11 minute read

Introducing

by AgriHQ

whether you place or not. It was great meeting all of the competitors, not just those in the sharemilker category. We look forward to those relationships continuing,” Bridget says.

Growing up on the family farm, Hayden knew he wanted to be a farmer. He attended Ōkato’s Coastal Taranaki School before going to Telford – Southern Institute of Technology for two years to study for a Diploma in Agriculture. He returned to work for his parents on the family farm for 18 months before heading overseas for 18 months. He returned to the farm for a further two years as farm manager.

people, and how they operate.

“Entering the awards will make you a better farmer gNZI is the most reliable tool for predicting the future performance of young sires’ offspring. gNZI has accurately predicted how international sires would rank once they get a daughter-proof here in New Zealand.

With the gNZI dairy farmers can select with confidence and drive their herds forward.

During that period he raised young stock to build a herd and took a 50:50 sharemilking job milking 550 cows for his grandparents on their 180ha Maxwell farm. It was around this time that he met Bridget.

“We met in 2011 through another doctor/farmer couple. I worked at Taranaki Base Hospital for the first two years before transferring to Whanganui Hospital in 2012,” Bridget says.

“I then spent 18 months at Palmerston North Hospital until I needed to move to Waikato Hospital for training. Hayden’s mum suggested that we move together rather than having a five-year longdistance relationship.”

Even though Hayden had successfully sharemilked for five years, he never heard back from any of his Waikato job applications. He ended up taking a farm manager’s job on a Morrinsville farm.

“It was good timing, because the payout dropped to around $4 and he was receiving a manager’s salary. New Plymouth hospital then became accredited for my training, and because we were missing our family and the sea, we set up an equity partnership company with Hayden’s parents and moved home,” Bridget says.

Forming an equity partnership allowed the farm to move forward with one set of goals. The company was set up with all aspects of the business included.

“Sharemilking would’ve been more lucrative, but the farm needed work done on it. We’ve been able to make capital investments in the farm that would have been harder to justify from a farm owner’s perspective if we were sharemilking,” Hayden says.

The couple want to live on the farm permanently, and are keenly focused on setting it up correctly for the future. As sharemilkers they may have been able to own the farm faster, but would then have needed to begin investing in its infrastructure.

“It’s good to be making the changes and utilising the new infrastructure now. We built a large covered feedpad and changed to a one herd system, which necessitated constructing new cow yards. This was done to make the farming operation more labour efficient,” Hayden says.

The farm nestles between Egmont National Park and the coast, and the mountain and ocean give the farm its unique topography and climate.

“You can’t get a tractor over a third of the farm, which makes pasture management challenging. Those areas can’t be mown or re-grassed, we only graze those paddocks during good weather. If you damage any part of them, they’re done for the year,” Hayden says. gets hit more regularly by wet northerly storms. It usually receives 2,000-2,500mm of rain, but this year there’s been so much rain that Hayden has given up measuring it.

Last season the herd produced 273,000kg milksolids and 483kg MS per cow. This is lower than their five-year average of 297,000kg milksolids from 610 cows. Last season they peak milked 565 cows and are trying to find the happy medium of profit and production.

The farm is run as a System 4 and they feed 2t of bought in supplementary feed per cow. They’re aiming to reduce the dry feed by 400kg per cow, because currently they’re not making an adequate margin on it.

The mountain and sea greatly influence their climate, and Hayden often checks the weather forecast on an hourly basis. The climate is warmer compared to when he was growing up, and there have been no frosts in the past two years.

The farm is mostly summer safe, but can have a dry year once every five years. It now

“Ten years ago it was all about production and the amount of kilos per cow. Now it’s come back to ‘What’s your profit?’ It’s easy to chase high production per cow and be worse off,” Hayden says.

“Reducing the herd size and the amount of supplementary feed should help counter the high farm working cost inflation. But I can see flow-on

Continued page 12 effects for the environment due to less purchased feed and a lower stocking rate.”

The farm has a 12.5ha runoff and 2.5ha leased runoff as support blocks used for maize silage, which forms the bulk of their supplementary feed and is used to winter some cows. They grow 10ha on farm, 15ha on the runoff, and buy in 250t.

They feed 1.1t of maize and 800kg of PKE per cow per season. Recently they’ve fed 250kg dry matter of DDG, 250kg DM of tapioca, and 450kg Proliq per cow. It’s processed through their mixer wagon along with the required minerals.

The also make 30ha of pit silage, and baleage is made from whatever the season gives them. They can usually rely on the pit silage, depending on what sort of late spring they have. If it gets dry, they may only get 100 bales of silage, yet in a good growing year they can crop 300 bales.

Supplemental feeding is heavy through to early spring to hold the round length. During the flush, the amount of supplement is reduced to match the production with the pasture.

