34 minute read

Equipment Introductions

Liebherr

Updated L 550 and L 556 XPower Wheel Loaders

The 222-hp L 550 XPower loader has a 40,896-lb. operating weight, a 27,558-lb. tip load and a 4.45-cu.-yd. bucket capacity, while the 249-hp L 556 weighs 43,210 lbs., has a 30,314-lb. tip load and a 4.8-cu.-yd. bucket capacity. Standard power-split travel drive increases engine power. Increased working hydraulic performance enables dynamic lift and tip functions regardless of the size or weight of the working tool. Structural modifications to the lift arms enable higher breakout, holding and retrieval forces. The fully automatic LIKUFIX quick-coupler system is now available, along with a range of assistance systems including active personnel detection at the rear with a new braking assistant. www.forconstructionpros.com/21343014

Komatsu

PC88MR-11 Excavator

The 67.7-hp PC88MR-11 reduced tailswing excavator has an 18,739- to 19,224-lb. operating weight, a bucket digging force (SAE) of 11,982 lbs. and bucket capacity of .12 to .26 cu. yds. Standard high-flow auxiliary hydraulics with proportional joysticks provide precise attachment control. Six working modes tailor the machine to the tasks. A high-efficiency Tier 4 Final engine and viscous fan clutch work together to lower overall fuel consumption by up to 13%. The standard 7-ft. 7-in. grading blade with new moldboard profile allows for improved backfilling and light grading. A quiet, climate-controlled cab comes with air suspension seat, Bluetooth radio and high-resolution monitor with rear view camera. www.forconstructionpros.com/21366856

Demag

AC 80-4 All-terrain Crane

The 110-ton class AC 80-4 has a main boom that is 196.9 ft. long and comes close to its lifting capacity with fully extended boom up to a radius of 98.4 ft. The unit has a line pull of 7.5 tons. Its reach can be expanded with a 21.3-ft. main boom extension that can be offset by 25° and 50° and has a capacity of 26.2 tons. An available 4.9-ft. runner has a capacity of 29.3 tons. The main boom can be lowered up to 3° below its horizontal position so the jibs can be installed quickly and safely. The unit features 19.5 tons of counterweight, a threesheave hook block on board, standard all-wheel steering and the IC-1 Plus control system. Power is provided by a 456-hp Mercedes-Benz Tier 4 Final engine. www.forconstructionpros.com/21244868

John Deere

SmartGrade 210G LC and 350G LC Excavators

The SmartGrade grade control solution is now offered on the 210G LC and 350G LC excavators, with four grade management options to choose from, plus upgrade kits so customers can adopt technology at their own pace. Options available include SmartGrade, SmartGrade-Ready with 2D, 3D Grade Guidance and 2D Grade Guidance. The technology uses GNSS for accurate horizontal and vertical positioning of boom and bucket movements to a precise design target. The selectable bucket control feature automatically maintains a user-defined bucket angle throughout grading passes. Precision technology features include Virtual Front, over-dig protect and virtual fence technology. www.forconstructionpros.com/21366838

Genie

GTH-1056 Telehandler

The GTH-1056 has been purposefully designed to lower total cost of ownership by 10% while delivering 20% more lift capacity at max height. It has a sidemounted engine and stronger boom design that delivers a 10,000-lb. capacity. The unit is able to lift 5,000 lbs. at its maximum height of 56 ft. 7 in. and 3,000 lbs. at a maximum reach of 42 ft. It boasts a 30% stronger boom and chassis. The boom with mid-pivot point uses a single lift cylinder. This simpler configuration, combined with a wider, stiffer horsehead, efficiently transfers loads in applications imposing high stress on the boom, such as pipe handling or suspended loads. www.forconstructionpros.com/21295398

Smart Truck Technology Minimizes Jobsite COLLISION RISKS

Vocational trucks are adopting on-road truck safety technology to prevent collision risks.

This has been a tough couple of years for heavy truck drivers on our nation’s highways. A U.S. Department of Transportation report compiling crash data for 2019 (the most recent year for which these figures are available) shows that fatalities for large truck occupants reached their highest level in more than 30 years. U.S. trucking fatalities for 2018 also exceeded a level not seen since 1988.

There are many factors that may play into this trend. It is no secret that the industry has been challenged to attract and train drivers to fill the pipeline. Manufacturers of on-highway trucks have stepped to the plate with upgraded collision mitigation technologies. But up until recently, many of these technologies were not available to vocational trucks customers.

That began to change with the most recent generation vocational truck introductions. These technologies promise to greatly enhance jobsite safety since it is more than the driver who is at risk. “Struck by an Object” accidents, which include contact with machinery and vehicles, continually rank in the top four reasons for construction worker fatalities. This situation is potentially compounded by the dynamic, ever changing work environment. Even the most experienced operator will encounter unexpected elements on the job.

Safety and productivity features recently introduced on the VHD include Volvo Dynamic Steering (VDS) and the next generation of Volvo Active Driver Assist. SAFETY TECHNOLOGIES MAKE THE LEAP OFF ROAD

Contractors need to investigate any tools available to mitigate Struck by an Object risks, as well as risks when traveling to and from the jobsite. With the latest vocational truck offerings, new technologies are allowing trucks to monitor and react to their surroundings. These technologies help alert drivers of potentially dangerous situations and even intervene when necessary.

