshop compared with a typical assembly routine requiring a separate, dedicated loader control system, joystick and hydraulics.

Once installed, as many as 12 additional functions become available, selectable via the tractor’s display terminal and set according to parameters defined by the operator.

NEW from Quicke is the Unigrip L+ grab, which builds on the current Unigrip design and is also available in an XL+ size. The range includes the Multifork L+, with profile cut Tufftines, and Silograb L+, with forged Q-tines. Both are designed for manure and silage handling, while bales can also be grabbed and loaded during the feeding process. The range also includes the

versatile Multigrab L+ and Multibenne L+ buckets.

All four models are designed for a lifting power of 4,500kg and machine weights up to 7,500kg. Specifically for bale handling and designed for large farms and contractors, the Unigrip L+ Robust Bale grab can carry two bales at the time when using a second bale back support.

ZURN’S Seed Terminator will be introduced in its Pro version to suit the most powerful combine harvesters, such as the John Deere X9 and the new Claas Lexion generation. This combine harvester attachment kills weed seeds before they are spread out to become next year’s weeds. The ‘AeroIMPACT 4’ mills which process residue coming from

the sieves using flails and rotors to push the material through multiple static screens now have increased throughput capacity and a more compact design. For European harvesting conditions with tough crops and high weed pressure, special ‘high-capacity’ screens are available to help process even green and wet material without blockages.

Continues over the page

RYETEC introduces the new Zocon precision tined weeder, which features seven rows of 7mm tines set 220mm apart, designed to offer accurate weeding across various crops and growth stages without damaging delicate plants.

Available in widths from three metres to 15m, its key feature is adjustable hydraulic tine pressure, ranging from 100g to 5kg, controlled by the RVS subframe.

This design ensures uniform pressure at any working height,

delivering consistent performance across field conditions. The weeder’s high ground clearance allows for repeat passes as crops mature, making it useful through multiple growth phases.

Tines can be adjusted for gentle surface harrowing or more intense crust-breaking work, adapting to soil needs and crop requirements.

The durable, galvanised frame ensures longevity, while the hydraulic settings enhance ease of use for operators.

ECOROBOTIX will present further developments to its ARA precision sprayer, which uses onboard cameras to collect images that provide data for targeted spraying on a plant-by-plant basis.

The company is now offering an algorithm for carrots as a commercial product, after a beta testing stage in 2024. The carrot algorithm expands the possibilities of ARA and its artificial intelligence (AI) technology.

Carrot growers can now use the carrot algorithm to apply herbicides,

fungicides, insecticides and other products precisely, saving on inputs by up to 95%. Other algorithms offered by ARA’s plant-by-plant AI technology cater to sugar beet, chicory, onions, lettuce, spinach and more.

Recent testing in Germany and the Netherlands, including the Dutch DRT-list, show that ARA can reduce drift by up to 95%, helping farmers comply with plant protection product regulations and environmental conservation efforts.

(Side

• For buildings with narrow access doors and passageways from 2m wide

• One vertical rotor

• Spreading to left, right and front. 0.5m wide, up to 8m throw

• No chopping, lowers dust levels, saves straw

• Spreads any bale in under one minute

• Self-loading, requires only one tractor / loader

• Improves efficiency, profitability and environment

GARFORD Farm Machinery will showcase its advanced mechanical weed control products, including a new advanced vision guidance system, electrical weeding technology and flexible hooded sprayer, all commercially available for the 2025 season.

Robocrop AI uses artificial intelligence to combine colour, infrared and depth information to precisely identify crop plants and stem location.

The multi-modal camera system uses infrared cameras, as well as a colour camera, plus depth imaging and calculates vegetative index.

Using data fusion techniques, the system accurately detects stem locations, even where multiple leaves overlap.

This allows hoeing closer to the crop and new levels of resilience towards varying light conditions and weed pressure.

Garford will also show the results of its agreement with electrical weeding manufacturer RootWave to co-develop new weeding technology and products, integrating electrical weeding into precision-guided toolbar systems, for high-value and high-intensive crops, as well as broadacre arable applications.

