Introducing the improved SM range - Your ultimate solution for liquid separation!

These dewatering separators effortlessly handle farm, biogas, food processing and abattoir waste.

Upgrade to the SM range for uninterrupted service life and efficient waste management.

Built to last, these separators boast robust 316 stainless steel and cast-iron construction, a double threaded Archimedean screw, and wedge wire filter.

Corrosion-resistant materials ensure a longer operational life, even in the toughest agricultural and industrial conditions.

Enhance your process efficiency with the SM range.

Valtra’s Q-series was shoe-horned between its T and S models, boasting a Fendt-derived CVT, power outputs from 230-305hp and a host of custom options through its Unlimited studio. Geoff Ashcroft speaks to a Shropshire user to find out how it fits into the fleet.

Sam Paxton has added various LED strobe lights and lightbars to the Q305, adding to the feel of Valtra’s Unlimited customisation.

Agility and power are becoming increasingly sought-after attributes as average tractor power continues to climb. It is one of several reasons why

Shropshire grower Taylor Organic Farms has been sizing up the Finnish maker’s brand, adding a Q305 to its mostly John Deere and JCB-favoured stable.

The farm was looking for a

replacement for a JCB Fastrac 8330.

And rather than add another heavyweight, it sought a power unit that offered much more operational flexibility.

At the extremes, it wanted a tractor that could support a hiredin JD 7310R on bed tilling duties, but also one that could be equally adept at handling trailers, yard duties and low-power field work.

That search focused on delivering more efficiency while also providing greater operational flexibility than the outgoing JCB 8330 could offer.

And the other key reason was that Q-series operator Sam Paxton, who recently joined the farm, is a keen fan of the colourful Agco brand.

“I spent a lot of time on a fourth generation Valtra T214 before joining Taylor Organic Farms, and it clocked up about 4,000 trouble-free hours in two years,” he says.

“The cab was comfortable; the

tractor was easy for anyone to hop onto and use, and it stood out from the crowd.”

“When I joined the farm, I was offered a new John Deere, but it just was not for me.

“And I was very fortunate to be given the option of choosing a brand that I enjoyed using, and one that I had considerable experience with –and that was Valtra.”

As farm owner Nick Taylor had witnessed the T214’s performance and reliability, the decision was made to try one out and assess its suitability among the fleet.

The Q305 joins a JD 8RX 410, four JCB 4220 Icons, plus an array of 6R250, 6R185, 6R155 and 6R145 tractors.

Packing a peak output of 305hp backed up by 1,280Nm of torque, Mr Paxton says the Q305 is anything but big and numb, with the

Q-series shares the Finnish maker’s T-series

place to spend long days.

ability to pile on the weight for heavy draft work.

“While the climb to the cab involves more steps and I am sitting higher up, the Q is not that much different in size to my old T-series,” Mr Paxton says.

“It is taller, yes, but only 50mm longer, so this one is really nimble and it packs a big punch.

“We have a variety of front weight blocks and the tractor could be given extra ballast using rear wheel weights if needed, but we did not feel the need to take that option.”

He says the Q305 is a considerable step up over the T214.

“As a fifth generation Valtra, this one gains a new in-cab display sat on the right-hand A-pillar that compliments the intuitive and easy-to-use SmartTouch terminal,” he says.

The Q pulls better and gets the power down more effectively through the Fendt-derived

“And it comes with a far better transmission than my old tractor’s Direct continuously variable transmission. The Q pulls better and gets the power down much more effectively through the Fendt-derived transmission.

“It does not whine or lose speed on the road like my old T214 did when it came to the shallowest of gradients.

“Nor does it seem to drink diesel – in fact, it is proving to be excellent on fuel.”

Though Mr Paxton says it lacks two key features that appear to have been reserved for Fendt models – that of a 60kph road speed, and VarioGrip onthe-move tyre pressure adjustment.

Even without these features, Taylor Organic Farms believes the Q305 easily outperforms Fendt’s 828 and John Deere’s 6R250 models.

“We do a lot of travelling around Shropshire to reach outlying blocks of land assigned to organic cropping and an extra 10kph would make a difference when it comes to downtime,” he says.

“And with varied field work, the ability to rapidly change tyre pressures on the move would be superb.”

At the 1,011-hectare Taylor Organic Farms operation, Mr Paxton is expecting to clock-up around 2,000 hours each year.

The farm grows mostly organic carrot and potatoes, but a significant acreage of onions, parsnips and

swedes are in the rotation, along with a complimentary selection of combinable crops that takes the business across Shropshire.

Roles are varied for the tractor fleet, with the need to be versatile at the top of the wish-list.

It means handling a wide variety of jobs, from heavy cultivations through to carrying front-mounted mechanical weeding rigs operating at speeds as low as 30 metres/hour.

“We do not plant headlands with veg, but we do keep them level and tidy, using a front-mounted dozer blade,” he says.

“Attention to detail is essential.”

As an ex-demo model from dealers Edwards & Farmer, the 73-plate

Q305 came complete with burnt orange livery and black wheels, courtesy of the Finnish manufacturer’s Unlimited custom studio.

In addition, the tractor specification also includes a premium interior with half leather/half suede seat, LED light package, and Unlimited carpet mat, and is backed up by a fiveyear 6,000-hour warranty.

Mr Paxton has a boots-off policy at the door, helping to keep the interior a clean and tidy environment and, now with almost 200 hours under its belt, the new tractor feel has worn off. Early impressions are positive.

“The cab is quiet, but not hushed and the engine note like most modern tractors, is muted through the

exhaust after-treatment,” he says.

“And this is a tractor that anyone could get on and drive, without too much tuition. With my T-series experience, this one feels every bit as familiar and user-friendly.

“Daily checks and greasing are easy, as is filling the diesel and DEF tanks.

“And I really do like the cab interior. It is comfortable, with a much more deeply scalloped right-hand side, which lets the seat and armrest twist further round, before it eventually hits the side of the cab.

“I also like the darker interior trim, which does hide dirt really well compared to the light interior of the farm’s John Deeres.”

He says that it looks and feels that bit classier and there is plenty

of storage space in the cab. However, like many tractors, Mr Paxton says tool storage comes up short.

He says: “Unlike Valtra’s custom studio, tool storage is not unlimited. We have fabricated toolbox frames that sit alongside the right-hand door and can carry our own boxes.

“It is a compromise, but it works and mine now really needs a new paint job to match the tractor.”

Usual Valtra comforts aside, Mr Paxton has added his own touches to make long days in the cab more entertaining, which stems from his time at the wheel of a high-specification truck owned by an international horse haulier.

He says: “Years of alloy wheels, roof lights, marker lights and lots of polish have helped me to make a

truck much more personal to me. And when you spend long days in the cab, it is important to feel part of the team, and this ethos has been carried over into my farming career.”

He says that having some personalised detail creates more pride, and a feel-good factor.

“We are all responsible for looking after our own tractors and, while others will use the Q when I have got days off, it is all down to looking after your gear and taking pride in what you do. And I actually quite like that level of individuality.”

He has added a host of strobe lights, beacons and LED lightbars, all of which can be controlled from a bespoke switch panel in the cab,

enabling colours to be swapped.

There is just enough room on the roof for a GPS receiver, with the machine using a Starfire 6000 dome, feeding a John Deere universal terminal that sits above the tractor’s SmartTouch terminal.

“A Solsteer auto-steer kit has been integrated into the Valtra, allowing the Q305 to operate with our existing Greenstar precision farming package and My John Deere telemetry,” he says.

“It is the best way for the farm to manage non-JD branded equipment with its existing Deere precision farming technology. And for the Q-series, it is the best of both worlds for me.

“Given the choice again, I would have another one exactly the same, right down to the colour,” he adds.

An organic grower in Germany shows how accuracy and speed are critical to cover acres and maintain good yields in maize crops. Farmers Guardian reports.

Mechanical weeding has formed a key part of the transition to organic maize production for Markus Wiggert.

Afive-year programme to transition a 5,500-hectare mixed farming operation in Germany from a conventional to a fully organic system by 2025 is benefiting from the integration of mechanical weeding as a key component to its weed control management, initially focused on maize crops.

In doing so, the system is demonstrating to both organic and conventional growers across Northern Europe, the efficacy of mechanical weeding in maize crop production and other broadacre arable crops, with the potential to remove or significantly reduce reliance on chemical inputs.

Markus Wiggert is the farm manager of Osterland Agrar GmbH, located in the southern part of East Germany, some 40km south of Leipzig.

Created from the merger of five agricultural production co-operatives which have been active in the region for more than 70 years, the whole farm operation is based

around sustainability and adding value to a local, circular economy.

A 1,000-head dairy cow operation, predominantly fed on homegrown feed and a major biogas plant, sits alongside the arable operation, currently producing legumes, potatoes, onions, sugar beet, wheat and barley, alongside some 300 hectares of organic maize.

For Mr Wiggert, organic farming not only means avoiding chemicals, but also involves wider crop rotations, cultivation of catch crops, organic fertilisers and careful soil cultivation.

This is where the move to mechanical weeding came in, following a step-by-step process to convert to fully organic which started in 2020.

Mr Wiggert says: “Ultimately, our focus will be on the dairy operation and biogas plant. By 2025 we will stop potatoes and sugar beet production and more focus will be on cereals, legumes and maize.

“The maize crop is purely for our forage needs.”

