29 minute read

BALANCE VOCATIONAL TRUCK SUSPENSION TRADE-OFFS

Advances in vocational truck suspensions provide options that change the weight vs. stability vs. articulation vs. ride quality equation.

Every vocational truck suspension option comes with its own unique performance trade-offs. The best choice requires an understanding of how the trade-offs match up to your application requirements.

“Mechanical suspensions are still the most popular for the vocational market thanks to their great stability, articulation and maintainability,” says Tim Wrinkle, Mack Trucks construction product manager. “Air ride suspensions are becoming more common, as they offer a better ride when unloaded. However, these suspensions can be limited in articulation and stability.

“Driver knowledge and training are also very important with air suspensions because drivers need to evacuate air bags before dumping the load,” he adds. “Depending upon the setup and a driver’s experience, this can also slow the dumping process for dump trucks.”

“Although there is a trend in spec’ing air suspensions for vocational applications, there are trade-offs between off-road and on-road performance,” agrees Peter Schimunek, marketing segment manager, Western Star.

The job of the suspension is to support and cushion the load. The suspension absorbs shock loads that would otherwise be transferred into the frame. If the truck frame is doing the job of the suspension by twisting and absorbing shock, then it stresses every component of the vehicle, eventually causing failures and maintenance issues.

Understanding the application and performance demands is the first step. The capacity of the suspension; whether it is for a single, tandem or tridem configuration; if the system is for a tractor or straight truck; and the nature of the terrain all play a role in narrowing the choice between air, rubber or steel springs.

There are multiple suspension options available to meet the many niches in the vocational truck market, each with unique features and benefits. Compare the suspension choices available to meet application needs — reducing weight, improving off-road mobility, increasing stability, minimizing torque reactivity or all of the above — while balancing upfront cost.

The type of loading and unloading performed must be considered. A dump truck hauling aggregate requires a different suspension than a mixer truck, for instance. There is more of a shock load factor when aggregate is loaded vs. ready-mix. In addition, a stationary load has different needs than a moving load, such as liquid bulk haul or a concrete mixer.

Be sure to account for worstcase scenarios. Sometimes the truck may be required to take on heavier loads than it usually does. These temporary loads may require a higher creep rating on the jobsite, thus requiring a heavier-duty suspension. Where the truck will operate — the type of terrain — can create