A notable example is the recently introduced Western Star 49X. It is the first vocational truck in the company’s line to come equipped with the Detroit Assurance 5.0 suite of active safety systems. While this technology is well-proven in the on-highway market, some have questioned its viability for vocational applications.

“We believe that safety is critically important, obviously to protect the truck, but it’s more important to protect the driver,” notes Dave Carson, senior vice president of vocational sales, Daimler Trucks North America. “We know that drivers are extremely confident of their skills and abilities, but there are conditions that exist that sometimes may create hazards. This suite of safety technology is really outstanding in its capabilities for preventing collisions and lane departure.”

As far as jobsite safety is concerned, this same technology can also prevent jobsite collisions. “In situations where you have different types of equipment and placement of material, there’s all different hazards that exist on a worksite,” says Carson. “There are customers who end up having different types of collision or damage, and anything that we can do to mitigate that through technology and training just creates a better value proposition for the business. We believe that technology is a significant leg up in the process of ensuring safety.”

Vocational trucks are often operated in urban environments. “It may not be a big city, but they’re usually operating within five miles of a town,” notes Carson. “In towns, you’ve got people, you’ve got automobiles.” This makes on-road focused technologies, such as pedestrian detection, valuable assets. “Say you’re going to the jobsite and somebody walks out in front of the vehicle. It will detect the pedestrian and apply the brakes.”

Vocational trucks in these environments also need to contend with traffic, and features such as adaptive cruise control can provide an additional measure of safety. Detroit Assurance includes Side Guard Assist, Active Brake Assist 5 and Adaptive Cruise Control to 0 mph.

“If you are in stop-and-go traffic because you are in a more urban environment, it has cruise down to zero,” says Carson. “You can set your cruise control and the truck will crawl along. Talk about something that fatigues people — stop-and-go driving is really a big drain on that operator. It’s more than just the jobsite, it’s the getting to and from the jobsite. I encourage everybody to consider it and at least learn more about it.”

Side Guard Assist detects objects on the passenger side of the truck and alerts the operator. Active Brake Assist 5 detects distance and speed to moving and stationary objects in the truck’s patch and determines if braking is necessary. The system is wellsuited for travel in congested

urban areas. It also recognizes pedestrians who are about to cross in the truck’s path, alerting the operator while partially braking. It will then apply full braking if the operator does not react and will bring the truck to a complete stop, if needed.

Adaptive Cruise Control reduces driver fatigue in stopand-go traffic. It automatically adjusts the cruising speed to maintain a safe following distance from other vehicles in the truck’s path. This allows the truck to remain in cruise control longer. When equipped with the DT12 transmission, the Adaptive Cruise Control will adjust the truck’s speed all the way to 0 mph. It also helps mitigate front and rear collisions as operators travel from one jobsite to the next.

Tailgate Warning alerts operators when they follow another vehicle too closely while traveling over 20 mph. It can report these events via Detroit Connect to help improve driver training. Automatic headlights and wipers help keep your view clear and your attention on what is ahead. Intelligent High Beams automatically disengage high-beam headlights when the camera detects tail lights, headlights or city lights, and turns them back on once these light sources are no longer visible.

Lane Departure Warning helps keep an eye on the road. It alerts the operator with a rumble sound and dash warning if the truck veers from its lane without signaling.

Detroit Assurance also offers forward- and driver-facing video capture. You can set the system to automatically take a 20- to 30-second snapshot of both the truck and driver activity during a severe traffic event and have it automatically loaded to a web portal for review.

COLLISION AVOIDANCE GOES MAINSTREAM

become a popular option across many vocational trucks. Now in its second generation, the camera- and radar-based driving assistance solution offers Automatic Emergency Braking (AEB) upgrades, as well as enhanced lane departure warnings.

The next generation of Bendix Wingman Fusion features improved following distance alerts with up to 3.5 seconds of warning before impact, and offers three levels of driver notification before the technology automatically applies the brakes using AEB. New detection feature upgrades enable Wingman Fusion to reduce vehicle speed by up to 50 mph to help mitigate collisions.

The improved technology also offers the ability for the system to brake if it detects a slow or stopped vehicle in the adjacent lane when changing lanes. If the object is definitively identified as a vehicle, the system alerts the driver. If necessary, the system then applies brakes through AEB.

Windshield-mounted cameras warn the driver should the truck begin drifting outside the lane or off the road. If multiple alerts are needed at the same time, the enhanced Wingman Fusion organizes them in order of importance, delivering only the most crucial alert to the driver to minimize distraction. At speeds above 37 mph, the system also alerts the driver when unintended lane departure occurs.

A driver-facing camera can monitor driver behavior. Along with a forward-facing camera, this feature can capture data for event recordings. The forwardfacing camera can also detect highway speed limit signs and warn the driver if the speed limit is exceeded.

Navistar International Corporation now offers the enhanced features of the Bendix Wingman Fusion collision mitigation system on the International LT Series, RH Series, MV Series, HV Series and HX Series vocational truck models. “Our DriverFirst philosophy drives us to continually improve product features that matter most to our customers, and safety is always a significant concern,” says Charles Chilton, vice president of Navistar’s Product Strategy and Planning function. “With our shared commitment to the driver, vehicle and highway safety, we’re proud to advance the safety features available on our products in collaboration with Bendix. By putting drivers in trucks equipped with safety aids, we are all contributing to a safer transportation network, from which everyone will benefit.”