Initially trialling a six-metre Garford Robocrop Interrow Hoe

on the maize crop two seasons ago, the key requirement was to maintain the good yields achieved under the conventional system.

A major limitation to achieving optimal yields is weed damage, specifically from the common weed fat hen, responsible for major crop losses in maize.

“If we can control weeds, there is no reason why we cannot achieve the same yields as the conventional crop,” he says.

Following the successful trial

with the rented 6m hoe, Osterland Agrar invested in a 9m Garford Robocrop Interrow Hoe, stepping up in size and increasing output based on the scale of the farm.

Low draft requirements allow Markus Wiggert to run the nine-metre Garford machine on a 160hp Fendt 720 Vario.

Mr Wiggert says: “Our original focus was to achieve a minimum of 65 per cent of our conventional crop yield, but last year we achieved 95 per cent with our maize crops.

“With other cereals, we are currently at around 65-66 per cent of the conventional crops, but this will increase as we adapt our approach based on crop rotations

and the use of digestate from our biogas plant.”

The precision-guided hoe is proving to be highly effective in the field, supported by the two-camera system, guiding row crop equipment accurately and at high speed.

The video camera creates images of the crop foliage ahead and these images are then processed by a computer.

This information is used to guide

the shares accurately along the crop rows.

“If one camera is obstructed by the headland or there is not good detection, it switches to the camera with the clearest picture,” says Mr Wiggert.

“Another positive we have seen is that when the maize is high and close to the maximum growth stage we can pass through the crop, wind can have an influence as the plant is

moving a lot, but the Robocrop camera works well, despite this wind movement and appears to retain accuracy.”

Another key benefit for Mr Wiggert is the lighter weight construction of the Garford hoe, a particular consideration when moving up to the 9m machine.

“Other wider machines were typically around four tonnes in weight, whereas our Garford setup

is about 1t lighter and this was key as we wanted to be using our 160hp Fendt 720 Vario tractors,” he says

“If you have a 4t machine, you may need to spend an extra €30,000 for the next tractor size, so to have a lightweight machine, when it comes to the lifting capacity of the tractor, is an advantage.

“You can go with a smaller trac-

If we can control weeds, there is no reason why we cannot achieve the same yields as the conventional crop

MARKUS WIGGERT

tor, as you do not need a lot of horsepower for pulling, it is just for lifting.”

After just one full season using the 9m hoe, it is too early for Mr Wiggert to make any definitive judgement on stability, but to date, his experiences have been positive.

Mr Wiggert also likes the Pressure Down system, allowing operators to hydraulically set up how much active pressure is put on the tines.

This, he says, also has a shockabsorbing and damping effect, meaning it runs smoothly even at quite high speeds.

“This is very effective for us. Crucial to us is accuracy, but also the need for speed and hectares covered per day. We could have a machine which does an excellent job at 3-5kph, but we would not cover the hectares,” he adds.

“I wanted a system where it is possible to cover hectares. If you go at higher speeds, you need tools that are at an angle that will not move too much soil and Garford is well experienced and has the right tools, such as the L shares, which are quite flat.”

Garford’s swept L share works

L shares offer stepless angle adjustment for shallow work or for covering weeds.

very close to the row, protecting the plant against being covered with soil, while cutting the weeds growing towards the neighbouring row.

L shares offer varied angle adjustment for shallow work, or for covering weeds.

“Running smoothly at a higher speed was a key reason why we chose Garford,” says Mr Wiggert.

Mr Wiggert’s experience supports the findings from recent NIAB research looking at different pathways to weed control, specifically the control of black-grass in winter wheat.

Using the Garford Robocrop Interrow Hoe, findings from the research found that there was an additional 15 per cent control of black-grass heads when adding interrow weeding to a herbicide programme on narrow rows, and double this in wide rows.

The research indicates that growers can achieve at least the same or marginally better margins over weed control than currently used methods, with the scope to deliver effective weed control while reducing reliance on chemical solutions.

Crucially, even considering the one-off purchase of new equipment, the additional costing of new tools for inter-row cultivation in combination with farm standard practices has been calculated at £15/ha based on two passes.

For larger scale operations that may fall below £10/ha.

While the research was undertaken on winter wheat, the results indicate similar potential for weed management in maize crops, as well as other broadacre arable crop production, in both conventional and organic systems.

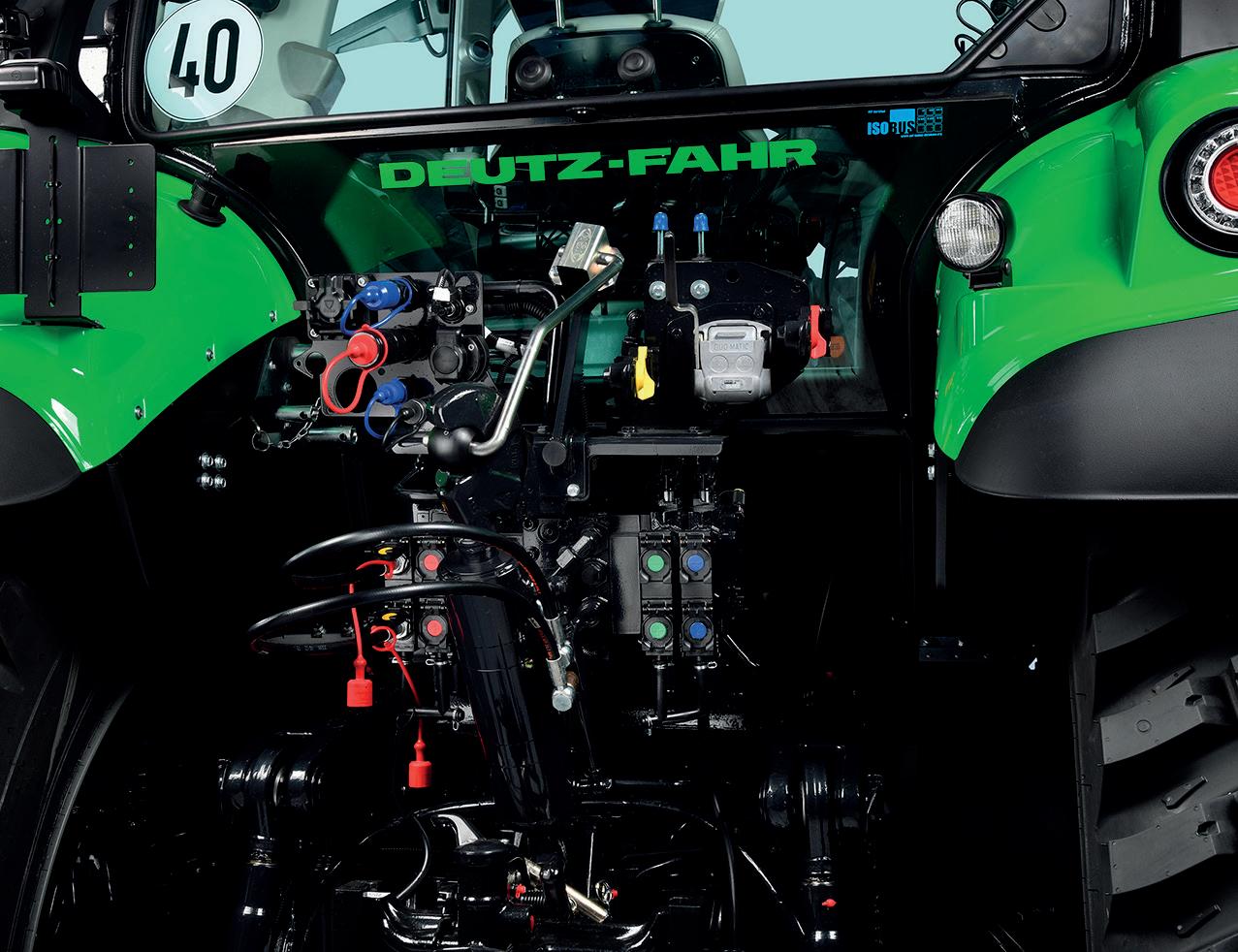

Navigating your way around tractor configurations can be mind-boggling. Jane Carley gets some help from Deutz-Fahr on understanding spec packages.

As tractor horsepower continues to grow, the 150-200hp machine is fast becoming the ‘bread and butter’ tractor across the industry, carrying out a range of operations from arable to dairy sectors.

Consequently, manufacturers offer a huge range of models in this power band, with four- and six-cylinder options in some cases. Powershift and continuously variable transmissions (CVTs), plus a wide range of mechanical and electronic hydraulic controls, also make specifying the right machine a conundrum.

David Jefferson, product and precision farming specialist at Same Deutz-Fahr (SDF), says: “You need to think about what the tractor will be used for and who will be driving it. Certain options and spec packages are very popular with owner drivers, who want a

level of control and convenience. Whereas in the businesses which use a lot of casual staff or where one tractor does a variety of jobs with different operators, a simple setup can save a lot of time when switching over.

Plus and Pro versions available to meet the needs of mechanical, mixed mechanical and electronic, and all-electronic rear spool configurations.

with the RCShift transmission in the MaxiVision+ package, and Mr Jefferson says that this is still a popular request.

BUDGET also plays a big part in these decisions.

Pricing for a 161hp 6160 RCShift with mechanical spools starts from £166,615 (retail). To upgrade this to the mixed valve adds £1,464, or £3,634 for full electric, including a different seat specification, full MaxCom armrest and external spool controls on the rear fender.