A 20-day round is utilised for most of the season, until midJanuary when it’s lengthened to the mid-20s. If it becomes dry it’s increased to 30 days.

During March a 30-day round is used, 40 days in April and

50 days in May. Depending on the weather, their winter round is 70 to 90 days.

“During winter the hay and maize is fed on the feedpad. The feedpad has rubber matting so we can use it to stand the herd off during inclement weather. During calving, every mob comes onto the feedpad daily,” Hayden says.

‘It’s a bit of a juggling act, but the feedpad has two sides, so one side is free for a second mob. If a mix-up occurs, we just run them through the cowshed drafting system.”

Calving begins mid-July and finishes mid-September and they keep 25% for replacements. Calves are collected twice daily during the busy period because of the farm’s terrain. If the calves are left to their own devices for too long, they wander into a gully, requiring a search to find them.

The calves are collected before the cows come onto the feedpad and another pick-up occurs in the afternoon. The calved cows are automatically drafted out when they go through the yards after feeding.

The calves are fed colostrum for three weeks before transitioning to milk powder. Meal is fed from the start, and they have access to the paddocks when they’re three weeks old.

There is one shed for the new calves and last season a new purpose-built spacious calf shed was constructed for the older calves. It opens onto paddocks allowing the calves free access to the pasture. There are 40-45 calves per mob and they’re fed with a 60-teat feeder.

Weaning occurs when calves weigh around 110kg . They are sent to Te Kuiti-based Koromiko Grazing Ltd before Christmas, where they stay for 18 months.

Artificial insemination begins on October 10 and lasts for nine weeks. Premier Sires are used for five weeks, before two weeks of Murray Grey used as a marker. Shortgestation crossbred dairy semen is used for the last two weeks.

The heifers are mated to a Jersey bull 10 days earlier than the main herd.

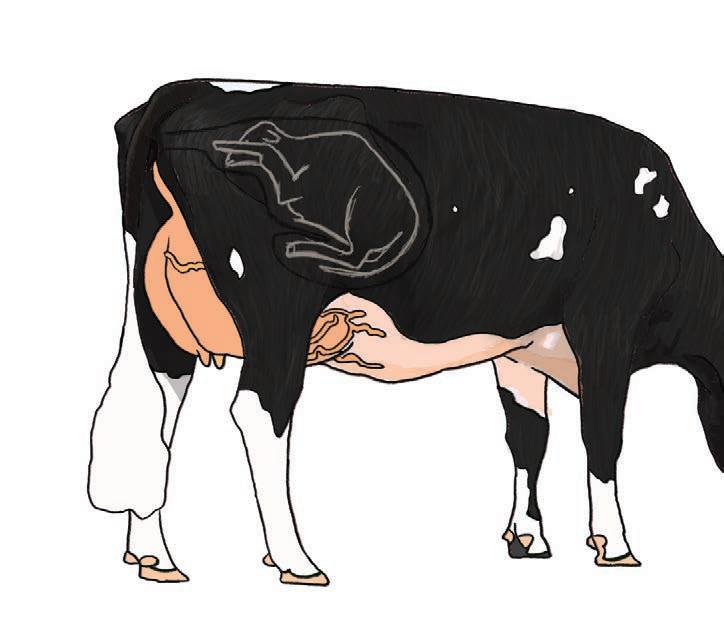

Their Friesian cows have now become too large for their farm. The cows usually weigh around 520kg, but their latest heifers were 560kg. Heavy animals require higher maintenance during winter and take a toll on the soil.

Typically, nominated bulls have always been used. This is the first year that they’ve used Premier Sires Daughter Proven team, solely because many of the bulls Hayden preferred were in that team.

For the past two seasons they’ve been using KiwiCross semen over their mostly Friesian herd to breed towards a crossbred herd.

“We want cows that are around 500kg and achieve a 1:1 ratio of milk solids to bodyweight. Even though there was sometimes 100kg of liveweight difference between the Friesians,” Hayden says.

“We aim for fertility, sound udders, capacity, and the bulls should have a good BW. The crossbred’s fertility BVs are massive compared to Friesians.”

Four years ago the herd was fitted with collars, which has cut out an entire labour unit during mating. There’s now no need for tail painting or for someone at the cowshed “cups off” station scrutinising the tail paint, because any cycling cows are automatically drafted.

Tail painting has proved to be less effective than identifying cycling cows with the collars. The collars showed that they were putting up cows for AI that weren’t in heat.

“They were cows that’d rubbed off some tail paint and then you did the ‘If in doubt, put her up’ scenario. We now use 20% fewer straws. We don’t pregnancy test because if the collars show that the cows are still cycling every 20 days, we know they’re not pregnant,” Hayden says.

The collars have also enabled them to remove bulls from the farm and solely use AI. They say not having bulls on the farm eliminates a potential health and safety factor.

