16 minute read

CHEESEWIRE

from FFD March 2021

Lower rents and altered shopping habits drive new openings boom

By Patrick McGuigan

A ra of new cheese shops has opened in the UK, as retailers look to capitalise on cheaper rents, changes in shopping patterns and a surge in demand for artisan cheese caused by the pandemic.

At least 10 new cheese shops opened before Christmas with research from the Local Data Company showing that 432 more independent grocers, including cheesemongers, opened in 2020, up by 5%.

The trend is being driven by the impact of COVID, which has seen an increased demand for food shopping in residential areas as people work from home more.

Landlords also seem to be more willing to negotiate on rents because of the uncertain economic climate.

Johnny McDowell, owner of Indie Füde in Belfast, opened a second cheese shop in a residential part of the Ormeau Road in December. He secured a 20% discount on the rent and six-month rent-free period.

“It’s a good time to be negotiating,” he said, adding that COVID was changing shopping habits. “People would previously have commuted into Belfast, but they’re now working from home and can pop to the shops a few times a week. I think that’s going to be for the long term.”

Neal’s Yard Dairy director Jason Hinds told FFD last year that he expected rents to fall. “Unless landlords want charity shops or empty shops, they are going to have to be more realistic in terms of rents, and food shops bring energy and people to the high street,” he said.

The company opened a new shop in a residential area of Islington in November, while other new cheese shops include Funk in Hackney, Wild Goose in Ipswich, The Cheese Station in Sta ordshire, Renoufs in Wimbourne, Grate in Jesmond and The Cheese Shed in Bovey Tracey. Two Belly in Bristol has also opened an additional store in the city.

The Little Cheesemonger in Rhuddlan, North Wales, opened a second outlet in Prestatyn in December when a unit previously used for children’s parties closed down due to the pandemic.

“We’ve had a surge of new customers over the past year because they want to support local food,” said owner Gemma Williams. “I’m expecting an absolute boom in the summer when restrictions are li ed because there are lots of caravan parks and campsites here.”

North Wales retailer The Little Cheesemonger has opened a second outlet

NEWS IN BRIEF

The Cheshire Cheese Company has stopped online sales to the public in the EU because of expensive new post-Brexit paperwork. The company, which specialises in waxed and flavour-added cheeses is now looking at investing in a new distribution centre on the Continent.

Scottish cheesemonger IJ Mellis was forced to start a new Instagram account after its previous handle, which had 15,000 followers, was held to ransom by hackers. The business, which has shops in Edinburgh, Glasgow and St Andrews, can now be found via the new handle: @mellischeeseltd

The UK’s Virtual Cheese Awards is set to return for a second year. The online awards will take place on 7th May with the number of entries increased from 300 to 400 cheeses across nine categories.

Can you hear me Glastonbrie? Although its fields will remain silent for another summer, Worthy Farm – home of Glastonbury music festival – has put the downtime to good use by launching a new cheese.

The Reserve Cheddar is aged for six months and made by Wyke Farms with milk from the Worthy Farm’s own herd, which grazes on the land used for world famous festival.

The cheese launched in Co-op stores last month, following on from the chain becoming the festival’s first ever retail partner at the last event, held in 2019.

THREE WAYS WITH...

Ossau-Iraty

This famous PDO sheep’s milk cheese from the French Basque Country has crowd-pleasing caramel and hazelnut notes, but can also have interesting gamey and animal flavours, which give it depth and complexity. This is particularly true of the raw milk OssauIraty exported to the UK by start-up company LX Food. The cheese, which is aged for eight months, is made on a small farm in Pagolle.

Cherry Jam In the Pyrenees, people traditionally serve OssauIraty with a spoonful of the local black cherry jam, which comes from Itxassou and is also exported by LX Food. Sweet and fragrant, it works beautifully with the cheese and provides a pleasing contrast to the saltiness.

Cider Red wines from the Irouléguy wine region of the French Basque Country – made with Tannat, Cabernet Franc and Cabernet Sauvignon grapes – are the favoured local tipple to enjoy with Ossau-Iraty, but cider is also a great match. Dry-to-medium styles work well, especially if there is some funky farmyard flavour to go with the meatier notes found in the cheese.