On a new TTV model, the standard default would be full electrical, starting from £186,515 retail, but selecting the hybrid mixed valve combination would save £2,777.

“We offer a range of packages in three categories: A, B or C spec. The top-range C spec is generally chosen by owner-operators or where farms employ a high-level operator,” says Mr Jefferson.

Deutz-Fahr’s Series 6 offers a lot of choices including the four-cylinder 6.4 and 6C ranges in the 100150hp sector, and there are also 160 and 170hp four-cylinder options.

With six-cylinder models from 161-230hp, the Series 6 tractors are available with three transmission options: a powershift version, which has a manual gear lever with five gears and six powershifts; the RCShift with the same amount of ratios, but with armrest fingertip gear change control; or full specification TTV models equipped with CVT transmissions.

MaxiVision cab specification creates packages for transmission and hydraulics, with Standard,

“While we offer our Series 6 with a powershift basic lever gearbox and two or four mechanical spools [A specification], for the UK the RCShift powershift is commonly chosen, with the MaxCom joystick rather than a gear lever and an electrohydraulic block on the gearbox,” says Mr Jefferson.

This gives five robotised ranges and six powershift stages, with smooth shifts made using the lever in manual or semi-automatic modes, or by automatic range and stage changes.

Simple mechanical hydraulics with four spools can be specified

He says: “Front linkage in this sector is very popular, which we routinely fit because they are useful, even if just for carrying front ballast weights.”

A very simple setup would be to have the supply connected onto the rear hydraulic couplings and to use isolator taps when you do not want to use the front linkage, he adds.

“The more popular choice utilises a cross lever that operates the front linkage via mid-mount electric spools, regardless of the mechanical or electric spool configuration. Connected to this, the Comfort Pack adds an extra hydraulic service for the front linkage, or you can specify two extra services – particularly useful if you needed it for a push-off function on a buckrake along with a hydraulic top link,” he says.

Mr Jefferson says the front pto are relatively easy to fit as and when required, but it is more complex to alter the hydraulic configurations, so a front linkage/ Comfort Pack are best specified from the

Front linkages are commonly fitted, but it is important to specify the required hydraulic service and control set-up at the time of purchase.

start if they are likely to be needed. Recently introduced, Deutz-Fahr offers a mixed spool configuration that gives two joystick-controlled electric valves, plus two mechanical

valves. This allows for operators who like the feel and control of the mechanical valve, but would also like to take advantage of the ComfortTip headland management.

This is where programmed hydraulic functions can be automated within the headland sequence – something that is not possible with mechanical valves.

The two electric valves use the cross lever joystick control, and if equipped with the front linkage, a split blue/green button at its base is utilised to switch over between

Colour-coded outlets for the different spools on the mixed mechanical and electronic control version.

the linkage and the hydraulic service, with an additional blue button deciding whether the sideways movement controls a rear spool or the front Comfort Pack outlets.

On tractors supplied loader-ready, this lever can also be configured to control the loader.

Mr Jefferson says that this is a popular package for multiple drivers, where it is easy to train an operator who has never driven the tractor before to jump in the seat for a day.

You need to think about what the tractor will be used for and who will be driving it

DAVID JEFFERSON

He says: “Powershift models have a simple 84 litres/minute gear pump, but the 120 litres/minute closed centre variable system –fitted as standard to the RCShift and TTV models – is more popular. This also gives you the option for power beyond to manage flow based on demand, ideal for Isobus implements or in the future for those using TIM [tractor implement management].”

Mr Jefferson adds that 160 litres/ minute flow is a further option, which could be a consideration for jobs like powering a hydraulic fan on a drill or for oil-hungry kit such as bale wrappers.

The RVShift transmission came in with the 6C tractors, and the launch of the 6.4 Series in late 2022 was accompanied by the larger MaxiVision+ cab.

“It is a full powershift, based upon the in-house CVT but with theoretical steps up to 50kph, rather than infinite speeds – the same gearbox as the TTV with simpler management,” says Mr Jefferson.

The simple configurable joystick has a thumbwheel to increase or decrease speeds, and buttons at its base to select field or transport

driving modes without shifting through gears.

“This is available with mechanical spools or the mixed hydraulics option, giving the two mechanical and two electronic valves. This is by far the most popular choice,” he says.

The cross lever can be used to set up flow rates for constant pumping.

“Select the percentage required and then, when the lever is pulled back, flow is delivered at that setting. It gives you finer control; for example, if an older type of potato harvester needs to be lifted out slightly in changing conditions,” says Mr Jefferson.

“With the Comfort Pack, the front linkage is also adjusted from this lever; the buttons operate the service and linkage, and you can choose to swap between using the lever for front and rear hydraulics.”

There is increased demand to use higher horsepower tractors with front loaders, and the cross lever can also be used to control a loader. Loader-ready spec includes a ‘stoll mode’ switch which changes over to the loader while, again, it is an easy switch to rear spools when these are needed.

The 150-200hp tractor can be expected to carry out a wide range of tasks with a variety of implements.

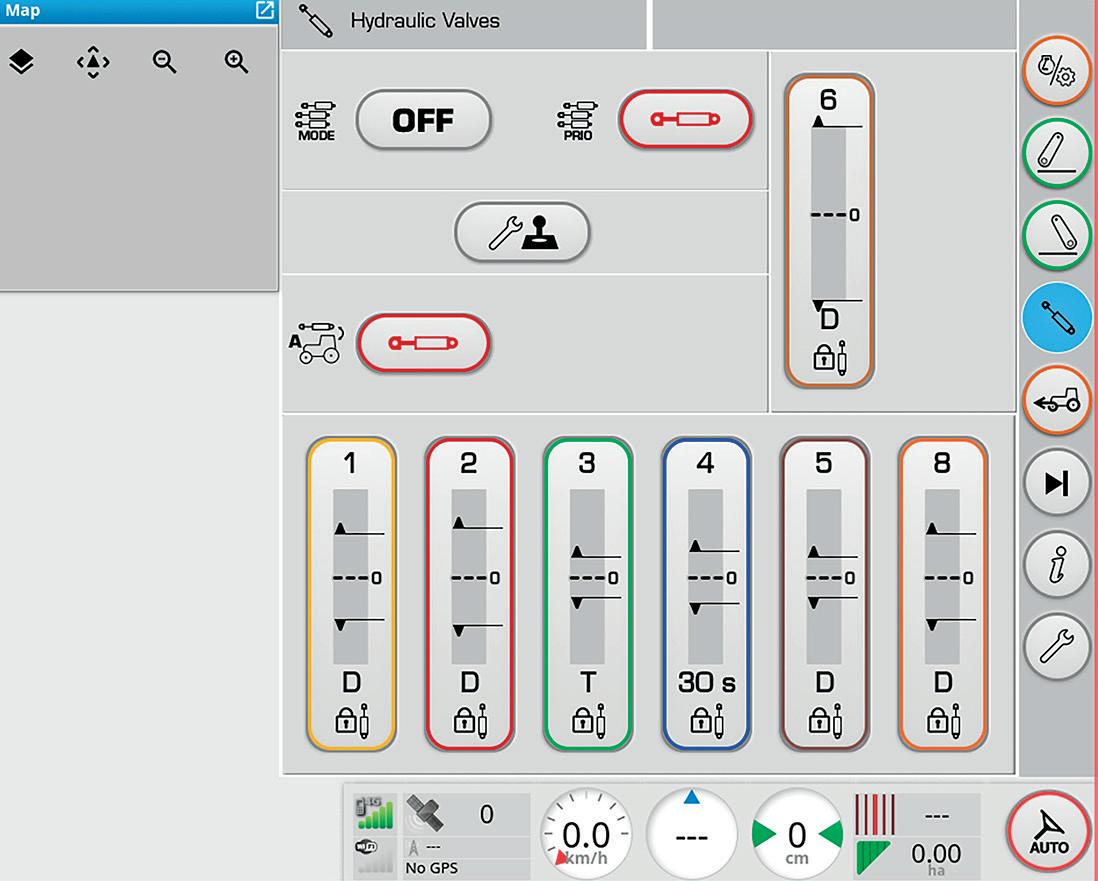

Deutz-Fahr Series 6 TTV models come with the MaxCom joystick, which incorporates the hydraulic controls and offers a stepless 50kph transmission plus an electronic handbrake.

The standard TTV fare is up to seven all-electronic valves, but at Agritechnica 2023, the company announced that it would also offer the mixed electronic/mechanical option on the new Generation 6 Series TTV up to the 6180

“This is ideal for the operator who needs the convenience and capability of a CVT but requires

simpler hydraulics for some operations; it is a first to have any manual spools on a TTV in the 12 years I have been working for SDF,” says Mr Jefferson.

The MaxCom joystick uses proportional roller controls for two spool valves, allowing flow rates to be set as required; additional spools are on the armrest and a cross lever on the joystick.

These models offer the choice of 120 or 160 litres/minute, with 210 litres/minute also a possibility on the larger models in the range.

While settings can be viewed in

the Infocentre dash display, there is also the option of the iMonitor 3 interface; a 12-inch control screen which can be specified for the MaxiVision+ and Pro cabs.

“The iMonitor allows the operator to view, assign, set and configure hydraulic controls and settings,” says Mr Jefferson.

“Colour coding which is repeated on the outlets makes it intuitive to use, plus it is fully programmable: you can also create and save settings profiles for specific operators

or operations. For example, you can set the plough up and save its hydraulic settings, and it is there when you come back to plough next season, saving time. There is also a notes section for details, and if you have a fleet of tractors, you can export these settings to another operator’s machine.”

