6 minute read

COVER

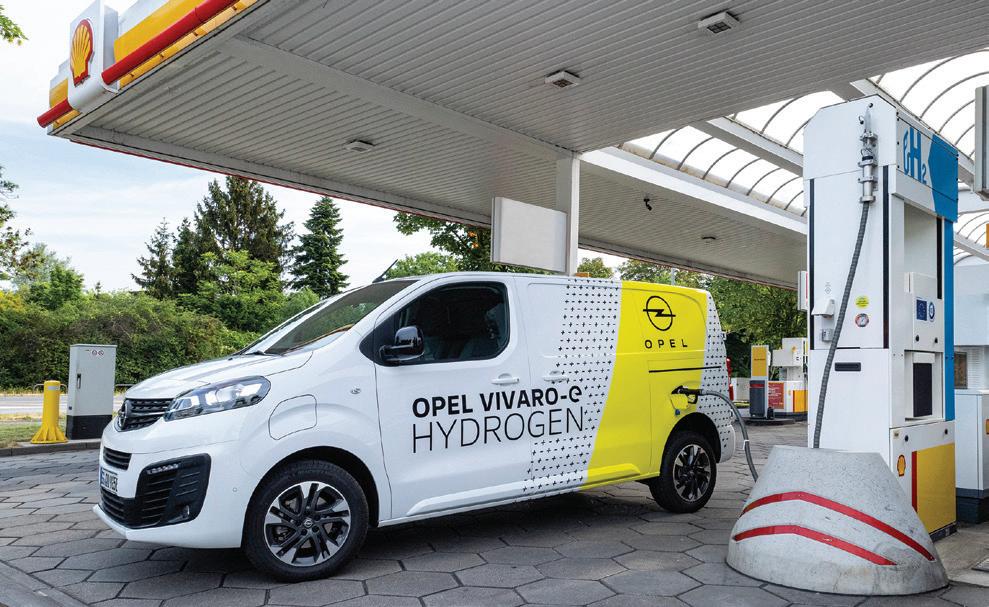

*New Opel Vivaro-e Hydrogen production ready

Russelsheim, Germany is where Opel is headquartered. It’s also the location of a Centre of Excellence for Opel’s parent company Stellantis where development of zero emission commercial vehicle technology is undertaken.

In recent years, the main focus here was on fuel cell hydrogen technology. The first versions have already hit the streets, with Fleet Transport being one of the chosen few to be offered a first drive in the brand new Vivaro-e Hydrogen.

Prior to undertaking this great opportunity, future strategy plans for Stellantis were presented by Carlos Tavares, CEO of the relatively newly formed corporation that merged Groupe PSA and Fiat Chrysler Automobiles. He began by stating that the parent

company and all of its brands are ‘extremely focused on green technology to meet the EU’s zero-emission target before 2030’. He added that this emission-free technology will extend right across the Stellantis Commercial Vehicle models from compact to large vans and from light duty to heavy duty pick-ups.

“By 2024, our large sized vans will be Battery Electric (BEV) powered and [we will] progress to [electric] pick-up trucks two years later (in North America through RAM),” he said, admitting that with the latter products, comparable towing capacity is key – a big challenge for its engineers.

Carlos mentioned that Russelsheim is taking the lead in full Fuel Cell Hydrogen (H2) technology in vans, a dual system with Battery Electric back up. In endorsing the promise, purpose, and potential of hydrogen, he said that ‘large fleets of hydrogen powered vans can operate efficiently, with one single point of refuelling and point of charge, adding up to a strong business case even for small to medium enterprises (SMEs)’.

Asked whether there is collaboration between Stellantis and its van supply partner Toyota Europe in the H2 development, he said there wasn’t, with no future plans either. He also noted that while all this investment in new technologies is ongoing, it invariably means that the vehicles, products and services stemming from it will become more expensive due to the high demand and shortage of raw materials – hence the increase in price of electric cars and vans. Regarding the future of the two British factories in Ellesmere Port and Luton, significant investment is being poured into modernising these facilities to produce BEV and H2 powered cars and light commercials. Not only will these vehicles instantly serve the growing local market (through national brand Vauxhall) but they will also cater for the loss of production capacity in Russia, following stoppages there in recent months.

