7 minute read

Nil withholding, for when she needs it.

by AgriHQ

enjoy having the stress of not feeding my cows very well,” he says.

“We don’t do random very well. I don’t like random.”

The wagons have scales, and everything is measured. Everyone in the

Continued page 22

To out her best, team knows the measurements and how much they’re feeding each day. To them consistency and simplicity are key.

Pour–On provides flexibility when drenching. With nil withholding periods for milk, meat and bobby calves, you can treat your cows if and when they need it.

Pour–On is long lasting, with 35 days protection against Ostertagia ostertagi. It kills biting and sucking lice too.

“Our nutrition is very simple, in the past I’ve just done all the blends myself for the sheds, and we use maize, palm kernel and grass silage on farm. We do have a farm consultant who will visit every four to six weeks. Darren Sutton from FarmWise has been with us the whole time, and it’s an opportunity for everyone to check in and make sure we’re on track.”

Having the accountability of an external team member has helped them stay on track with their goals, and they both like that it gives an opportunity for everyone in the team to bring forward their opinions and challenge new ideas.

“You’ve got really good discipline to go out and condition-score your cows every month. It sets those disciplines for us and helps us to try and make things right.”

The farms are run as medium input with a stocking rate of 3.5 cows per hectare, and that’s just the way Craig likes it. He believes it’s easier to manage the farms this way, as “you’re always filling a deficit”. He says it’s easier for his team too, as back-calculating a deficit can be a lot simpler than managing grass alone.

“We look to hit residuals and fill feed gaps if necessary,” he says.

However, the weather over the last year has presented some challenges. Particularly with the maize grown on farm. This means they’ve had to contend with the weather changes and adapt to ensure their cows remain well fed.

“This season we’ve replanted our maize twice, losing it both times to flooding. In December we replanted again, thinking we’d be okay because it’s summer.”

The most recent weather events caused 52ha of maize to be either flooded or lodged.

Nutrients and fertilisers are put into the soil on the farms based on recommendations from Ballance.

Craig says they try to run “pretty high nutrient levels”, but ultimately go off recommendations from experts within their network. They place high value on working with and trusting the opinions of industry experts.

Effluent is spread by travelling irrigator, and they try to use recycled green water wherever they can.

They know that ensuring their cows and calves are well nourished and taken care of goes hand in hand with reproduction and are hoping to use the data collected by the CowManager monitoring system to help them make informed decisions on farm.

They are constantly looking at what changes can be made on farm to cause overall improvements.

“Our main goal is reproduction, which feeds back into nutrition. But we like to always consider what we can do within

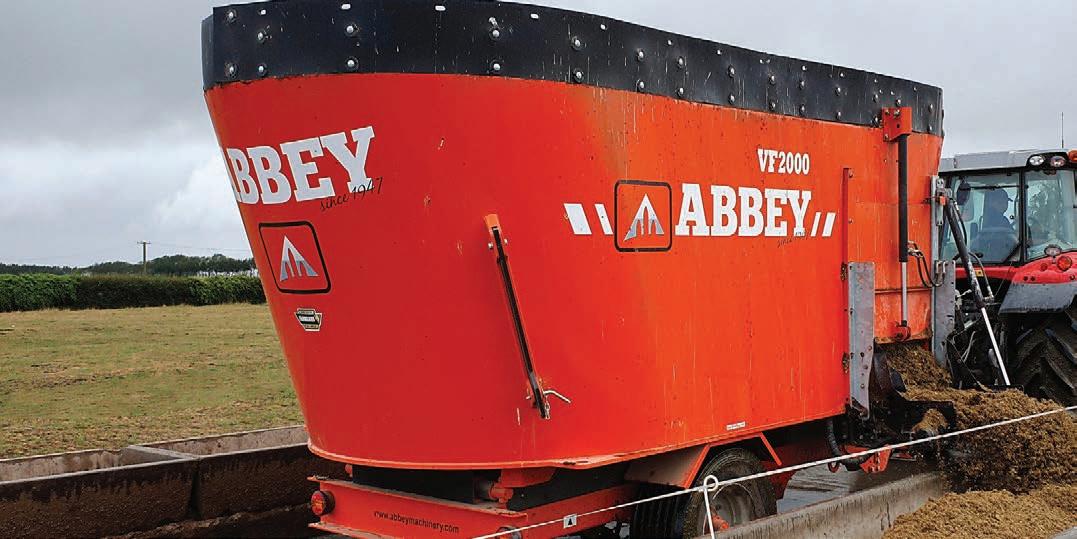

‘MIX IT UP’ WITH PRECISION. Talk to us now about which

‘MIX IT UP’ WITH PRECISION. Talk to us now about which our budget. Are there little things we can do to make changes to produce better or hold condition, or what are we missing?”

ACCURATE MIXING IS IMPERATIVE TO ACHIEVE QUALITY RESULTS FROM YOUR FEED. QUALITY BUILT AND PACKED WITH FEATURES, THERE’S PLENTY OF REASONS WHY YOU’LL SEE AN ABBEY ON A FEED PAD NEAR YOU.

ACCURATE MIXING IS IMPERATIVE TO ACHIEVE QUALITY RESULTS FROM YOUR FEED. QUALITY BUILT AND PACKED WITH FEATURES, THERE’S PLENTY OF REASONS WHY YOU’LL SEE AN ABBEY ON A FEED PAD NEAR YOU.