The iMonitor allows the operator to manage all key machine functions from the screen. Another benefit is its telematics capability, offering remote support, service back-up and fleet management functions.

Looking for the ultimate clamp solution for its 4,850-hectare silage workload, one Hertfordshire contractor has opted for JCB’s flagship wheeled loader, the 282hp, 20-tonne 457S. Geoff Ashcroft finds out more.

By his own admission, Joe Williams is borderline obsessive when it comes to logistics. So much so, that time and effort are regularly spent assessing equipment performance and productivity, to ensure his silage operation runs like clockwork

Mr Williams, of Eastern Counties Straw based at Rooks Nest Farm near Royston, Hertfordshire, says: “I do not want to see tipped loads waiting to be pushed into a clamp.

“Logistics is a passion of mine, and I want all my kit to keep moving, not waiting. If everything is matched and flowing smoothly, then we can maintain a throughput of 300 tonnes/hour from the forager. Though it does mean having a little bit of surplus capacity at the clamp.”

That surplus capacity has arrived for the 2024 season in the guise of JCB’s flagship wheeled loader, the 457S. As the first of its kind to be sold into agriculture, the 20-tonne loader was bought to replace the firm’s previous king of the clamp, a Fendt 1050 with a front-mounted blade.

Mr Williams says that the Fendt 1050 was considered to be a stepup from a 936 model, with more power, though he says it lacked the smoothness and controllability of its smaller stablemate.

“The 1050 was just too aggressive, whereas the 936 put its power down so much better for clamp work,” he says.

“But it just

lacked productivity, so we had to look at going back to a shovel. And with grass chopped at 6mm for anaerobic digestion [AD] use, the clamp surface needs the right approach as it can be like porridge compared to a longer chop length favoured by livestock.”

Joe Williams (inset) bought the 20-tonne JCB 457S loader to replace the firm’s Fendt 1050.

and produces around 25-30,000 big bales of straw for power stations.

He says that having a 457S on demo in maize last year proved a game-changer for the business.

“This new JCB was something very special indeed,” he says.

“I was very impressed with it, and with a 4.8-metre folding fork, it could just annihilate a tipped load. It walked all over the Fendt 1050, without even trying.”

Providing contract foraging services for the AD sector, Eastern Counties Straw handles a 4,850-hectare silagemaking workload

The 2023 season saw 30,000t of grass chopped from about 1,620ha alongside 3,240ha of maize and wholecrop.

“We cover most of East Anglia, and travel out to Oxfordshire, Northants and Kent,” he says.

“We use low loaders to move the forager and loader, with a full support package in place, and portable accommodation for the team so we can stay on-site to get the job done.”

At the heart of the operation is a Krone Big X 1180 with various headers, including a 12-row maize unit. Until recently, there was additional forager support from another contractor, who has now retired, so a second Big X 1180 is on the radar, ensuring there is capacity available to grow.

If everything is matched and flowing smoothly, then we can maintain a throughput of 300 tonnes/hour from the forager

JOE WILLIAMS“Some customers run their own clamps, where we just provide a chopping service or a field-to-road chaser solution that loads into waiting artics,” he says.

“So we are unlikely to need a second JCB 457S. But when we are on a full team harvest, we will pull in a Fendt as a support tractor, because we will always need to use a tractor to just keep rolling.”

A 4.8-metre Redrock folding fork should make the most of the 457S’ 282hp.

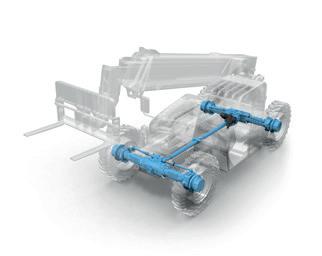

JCB’s 457S joins the 419S and 435S as purpose-built machines for the farming sector. While the 457S shares some of its design elements with its quarrying stablemate, JCB says the ‘S’ version brings a new rear chassis and coun-

terweight, and new transmission and axles, with different wheel and tyre options.

That revised rear counterweight offers an increased departure angle for climbing clamps, and the ability to conceal a 400-litre fuel tank to keep the Cummins B Series 6.7litre engine well-fed.

The 457S also features selectable power modes. In its economy mode, the loader delivers a modest 224hp. Selecting its dynamic mode summons a total of 282hp at

1,900rpm and 1,200Nm of torque at 1,300rpm.

A six-speed powershift transmission with selectable torque converter lock-up puts power to the ground through ZF axles, with limited slip or auto-locking differentials. Depending on specification, 40kph or 48kph is available. The powershift box can be operator-configured to select lock-up

in any reverse gear, in addition to the lowest three forward gears. Operators get JCB’s Command Plus cab, which includes a heated air-suspension seat while adding the Contractor Pro pack finds the 457S dressed with 360-degree LED lighting, carpet, half-leather heated and ventilated seat, twin beacons and a stainless steel exhaust.

“Physically, it is a big loader,” says Mr Williams.

“If we were on crushed concrete work, we would probably have a Volvo – but for clamps, it has got to be a JCB. And for us, the 435S is just not big enough, whereas the 457S is ideal for the open spaces of an AD clamp.”

A selection of attachments for the 457S includes a 4.8m Redrock folding fork, plus a tip-toe bucket, general-purpose bucket and pallet forks. In addition to clamp work, there is a requirement to load muck spreaders in the shortest possible time. The 457S is unlikely to disappoint.

Getting forage from field to store is tailored to suit the customer’s requirements and the location, with logistics given full attention. Tractors and tri-axle Bergman trailers with walking floors or Scania 8x4 lorry chassis carrying Kaweco bodies are the preferred option.

“The lorries are a superb solution, and this is the way forward for us,” he says.

“They are quicker and far cheaper to own and operate compared to tractors and trailers. And they are much safer, too.”

Mr Williams says that with walking floors, the kit can be reversed up onto the clamp to eject.

“With the 8x4 Scania lorry, the weight of silage is over the twin rear axles, so we can reverse up the clamp at full power until we lose traction,” he says.

For us, the 435S is just not big enough, whereas the 457S is ideal for the open spaces of an AD clamp

JOE WILLIAMS

“There is no danger of tipping over, and we can eject a load much closer to where the loader operator needs it to be, rather than tipping at the bottom of the clamp. And that also means the 457S will benefit from doing less running up and down the clamp.”

He says that non-tipping bodies offer a further advantage, as the walking floor design can be used to put material down in a layer.

“By moving slowly down the clamp while ejecting, the load can be spread very effectively,” he adds.

“And in turn, this means there is less work for the 457S. Instead of having to push and spread full loads, the operator can work with a thin, wide layer which means we will get tighter consolidation from compacting thinner layers.”

“It is going to be an interesting season,” adds Mr Williams.

Plans are underway to ensure next year’s LAMMA Show is bigger and better than ever. Farmers Guardian reports.

Next year’s LAMMA Show will open for longer to give visitors and exhibitors more time to connect.

The UK’s leading agricultural machinery show, which is owned by Farmers Guardian’s parent company Agriconnect, will open 30 minutes earlier and close 30 minutes later in response to feedback from exhibitors.

The feedback was received as part of a recent event which gathered seasoned exhibitors alongside newcomers to formulate plans ahead of the 2025 show at the NEC in Birmingham.

Attendees benefited from presentations delivered by the experts at LAMMA, including members from sales, marketing and operations.

These presentations offered advice on best practice to maximise success

■ LAMMA will take place on January 15-16, 2025, at the NEC, Birmingham

at the event. A dynamic Q&A session produced positive discussions, the feedback from which ensures LAMMA continues to grow.

Sarah Whittaker-Smith, event director, says: “We were delighted to welcome a diverse and engaged group of LAMMA exhibitors to the 2024 Exhibitor Day. The valuable feedback received will fuel our ongoing efforts to innovate and grow as a show.”

Building on the success of LAMMA 2024, this year’s Exhibitor Day reinforced LAMMA’s commitment to excellence for both exhibitors and attendees. Plans for follow-up webinars later this year are underway, inviting further input from exhibitors to continue shaping the future of LAMMA. There will also be a marketing workshop to help exhibitors make the most of their presence at the show.

LAMMA 2025 will open 30 minutes earlier and close 30 minutes later than last year.

Webinars are being planned to welcome further input from exhibitors.

■ To apply for a stand or request more information, please contact events@agriconnect.com

■ Stay updated on future developments and announcements by visiting agriconnect.com More

■ Limited exhibition space for the 2025 event is still available, but spaces are filling up fast, with more than 70 per cent of the space already sold

Kuhn’s Karl autonomous tractor project offers an insight into the manufacturer’s vision of how machinery will be operated in the future. Toby Whatley reports.

Farmers have been given an insight into how autonomous tractors could be used on their farms in the future.

Kuhn’s twin-track autonomous tractor uses a 175hp Volvo diesel engine working through a hybrid electric drive. This is combined with a high-voltage take-off to power implements, alongside a twin conventional linkage front and rear.

Senior project manager David Hild says the use of the engine supplier and drive system is due to the manufacturer’s experience and technical flexibility.

He says: “We already work with Volvo to supply the engines for our self-propelled sprayers, so for us, it was a simple choice to install one in Karl. The choice of the hybrid drive is more focused on the simplicity of an electrical drive.

“It allows immediate start-up torque, infinite speed control and much simpler sensing technology to easily monitor the functions of the product – something which is key with an autonomous machine.”