One of the main

engineering challenges ahead is how to reduce the overall weight of BEVs, using more powerful and more compact batteries and reducing the number of raw materials used. He mentioned that back in the 1980s, cars averaged 800kg and are now weighing in at double that figure. In conclusion, Carlos praised all of the workforce, observing that the required solutions will be found ‘by everyone working together’. Xavier Peugeot, Senior Vice-President Commercial Vehicles Business Unit at Stellantis, reminded the assembled journalists that fuel cell technology has been worked on by Opel for twenty years. Along with BEV developments (include refurbishment), he said that Xavier Peugeot, Senior Vice-President Commercial the two power sources will meet the Vehicles Business Unit, Stellantis challenges of a changing world – even beyond the 2030 zero emission deadline. Among these challenges are city regulations, Low Emission Zones,

Congestion Charges, eCommerce business growth, last mile deliveries, green fleet company trends and zero emission supply chains. “To date the electrification momentum continues with a European target for BEVs to be 30% of the market by 2025 and up to 70% plus by 2030. The Stellantis Commercial Vehicle Electrification offensive, which became 100% electrified since 2021 and subsequently gained leadership in the European E-CV market, now continues with hydrogen fuel cell LCVs.”

Why hydrogen? “It is a zero emission solution in addition to pure BEV with fast refuelling, increased range and no compromise usability. All missions can be catered for such as services, delivery, construction, municipal and utilities.”

To endorse the company’s move in this direction, its executives can look to France and Germany, which are investing a combined €18 billion until 2030 in hydrogen infrastructure deployment. “Today there are 200 stations in these countries, by 2030 that figure will increase to 2,500 with 450,000 Fuel Cell LCVs in operation. Currently in Germany, over 100 H2 refuelling stations are in operation which are open to the public 14/7 with 700 bar pressure and with a fixed retail price of €12.85 per kg. However in France, 50 service stations retail the gas at €10 per kg. It is envisaged that with increased infrastructure and higher volume sales, that overall prices will drop to €8 per kg,” he said.

By the end of 2021, Stellantis’ ‘Go to market’ policy was in place with its three main hydrogen powered mid-sized vans from the Peugeot, Citroen and Opel/ Vauxhall brands delivered to customers in Germany and France.

Mr. Peugeot explained that these markets were chosen due to their readiness regarding having an existing refuelling station network, a high level public funding framework and with Government incentives. On the operator side, a seamless handover process and post-sale customer experience were put in place, as well as the brands offering a 160,000 km/8-year warranty and service contracts. He outlined the timeframe for the rollout of current and extended model ranges such as large vans and pick-ups. Over the course of 2022 and into 2023, production schedules are in place to assemble 1,000 units at a dedicated facility in Russelsheim and by the end of 2024, with the additional models going on sale, 10,000+ units will be turned out.

North American deliveries are planned for 2025 with the electric Fiat Ducato variant (wearing a RAM badge).

Xavier concluded by highlighting 4 key benefits of the Stellantis H2 initiative: 1) Zero Emission; Only water vapour, 2) Fast, easy and safe refuelling <3minutes 3) Long driving range and plug-in options <400km 4) No compromises on LCV usability – Same cargo volume as ICE – 1,000 kg payload and 1,000 towing.

‘Hydrogen Fuel Cell LCVs – A Zero Emission solution complimentary to BEVs for customers, who frequently drive long distances and/or need to refuel quickly’

As explained by Dr. Lars Peter Thiesen, Manager H2 & FC Development Strategy, Stellantis decided to develop a mid-power concept ‘designed to maximise customer benefits’ – in other words a hybrid system. Other options could be BEV/H2 Range-Extender or full H2 power. The Stellantis H2/BEV system features a 45 kW fuel cell, 4.4 kg H2 tanks and a 10.5 kWh battery pack, and according to Lars Peter has many advantages, such as packaging, performance, durability, energy reserve (PHEV) and return on investment.

Text & Photos: Jarlath Sweeney – editor@fleet.ie

Battery refurb

TWO SIZES OF VANS ARE AVAILABLE IN STANDARD AND LONG WHEELBASE FORMS

Model Cargo Volume Payload Height Length L2 Std 5.3m3 1,000kg 1,965mm 4,959kg L3 Long 6.1m3 1,000kg 1,975mm 5,306mm

HYDROGEN STORAGE SYSTEM

Type: 3 compressed hydrogen vessels/tanks Operating Pressure: 700 bars Usable capacity: 4.4kg Refuelling time: 3 minutes

BATTERY SYSTEM

Type: Lithium-ion Power: 90 kW Usable Energy: 10.5 kWh Recharging time: 90 minutes – wallbox

FUEL CELL STACK

Type: Proton Exchange Membrane Power: 45kW

ELECTRIC PROPULSION

Maximum power/torque: 100kW/260Nm

DRIVE PERFORMANCE

Top Speed: Acceleration: Range: Modes: Brake : Drive 110 km/h 15 sec (0-100 km/h) 400km (WLTP) – H2; 350 km + BEV: 50 km

; Eco – 60kW/190Nm ; Normal – 80kW/210Nm ; Power – 100kW/260Nm