McHALE introduces its F5 Range of fixed chamber balers, successor to the F550 and F5000 ranges. There are four models: one non-chopping baler, a choice of 15-knife and semiautomatic baling or 25-knife and fully automatic baling and a 25-knife fully automatic film-binding version.

Features include the new Profi-Flo pickup, designed to increase crop intake through more efficient crop flow, with a tapered feed channel to encourage the crop to flow from the pickup towards the rotor and into the bale chamber.

Adaptive intake allows the intake area to automatically adjust up and down to changes in material flow. All machines in the F5 range are equipped with a 540rpm gearbox as standard, with the option of a 1,000rpm gearbox. The McHale F5-550 can be specified with IsoBus as an optional extra and F5-560 and F5-560 Plus machines are IsoBus-compatible as standard.

McHale will also show a new addition to its ProPel tedder range, the 10-rotor trailed T10-1260 tedder, which has a working width of 12.6 metres.

POTTINGER will show the Jumbo 5390, part of a new mid-range series of loader wagons. The Jumbo 5000 is available in six new models ranging in DIN capacity between 32 and 54cu.m.

It can be specified with a six-row all-rounder pickup with an effective width of 1,890mm or the seven-row Profi pickup with a DIN width of 2,350mm, both controlled from each end by a steel cam track. The central component of the

Jumbo 5000 is the 1,580mm-wide loading rotor which has a diameter of 800mm and a helix eight-row tine arrangement to actively feed the forage smoothly through the chopping system.

It also features the Powercut short-chop chopping system with 45 knives to cut forage to just 34mm in length. The Easy Move swing-out knife bank makes it easy to change and reverse the knives and Autocut knife sharpening is an option.

RETURNING to LAMMA show with an extensive display of arable and grassland equipment, Kuhn will show two new products for the first time in the UK.

The 13.4-metre Kuhn GF 13003 is the widest mounted tedder on the market. Its innovative folding design complies with road width and height restrictions, but offers greater

output in fields which cannot be accessed with a trailed machine.

Also making its UK debut is the GMD 3515 rear vertical folding mower. The rear vertical folding design improves stability during transport, allows better access to tight gateways and occupies less floor space due to a vertical storage frame.

A NEW generation of flagship butterfly mower, the 55100MT Vario will be introduced by the Kverneland Group. The 55100MT replaces the 53100MT, and is an IsoBus-equipped butterfly mower which now comes with Curve Pilot.

Curve Pilot automatically controls the side-shift on both rear mowers in response to tractor steering. This feature minimises stripes between the front and rear units when following curves.

It also enables the operator to make full use of the working width, rather than having to accept a generous overlap on headlands, for example, which can restrict the working width.

Curve Pilot operates with a gyroscope fixed onto the butterfly mower’s headstock to sense steering angle, which then side shifts the rear mowing units up to 400mm to compensate for directional changes.

BX swath groupers can be added to this outfit, which uses two ninedisc cutting beds and has a working width of 9.8 metres.

GRASS harvesting machinery specialist SIP will focus on raking technology, with an example from its new two-rotor Star rake range, which offers high raking capacity for farms where the land and other equipment may not be suited to a four-rotor rake.

The Star R 930 28 TC (9.25-metre maximum working width) centre delivery rake on show boasts a maximum working width of 9.3m and a capacity of 13 hectares/hour; H-line specification offers Hydro Pneumatic Suspension and hydraulic rotor adjustment and includes a central swath curtain ensuring the production of uniform trapezoidal swaths, regardless of the amount of forage.

SIP also offers a trailed four-

rotor rake, the Star HG 1250 50 TC, which has a working width of 12.5m and output up to 18.5ha/hour for larger farms and contractors looking to produce a swath for high-capacity forage harvesters.

The latest technology in raking is represented by the Air Pickup Rake range. Forage is collected by a pickup unit with small diameter rotor which ensures a smooth flow of crop, preventing leaf loss and preserving nutrients in the forage. It is carried onto a belt conveyor and placed in a row, which can be to the centre or the side on the Air 900.

The Axial-Flow combine has been redesigned from the ground up with the new AF Series, the most powerful combine series o ered by Case IH with the world’s largest single rotor – designed to maximise productivity through capacity, automation and built in harvesting technology.