Karl is not the brand’s first presentation of autonomous machinery, with the Aura total mixed ration feeding robot launched in 2020 and shown to the press in early 2022.

Although operating in separate parts of the business, the two engineering teams have worked closely on the two projects, with some components shared between them.

Mr Hild says: “The Aura and Karl

A 2.5-metre working width permits easier transport between sites.

are developed for very different applications and environments, so mechanically there is very little shared between them. Where we see a crossover is in the control software, some of the environmental sensing equipment and the control ECU’s.”

Currently, the drive for the unit will remain diesel-powered, but Mr Hild says that the electrical functions of Karl will lend it to a complete electrical drive if battery technology progresses and becomes available as an alternative.

The development of Karl began in 2018 with the Kuhn-supported Centeol challenge, which took place in Bourgogne, France. The project was operated with partners including startup AgreenCulture, Dupont and telecoms provider Orange, and worked to cultivate, establish, fertilise and mechanically weed a 50-hectare crop of maize.

The outcomes of this project were the background to the development of Karl as a more commercial offering.

drive to be easily reversed. With the machine working remotely, any blockages – such as stones – can be removed by lifting the implement and running the drive backwards.

“This helps reduce the need for the machine to stop and alert an operator, and also improves the ability of the machine to solve its own problems and continue working.”

Despite offering implements for arable and grassland customers, Karl will remain a machine for arable cropping, with no current plans to offer the unit for grassland tasks with an alternative non-track drive.

Drive for the machine is a diesel-electric hybrid from a 175hp Volvo engine.

Operating with the unit, a modified HR2520 2.5-metre wide power harrow uses an electric drive as a pto replacement, and several additional sensors to monitor the working characteristics of the cultivator, which can be fed back to Karl or the operator to make adjustments.

Mr Hild says the use of an electric drive to the power harrow offers some additional advantages.

He says: “Using an electric drive allows the same type of sensing technology to monitor the machine as it is working, but also allows the

Mr Hild says: “Karl has been developed specifically for arable cropping and will be developed to work within the full crop production process including cultivation, planting, weed control and fertiliser applications.

“Kuhn is an implement manufacturer so the machinery that will be developed for Karl could also function with another electric tractor as machines like this are released to the market.

“We currently have seen the machine working with a 2.5m-wide

Karl has been developed for arable cropping and will be developed to work with the full crop production process

power harrow, but a wider range of electrically compatible machinery will be seen as the project progresses.”

The development of the machine has been driven by the reduction of available labour across multiple markets, with the challenges seen in greatest focus in Europe.

Mr Hild says: “Karl can work as a single unit or as a fleet of machines working together to cover a wider area. The flexibility of its operation is an important part of its design and can

Implements are electrically driven – the unit is currently operated with a power harrow, but more equipment will be offered.

accommodate additional machines as a task is completed.”

“This variation in work practices should allow a fleet of machines to begin individual tasks and join together as they complete their respective

roles to maximise the productivity of each unit. Currently, the 2.5m working width has been created to allow easier road transport on trailers between sites without any widthrestriction challenges.”

Commercial availability of Karl is still unconfirmed, however Kuhn is hopeful that a five-year timeframe should be realistic as more field tests in real-world conditions take place over the next few years.

One Kent dairy farm has chosen a Volvo L70H wheeled loader to take care of silage clamps and daily feeding duties for its 1,500-cow herd. Geoff Ashcroft catches up with operator Rob Joules to find out how the kit is standing up to farm life.

When it comes to materials handling, PHR Farms in Kent is not blind to the capabilities of a wheeled loader. The 1,215-hectare, 1,500-cow operation has favoured the industrial might of a loading shovel since the mid-1990s and is unlikely to turn its back on the format.

Rob Joules, who farms in partnership with his parents Peter and Hilary Joules at Bircholt Court, near Ashford, says: “There is not a telehandler out there which can compete with a wheeled loader. It is not just about being able to work successfully on a clamp and keeping up with a forager. For us, that is a small part of what we need a loader to do.”

The lion’s share of PHR Farms’ daily materials handling workload is filling the 40cu.m trailed feeder wagon to keep its livestock fed.

Mixes

Mr Joules says: “Through winter, we will be making seven mixes per day, reducing to four mixes through summer. It is enough for a loader to clock up about 100 hours per month and for that we need reliability, flexibility and manageable running costs.”

For those considering a wheeled loader, there are of course attachment choices to consider. But with the industrial machine market tending to favour Euro quick-hitch headstocks, the compatibility issues which steer

so many telehandler buyers down a rabbit hole are easily swept aside. And then there is the fixed length boom.

Mr Joules says: “This has never been a problem. With a 4.5cu.m tip bucket, we can load over the side of our feeder wagon with ease, and all our previous loader attachments are compatible. We have a 4.8-metre BAC folding fork which makes pushing silage into our clamps effortless.

“There have been a few attachment hoses which needed extending, as the couplers terminate on the boom, not on the headstock.”

Mr Joules adds that the farm has worked its way through various JCB 412 and 416 models over the years and

it still operates a TM320S telehandler, along with three Claas Torion 530s.

The latter are used mostly for yard-scraping duties.

He says: “But when you want much more performance and productivity than what a telehandler can provide, you need to look at a much wider market and think a bit beyond the farm gate.”

PHR Farms has recently replaced its seven-year-old, 8,400-hour Cat 924K wheeled loader with a Volvo L70H.

Duxford-based SMT, Volvo Construction Equipment’s UK dealer, has recently been pushing to get its kit more widely accepted in agriculture.

Its dedicated agricultural-spec seven-model loader range spans the compact L45H up to the 276hp, 21-tonne L120H.

The L70H in use at PHR Farms uses Volvo’s own 5.7-litre D6J six-cylinder engine, which offers maximum power of 176hp from 1,400-1,800rpm, with 863Nm of peak torque delivered from 1,200-1,400rpm.

Volvo’s own HTE125 four-speed powershift transmission with a single-stage torque converter supplies power to Volvo axles – the rear uses a limited slip diff, while the front offers mechanical locking.

With an operating weight of about 14t and a full turn tipping load of about 7.5t, it had enough muscle to match the outgoing 924K.

Mr Joules says: “The Cat had been a brilliant machine, although we got through six sets of tyres while we had it. Fuel use was outstanding.

“On the clamp, it would only burn 19 litres per hour – it was all about hydraulic performance and we did not want, or need, a physically larger machine.”

Mr Joules realised that a similarsized model to the 924K was going to fit right into the clamps, yard spaces and buildings, without complication. And having looked at other makes, he says that having a demonstration on the clamp quickly reduced his choices into a two-horse race.

Yards are tough on tyres, and the Michelin Mega X Bib 750s are unlikely to survive through to the end of this year.

He says: “Some other machines could push, but were all noise, revs and fuss. And when it came to pricing, some of the things you want were optional extras, and that saw the cost

rise. The Cat options were just two –choose from longer loader arms and auto-lube. And it was much the same with the L70H.

“What clinched it was the cost. And

On the clamp, the L70H has enough performance to keep up with the farm’s self-propelled forager.

with a fixed price service package, that means you only pay for the hours you have clocked, so the L70H became our machine of choice.

“The only concern was after having

the security of a five-year warranty, the Volvo’s one-year, 1,000-hour warranty seemed a little unnerving.”

Having clocked 870 hours since arriving in winter of 2022 ready to start

A sprayer with more capacity, more output and no compromise

The new Pantera 7004 self-propelled sprayer comes with a tank size of 7000 litres (6,600 nominal) and boom widths up to 48 metres.

The new, weight-saving chassis design offers machine self-levelling and independent front to back track width adjustment, so more focus on ergonomics and comfort.

Don’t get left behind; spraying technology is changing and the AMAZONE Pantera is leading the way in intelligent crop protection.

Offset track width driving helps minimise soil compaction.

the 2023 grass season, Mr Joules says the Volvo is so far living up to expectations, with fuel burn backed up by Volvo’s telematics package.

He says: “Whole-life fuel consumption is averaging 20.5 litres/hour, and for a machine which packs about 25hp more than the Cat and weighs a tonne more, it is proving to be an impressive package.

“It just does everything without feeling like it is rushing around or revving hard – it is an effortless performer.”

Mr Joules says the way the L70H is set up for farm use is different to how it would be used in a quarry scenario.

He says: “This model has separate cooling for hydraulics and transmission, torque lock-up in first gear and a change to the reversible fan settings.

Transmission

“The joystick is familiar, but the transmission control is not what you would expect. It takes a while to get used to the joystick’s rocker switch for direction changes, as it moves directly from forward to reverse and vice-versa. It does not go through neutral – there is a separate button on the joystick for neutral, which is not natural to use.

“And when you have climbed to the top of a clamp, it is handy to just have a pause as the machine settles on the grass, before changing direction.”

He says that Volvo’s driveline performance eliminates the need to run the loader at full throttle, for an operator to get the best from it.

Mr Joules says: “There is added pressure pushing back beneath the foot throttle, so you have to make a

conscious decision to hit full throttle, although it is rarely necessary.

Even with our Claas Jaguar 870 sending in 105ha/day, I can keep up no problem.

“Most of the time, I am in first gear on the clamp. It does not matter how

much grass or maize is in front of me, it just picks it up and goes.”

Mr Joules also has considerable praise for the L70H’s cab.