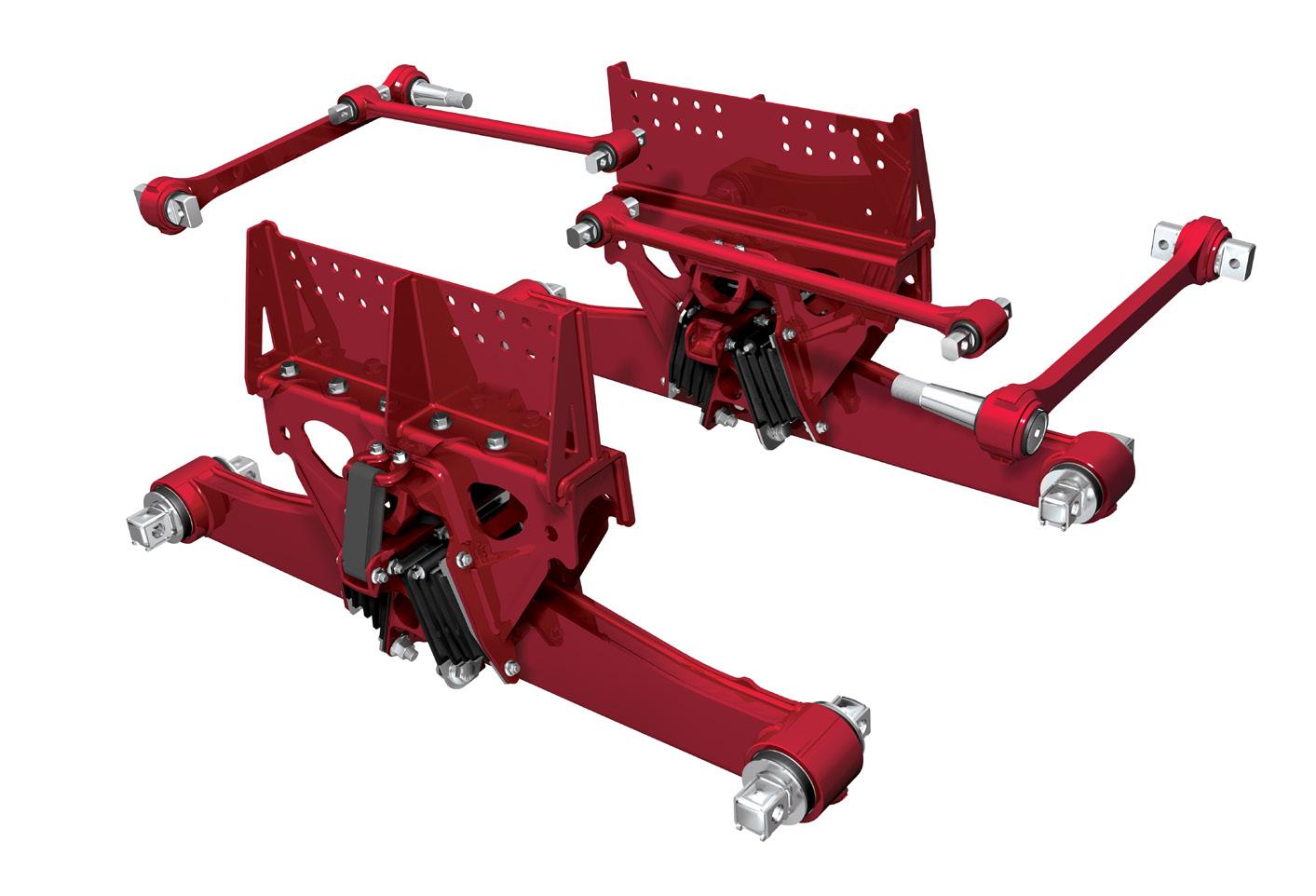

The Mack mRIDE provides extreme articulation and constant tire contact, delivering enhanced traction on rough terrain. The spring leaf design and V-shaped torque rods help ensure stability to efficiently transmit forces into the truck’s frame.

different needs for articulation and ground clearance.

Serviceability gains importance in remote locations. For example, if it is going to be in the middle of an oil field with no immediate access to a dealership, it’s important to spec the suspension to be serviceable by the driver.

NARROWING THE GAPS

Avoid relying on past history to spec today’s suspensions. Suspension designs have become more streamlined and versatile over time.

In the past, bigger, bulkier and heavier suspensions suited for tougher applications also provided a rougher ride. With the introduction of air ride suspensions and other innovations, drivers now have a more comfortable ride and the loads are better protected from rough terrain.

There used to be a large gap between the comfort of on-road suspensions and the durability and stability of their off-road counterparts. The gap has closed significantly in recent years, with off-road suspensions getting very close to matching the comfort and performance of those targeted for on-road applications.

Mack recently made improvements to its mRIDE mechanical suspension. “The Mack mRIDE spring leaf over rubber block suspension is ideal for customers needing improved stability and greater traction on jobsites,” says Wrinkle. “The mRIDE’s parabolic springs are thickest at the center to ensure the clamp load area offers the greatest strength, and are tapered to improve driver comfort.”

The improved suspension provides extreme articulation and constant tire contact for greater traction on rough terrain. “The spring leaf design and V-shaped torque rods help ensure stability to efficiently transmit forces into the truck’s frame,” says Wrinkle.

“The Mack mRIDE has been our lightest vocational proprietary rear suspension and earlier this year we lightened it even further, now offering additional weight savings for increased payload when paired with proprietary Mack axles,” he adds. “Available at 40,000- and 46,000-lb. suspension ratings and with standard track axles,

customers can save 140 lbs. with drum brakes and 146 lbs. with air disc brakes as a result of casting suspension components into the Mack axle housing.”

With advancements in technology, the gap between lighter suspension weights and life-cycle durability has also narrowed. For example, Hendrickson’s next-generation HAULMAAX EX rear tandem rubber suspension is lightweight yet is designed to handle applications such as dump, concrete mixer and crane/boom with a 40,000-, 46,000- and new 52,000-lb. capacity. The suspension utilizes a unique rubber spring design that balances empty ride quality and loaded stability. Angled bolster springs and a progressive load spring provide extra stability for demanding applications.