The launch of the new Case IH Farmall C series brings a bold new chapter to this legendary utility tractor. Expect increased comfort, a refreshed design and precision technology.

Get the first UK glimpse of both the AF10 combine and new Farmall C on the Case IH stand at LAMMA ‘25.

GRANGE Machinery will show a number of new developments. Fresh from being put through its paces for

the first time this year is the Top-Tilth Cultivator, which features a dual-disc system which is hydraulically lowered

into work independently of the frame to offer a three-in-one cultivation implement.

OPICO will use LAMMA to showcase its new Alpego range of products.

The Alpego DMAX 800 will be exhibited for the first time in the

UK. Featuring an additional rotor, this power harrow has a working width of 803cm. The central join of the two power harrow beds is now

offset to the join in the two rear rollers, designed to reduce the ridge of soil which is left.

Newly updated side plates with

THE single-leg Claydon Mole Drainer combines the benefits of mounted and trailed designs,

enabling mole drains to be formed easily and accurately. The userfriendly design means it is easy

to adjust and can be handled by a well-ballasted 200hp tractor even on heavy land.

It can be used as a low-disturbance loosener with the discs lifted out, a full-width shallow disc cultivator with the legs hydraulically lifted out or a seedbed preparation tool with all components engaged.

The company will also show its new Tine Drill Toolbar, which has performed in the most exacting conditions for its debut season.

To be unveiled at the show is the Front Mounted Disc Bar, designed to be fitted to the front linkage of the tractor to add a pre-cultivation pass ahead of a drill or to aid in a primary cultivation system.

It consists of a full-width set of wavy discs, able to cut through trash and cover crops, clearing the path for the drill to both improve seed-to -soil contact and aid in trash flow.

More details of this useful new tool will be unveiled at the show.

wearproof skids also create optimal soil flow towards and under the rear rollers.

The DMAX 800 features Twin Force MAX rotors, which utilise twin, wide-spaced Timken taper roller bearings to strengthen the driveline and guarantee unbeatable reliability when used with highpower tractors up to 500hp.

This allows Alpego to offer a three-year warranty on the DMAX Power Harrow range.

Another key feature is AI-Guard, which provides in-cab monitoring of the driveline, as well as alerting the operator to upcoming service intervals.

Three-point linkage mounted, the implement features a long, narrow beam, which allows the 75mm-diameter mole bullet and following 100mm ceramic expander to run parallel to it, producing a uniform, stable channel at the correct depth and angle.

Chains linking the headstock to the beam allow the tractor to turn easily and lift the beam progressively, enabling the mole to ski out of the ground gently with minimal soil disturbance.

Claydon will also show its recently launched drill toolbar and front tank combination.

AGRICAST introduces the GLX 150 Ultra grassland point, joining the LDX and STX in the company’s low-disturbance line-up.

The GLX 150 Ultra is similar to the GLX Ultra in that it features tungsten chip hard facing on the shin, a large tungsten tile on the nose and a high chrome hard facing on the nose and wings.

Additional tungsten carbide

has been added to the wings to offer increased protection. As the name suggests, the new point is 150mm wide, as opposed to the 112mm standard GLX.

MAKING its UK debut, the Seed Hawk 600-900C is a versatile no-till seed drill available in six-, eight- and nine-metre working widths. Equipped with tine coulters, it creates precise seed slots, placing both seed and fertiliser on undisturbed soil.

Built around the proven Seed Hawk knife coulter system, the 600-900C brings advanced technology to the

Agricast’s original GLX point was introduced in December 2020 and was the company’s fastest selling product. Customers have commented that the GLX Ultra lasts up to 50% longer than previous points. Continues

field. Its Fenix III metering system ensures an even product flow to both seed and fertiliser coulters, and operators benefit from the intuitive, iPad-based Vaderstad E-Control system.

For added versatility in heavy crop residues or after cover crops, a front disc can be included to enhance the Seed Hawk’s performance further.

KRM will show the new Bredal K110, the latest addition to the company’s range of lime and fertiliser spreaders. This tandemaxle model bridges the gap between its largest single-axle machine, the K105, and smallest tandem-axle machine, the K135.