He says: “Visibility is really good, particularly when changing attachments, and there are extra mirrors

Cab interior is described as quiet and comfortable, with a good view. Inset: The joystick’s transmission control uses a separate button for neutral.

and a reversing camera, plus fulllength glazing on both sides of the front windscreen. You can also set your own operator preferences through the dashboard to suit how you want to work.”

Attachment hoses were lengthened to suit boommounted pipe couplers.

He says that daily checks are easy to achieve at ground level, and the electrically-opening bonnet conceals fuel and DEF tanks at the rear of the machine.

“Opening the bonnet to refuel encourages you to look around the machine when refuelling,” he adds.

“We like to look after our kit, so it is no bad thing spending a few minutes just having a look over when refuelling.”

With a fixed price service package, that means you only pay for the hours you have clocked, so the L70H became our machine of choice

ROB JOULES

Refuelling and cooling pack cleaning are effortless.

High speed efficiency, low speed control; all in one transmission.

Scan here for more details

Following the launch of the 300M series late last year at Agritechnica, the UK rollout of John Deere’s new self-propelled sprayer has been long anticipated. James Huyton takes one of the first machines out to find out more.

John Deere is no newcomer to the sprayer market, with a range of both trailed and self-propelled sprayers including the larger R41 series.

Although popular with some loyal customers and the claimed market leader in France, the R41 tool carrier format with its front-mounted engine has rarely been met with significant UK market demand.

In 2017, John Deere acquired Italian sprayer manufacturer Mazzotti, with an ambition to increase sprayer market reach and provide an opportunity to

supply machines into the more popular – and competitive – mid-engine and forward control cabin self-propelled market.

Following the acquisition, John Deere has set about making several subtle mechanical and cosmetic changes to bring about the 300M series into fruition, after initially offering machines in its original yellow and black Italian livery.

Fundamentally introduced to aid manufacturing, service and support of the machine, John Deere has incorporated several features into the 300M from existing product lines.

From cabin to spray system, the

machine has seen significant changes from its former Mazzotti days.

To find out more about the changes which have been made

AS expected, the new series now incorporates an in-house supplied DPS PowerTech engine and driveline.

Fitted in the larger 340M, the 6.8-litre, six-cylinder power plant pushes out 225hp.

and how the machine handled itself, Farmers Guardian had a first drive of one of the initial green and yellow machines to come into the UK market.

familiarity and serviceability expected from the tractor ranges. Access to the engine bay is good with the unit mounted neatly behind the cabin, with a refreshing provision of space around three sides of the engine bay for serviceable access.

Prospective buyers not requiring the power output of a six-cylinder may wish to consider the smaller 332M which incorporates a four-cylinder, 175hp unit.

Running a John Deere power plant also gives users the same

The 340M’s 225hp power plant gave the feeling of ample power delivery during our first drive, however, the test farm lacked the rolling hillsides required to truly test a fully laden sprayer’s hill-climbing ability.

The 340M is fitted with John Deere’s own 6.8-litre, 225hp, six-cylinder power plant.

BOTH machines in the range use the same cabin, which although a Deere in-house assembly, is normally found fitted to machinery in the South American marketplace.

The cabin choice gives both distinctive brand styling and incorporates a pitched front windscreen; which many operators will have come to expect on modern self-propelled sprayers.

Operators also benefit from the fitting of a category four, pressurised filtration system, although visually from the outside it appeared somewhat of an afterthought with the module protruding from the cabin roof.

A benefit of its external location was the inclusion of a significant work platform to the rear of the cabin to allow easy access for filter removal.

control with the test machine supplied with the manufacturer’s latest 10.5-inch G5 terminal.

Prospective buyers requiring a larger screen area can also optionally specify the 12.1in touch-screen terminal.

Linked with JD’s operation centre, farm businesses can set a job sheet in the office before going to the field.

The machine will then register its locality to the field and request if the operator wishes to carry out the task.

Completed jobs can then be recorded through the G5 terminal with the information transferred back to the office for record-keeping purposes. Precision options for variable rate spraying can also be activated through the G5 display.

Both the G5 terminal and sprayer dashboard offer clear visual clarity when operating. The terminal indicates working instrumentation with tank information and individual nozzle operation indicated.

Moving the GPS receiver away from the cabin roof to a more central location behind the engine bay also gave improved ease of access for the operator, particularly if required to remove and refit daily.

Incorporating the joystick from the manufacturer’s X9 combine range and the latest G5 touchscreen terminal, provided the operator both an ergonomic and configurable operating experience.

The cab interior follows a similar formula to other John Deere products, with the feel, fit and finish familiar to other products in the brand’s portfolio.

Button positioning on the joystick has an intuitive nature for sprayer

The test machine was fitted with the largest boom option of 36m.

THE 340M can be supplied with four working width options of 24, 28, 30 and 36 metres, and the test machine was fitted with the largest 36m design.

The same engineered assembly of the boom is shared across the whole range with the manufacturer

FITTED with the brand’s PowrSpray system taken from the 700 series trailed sprayer range, the 340M has a filling capacity of 600 litres/min and a maximum spraying output of 750 litres/min.

The 340M provides an operation pressure from 1.0-8.0 bar and carries

■ Engine: 6.8-litre six-cylinder John Deere

■ Horsepower: 225hp

■ Tank capacity: 4,000 litres

■ Boom width: 36 metres

■ Spraying pump: 750 litres/minute

claiming that the use of Domex steel reduces the risk of cracking and bolsters strength along the boom section.

Each of the section’s folding cylinders is fitted with a relief valve which allows oil to circulate from one side of the cylinder to the other.

a 4,000-litre tank alongside a 460-litre rinse tank which can be drawn upon for continuous dilution at the end of applications. This provides the operator with the ability to spray out at a minimal dose rate, with water continually drawn from the clean water tank until empty.

■ Filling pump: 600 litres per minute

■ Transmission: Hydrostatic 50kph

■ Weight: 9,500kg

■ Tyre size: 540/65R 38

■ Price as tested: £451,750

Pressure release valves allow for boom brake-back at each of the booms’ main pivot points.

This is designed to allow a hydraulic break-back of the main boom sections in the instance of a collision.

Sensors along the length of the boom are used to maintain the working height from the crop canopy and allow concave and

convex boom control on undulating terrains.

The system also compensates for bare ground by preventing the boom from diving. Nozzle bodies are mounted within the boom section to reduce the risk of damage.

THE 340M is fitted with Poclain MHP11 hydraulic drive motors mounted within each wheel hub which provide the option of 40 or 50kph road speeds.

Inside the cabin, the two-stage gate on the joystick gives control of both forward and reverse.

The hydrostatic transmission gave smooth engagement of travel in both forward and reverse with a toggle on the armrest allowing the operator to set a maximum forward speed for field operation.

Multi-plate brakes are fitted to the front drive motors for braking, with the wheel motors also providing transmission breaking downhill, which

provides an operator experience similar to engine braking.

Set in Eco mode for transport work, the 340M operated comfortably at 1,750rpm, with field operations running at about 1,900rpm.

Operators can also program the 340M for speed-related four-wheel steer. The test machine used hydraulic track width adjustments with three spacer ranges of 1,500-1,800mm, 1,800-2,250mm, and 2,250mm3,000mm.

Operators wishing to make regular track width adjustments may consider the optional automated track width adjustment system.

RELEASING the left-hand side panel reveals the sprayer filling area.

Rather than a spring-loaded system, the 340M makes use of an electrically-driven hydraulic cylinder to lower the induction bowl to filling height.

The 50-litre induction bowl presented a good operating height and size for filling.

Traditionally, sprayer manufacturers opted for a system of cascading water to clear chemical residue in the induction bowl.

With the 300M, a series of jets line the induction bowl for a more thorough clean and chemical induction.

Full operator functionality is linked back to the cabin terminal through the filling station’s touchpad allowing the

operator to select product induction quantity and circulation. For dusk or night-time filling, the station also incorporates a LED work light.

The induction circuit’s active pause system allows operators to stop water filling while continuing to fill products through the induction hopper.

A toggle for throttle control allows engine rpm adjustment at the filling station alongside a dead-man switch to stop the engine if needed.

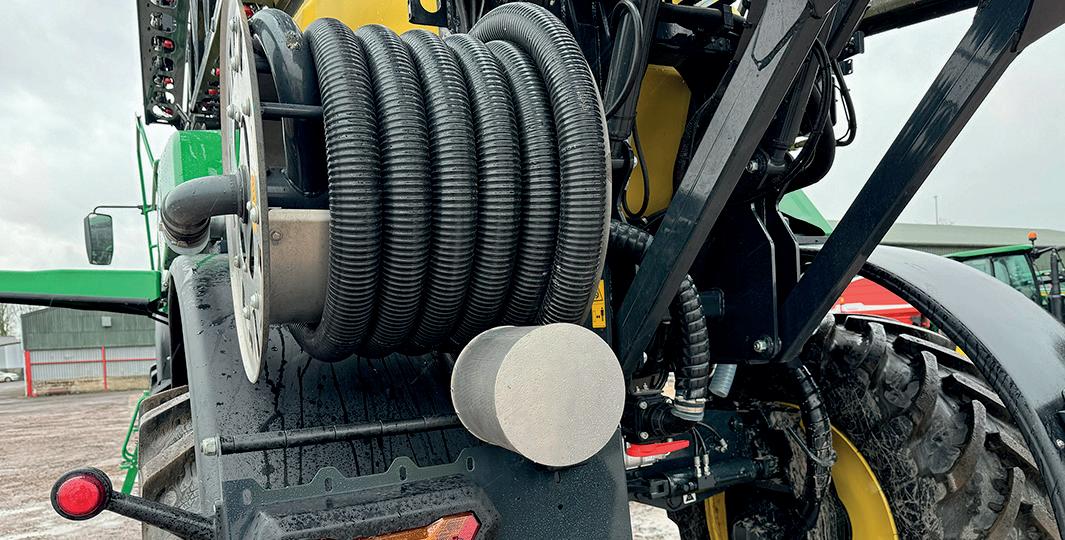

Alongside the induction hose couplings mounted at the filling station, the tested machine also carried a fully electrically retractable filling hose and filter to the rear of the machine, allowing further filling opportunities with portable bowser systems.