The collars have the added benefit of monitoring animal

Continued page 14 health and picking up any issues quickly.

“We now notice E coli mastitis very early. When a cow’s rumination crashes, the collars alert us before we’re able to notice the problem. We can quickly treat the cows and save most of them,” Hayden says.

“We recently had a cow with Hardware Disease. Usually, by the time you’ve noticed, it’s too late to save the cow. If you pick it up early you can usually save them, and that’s exactly what the collars enabled me to do.”

The collars record and monitor the rumination minutes on a daily basis. During summer, if it’s seen to be going too high it usually means that the pasture quality is slipping and the herd is getting too much fibre.

When it drops below a certain threshold during spring it’s a prompt to add more feed. When rumination drops, the drop in milk production doesn’t occur until the following day.

The collars also monitor summer heat stress. “We let the cows onto the covered feedpad at 10.30am. When the outside temperature reaches 20degC, their heat stress quickly rises. The feedpad is 4degC cooler, and as soon as the cows get into the shade the heat stress immediately drops,” Hayden says.

Over the past few years they’ve focused on reducing their mastitis rates and the herd SCC has dropped to 100,000-120,000.

“We use a Mastatest system. Every infected cow’s sample is cultured and a treatment recommendation is e-mailed to me within 24 hours. After herd testing, we draft the cows with a high SCC and test them,” Hayden says.

“We cull cows that have chronic mastitis. You don’t notice much of a difference in the first few years, and then suddenly you make a drastic improvement. We once needed to strip the herd every week, now we only strip about four times a year.”

There has been a corresponding drop in lameness too after they began targeting the problem. The feedpad and cowshed yard have rubber matting on the concrete pads to minimise hoof stresses.

They run the farm with three full-time equivalent staff and they have employed a herd manager for this season and a farm assistant.

The extra labour unit is made up by two international students on a one-year New Zealand Certificate in Agriculture (Level 4) course at New Plymouth’s Western Institute of Technology. They spend 20 hours in paid work and 13 hours training per week.

“It’s a lot of work on my part, because the students are completely new to the industry. The international students are incredibly motivated and desire a bright future. It’s a way for us to try a different solution to our labour problem,” Hayden says.

“We had 90 overseas applicants for the herd manager role, but none had visas. Through the WITT course we can offer the students a fulltime role after training, or continue taking on trainees which would provide two trained staff to go to local farms.”

The roster is organised so that the staff don’t feel like they’re overworked. They all have two one-hour breaks per day and three-day weekends throughout the year.

An 11-on, three-off roster is used for most of the season. During calving it’s split up so they all have two days off and the longer period is broken up with a day off in the middle. This ensures no one works for 11 days straight during the busy spring period. They try to structure the roster so everyone receives weekends off.

Organisation and communication are key to the farm running smoothly and for Bridget to successfully pursue her profession.

They play to their strengths. Bridget has nothing to do with the day-to-day farming operation; that’s Hayden’s expertise. She has an active interest in the financial and human resources aspects of the business.

“I introduced structured monthly meetings with Hayden’s parents, which have been important for the successful running of the business. Meetings give us the opportunity to have difficult conversations. Once those meetings are concluded, it’s all over and we don’t need to talk about the business until next month,” Bridget says.

Many farm jobs are predictable. So rather than becoming stressed about them, she made up a farm management plan wall chart for everyone to utilise. It’s divided up into all the various aspects of the farm; and mapped out for the entire year. It only takes a glance to see what and when tasks need to be done.

The environmental jewel in the Taranaki’s farming community’s crown is the region’s Riparian Management Programme – Taranaki Mounga Project trapping, which they are a part of. The Goble’s farm has 8.6km of fenced riparian planted waterways and 31ha of fenced native bush.

“Farming must be sustainable, we won’t survive if we don’t adapt to future environmental pressures. New Zealand has the lowest dairy carbon footprint and we must stay ahead of the curve to maintain that international competitive advantage,” Bridget says.

They believe that greenhouse gas emissions are going to be the next issue on the horizon so started early and are attempting to calculate the balance between stocking rate and profitability. Looking ahead, they hope to own 51% of the farm business in 10 years’ time. The farm, runoff, herd and machinery are all encompassed in the business.

They believe that the key to their success has been that Hayden’s parents have been prepared to change and aren’t stuck in their ways. When

Hayden and Bridget propose ideas to them, they’ll consider them, and often say yes.

“Dairying is an industry where you can start off as an 18-year-old and have a pathway to farm ownership. You just have to work hard and put the hours in,” Hayden says.

“I love the farm, the business, and its beautiful location. It’s a great place to raise kids and we think that farm kids can be any kind of adult,” Bridget says.

“The closest bushwalks are only 10 minutes away and we love the sea. Summer revolves around the beach for us. Hayden grew up in this community, and it’s a welcoming community to be a part of.” n