Kenworth recently added the HAULMAAX EX suspension as an option for its Class 8 vocational models. “The Hendrickson HAULMAAX EX is an excellent choice for Kenworth vocational customers seeking a lightweight, durable suspension equipped to handle rugged operating conditions and provide a smooth on-highway driving experience,” says Genevieve Bekkerus, Kenworth marketing director. “Now that this suspension line is also available with a 52,000-lb. suspension rating, [our customers] operating in heavy applications have a viable new suspension option to consider.”

To further reduce weight and increase ride quality, lightweight air ride suspensions have gained off-road capability. Newer air suspensions use casting technology and innovative designs for increased durability and performance.

CONSIDER MAINTENANCE

The suspension choice helps drive ownership cost. An improperly spec’d suspension can result in costly repairs down the road, wearing out components faster and increasing overall maintenance costs and downtime vs. a properly specified product.

Balance maintenance requirements and expected performance. Different suspensions have different requirements for maintenance, such as frequency and type of lubrication and replacement of bushings. The application and operating environment may also affect maintenance requirements.

The complexity of the suspension helps determine maintenance costs. Generally speaking, steel suspensions are the least expensive to maintain, while air ride suspensions are more complex and therefore more likely to require maintenance. This is because air ride suspensions have air in the system that needs to be regulated with control valves. Also, depending upon the type of environment or application, air springs can get cut or cracked if stones get embedded.

HIGH ARTICULATION SOLUTIONS

Mechanical suspensions typically offer greater articulation than air suspensions. They can also be designed to maximize stability. But a trade-off between articulation and stability is not necessary. Mack offers its Camelback and mRIDE as examples that offer both high articulation and stability.

It’s important that any mechanical suspension used in a high articulation environment be able to evenly distribute the load. Freightliner recommends a trunnion suspension such as TufTrac, which is Daimler Truck North America’s proprietary suspension for Freightliner and Western Star trucks. Trunnion suspensions are best suited to handle bumps and ridges without bottoming out. TufTrac specifically keeps a uniform load over each wheel during articulation.

Walking beam suspensions have traditionally been favored for high articulation applications. Floating walking beam suspensions allow maximum articulation and can offer maximum roll stability. The floating beam suspension with soft ride restrictor can provide a superior ride quality that compares favorably with air ride when on the road. This feature is available for specific truck applications and tractors, as well.

Walking beam suspension systems are also extremely durable. Depending upon the spring medium design, walking beam suspensions can have a little bit harsher ride and may require more maintenance, because they have a more complex design than spring steel suspension systems.

The primary benefit of the walking beam design is its ability to equalize the load. Modern walking beam designs are integrated into advanced rubber spring systems, which bring additional benefits to the suspension system. Walking beam suspensions have advanced to provide the highest amount of articulation while achieving the stability required for off-road work.

In high center of gravity applications, you will want to consider the benefits of a mechanical suspension. Mechanical suspensions with high roll stiffness and high roll centers are best suited for high center of gravity applications like concrete mixers.

The choice of uspension is especially important in concrete mixers, which typically need to perform both on- and off-road. “Mixers have a high center of gravity and extra offset center of gravity with the spinning barrel carrying approximately 40,000 lbs. of concrete, so they are more prone to rollovers than other vocational applications,” Wrinkle points out. “With this in mind, high-stability mechanical suspensions are typically used to help reduce the risk of rollover. Mechanical suspensions with high roll stiffness and high roll centers are best suited for high center of gravity mixers.”

The stability of a walking beam suspension can be a definite advantage in these applications. They are roll stable due to limited movement and compression within the suspension spring. But it is important to choose one that can distribute the load equally to all four wheels even during severe articulation. That can be done by choosing a floating beam suspension, which is suited specifically for high center of gravity applications. It’s important that any mechanical suspension used in a high articulation environment is able to evenly distribute the load. Freightliner recommends a trunnion suspension, such as TufTrac, which is Daimler Truck North America’s proprietary suspension for Freightliner and Western Star Trucks.