WITH an unladen weight of 9,500kg, the 340M is less than compact, but its 50-50 weight distribution did help spread its in-field mass.

Integrating the same tried and tested PowrSpray system used on the 700 series trailed sprayers does give some reliability and capability to a relative newcomer on the UK market.

Incorporation of the manufacturer’s onboard precision farming technology gives brand familiarity to the 340M, with many operators accustomed to John Deere’s operating systems.

The G5 terminal offered the operator a clear and configurable display to set and run spraying operations.

The arrangement also allowed the operator to adjust and tune sectional control and individual nozzle shut-off while operating.

Linking with transferable information to the filling station gave the operator the ability to

view and set automated filling volumes from the cabin.

The use of the joystick from the X9 combine provided ergonomic functionality, with the cabin also offering a forward seating position with good visibility along the length of the boom.

The 300M series has been positioned to offer direct competition to some very well-established rivals, many of which are UK-built with highly regarded levels of manufacturer service support.

Where the 300M could find a niche in this increasingly tight marketplace may be through its integration of technology and data software.

Functionally, the sprayer draws from some established pedigree.

The seamless option to create, record and transfer data into the wider – and very capable – John Deere precision farming system will certainly be an attractive feature, particularly for those carrying out contract applications.

Heavy duty Icon front/rear flail mowers feature hydraulic offset and a powerful, vibration-free rotor drive with high tip speed for clean cutting The large intake and hammer blades making these robust machines ideal for fine grass, set aside and field margins as well as reeds, thick brush, gorse and saplings

Running a trio of 300hp tractors might be unnecessary for many farms, but Martin Bramley’s operation requires all three at peak times and his latest MF 8S.305 has versatility beyond being a traditional high horsepower field lugger. Farmers Guardian reports.

Operating an arable and contracting farming operation along with other diversification projects means Martin Bramley requires reliable horsepower which can tackle a wide variety of jobs from hauling grain to drilling cereals.

Based at Sherburn in Elmet, near Leeds, the farm has run Massey Ferguson tractors since 1940 but has always kept a close eye on the market and resale values to make sure it runs what it feels is the best machine for the job and reliability is maintained.

Mr Bramley says: “We run Massey tractors as they offer us the right blend of operator comfort and workload versatility, with competitive prices and strong resale values.

“We are not afraid to look at other brands and often do when we are in the market, but the deal has to make financial sense, along with dealer back-up being very important to our business.”

His latest purchase, a 2022 Massey Ferguson 8S.305, arrived on the farm to replace an MF 7726S, which had forced the change sooner than anticipated due to a fire when baling midway through harvest. Mr Bramley’s dealer, Peacock and Binnington (P&B), helped him out with a demo machine to get through harvest, which proved the benefits of keeping strong dealer relations.

Mr Bramley adds: “With the cost of

replacement nowadays, it gets harder to justify what we are paying for new machinery. I need to know there is good value in what we are trading in to make the cost to change acceptable. We look after the machines well to maximise what we get back at the end.”

Mr Bramley works on a five- to sixyear replacement policy for his three frontline MF machines, although it can be flexible depending on workload. The hours begin at more than 1,000/year when a machine arrives, and gradually reduce the longer the tractors are on-farm and as younger models are drafted in. The tractors must do a minimum of five years to justify the initial investment.

Although the farm has run MF tractors for decades, he is convinced they offer the right mix of competitive pricing, good reliability, and strong resale values.

“The purchase price is very competitive with the competition, the operational running costs must be stomached for any tractor, no matter the colour, and the cost to change and trade in values have always been good with MF, so we can maintain a modern fleet and have access to the latest technology.”

The MF 8S.305 became the third tractor on the farm to offer more than 300hp, however, unlike the MF 8730 and MF 8732 already on-farm, it delivered it in a smaller frame with better visibility and a redesigned cab.

The versatility when changing between road and field is one of biggest improvements compared with the existing tractors, adds Mr Bramley.

“We run a mounted six-furrow Rabe plough that requires a delicate touch on the road. In the 8700 tractors, we struggle to reach 40kph with the plough on the back before feeling unsteady, whereas the 8S is well-balanced to cope with the plough on the road and in the field. It offers all-round versatility, where the 8700 machines are dedicated field machines,” he says.

Other differences with the 8S include the new cab, which features an 180mm gap between the bonnet and cab glass to reduce sound and noise transfer. The tractors all feature the Datatronic 5 screen and Trimble GPS, which is easy to use and familiar so all operators can set it up.

“There are more functions with the joystick, and we can customise it to control more features than the older models. However, like any new machine, it takes a bit of getting used to as we have become so accustomed with our current machines and the joystick is still a bit unfamiliar. However, the visibility is much better and its size means it does not feel like a 300hp tractor,” Mr Bramley says.

All tractors feature the Dyna VT transmission that offers the ability to

The farm runs a trio of 300hp tractors, including an 8730 and 8732.

The new 8S offers a much improved cab with greater visibility.

customise settings to reduce fuel consumption both in the field and the road.

Mr Bramley wants to make sure he is getting the best machine for the workload and has demoed several other makes in the 300hp horsepower sector to make sure the chosen model is the best fit for the farm.

He adds: “We did some in-house comparisons with a couple of wellknown brands to assess the tractors across the workload we have. This included monitoring fuel use during

both road and field jobs and we were pleased to see the 8S offered a good match for the more expensive brands we compared it with.”

The decision to run tractors to six years and go beyond a standard warranty period is a calculated one. All new machines arrive on-farm with a three-year warranty, which means repairs and servicing in the final two/ three years are handled in-house. Mr Bramley says he has the confidence to

do this as he runs three similar powered machines, but back-up from dealer P&B is also a major reason.

“We had a few issues with our MF 8732 and P&B looked after us very well. They have good mechanics that know the machines fully and nowadays the dealer is as important as the colour of machinery. When we had the fire, P&B got us out of a hole and this, coupled with the strong resales and good reliability are key reasons why we favour the MF brand,” adds Mr Bramley.

With greater capacity and a lower horsepower requirement, non-conditioner mowers are still a popular option for some businesses. Toby Whatley looks at the market options.

Mounted and trailed mower conditioners can offer significant time-reduction advantages for hay and silage crops, but their cost and power requirements can limit their appeal for farms looking to optimise feed quality and cut their own grass

THE Disco range from Claas extends to 15 models across three configurations of front, rear and large-scale. Two front-mounted machines are offered with three-metre working widths and a choice of direct linkage or springassisted ground following.

The rear-mounted range covers nine machines across a working width of 2.2 metres to 4.2m. All machines provide a narrow folded width through the use of a 120-degree vertical fold. Ground following can be achieved

with mid-sized, multi-use tractors.

With many farms focusing on the cut timing and cost of winter fodder production, multiple models and sizes of plain or non-conditioner machines are available for businesses looking to bring mowing back in-house and retain greater control of forage production.

through either a spring-assisted or hydropneumatic system.

Four large-scale butterfly units are provided in the manufacturer’s Trend specification, with working widths from 8.1m to 10.7m.

All Disco mowers feature the brand’s MaxCut beds, which incorporate a wave-shaped base plate to enable maximum overlap between the discs. Hubs are colourcoded for their direction of rotation to assist with the correct blade fitment.

FORAGE specialist Krone divides its mowers into two machine groups of ActiveMow and EasyCut. This comprises two rear-mounted ranges, a butterfly series and a front-mounted range. A total of 14 machines are provided, with a working range of 2.05 metres to 10.1m.

Unique to Krone, the manufacturer provides a 4.04m-wide front-mounted machine, which incorporates a twin rotary fold of the outer sections of the bed to reduce the machine to a more suitable transport width.

Krone says this design offers advantages of productivity and increases the overlap between front and rear units when operating in field corners, allowing a tighter turn

without the creation of uncut strips. In transport, the narrower front machine is helpful for users with narrow lanes and tighter field entrances.

All of Krone’s EasyCut machines are fitted with its quick-change blade system. This uses a specific lever tool to release the blade from the hub for reversal or replacement without any additional tools.

The elliptical hubs within the bed include a shear pin breakaway, which releases the drive during an impact. Krone says this design prevents the discs from colliding and allows a quick replacement of the retaining pin.

THE Slicer range from Fendt is supplied with three different designs of cutter bar depending on the model across its 14-model range. All cutter bars include a reversible blade, bolt-free, quick-change system through the use of an onboard tool. Working widths of 2.4 metres to 9.6m are offered across front, rear and butterfly combinations.

Terrain following is achieved with side or centre support, with the option of an alpine pendulum frame on some front-mounted

models. This allows the unit to be side-shifted 210mm left or right to account for the crabbing of the tractor across a slope.