It features the same design of floor belt and spreading system as the rest of the K series range, making it capable of applying a wide variety of materials, including lime, fibrophos, chalk, sand and all grades of fertiliser.

All tandem-axle spreaders come as standard with hydraulically driven discs which run from a pto pump pack and are controlled via IsoBus.

The tandem axles are suspended for greater comfort and even load distribution. With their passive steering rear axle, the machine pivots round the front axle when cornering, resulting in better tractor wheel following and greater manoeuvrability. The passive axle can be hydraulically locked straight when reversing.

The K110 has a capacity of 9cu.m, which equates to about nine tonnes of fertiliser or 14t of lime. The machine comes as standard with IsoBus Auto Rate Control and options include weigh cells, a fertiliser kit, hopper cover, hopper extension, various tyre options and a stainless steel hopper.

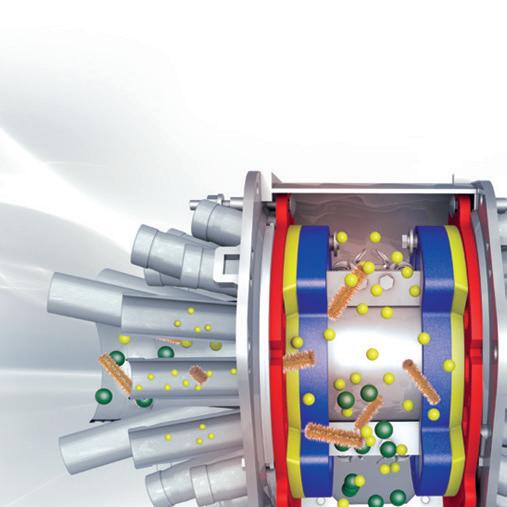

STORTH Machinery will introduce a new telescopic pump mast and chopper pump with a Cobrafill arm. Both these machines have been developed using current products as a base, but adjusting elements to satisfy customers.

The telescopic pump mast has been designed to complement Storth’s range of three-point linkage pumps by providing the ability to use the pumps on smaller above-ground tanks or on semi-submerged tanks.

The chopper pump with Cobrafill arm is equipped with a centrifugal chopper pump, which is force-fed

by a six-inch hydraulically driven Cobra pump.

This ensures optimal flow rates can be achieved by the umbilical pump, even in tricky conditions, such as deep lagoons and thicker slurry, where a traditional pump may be difficult to prime and would suffer an output reduction.

These developments complement Storth’s premium slurry tankers, which range from 7,956-20,457 litres on single and tandem steering commercial axles and are compatible with the company’s existing dribble bar and trailing shoe products.

BAUER’S new plug and play slurry elevator offers increased flexibility for the company’s mobile separator packages, designed for contractors providing an on-farm separation service.

The new elevator version can be trailer-mounted, but also has a parallel lift structure, incorporating slurry intake and separated dirty water pipes, so the separator can be positioned to discharge the solids into a trailer or spreader, or into a large loader bucket.

It consists of a galvanised steel frame housing a pump, all necessary

pipework and an enclosed control panel, with a choice of screw press separators mounted on top.

The Bauer S655 and S855 (and equivalent FAN) screw-andscreen separators are suitable for the new Elevator package. Mobile separation packages require minimal permanent infrastructure, so can be useful in situations where planning restrictions hamper a fixed installation, and Bauer Group’s FAN separators in mobile form are a useful option for multi-site anaerobic digester plants.

THE VERSATILITY YOU LOOK FOR

Make it the perfect ally for all types of farms

THE LEVEL OF QUALITY YOU ENJOY Keep functions at your fingertips, in its roomy cab THE FACTORY-FITTED OPTIONS YOU BENEFIT FROM Enhance your efficiency with a wide range of factory-supplied options For

NEW from Hi-Spec will be a 20-tonne version of the Xcel rear discharge spreader.

As with the current 12t Xcel 1250, the new Xcel 2050 features the Hi-Spec chain and disc spreading system. This consists of rotormounted chains with Hardox flails contained within a full-width deflector hood, which breaks up even the hardest of manures, prior to being spread up to 24 metres by two spreading discs.