— Tim Wrinkle, Mack Trucks

Hendrickson Chalmers

Hendrickson’s next-generation HAULMAAX EX rear tandem rubber suspension is lightweight yet doesn’t sacrifice on durability. It is designed for applications such as dump, concrete mixer and crane/boom with 40,000-, 46,000- and a new 52,000-lb. capacity. The suspension utilizes a unique rubber spring design that balances empty ride quality and loaded stability. The suspension absorbs shock loads that would otherwise be transferred into the frame. If the truck frame is doing the job of the suspension by twisting and absorbing shock, then it stresses every component of the vehicle, eventually causing failures and maintenance issues. Chalmers offers a low-maintenance and high articulation tandem rubber spring rear suspension. It provides rubber bushings without greaseable joints, reducing maintenance costs and increasing uptime.

The walking beam can be paired with rubber spring technology. Rubber spring components are lower weight, easier to maintain and provide greater ride quality and stability over steel spring suspension systems.

Western Star offers a walking beam suspension in the form of the six-rod TufTrac Gen2. “The inherent stability of the design provides an excellent platform for high center of gravity applications of this high-performance and durable vocational suspension,” says Schimunek. “The high ground clearance feature of this suspension performs extremely well in vocational applications, including construction, asphalt spreader, heavy haul, mining and logging.” It is available in 40,000-, 46,000and 52,000-lb. tandem axle capacities.

“The TufTrac walking beam design allows the suspension to maintain a uniform load over each wheel in laden and unladen conditions as the suspension articulates,” says Schimunek. “By maintaining a uniform wheel load, the TufTrac suspension maintains maximum traction, providing increased confidence to cross even the toughest jobsite, maximizing productivity. By isolating the moving joints in rubber elastomer bushings, this suspension provides one of the quietest rides among vocational suspensions, keeping the operator comfortable.”

The Comfort Ride version of the TufTrac Gen2 suspension is available in 40,000- and 46,000-lb. tandem axle capacities, providing a softer ride for increased ride quality and driver comfort. “The reduced spring rate combination with four shock absorbers and a stabilizer bar provides a smoother ride, whether loaded or unloaded, minimizing wear and tear on both truck and driver,” says Schimunek. “Comfort ride is ideal for applications that require both on- and off-road usage, such as dump trucks.”

For high articulation applications, Western Star offers the Chalmers 800 Series low-maintenance and high articulation tandem rubber spring rear suspension. “This rear suspension provides rubber bushings without greaseable joints, reducing maintenance costs and increasing uptime. High articulation greatly increases stability and cornering, improving driver comfort for increased productivity and safety,” says Schimunek.

Chalmers 800 Series rear suspensions are available ranging from 46,000 to 70,000 lbs. “The suspension is ideal for on/offroad applications, such a dump trucks, logging, heavy haul, oil field and bulk haulers and can be used in straight truck or tractor applications,” says Schimunek.

AIR SUSPENSIONS PROVIDE BEST RIDE QUALITY

It’s hard to beat air ride for driver comfort. Creature comfort and the reduction of shock to other components of the chassis are real reasons to look at these suspensions.

That said, air ride does have limitations. No manufacturer has been able to offer both stability and articulation.

Air ride suspensions continue to expand in certain vocational applications, such as dump trucks and heavy-haul tractors. They provide consistent ride quality in any load condition, which will help lessen driver fatigue while protecting equipment and chassis components from damaging vibration and road inputs.

Western Star’s proprietary Airliner rear suspension design reduces weight, which allows for a greater payload. “The maintenance-free, double-bonded rubber bushings on moving joints ensure a long life expectancy,” says Schimunek. “The stability and cushioning of this suspension system significantly reduces freight damage and driver fatigue, improving the overall driving experience.”

A full selection of single (21,000 to 23,000 lbs.), tandem (40,000 to 46,000 lbs.) and tridem (69,000 lbs.) drive versions are available and tuned for almost any application. “Some air suspension models are best suited for highway applications, however, so we recommend adhering to manufacturer recommendations for your specific applications and weight-carrying capacity,” Schimunek advises.

Weight savings is another advantage with air ride systems. Some mandated federal requirements, such as selective catalytic reduction (SCR) and diesel particulate filters (DPFs), have added weight to trucks, which is one reason customers are moving to the lighter air ride suspensions. While they are not the best for every job, they provide ample capability and capacity for dump applications.

Purpose-built air suspensions can overcome many of the previous limitations — primarily stability and off-road mobility. Stability does not need to be sacrificed if choosing the proper vocational air suspension. For example, Hendrickson’s PRIMAAX EX promises up to two times the roll stability of competitive air suspensions, equaling the stability of a steel walking beam.