Its centre-suspended rearmounted range can be supplied in working widths of up to 4.5m, with the unit allowing a 13-degree lateral movement and 22-degree swivel breakback angle.

The larger butterfly combinations are supplied with Isobus control and offer a pendulum support system with a wide angle of flexibility across the chassis.

KUBOTA’S plain mower range covers working widths from 1.65 metres to 9.50m, and includes front, rear and butterfly configurations. All machines use a three-blade disc design, and the widest machine is fitted with 20 discs over its working width.

Each mower has a lower upfront power requirement than competitive models, with ground-following suspension offered in spring assist

and hydraulic support depending on the model size. There are 14 different machines available: 10 rear-mounted units, two butterfly and two front-mounted.

Its smallest machine in the rear-mounted range incorporates a headland lift system to bring the machine out of work without raising the linkage, with cutter bar protection provided by spring or hydraulic breakback.

FRENCH implement manufacturer

Kuhn provides a range of machines in two folding configurations and one trailed unit across nine cutting sizes.

Unlike other manufacturers, Kuhn does not offer a non-conditioner butterfly combination, but it can provide a 5.2-metre-wide trailed machine with a rotating centre pivot, plus transport wheels to support the machine for road transport. Its range of mounted machines can be supplied as a vertical or horizontal fold to the rear, with

working widths from 2.4m to 4.35m. The three smallest vertical folding versions use a mechanical spring suspension system, with the larger versions utilising the manufacturer’s Lift-Control hydraulic suspension system.

Kuhn says this design provides consistent contour following with the addition of an impact safety mechanism, where the machine moves backwards and upwards if hitting an obstacle before returning to work.

IRISH manufacturer Malone has developed a reputation for producing robust, mechanically straightforward mowers designed for heavier and wetter crops.

Its non-conditioner range covers 11 mounted and trailed machines from 2.1 metres to 3.8m, and one 3m front-mounted version. All machines use Comer cutter bars and gearboxes with spring or

hydraulic suspension systems. Reversible blades are removed using a bolted quick-change system, with nine discs on the manufacturer’s widest 3.8m model.

All mounted machines fold vertically for transport, with the trailed units using a mechanical lock to secure the implement behind the tractor. Trailed versions do not reduce in width for road use.

NORWEGIAN manufacturer Kverneland provides 15 machines with a working range of 1.66 metres to 9.5m. All machines use a fully-welded cutter bar with a combination of spring and hydraulic breakback.

The larger ProFit range mowers, from 2.81m to 3.92m, use a centre suspension mounting for improved ground following, with the option of a twin-speed gearbox. When folded for transport, the machine lifts up to a 125-degree vertical position for a reduced width,

and can be removed and parked in the vertical position.

Three front-mounted machines with working widths of 2.8m to 3.2m are provided, which incorporate a 640mm vertical travel range for ground following with an up and backwards breakaway system.

Depending on user preference, a swathing kit can be provided for reducing the cut material to 1.3m for front-mounted machines, which prevents the crop from being compressed by the tractor.

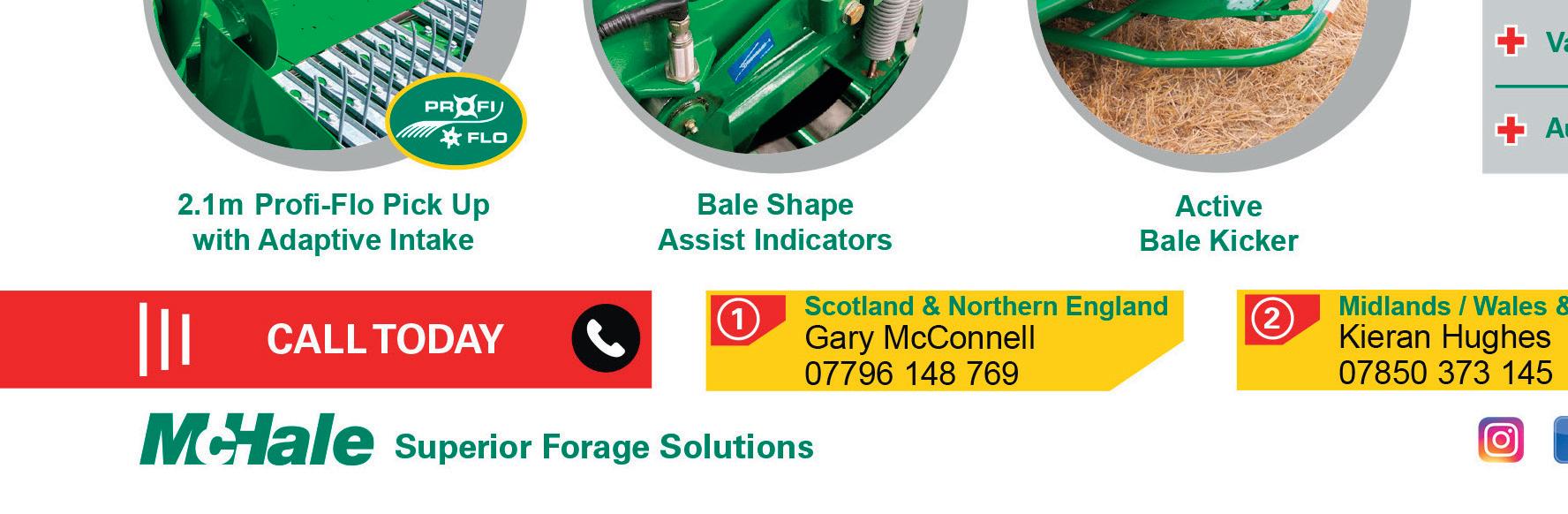

INTRODUCED at LAMMA 2023, McHale’s non-conditioner ProGlide R310 is the only model offered by the Irish manufacturer.

Providing a 3.1-metre cutting width, the unit uses a heavy-duty, fully welded cutter bar with seven twin blade discs. Each mowing disc has its own individual protective safety mechanism which will shear in order to protect the drive during a collision. Similar to its conditioner versions,

the R310 uses the manufacturer’s ground following technology, which McHale says provides three-dimensional ground contour tracking and allows the mower to easily mow on rough or undulating terrain.

The implement uses a mechanical breakback, which is designed to swing the unit backward, up and away from the object before returning to work.

THE mower range offered by New Holland incorporates many of the features originally seen on the machines from its purchase of Kongskilde in 2017.

However, New Holland says the eight-model range has seen several design updates since.

The range covers working widths from 2.4 metres to 8.6m, and incorporates five rear-mounted, one front and one butterfly combination.

Pendulum Rear-mounted mowers can be specified with a vertical or horizontal fold for some larger models, with ground following support provided by either a pendulum mechanical system or a contour-floating, hydraulically supported variant.

LESS well-known in the UK market, Slovenian manufacturer SIP provides two ranges of plain disc mowers in the form of its Alp and Silvercut series.

The 16-model range covers front-mounted, rear-mounted and butterfly combinations, with working widths from 2.16 metres to 10m. The entry-level Alp series covers front- and rear-mounted machines with a maximum front width of 2.99m and a rear width of 3.4m.

SIP says these models are designed to be very agile and suitable for working with smalland medium-power tractors.

The higher specification Silvercut series includes a wider range of fixed width front units

up to 3.32m. Silvercut frontmounted mowers can be specified with mechanical dual spring or hydropneumatic suspension.

Rear-mounted versions cover a working width of 3m to 3.8m, with the larger butterfly version providing a 9m or 10m working area.

All SIP cutter bars use a brass pin overload protection system. The pins shear when encountering an object, which SIP claims prevents any further damage to the driveline, and they are also easy to replace.

Blades are protected by a spring holder which retracts during an impact.

The twin blade disc uses a quick-release system through a compression tool which is mounted

on the implement. Its front-mounted offering provides 550mm of vertical movement through its trapezium

mounting system and can compensate for side inclinations of up to 12-degrees.

REFLECTING the more typical use of non-conditioner mowers in its Austrian home market, manufacturer Pottinger provides a range of 26 different options across rear, front and butterfly combinations.

Working widths of 2.2 metres to 10m are offered, with horizontally folding rear machines providing a working width of up to 4.3m.

The entry-level Novadisc variants are vertically folded and use a belt drive for an up to eight disc cutter bed, and are also supplied with a mechanical breakaway. The larger Novacat range includes front- and

rear-mounted versions, with hydraulically supported ground following. The left-hand link arm of the mower is equipped with a hydraulic cylinder, which Pottinger claims allows easier hitching and levelling.

The larger Novacat butterfly models are split over three working widths, with bed combinations of up to 3.5m each. Control of folding, headlands and operating width is managed through an Isobus connection, with vertical or horizontal folds offered.

MASSEY Ferguson offers 14 different machines split between its Farmer, Pro Series, HD series and Professional Series ranges.

Working widths across the range from 1.66 metres to 9.6m are provided with the HD and Professional series, operating with the manufacturer’s heavyduty spear gear bed and TurboLift suspension system.

This system is claimed to reduce crop contamination by

using a hydraulic suspension to allow a floating cut above the surface, ensuring the sward height is left at the optimum length.

To cope with undulations and awkward-sized fields, the mowers have up to +30-degrees and -19-degrees of lateral movement during work to provide uniform terrain following.

COVERING a working width of 1.6 metres to 9.5m, the range offered by Vicon uses a contra-rotating triangular three-bladed disc design across all 14 models.