Mack Trucks also added the next generation of Wingman Fusion to its Granite vocational truck line, improving safety for those on the road or traveling to a jobsite. Mack Trucks made the announcement last February during World of Concrete 2020.

DRIVER ASSISTANCE FEATURES IMPROVE SAFETY

Volvo AB, and its subsidiaries Volvo Trucks North America and Mack Trucks, have been at the forefront of safety technologies for vocational truck technologies.

The company’s approach to safety technology was on full display when the company recently launched the new Volvo VHD. “Everything we’ve done to improve the model to make it more versatile and reliable also extends the life of the vehicle and increases driver productivity, safety and comfort,” says John Felder, product marketing manager, Volvo Trucks North America.

Safety and productivity

features being introduced on the VHD include Volvo Dynamic Steering (VDS) and the next generation of Volvo Active Driver Assist (VADA).

Available only on VHD axle-back versions, the VDS system delivers a safer, more comfortable driver experience by adding torque to reduce steering strain at low speeds and remove vibrations caused by rough terrain. “VDS reduces the force in the steering wheel up to 85%,” says Andy Hanson, vocational product marketing manager. “It also reduces steering wheel inputs from rough surfaces. Both of these elements help reduce driver fatigue.”

VDS also adjusts to improve stability at road speeds when encountering crosswinds, highway crowning, soft shoulders or emergency situations such as tire failure. The system features a powerful electric motor mounted above the hydraulic steering gear to provide additional torque when necessary. It receives input 2,000 times per second from sensors throughout the truck, which monitor yaw rate, steering angle, wheel speed and the driver’s own actions.

The next-generation VADA provides integrated radar/camera capabilities, automatic emergency braking, highway departure warnings and adaptive cruise control. It reduces front and rear end collisions by up to 82%.

The technology combines camera and radar sensors to detect metallic objects and vehicles that are stationary or vehicles braking in front of a truck. If a metallic object of size is detected, audible and visual warnings are made to alert the driver, including red warning light flashes reflected on the windshield. Warnings are displayed up to 3.0 seconds before an imminent impact with the stationary object. If the system recognizes the stationary object as a vehicle and the driver does not take action, VADA will automatically alert the driver and engage the brakes to help the driver mitigate the potential collision.

Mack Trucks’ version of driver steering assist technology is called Mack Command Steer and it is available on Granite axleback models. Mack Command Steer reduces driver fatigue and can help cut muscle strain up to 30% by combining an electric motor with the existing hydraulic steering.

In addition to significantly reduced steering effort at slow speeds, Mack Command Steer helps filter out uneven terrain such as the holes, dips and ruts common to most jobsites. When such an irregularity is detected, the system reacts to counter the steering force, smoothing steering feedback and reducing the possibility of steering wheel “kicks.”

“While drivers will experience a significant reduction in steering effort, particularly on uneven jobsite surfaces, Mack Command Steer brings many benefits to on-road driving, as well,” says Roy Horton, Mack Trucks director of product strategy. “The system will also compensate for situations like strong winds and crowned roads, helping drivers maintain greater control so they can focus on the task at hand.”

The system also features a return-tozero capability that automatically returns the steering wheel to the zero or center position in forward and reverse. This helps simplify tight maneuvers, such as backing a trailer or positioning a dump or mixer to unload.

Electronic stability control technologies continue to gain acceptance in the vocational truck market. Often, trucks used in the construction industry utilize upfits that raise the center of gravity, making the trucks more prone to rollovers during aggressive cornering maneuvers.

Loss of control, jackknives and rollovers are three of the most dangerous incidents a driver can face. Volvo Trucks offers Volvo Enhanced Stability Technology (VEST) on its line of VHD tractors. VEST continually monitors driver inputs and driving parameters. When it detects the truck is dangerously close to an event such as a rollover, the system automatically reduces engine torque, downshifts the transmission and selectively applies the necessary wheel end braking to help get the truck back on course.

Kenworth recently announced that the Bendix ESP Electronic Stability Program is now available as an option for the C500 truck, which offers a GCWR up to 500,000 lbs. The system comes with a 6S/6M configuration, which has six sensors and six modulators. It also includes Bendix Smart Automatic Traction Control and Bendix ESP.

The technology is designed to help stabilize the vehicle during loss of control situations on dry, wet, snow- or ice-covered roadways. In addition to using sensors that monitor lateral acceleration, as found on some roll systems, the Bendix full-stability system also uses sensors to monitor steering angle and vehicle direction. This allows for detection of a vehicle’s impending loss of stability and automatic intervention through de-throttling of the engine and selective application of tractor steer and drive axle brakes, along with trailer brakes, helping the driver to maintain control of the vehicle in a variety of situations.

Bendix notes that its safety technologies complement safe driving practices and are not intended to enable or encourage aggressive driving. While these technologies will help reduce risks, it is worth noting that safety technologies cannot replace a skilled driver and comprehensive driver training. ET

— Charles Chilton, Navistar

Some things can’t be Googled

How many of my assets are underutilized? How many of my assets are inactive? How many of my assets are owned? How many of my assets are rentals? What is our total rental spend? How many of my assets are being rented out? Is it more economical to own or rent based on utilization?

Go Beyond Tracking

Get the answers you need.