The new Xcel 2050 features an angled side panel design which

widens towards the rear, that provides increased internal volume for greater capacity, while also reducing the risk of bridging.

The specification for the Xcel 2050 also includes a hydraulic drawbar and a tandem steering axle with air brakes, plus central greasing of both the driveline and tandem axle.

Hi-Spec will also be displaying a purpose-built, 18,184-litre capacity 4000 TD-R tanker, with a recessed sprung parabolic tandem axle, weight transfer system, electro-hydraulic controls and a fixed rear linkage.

BARE-ROOT HEDGING

PLANTS AVAILABLE FROM AS LITTLE AS £2.25 PER METRE

TreesPlease hedging plants are:

· Extremely hardy

· Suitable for planting on most sites and situations

· Available for dispatch all over the UK

· Grown by a dedicated team of growers

· Great for wildlife

RICHARD WESTERN

RESPONDING to farmers’ cost constraints, Richard Western will introduce the new Delilah D series of vertical beater manure spreaders, which provides simpler alternatives to the Delilah DV models.

Retaining the Delilah beater format of five complete spiral flight sections with six tips per section, the D series (D10/D12/D15, with corresponding cu.m capacities) features a reduced body width of 1,500mm, decreasing the overall width from 3,000mm to 2,800mm.

In combination with a greater use of high-strength materials, this has cut the overall weight by 10%.

The rotor diameter has been reduced from 890mm to 800mm without detriment to shredding performance or overlapping.

The D series spreaders feature floor sprockets with six rather than seven teeth, reducing the torque required to drive the floor.

The company will also show a lower-cost option in its trailer range with the new simple-specification Weeks trailers.

VOGELSANG’S new X-Split Compact press screw separator is a smaller, more affordable option for farms looking to improve slurry management. It features much of the same technology as the full-sized X-Split model and can separate up to 40% dry matter, but is better suited to farms with up to 100 cows.

It is a fixed separator and, due to its compact dimensions, it can be housed more easily in smaller farm buildings and moved between buildings if necessary.

Capable of up to 10cu.m/hour, the unit weighs just 875kg and features a 4kW power pump.

The X-Split Compact features VarioAdjust, a hydraulic closure unit which provides full control over solids output, dry matter content and throughput. A pressure gauge offers precise control up to a pressure of 25 bar using the hydraulic pump, and no tools are required.

The Vogelsang stand at LAMMA will also have the full-size X-Split in its trailer-mounted mobile specification, which is likely to appeal to contractors.

BUNNING will have a focus on achieving timely applications and reduced soil compaction by choosing wider VF flotation tyres as highlighted by its Lowlander 175 HD HBD spreader on display.

The Lowlander 175 HD HBD is the largest single-axle spreader in Bunning’s range. On the LAMMA stand, it will be fitted with BKT 710/70 R42 VF tyres featuring a high 193D load rating, which Ben Johnson, Bunning’s UK and IRE sales manager, says is a vital characteristic.

He says: “Fitting these tyres to our Lowlander 175 HD HBD allows us to demonstrate the increased load carrying properties. These tyres are capable of a 17.5-tonne load, which does not reduce the carrying capacity of the spreader, but contributes to lowering soil compaction and helps increase spreading windows.”

The Lowlander 175 HD HBD will be fitted with weigh cells and an application rate controller. This is available through IsoBus or via one of Bunning’s compatible Topcon screens.

BVL will be unveiling a new highercapacity 25cu.m version of the V-MIX Drive Maximus Plus self-propelled diet feeder, which will also include a number of updates and new features to the specification.

It features the BvL loading head fitted with tines instead of knives to effectively comb the silage from the clamp face, thus preserving its plant structure. When loading at the silage

clamp, the creep speed function enables operators to set the maximum travel speed to suit their needs, allowing sensitive control of the accelerator pedal. Fine adjustment of the speed simplifies manoeuvring at the silage face.

The BvL V-Connect dairy feeder feed management system has also been updated and incorporates a number of new features.

MAJOR Equipment is introducing a rotary head for excavators, based on its recently launched MJ39 Rotary Hedge Cutter replacement head.