ACCURATE MIXING IS IMPERATIVE TO ACHIEVE QUALITY RESULTS FROM YOUR FEED. QUALITY BUILT AND PACKED WITH FEATURES, THERE’S PLENTY OF REASONS WHY YOU’LL SEE AN ABBEY ON A FEED PAD NEAR YOU.

Built to mix efficiently an ABBEY mixer wagon reduces waste and ensures your stock get all the nutrients they need.

Built to mix efficiently an ABBEY mixer wagon reduces waste and ensures your stock get all the nutrients they need.

Built to mix efficiently an ABBEY mixer wagon reduces waste and ensures your stock get all the nutrients they need.

One thing they’ve decided to do to help inform these sorts of decisions is enlist the help of Dr Krispin Kannan from Veterinary Enterprises. Kannan is a veterinarian whose business role focuses on technology solutions on farm and has spent the past 14 years as a dairy vet.

More recently he has been familiarising himself with new wearable technology and helping farmers turn data collected from their monitoring systems into meaningful, practical action.

He says “it’s about adding more value via insights and interpretation of the data this is already collected for the farmer by their systems”.

They didn’t originally seek out the system for the purpose of monitoring nutrition but have found the insights invaluable.

“The thing we are trying to find out by working with Krispin is, are we fully feeding them? We can think we are, but looking through the CowManager data, what are we feeding them, and what improvements can we make?” Craig says.

He hopes that adding someone like Kannan, who is experienced in turning data into action, will help the team make changes that will have a direct effect on their farming system.

“You’d think after 10 years of farming you could just flip back and look at each

Continued page 24 month to work things out, but it is quite different,” he says.

With Kannan on board, they’re hoping to get back to the data. Soon they will have over two years of nutrition data on the herds and will be able to understand better what is happening during crucial times of the season.

Even though they’ve brought in experts to help sort through the data, they know any changes they make are going to be simple ones.

“Any changes and purchases still have to fit within a simple system and use the resources available to us to manipulate it to see if we can improve outcomes,”

Craig says.

Each of the farms has different topography, so this is something they consider within their mating goals. They’re currently aiming for a smaller cow for two of the farms, as one requires the cows to walk long distances and the other is flatter and wetter. Apart from that, Craig says, his goal is to breed the type of cows you don’t notice. Some of the herds are mated with Kiwi Cross, and he jokes that it doesn’t take long to see some colour coming through over the years of mating them to Friesian.

He reckons mating is like the Da Vinci Code, so they’ve tried to make processes as simple as possible for everyone in the team. Mating begins in October, and they start mating for all farms within the first week of the month.

“We only do spring calving and heifers start around July, so we send milk roughly in the first week of July, give or take.”

AI is around 10 weeks across the farms, and they calve in about eight and a half weeks, and AI all their heifers.

“About four and a half weeks is getting replacements, and then we move on to short gestation after that, so everything is calving about 10 days earlier than it normally was,” Kylee says.

Each year, they aim to get replacement numbers of around 25% for each herd, and do well to hit that goal.

They have similar six-week in-calf rates across the four farms, ranging from 70 to 80%, and hope to continue improving those numbers each year. The average empty rate is 12% this season, which is something they’re proud of in what has been a challenging year.

Kylee rears the calves on one farm but oversees all the farms during calving.

They’ve started looking into how they can adapt and change their processes to give their cows everything they need from day one.

“We’re just sort of reviewing potential around improving our calf-rearing and looking at that slightly differently as well. You know, are we feeding the calves to their potential, or are we feeding them to a system? And I would question that we, like most New Zealand farmers are feeding to a system, rather than looking at ways to maximise growth.”

This year, they’ve started fortifying the milk with milk powder, so they’re getting the same number of litres but there’s an increase when it comes to the nutrients they’re getting.

They’re switching their thinking from what they call a milk litres-based system to a milk solids-based system, in the hopes that the extra care in accuracy will allow them to ensure their calves are well fed.

“If, for example, we feed them four litres, why do we feed them four litres?

It’s just what we’ve always done. And if you ask someone else, everyone in New Zealand will have a different feeding system, but why?”

They aim to continue to make small changes while keeping things as simple as possible so they can retain the team they value highly.

“We just bumble along,” Craig laughs.

“There are probably too many things we’re focused on to be fair, we try get a lot of stuff right and we try to do things right. I suppose like everyone, we’re just trying to improve everything all the time.”

Craig and Kylee are aware that their animal health cost per cow is higher than most, but they know that those costs are proactive, and they prefer that over reactive farming. Using technology and simple processes to their advantage, they’ve been able to stay ahead of challenges brought forward from quick growth while remaining true to valuing the people who have helped them over the past 10 years.

“Our goal is to keep retaining people, obviously we’re going to go through some changes but we’re just trying to do all the little things right so we can hopefully get the benefits at the other end. We’re always running to try and keep up with what’s going on.” n

We were introduced to Animate at the beginning of the season and what a game changer it has been for us. We had a total of six down cows for the entire calving, something we can only put down to Animate.

It was easy to use, the cows loved it, was a massive time saver and there is nothing better than seeing your cows happy and healthy.

Sarah Woodley, 420 cows, Clandeboye, South Canterbury.