55

Soil Connect

FOUR TRENDS Behind the “Explosion” in Technology Adoption

Key trends behind the substantial increase in tech adoption in construction, as well as how to assess the value of technology investments.

As the Soil Connect app shows, the gap between consumer and commercial applications is starting to narrow, with contech becoming more “consumer level” in its approach.

Construction technology, or contech, is “exploding,” noted Cliff Fetner, founder and CEO, Soil Connect, during a live simulcast hosted by his company on March 16. He cited a recent article that stated venture capitalists have invested 10 times more into construction over the past three years than in any other industry.

Fetner was joined by Aaron Toppston, managing director for Walsh Investment Group, the investment division of The Walsh Group. Toppston manages all of the infrastructure investment activities at Walsh across North America, and is the founder and leader of Walsh’s analytics team.

According to Toppston, the construction industry has — at least on the surface — been ripe for change in the form of technology growth for decades. He proposed four reasons why the industry is only now seeing changes in the rate of adoption.

LEARN MORE ONLINE

Three Keys to Technology Adoption in the Construction Industry — www.ForConstructionPros.com/21115716

Pandemic Pushes Construction Technology Adoption and Productivity Forward — www.ForConstructionPros.com/21198998

Will Construction’s High-Tech Embrace Continue Post-pandemic? — www.ForConstructionPros.com/21307343

How Incremental Innovation Can Benefit Your Construction Business — www.ForConstructionPros.com/21174884 1. CHANGES IN THE TALENT POOL AND TECHNOLOGY

Engineering and construction has always been an experiencedriven industry. “What your experience is on a jobsite on a specific project [is placed] as really the precipice of defining one’s career and how we execute work,” said Toppston. “But today, we’re having a growth in new talent in the industry, and the workforce coming in has a higher aptitude, a higher willingness to use technology.”

The gap between consumer and commercial applications is also starting to narrow, with contech becoming more “consumer level” in its approach. Toppston cited a recent presentation by Caterpillar where it was noted that the directive for the company’s IoT division is that everything must pass the “Apple store test” in terms of look, touch and feel; otherwise, adoption rates tend to be lower.

As technology has become both more familiar and more accessible, Toppston surmised, “I think folks are getting more comfortable seeing technology on jobsites and more comfortable relying on and utilizing it.”

Because different construction activities often have unique requirements, The Walsh Group allows each project manager to decide specific types of technology that are appropriate for a project. 2. INCREASED PROJECT COMPLEXITY

“Ten years ago, a $500 million project was enormous. Today, there are billion dollar and multibillion dollar procurements both in the private sector and the public sector,” Toppston pointed out.

As the size of a project gets bigger, complexity increases and administrative reporting requirements grow exponentially. “Today, with how big projects are and how complex the administrative requirements are, in addition to the execution of work requirements, it means one person can’t remember everything, and pen and paper or older style recording simply isn’t enough,” said Toppston.

3. BUILDERS AS PROFESSIONAL SERVICE PROVIDERS

“For decades, there has been a divide about how the trades, GCs and architects are looked at in the industry,” Toppston commented. “Particularly architects or engineers have historically [been viewed as] professional services firms. And that was in comparison to the way builders are viewed. Builders were viewed

as executing against blueprints. Where we think that this is wrong is everyone on a jobsite is a professional service.”

Project owners expect to be able to trust all stakeholders on the project to do good work, not just those traditionally viewed as “professional services.” This has led to greater parity, and collaboration, between various project entities.

“I think the realization that there’s a lot more in common with everyone [involved in] building a road or bridge, a water treatment plant, etc., and how they operate as a professional services firm and the communication and accuracy of decision making, means quite a bit,” said Toppston. “Therefore, the technology adoption up and down that value chain has become more available. And frankly, [there’s] more of a willingness to talk about that shared experience rather than different.”

4. TECHNOLOGY COSTS HAVE DROPPED

Cost has played a significant role in technology’s expanding role in the industry. “The cost of technology is going down. Construction is a very low-margin business. We’re just above running grocery stores. And because of that, there is hesitancy to invest a lot in R&D,” Toppston stated.

While construction is an enormous industry by volume, representing trillions of dollars globally, it doesn’t “scale well.”

“If we don’t scale well, we don’t have high margin, it has to be very affordable,” said Toppston. “Technology today can be used on an individual project, and the decision making can often be for just one project. That ability to take a ‘bite size’ at a low cost means quite a bit to adoption of tech.”

MORE WILLINGNESS TO EMBRACE TECHNOLOGY

Fetner comes from a family business of builders and developers of homes in the metro New York area. The company he more recently founded, Soil Connect, is a marketplace that connects those who have dirt with those who need it. It came about as a result of the struggles his family’s business faced in finding and getting rid of dirt on projects.

Like his father, who was an early tech adopter who introduced the building company to its first computer in 1984, Fetner has always looked at technology as an investment rather than an expense. “After you go through the initial speed bumps, and the onboarding of employees and staff and learning the new tech, you just become more efficient,” he commented.

The Walsh Group is a family business, as well, but on a much bigger scale. It, too, embraces technology, both on a project and on a corporate level.

“On projects, we really like to pilot ideas — find project-specific applications for certain technology — and use it as a decentralized decision making,” Toppston noted.

Not every technology is suited for every project. Even proven technologies may work well in one situation and not in another. For example, working on a bridge over water is much different than constructing a building in downtown Chicago. “[They have] a lot of different requirements for reporting, compliance, monitoring, etc., that will demand different use of tech,” said Toppston.