Smoked Mutton Ossau-Iraty works well with a wide range of charcuterie, but there’s something fitting about serving it with smoked mutton – a sublime creation from Capreolus Fine Foods in Dorset. Leg of mutton is cured with rosemary, juniper, garlic, black pepper, and port, before being air-dried and then smoked over beechwood. It has a wonderfully scented, fruity and smoky flavour that is a natural fit for the cheese.

Traditional Cheese Dairy’s new owner to relocate production

By Patrick McGuigan

The new owner of the Traditional Cheese Dairy in East Sussex says he wants to “make dairy farming great again” by highlighting the positive contribution it can make in areas such as the environment, animal welfare and the community.

Third generation dairy farmer Joe Delves bought the cheese company from the Dyball family last year and plans to move production from its current site in Stonegate to his nearby farm in Horam, where he keeps a herd of 220 JerseyFriesian cows.

Here, he aims to raise the pro le of the cheeses –including Burwash Rose, Lord of the Hundreds and Olde Sussex cheddar – by focusing on new measures being taken on the farm, which is based on a high-animal-welfare, grass-fed system.

“I don’t want to sound like Trump, but we need to make dairy farming great again,” said Delves. “The industry has been sand-bagged by vegans and animal rights groups, so we want to promote our farming credentials. We’re working on our carbon footprint and environmental schemes, we’re improving our land every year and we do good in our community.”

The Traditional Cheese Dairy was previously owned by Cli and Julie Dyball, who have now retired. Delves’ father Andy makes the cheese full time in Stonegate, while a new dairy is being built in Horam.

“Because we control the milk, we could produce a grassbased cheese – using raw milk from one point in the season to get a cheese that really re ects what the cows are eating.

“I get excited by the idea of cows grazing herbal leys and then making cheese from that milk.”

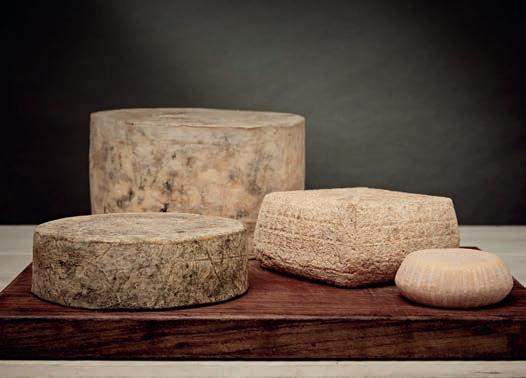

The Traditional Cheese Dairy ranges includes Lord of the Hundreds, Burwash Rose and the cheddar-style Olde Sussex.

CALLING ALL CHEESEMONGERS

Mick James, Queso Fine Artisan Cheese, Birmingham

Mick James has built a loyal following selling cheese at markets and through home delivery, and his stalls at Kenilworth and Stratford-upon-Avon have been busy during the pandemic.

Honesty and integrity are key to Queso’s success, he says. “People sometimes have a prejudice about cheese at markets. They think they might get ripped off or it’s all reconstituted cheese. So I make sure people can see the scales and clearly show them how much it’s going to cost.”

James cuts fresh to order and doesn’t oversell so that the cheese remains in good condition. “If there’s a few hundred grams left at the end of the day it goes in my cheese sauce at home. It doesn’t pay to be mean.”

His other tips include wearing plenty of layers and thick boots, standing on cardboard to keep warm, and using a trolley to set up – which prevents back problems down the line. “When it’s really hot, it also pays to be friendly with the market manager, so you can get a pitch with some shade,” he adds.

CHEESE IN PROFILE with

Teifi Natural

What’s the story?

Caws Teifi Cheese has been making artisan cheeses at Glynhynod Farm (it means ‘Remarkable Valley in Welsh) in Llandysul, Wales since 1982, when the company’s co-founders John and Patrice SavageOnstwedder moved from Holland and set about reviving the lost tradition of using raw milk from local farms to make high-quality cheeses. Today the farm is run by John and Patrice’s sons John-James and Robert.