The 1.43-metre deck is now available for power arms and excavators in the 10- to 14-tonne range. A single-rotor head in a 0.8m working width is now available for excavators in the 2.5-10t range.

The MJ39 rotary head uses a gearbox driveline to power rotors with four cut-and-mulch blades designed to deliver a tidy finish when thinning material or clearing dense brush, all in one pass.

The hydraulic motor is fitted with an overrun clutch, protecting the hydraulic system when the motor stops.

SHELBOURNE Reynolds is introducing a new model in its 7000 series hedge trimmer range: the 7065T telescopic, with a true 6.5-metre reach.

The 7065T is designed to be compact and thus suitable for narrow lane work, but offers a heavy-duty trimmer with a 6.5m reach from midtractor to the furthest flail when fully extended, says the company. The reach is 5.4m when retracted.

A fixed mounted head means the advertised reach is actually the true reach available to the operator,

whereas the reach of machines with clamp mounted heads is typically advertised reach with the head fully offset which is not a practical operating position.

The 7065T continues the 7000 series specification with a standard 70hp hydraulic system (optional 85hp) developed to run with high pressure, and low flow to reduce the pressure drops throughout the system, which in turn generates less heat and maintains maximum power to the cutting head.

RAZORBACK will introduce the 57 reach mower, which features a new hitch system designed to avoid forces on the tractor’s link arms from the weight of the hedgecutter with the head outstretched, which cause them to lift and twist.

of chains and turnbuckles to equalise the forces during operation for increased stability. The system is designed to be easy to fit and adjust, making it simpler to switch hedgecutters between tractors.

This can be overcome by using axle brackets, says the company, but these can be awkward and time-consuming to fit, as well as limiting which tractor the implement can be fitted to.

Razorback’s hitch uses a series

Other features include a compact tank to enhance operator visibility and overall balance. The machine can be configured with the Razorback Active Contour Intelligence system, an active suspension which tracks and reacts to the contours of the verge for hands-free height adjustment.

KRM spreaders are bristling with features to increase accuracy and reduce waste: Double, Double Overlap, Weigh Cell control, Dynamic Section Control, Trend Headland and GPS automatic headland on/off with Tempo Tracker It all adds up to a BIG saving!

TONG Engineering will announce a new strategic partnership with VHM Machinery, a Dutch manufacturer of high-performance

box and big bag handling systems. VHM’s sophisticated equipment range spans flexible box feeding and discharge to and from the production

process, to completely automatic stacking and destacking of the boxes at either end of the handling process. VHM equipment is designed to bring

continuous, high-capacity box handling solutions which dramatically reduce or even remove the need for forklifts.

A LAMMA award-winning app has proved a hit with contractors both at home and abroad. Jane Carley finds out how they are using Ag-drive.

Winner of the Founders Trophy digital innovation award at LAMMA 2023, Ag-drive is a job management and invoicing app for farmers and contractors, developed by Will Dunn, whose family has a contracting business in Yorkshire.

The app offers GPS job scheduling and recording, field mapping, timesheets and online invoicing, which links to accounting software packages such as Xero, Sage and Quickbooks.

Timesheets become paperless,

offering convenient recording for work hours and travel time.

Ag-drive has also seen a number of updates since its launch, including a new calendar view for the jobs page to make job scheduling and planning easier to view, while there is also an improved offline working mode.

Mr Dunn plans to launch a machinery maintenance and reporting section in early 2025.

In addition to UK customers, Ag-drive is in use with contractors around the world.

BRITISH Farming Awards Contractor of the Year 2024, N.D. Harper has a diverse business with a portfolio of services from straw grinding to muck and slurry, all aspects of grass and silage work to combining and spraying. The business also includes two dairy farms near Holmes Chapel in Cheshire.

“I was looking for an app to record jobs when I saw Ag-drive advertised,” explains founder Nigel Harper. “Previously, we just used diaries.”

With a team of 40 staff including 22 on the contracting side, it can be difficult to manage timesheets, he adds, but Ag-drive makes recording and pricing work easier.

“Even when the job is charged by the acre, we can see how long it takes in real time so can check that charges are accurate.