For this reason, The Walsh Group allows each project manager to decide specific types of technology that are appropriate for a project. According to Toppston, the project manager has a better understanding of how the work will be executed and how operations may be influenced through use of the technology, thus ensuring its value on the project.

Decisions on the corporate side are based around analytics. “What I mean by that is, what have we learned as an entity, as a global company, to improve our operations or consistency and reduce volatility?” Toppston posed.

Where other industries may spend a million dollars with the understanding of a payback period within two years, in construction, such a valuation is more difficult. “The reason being is construction returns are quite volatile. One project can be a home run and one can not,” said Toppston. “That volatility, that inconsistency, on individual financial returns per project matters as much to the overall company as the individual ROI for an application. So, tech that can reduce that volatility is the path to an ROI.

“That’s where we build it into corporate understanding,” he added, “and how we analyze what’s worked and what hasn’t across the portfolio of 500+ projects that we have as a firm.”

FIND VALUE REGARDLESS OF SIZE

The tech needs of a company like The Walsh Group, which constructs bridges, tunnels, airports, etc., across the country, are much different than those of a small- to mid-size construction firm with, say, five to 20 employees, Fetner acknowledged. Yet, the need to identify the value of technology is just as pressing for these companies.

“They’re adapting to the new technology today on a much smaller scale, where they would never really be interested in a Procore,

Builders are increasingly being seen as professional service providers. Technology up and down the “value chain” of a construction project has become more available as a result.

for example, because that takes on a different size firm,” said Fetner. “But every firm kind of has to wrap their head around any investment in technology on whatever level.

The key, he added, is to implement the technology, then help your team to understand and embrace it, “because the technology will just make you more efficient” as an organization. ET

Intelligent Hydraulics Enhance Machine CONNECTIVITY AND PERFORMANCE

Integration of electronics and software into hydraulics is aiding the push toward automation and connectivity.

Integration of electronics and software enables improved hydraulic and overall machine performance.

These days, almost every component and system in a piece of heavy equipment is becoming more intelligent through the incorporation of sensors and the Internet of Things (IoT).

“The core vision of IoT for mobile machines is about implementing digital tech-

nology to capture actionable data about the performance of mobile machine systems autonomously, do it in real time and deliver it to machine end users and OEM suppliers so they can maximize the uptime and flexibility of their machines,” says Terry Hershberger, director, Sales Product Management & eSystems, Bosch Rexroth.

In hydraulic systems specifically, there are two major trends driving increased intelligence, says Ben Hoxie, director of engineering, power and motion

controls at Eaton. The first is distributed intelligence enabled by low-cost computing and sensing, which gives rise to all types of new machine functions. Eaton refers to this intelligent machine movement as Dynamic Machine Control.

The second key driver is “a step change in connectivity” through mobile and industrial communication protocols that can cost-effectively transmit significantly more data. “This improved connectivity is enabling big data innovations that will yield new insights into how machines operate and the behavior of machine operators,” says Hoxie.

Automation is also driving the push toward increased intelligence. “Digitalization of the machine by incorporating robust controllers, sensors/feedback devices and the connectivity unit provides for additional workflows or other apps that could allow for remote-controlled worksites to be managed more safely,” says Hershberger. “A fleet manager could control an area that the vehicle is allowed to operate, and of course provide for diagnostics of the system. However, it is not without challenges.”

Overall, creating more intelligent systems helps improve safety, productivity and cost of operation through better machine control, says Hoxie. “One example of how an intelligent hydraulic system has delivered such benefits is our Boom Stability Control solution. By reducing boom oscillation up to 75%, the system delivers both safety and productivity benefits to end users,” he explains. “Another example is auto-guidance steering solutions. Eaton’s system combines our GFX GPS receiver, SFX safety-rated controller and SBX advanced steering valve to enable automated and semi-autonomous vehicle steering operation.”

METHODS FOR ADDING MORE INTELLIGENCE

There are a variety of ways manufacturers are creating smarter hydraulic systems, including incorporation of more sensors and software.