The family now makes some 15 multi-awardwinning cheeses, many in the style of Dutch Gouda, using raw Jersey and Friesian milk from a neighbouring organic farm in Llanboidy. The business and original cheese, Teifi, are named after a river which runs through the farm.

How is it made?

Teifi Natural is made to a Gouda recipe – a washedcurd cheese. During the stirring of the curd, some of the whey is drained off and replaced with warm water. This rinses lactose from the curds resulting in a golden yellow paste with a high degree of elasticity. After of the cheese weigh at least 3.8kg.

Variations:

This cheese comes in a number of varieties, flavoured with additives such as Seaweed, Sweet Pepper, Cumin, Garlic, Garlic & Onion, and Nettle.

Cheesemonger tip:

Offer Teifi as an alternative to traditional Dutch Gouda. When finely grated, it is also a great Welsh alternative to Parmesan.

pressing and brining, the cheese is coated in wax and left to mature for up to 12 months. For the many flavoured versions of this cheese, the additive is mixed into the curd before moulding. smooth and elastic texture. It is pale yellow in colour and mild and buttery when young, while aged cheeses have an intense toffee sweetness. Whole wheels

Chef’s recommendation:

This cheese pairs well with baked ham, crusty bread and strong, slightly sweet coffee.

While traditional classroom courses are suspended due to the COVID-19, delegates can still sign up to Academy of Cheese Level 1 & 2 courses online as self-study eLearning, or interactive virtual classroom courses. www.academyofcheese.org

ZERO-WASTE SPECIAL

Less waste, more cheddar

Traditional cheesemaker Keen’s is using modern solutions to reduce its wastage

By Patrick McGuigan

IT’S NOT JUST the cows that need feeding at Moorhayes Farm near Wincanton in Somerset. Round the back of one of the sheds is a strange metal structure that looks like a circus big-top, but is actually the farm’s anaerobic digester, where an incalculable number of hungry microorganisms need constant nourishment.

“It’s basically a big stomach that needs to be fed,” explains h-generation cheesemaker James Keen (pictured above). “Cow muck and whey goes in and the methane the bacteria produce is turned into electricity using two 20kw engines.”

With a herd of 250 cows and 120 tonnes of Keen’s Cheddar made each year at the farm, there’s plenty of cow muck and whey to keep the bacteria satis ed. So much, in fact, that the farm sells electricity back to the national grid, while also massively reducing waste.

Like many cheesemakers, knowing what to do with le -over whey was long a conundrum for the Keen family. “We used to have pigs and feed the whey to them, but it wasn’t worth it economically, so we then we gave it away to other people with pigs,” says Keen. “But a er foot-and-mouth that wasn’t allowed, so we used it as fertiliser, but if you don’t do it right there is a risk of leaching it into rivers.”

The anaerobic digester cost around £100,000 with payback taking roughly ve years, helped by government feed-in tari s, but the technology hasn’t been without its challenges, admits Keen, as repairs and new parts have been required regularly.

The farm has also invested in ve automatic robot milking machines, which the cows use to milk themselves as and when they want. The technology takes information from the animal’s collar and uses lasers to guide a cup onto its teats. On average, they are milked between three and four times a day this way, providing 30% more milk compared to traditional morning and evening milkings.

“The animals are less stressed because they don’t all have to be milked at the same time, and the machine weighs and takes their temperature, so we pick up health problems quickly, which means fewer antibiotics.”

The Keens’ modern approach to farming is echoed in the dairy, where the family took the big decision to change how they wrap their famous traditional farmhouse cheddar. The 25kg truckles are still cloth-bound and larded in the classic way, but now also receive a nal coating of breathable plastic, which has dramatically reduced wastage caused by cheese mites and cracking.

“We were getting 20% waste in some batches. Our cheese would go to cutting lines for supermarkets, but a lot would come back because it had blue veins,” says Keen, whose cheddar is sold by Waitrose and Morrisons, as well as independents. “If you’re selling on a deli counter, you can talk to customers about blue veining in cheddar, but for supermarket counters, if there are any blemishes, then customers won’t touch it.”

Previously, the company would sell its cheese at 10 months before blue veins developed, but with the plastic coating, it is now going out at 12 months and can be aged up to 18 or even 24 months.