“The operator logs in as he leaves the yard and logs back off as he comes in, which also allows travel time to be included. In addition, it helps with lone working, as it is possible to check in and see how an operator is getting on without having to phone and interrupt him.”

Mr Harper notes that there has been an increase in productivity and says that the staff are happier in the knowledge that jobs are on the app so they can always see what is happening the next day.

Once a job is completed, Mr Harper approves it and the draft invoice is sent directly to the Xero accounts package for invoicing.

N.D. Harper uses Ag-drive to manage a large and flexible labour force with multiple contracting roles.

“There are other useful functions –for a spray job for example, the operator can take a photo which attaches to the job and provides the customer with a record in case of any queries. You can also load up fields in the app so margins and obstacles can be added.”

The business collaborates with other contractors and at the end of a

job the report can be emailed to them for their records.

Mr Harper stresses the importance of getting operators familiar with the app, having used the quieter winter months to load all the jobs up ahead of the first season.

There is also flexibility for

businesses which use seasonal employees, he points out, as extra users can be added to the subscription when required.

‘Active users’ go on the list in the summer and come off in the winter, with charges waived when they are ‘deactivated’.

OFFERING a range of grassland and arable services plus forage and straw sales, McCarthy Contracting is located in the Selwyn District of Canterbury, New Zealand.

Rachel McCarthy explains: “We operate between the two rivers Rakaia and Waimakariri, although we do fodder beet harvesting in the north Canterbury area and go further afield when carting.

“We have about 12 permanent staff all year round and peak at 30 staff in the summer season.”

All the operators use Ag-drive and it integrates with the company’s Xero software for invoicing.

“Will Dunn came and visited us two winters ago and we found out about Ag-drive from him,” Ms McCarthy explains.

CCS Contracting and Biomass offers a range of services to farmers in the Dumfries area as well as biomass, woodchip and forestry operations.

“All our work is scheduled into Ag-drive with maps and job instructions which are then allocated to staff when they are ready to start the work.”

Staff use the programme to record all the job details and it is then processed in the office and sent to Xero for invoicing.

“The support from Will has been really good and the time difference does not really affect us. He also keeps up in the loop with ongoing software changes.”

“For us, Ag-drive has been a game changer.

“We are a very diverse business and this is the only software scheduling and recording package that can handle what we do.

“We have been paperless now for around 12 months.”

Director Alistair Cowan says: “Summer work entails lots of small jobs for eight to 10 operators so some operations could be missed off records.

“As the owner of a small business I also do all the invoicing myself through Sage so the idea of an app to streamline this was also attractive.”

He says that he can create the invoice simply by sending the data from the app to Sage with the total acres or bales, for example, at the end of each day.

getting on. We are a young team so there is no issue with the tech and all machines and customers are already loaded onto the app so they just go into the field and get started,” Mr Cowan explains.

In three years of using the app, there have been a number of software updates, which have been automatically uploaded and notified via email.

He says: “We have seen quite a few improvements such as the ability to go back in and look at individual customer records more easily, while the interface has also improved.”

Another useful feature is creating a job report for a customer, and for the biomass side of the business this can include more detailed information such as weigh tickets.

“You can easily see where operators are and how they are

Ag-drive was introduced to the business at a key time when Mr Cowan was taking over from his father and he adds that eliminating paper timesheets and simplifying invoicing streamlined the process.

He says: “We used to invoice whenever we had time; it is now easy enough to send then at the end of the working day and this certainly helps with cashflow.”

Ag-drive was introduced to the business at a key time when Alistair Cowan was taking over from his father.

ROUL VanAsch’s Ion Ag business ranges across all of Western Canada, travelling 1,300km between Alberta, Saskatchewan and Manitoba, with the tractors travelling for up to 28 hours to jobs.

Services include liquid and solid manure handling; mowing, raking and tedding; bale stacking and hauling; clamping and hauling silage.

Arable work includes planting, tillage and harrowing, plus rock picking and root crop haulage.

There is also some light earthwork and machinery haulage.

“We do all this with four tractors and six operators,” Mr VanAsch says.

“We normally have two tractors in Alberta and two in Manitoba or Saskatchewan.