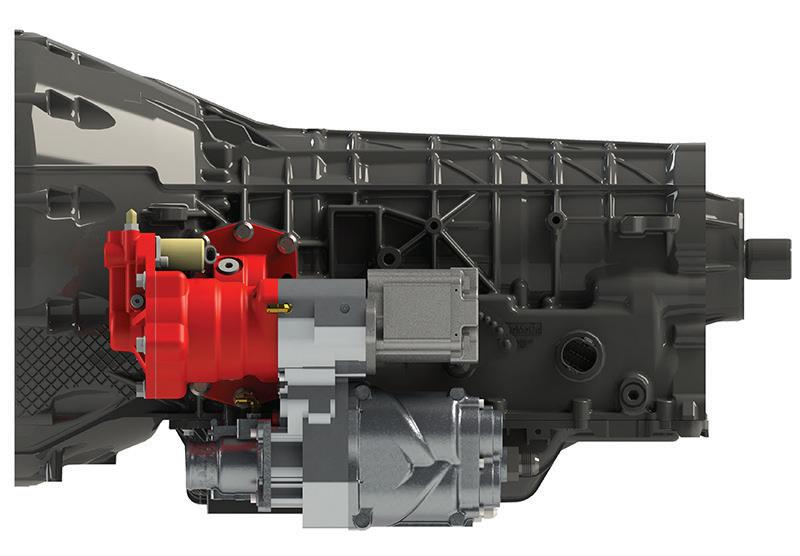

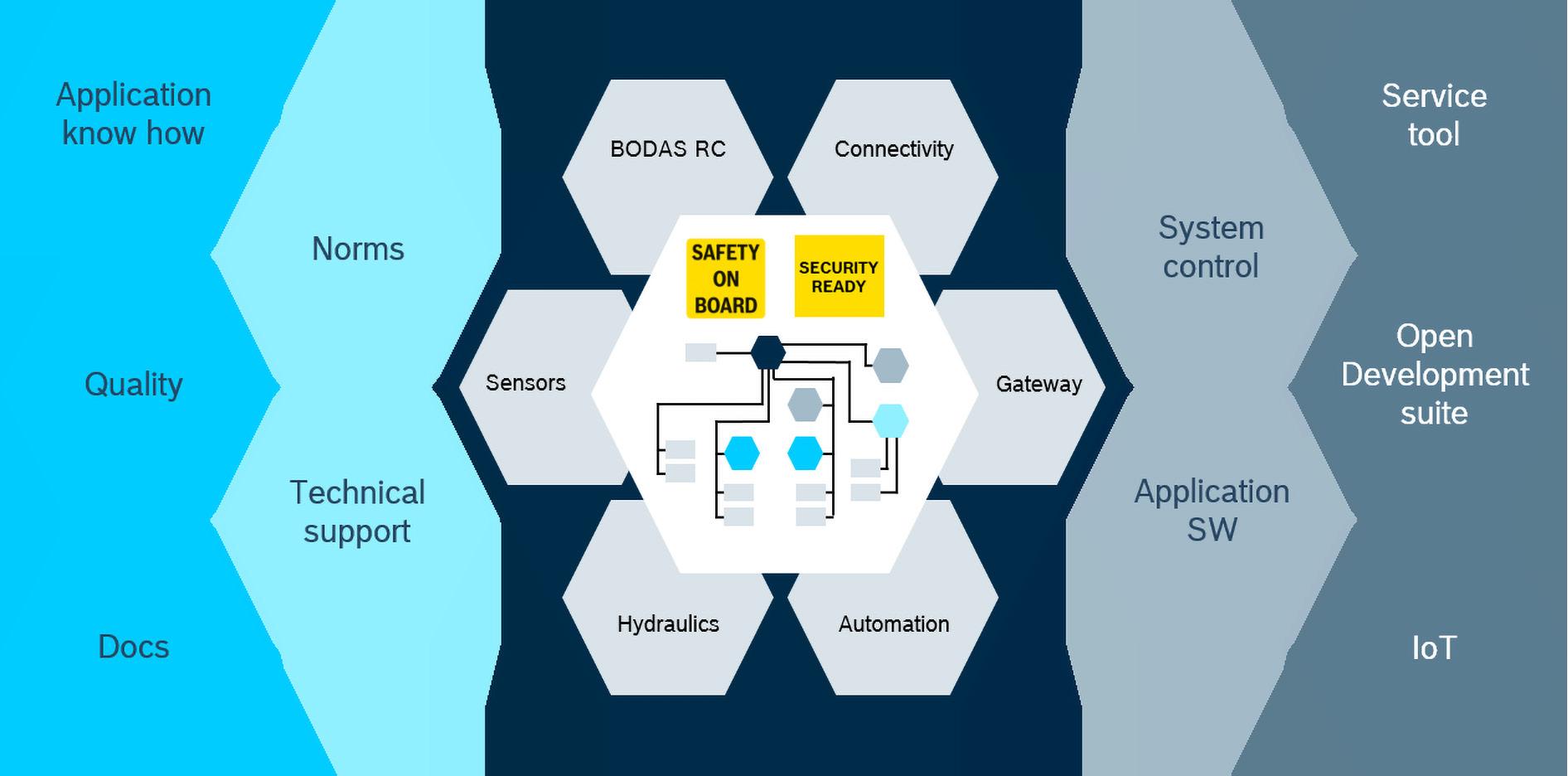

The Bosch Rexroth Digital Application Solutions (BODAS) portfolio of IoT solutions, software and electronic hardware exemplifies the digital enhancements the company is making for off-highway equipment. “Together with Bosch, we also offer the suitable IoT infrastructure and cloud-based analytical apps,” Hershberger says. “It combines competence and application experience in the decisive fields of mobile hydraulics and electronics, edge analytics and IoT.”

In general, the company has enhanced the integration of sensors where necessary in order to provide real-time data on hydraulic performance metrics. In addition, it is engineering its digital technology offerings — including hardware, software and connectivity and analytical systems — to work together as complete solutions.

Hardware options include an open, scalable and freely accessible mobile electronics platform

which consists of control units, connectivity devices, sensors and human machine interface (HMI) components such as joysticks and displays. Bosch Rexroth’s software is modular and includes tools for programming, parameterization and diagnostics, and is based on deep insight into hydrostatic and electrohydraulic functions, says Hershberger.

“The fundamental building blocks of IoT are the ‘things’,” says Hoxie. As such, Eaton is developing a suite of intelligent devices such as its CMA valve with deeply integrated sensing and control. Its AxisPro valves feature onboard “white space,” which allows users to build application-specific solutions and thus tailor the valves to the needs of the machine design.