“We think our cheese tastes best at a year and over,” says Keen. “Cheddar was originally designed to be made in the summer and eaten in the winter so didn’t need to last more than about six months, so people have always had to adapt. Cheese doesn’t always stay the same.”

keenscheddar.co.uk

CROSS SECTION

Keen’s Cheddar

1

Cheddar has been made at Moorhayes Farm since 1899. Brothers George and Stephen Keen and their respective sons, James and Nick, are the fourth and fifth generations of the family to take up the mantle. James makes the cheese, while Nick looks after the farm (and the anaerobic digester).

Raw milk from the farm’s herd of Friesian cows, which have been crossbred with Ayrshires to improve yield, is used to make the cheese, along with traditional pint starter cultures and animal rennet. The cheese is ripened for at least 12 months and has a relatively moist texture and bold savoury and mustard notes with a pronounced cheddar tang.

2

Quality at every stage

Whether it’s through direct sourcing relationships, expert roasting or extensive barista training, Yorkshire’s Dark Woods Co ee ensures its customers will get the very best in their cup

COFFEE FOR EVERYONE More than anything else, Dark Woods wants the nest co ee to be both enjoyable and accessible to everyone. That’s why the company o er a range of roasts and styles that truly re ects the co ee that people want to drink.

HOSPITALITY & RETAIL Dark Woods specialises in supplying independent retail and hospitality businesses with a range of co ee products. Its customer base includes farm shops and delis (especially those with cafés), speciality co ee shops, restaurants, boutique hotels, visitor attractions and universities across the UK.

SOURCING Dark Woods has direct sourcing relationships in over 15 co ee-producing areas, and it returns to those producers time and time again for the quality of their harvests.

“From farms and producer groups in Brazil, Colombia, Peru and Panama in Latin America, to the mountainous regions of Ethiopia, India, China and the Yemen, we are always looking for co ees with beautiful avours and provenance,” says Blackburn.“Paying more for better co ee naturally bene ts producers and their communities, but this alone is not a solution to the inequalities that are rife within the industry. We develop lasting relationships, with long-term contracts. By investing directly in those communities we hope to make real and meaningful di erences.”

ROASTING CRAFT At the roastery in the Colne Valley, Dark Woods takes an artisanal approach to production – hand-roasting in small batches and hand- nishing retail products with signature rivets and tags. The business is proud to have won over 40 Great Taste awards in the past 5 years, and 2 prestigious Golden Fork awards. The teams sees this as a re ection of their commitment to quality across a range of styles. It also helps customers sell more of the product from the shelves and in their cafés.

PACKAGING & PRESENTATION “It’s about ensuring there is a co ee for everyone’s individual tastes,” says Blackburn. The core range of co ees comes in striking retail bags (both beans and ground) and is well-suited to everyday and gi purchases. Nespresso compatible pods and re-usable co ee tins are also available.

The Producer Series is dedicated to seasonal, single-origin co ees from farmer suppliers while the Reserve range focuses on very small batch, limited edition co ees that push the boundaries of aroma and avour.

“We support our customers with a range of A-boards, posters, postcards and consumer lea ets to help promote the products in a very visual, informative manner,” adds Blackburn. COMMUNITY & ENVIRONMENT Dark Woods is a Certi ed B Corporation and a Living Wage Employer. Taking a hollistic approach is part of the company’s DNA.

“Co ee is a very global product but we’re proudly Yorkshire-based, too and the business is committed to reinvesting 2% of its annual turnover in both the local community, and in projects centred around our producer partners,” says co-founder Ian Agnew. “In 2020, that included over £5,000 to the Welcome Centre food bank in Hudders eld, funds to our local Mountain Rescue Team, helping to establish a Farmer Radio project in Panama and backing three Café Femenino Foundation projects in Peru, to help preserve water resources.”

TRAINING & SUPPORT “Training is integral to what we do, helping our customers and their sta to feel comfortable working with co ee equipment and presenting beautiful, tasty cups of co ee to their customers,” says co-founder and expert barista Paul Meikle-Janney. “This can mean training at the roastery’s dedicated facility, or on site. We can provide both certi ed, globally recognised barista training and accessible, in-house modular training sessions.