“We came across the Ag-drive app after making enquiries on a social media post – it was the one with the most feedback so we gave it a try.

“It took a few phone calls with Will to get everything set up how we wanted, but now we are up and

Ag-drive helps Roul VanAsch keep in touch with the progress of operators who can be 28 hours’ drive away from his base in Lethbridge, Alberta

running it is awesome. Between clocking in, recording travel time and jobs and just about everything else it

has made keeping track of jobs, customers, booking and billing 100 times easier for myself.

“It is nice and simply laid out, which is ideal because I am not good with computers.”

As an agricultural entrepreneur, you know it’s important to plan for the future. But you’re dealing with unpredictable weather, regulations, market demands and fluctuating energy prices. Storing with Omnivent gives you certainty.

We’re happy to show you how easy it is to:

• Store your products in perfect conditions, regardless of outdoor weather.

• Use ventilation and cooling in a sustainable and eco-friendly way.

• Save time when controlling your storage.

• Always know the current storage conditions of your products.

• Manage the energy costs of your storage.

Visit us during LAMMA ‘25 at stand 18.274

Held for the fifth time at LAMMA, the Young Engineer Award promotes the people behind future innovations at the event. Toby Whatley looks at the finalists for the 2025 award.

The Young Engineer Award highlights the work and talent of young engineers in the sector. The finalists and overall winner have been chosen from a panel of judges, including the chief executive of the Institution of Agricultural Engineers, Charlie Nicklin, and AGCO aftersales and training manager, Charlie Rollason.

The Young Engineer Award is designed to highlight innovations and contributions of young engineers working in the agricultural sector.

It celebrates individuals or teams who have developed a piece of agricultural machinery, equipment or technology which has significantly enhanced efficiency, profitability or sustainability in farming operations.

Previous winners have included

Welsh engineer Ieuan Evans in 2024 with his Smart Slurry Pump. The system uses real-time telemetry to monitor key information from a remote-controlled tractor and umbilical slurry pump and provides it to the remote operator at the application end of the pipeline.

In 2023, the award was collected by Daniel Broderick, Omagh, with his innovative self-propelled Cubi-Care machine. Enabling quicker cleaning of dairy cubicles, it features a rotary brush to clean material from the beds, a scraper to remove waste material via floor slats or out of the building, and a self-loading hopper with blower to dispense fresh material onto the beds in the form of lime, sand or shavings.

The Imants spaders achieve a higher efficiency and a higher yield per acre with less passes for all soil types.

Tried and tested technology, grass seed is delivered precisely with 2 sharp discs that cut a V-shaped slit in the ground.

ALEXANDER Sluijmers, a development engineer at Perry of Oakley, has created the Grain Sentry, an automated moisture control system for continuous flow grain driers. Using near infrared technology, the Grain Sentry ensures precise

moisture measurements and automated drier adjustments to optimise grain drying processes. It uses pneumatic conveying to collect samples and employs self-teaching algorithms to regulate dryer speed, maintaining optimal moisture levels.

Traditional drying systems require intensive manual oversight, but Grain Sentry automates sampling and control, enabling remote operation via a PLC panel or app.

Alerts are sent for any issues, allowing farm managers to allocate staff more efficiently. The system prevents costly over- or under-drying, which reduces fuel and electricity usage, avoids fungal risks and ensures higher grain sale value.

Grain Sentry is versatile, compatible with multiple crops and can be retrofitted to existing dryers. It significantly reduces labour needs and improves profitability.

Savings on drying costs can range from £21,500-£53,500 per season, depending on drier capacity.

Developed over six years with input from senior engineering manager Brian Hagan, Grain Sentry was launched at LAMMA 2024 and is commercially viable, addressing key challenges of profitability, efficiency and sustainability in modern arable farming.

Continues

JASON McVerry, a mechanical design engineer at Redrock Machinery, has developed the Two-Stage Self Fill Slurry Boom, an innovation designed to enhance slurry handling efficiency.

This hydraulic boom fills slurry from storage tanks and offers two configurations: a flexible suction pipe for underground tanks; and a portable docking station integration.

It can operate on either side of the machine and integrate a centrifugal pump for faster filling.