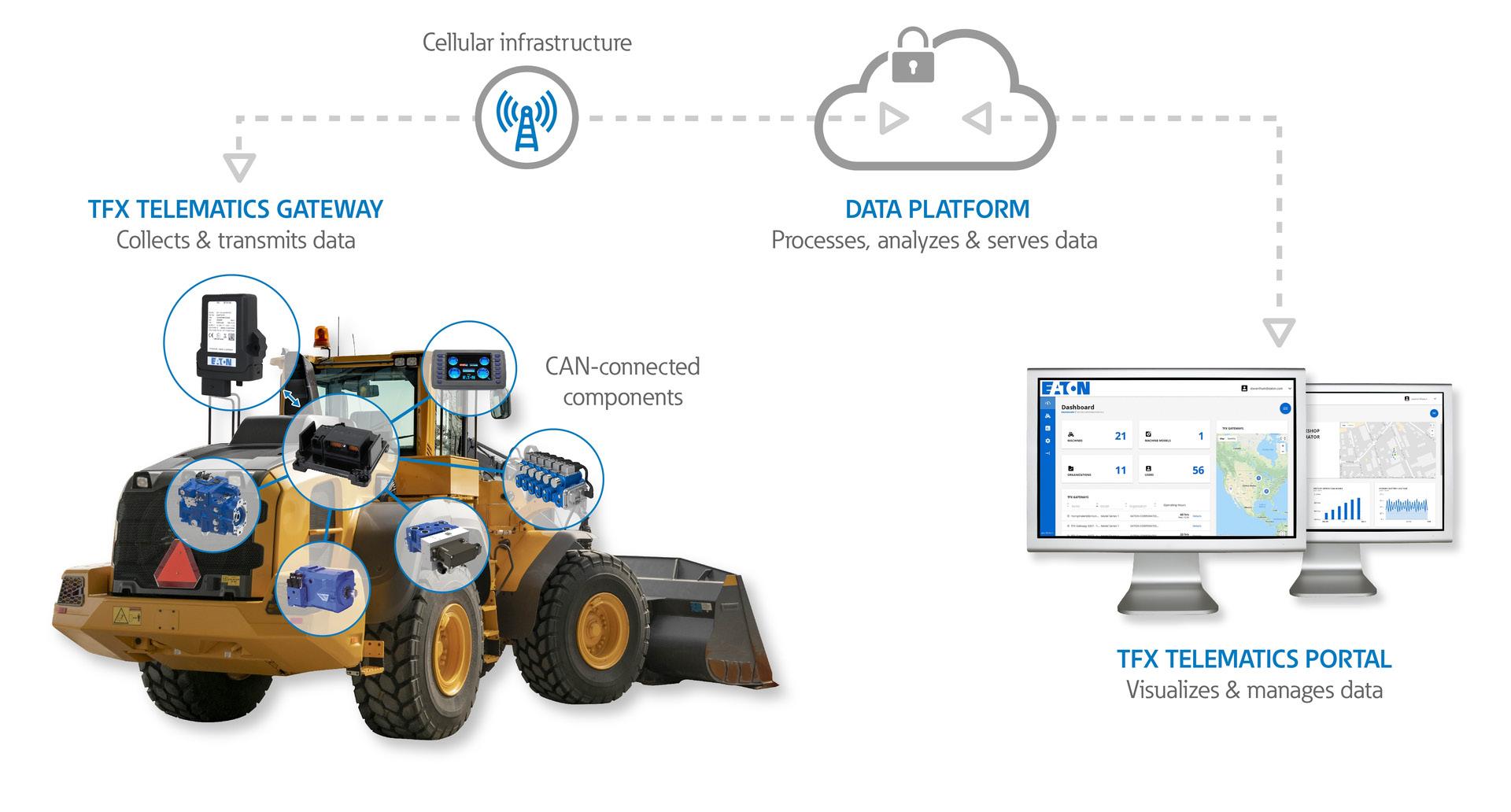

“We’re also continuing to build upon our Pro-FX suite of controls and software solutions,” Hoxie continues. “This library of machine control function blocks enables quick and easy system development and tuning to match machine builders’ needs. Finally, on the connectivity and cloud storage side, our TFX telematics solution enables machine builders and fleet managers to monitor, upgrade and diagnose their machines, all remotely.”

SENSORS EXTEND TO FLUIDS AND FILTERS

For its Filter Minder technology, Donaldson Co. Inc. has developed sensing and analytics solutions to enable accurate monitoring of filter and fluid life. The biggest advancements to date for its air filter monitoring solution have been around enhancing analytics capabilities to help users make better sense of the data that is aggregated, says Nate Zambon, director of Filter Minder at Donaldson.

Now the company is focusing its efforts on liquid filter and fluid monitoring, such as for hydraulic filter and hydraulic oil condition monitoring. “Coming up with the intelligence and algorithms [for] fluid condition monitoring is more complex than air filtration monitoring,” says Zambon.

Determining end of life for an air filter is a bit simpler because it is largely based off when there is a pressure drop, which can be measured by pressure sensors. However, there are a variety of different things that can indicate when oil is at the end of its life or if there are contaminants within it. This requires different combinations of experiments and tests to validate and characterize oil life cycle, making the development of sensors and analytics for doing so more complex, says Zambon.

“We’ve really been making a very strong push leveraging Donaldson technology teams, and have some external partnerships that we put in place to support our development of those capabilities within Donaldson,” he adds. The company is also scaling out field testing, “because ultimately, in the field is where you prove the viability of the technology.” Bosch Rexroth’s BODAS electronic architecture is comprised of more than just components; it is a complete electronic ecosystem for the control of mobile equipment.

Bosch Rexroth

SECURITY AND OTHER CHALLENGES REMAIN

The expansion of intelligent machines requires skills in systems engineering, mechatronics, embedded controls, software engineering and data science, which can be challenging for machine builders to acquire. “It is no longer enough to know how to integrate hydraulic components. Machine builders need to excel at bringing together mechanical, electrical, electronic and software domains to deliver top performance,” Hoxie points out.

Because of this, Eaton is developing technologies like its Pro-FX portfolio, consisting of smart components, controllers and software designed to enable easy integration into machine designs. “By leveraging an open architecture platform, Eaton simplifies the machine control challenge while ensuring the machine builder has the control and flexibility to differentiate their machines,” says Hoxie.

Offering a suite of technologies as Eaton and Bosch Rexroth do allows OEMs to get the majority, if not all, necessary components from a single source. This helps ensure components will all work together as needed. It also simplifies and reduces design time.

As the demand for more intelligence and automation progresses, device reliability and security as well as machine safety monitoring and software management are challenges that will also need to be addressed.

“When we start to work in this connected world, no one envisions their machine could be hacked by someone

AVAILABLE EXCLUSIVELY AT VERMEER DEALERS WORLDWIDE!

The BRON 175 utility tractor features 225 HP (167.8 kW) stage V engine, dual telescopic reel carrier, variable speed hydrostatic transmission, decelerator pedal, oscillating undercarriage and V75-3 offsetting plow.

873 Devonshire Ave., Woodstock ON N4S 3B6 1.800.263.1060 | ON:519.421.0036

610 Main St. West Leroy MN 48039 507.547.2864

© 2021 Vermeer All Rights Reserved BRON is a registered trademark of RWF Industries, a division of Roberts Welding & Fabricating Ltd.

in cyber space, but it is real and your controllers, sensors and connectivity devices need to be protected,” says Hershberger. “Imagine in the middle of a software update that the communication link is hacked and the wrong information is loaded on the controller. This could lead to unexpected movement or operation of the machine, or possibly the machine is

BETTER MACHINES

APPLIED MACHINERY SALES inoperable and not usable. Additionally, unauthorized connection to the machine that allows for operational parameter changes could cause unexpected operation.”

To help overcome these challenges, Hershberger says it is necessary to incorporate hardware security modules into controllers or certify components to certain performance levels. In addition, there must be cloud security and IT infrastructure in place, as well as methodologies to “push” software updates to machines when they are in a safe state. “It is not only the management and transmission of data; it is how that connectivity device and the background infrastructure is put together in what we call device management that is critical,” he states.

Machine connectivity and the vast amount of data that can be collected and transmitted also poses challenges. “Intelligent, useful, big data is expensive and may be cumbersome to manage but ever so important when we talk intelligence,” says Hershberger. “Therefore, a continuing challenge is one of data compression and filtering out and sending the relevant actionable data.” This is key with the connectivity device, and an area Bosch and Bosch Rexroth are working to overcome through the use of Edge Analytics.

Donaldson

The end user of a machine may be driving the adoption of connectivity and data, but may not be focused on the associated challenges, Hershberger acknowledges. So, it is up to the OEM and solution supplier to be prepared to provide a reliable, robust and state of the art system.

A PANDORA’S BOX OF OPPORTUNITY

The recent acceleration of IoT and connectivity is the next step in the ongoing journey toward ever-smarter machines. “Starting from the first electrohydraulic machines decades ago, the industry has been on a continuous journey of ever-more capable machines,” Hoxie comments. “Over the last decade, we have seen driver-augmented and semi-autonomous agriculture, construction and materialhandling machines move into the mainstream. Even now, our industry is on the verge of fully autonomous mobile machines.”

As such, he says Eaton is ready to help both OEMs and end users embrace the opportunity for continued progress. Hershberger says the ability to connect to machines remotely opens a “Pandora’s box of opportunity.” This can be seen through fleet management functionalities such as geo-locating and viewing operational data or diagnostics. “With sensors monitoring controller data or critical machine information, the ability to inform the owner of the machine about when a filter needs to be replaced or an indication of a problem on the machine is at their fingertips,” he points out.

As technologies continue to advance, so will the intelligence and capabilities built into components and systems. “Instances of upgrades to a machine with flash over-theair or changing parameters on the machine to enhance operation for the environment the machine is working in will be commonplace,” he predicts. “The connected machine will become more and more normal.” ET Eaton’s SBX advanced steering valve enables machine designers to tailor steering performance to the operator’s preferences and operating conditions.

Eaton’s TFX remote monitoring system provides fleet and equipment managers with a comprehensive view into machine location and performance.

SALES & RENTALS

AMS-MERLO.COM

INFO@APPLIEDMACH.COM / 803-327-4949 TWO LOCATIONS TO SERVE YOU ROCK HILL, SC & OLATHE, KS

BOOTH W941 WEST HALL JUNE 8-10, 2021