“This suspension features a robust structural design with optimized suspension geometry for exceptional stability, durability, reliability and handling characteristics,” says Schimunek. “The PRIMAAX EX minimizes suspension-induced driveline vibration and significantly controls suspension windup and corresponding frame rise compared to competitive trailing arm suspensions, resulting in higher driver comfort and less premature wear on truck and body equipment.

“This suspension is ideal for a variety of vocational and severe-duty applications,” he adds, “including construction, mixer, logging and heavy-haul applications. It’s available in 46,000- and 52,000-lb. tandem axle capacities.”

The Neway ADZ Series air suspensions feature a streamlined design that has reduced weight by more than 220 lbs. per axle (compared to previous models). “The durable suspension is ideal for high center of gravity, severe-duty and heavy-duty vocational applications optimizing operating efficiencies,” says Schimunek. “High cross-articulation provides superior traction in wet, muddy and uneven terrain such as logging tracks, hillsides, oil sands and fracking sites.”

The ADZ Series suspension is available in single, tandem and tridem axle configurations ranging from 26,000 to 78,000 lbs.

STEEL SPRINGS OFFER SIMPLICITY

Simplicity rules in certain applications. Spring steel suspensions are simple, stable and durable. Walking beam suspensions are usually heavier, depending upon the design of the steel springs.

Steel spring suspensions are known to be simple suspension designs, resulting in an economical upfront purchase. Common use of the simple design also leads to familiarity of maintenance.

Drawbacks for steel spring suspensions will often be heavier weight and the unladen ride quality. Maintenance requirements actually depend on the design of the steel spring suspension. The more complex designs may increase maintenance costs. For example, a multi-rod or six-rod type of suspension will require substantially more maintenance due to the fact that they have more bushings and end rod connections, as well as leaf springs.

Three major drawbacks with steel spring suspensions include breakage, deflection change and weight. ET

Advance Metalworking Lo Riser Inclining Platform Trailer

The Lo Riser uses hydraulics to lower the deck to ground height to provide easy drive-on access.

•6,000-, 10,000-, 12,000-, 14,000- and 16,000-lb. load capacities in two-wheel or four-wheel configurations •High strength low alloy steel construction •Minimum 4° angle when lowered •Includes six D-ring tie-downs and built-in tie-down rails •Breakaway kit with chains, a load check safety system and electric brakes on both axles provide added security •Combination of hydraulics over rubber suspension provides smooth travel even when empty www.forconstructionpros.com/21533587

Stellar SI-30/40 Cable Hoist

The SI-30/40 can handle containers ranging from 18 to 22 ft. and has a lifting capacity of either 30,000 or 40,000 lbs. based on a single-axle or tandem-axle chassis.

•Counterbalance valves prevent cylinder movement in case of pressure loss •Enclosed reeving cylinder decreases exposure to damaging debris •Dump cylinder mounted above and outside of frame rails for easier access and stability when dumping •Includes bronze bushings in rollers and sheave for reduced friction operation •All models include hydraulic gear pumps, zinc-plated pins, improved cable routing and decreased shipping weight www.forconstructionpros.com/21563135

Felling Enhanced EZ-Tilt Fender Design

The enhanced fender design for the EZ-Tilt ground-level loading trailers opens from the top to allow clearance for the wheels when the trailer is lowered to the loading position.

•Wheels/tires lift top of fender as axles rotate and lower bed to the ground •Lid/top attached to fender body using a series of hinges, concealed and protected inside fender to maintain a sleek profile •Dual Spring Action aids in closing fender when returning to transport position and holds lid/top closed during transit •Shock-absorbing rubber bumpers cushion lid/top and reduce vibration during use •Main body constructed of heavy gauge material for structural integrity www.forconstructionpros.com/21563105

Peterbilt Model 537 and Model 548 Class 7/8 Trucks

The Model 537 and Model 548 are built upon a customizable chassis and multiplex electrical architecture and deliver seamless body builder integration.

•Available with vocational three-piece Metton hood with stationary grille and full through rail or a three-piece SMC aero hood for maximum visibility •Utilize a variety of vocational and FEPTO bumpers to fit different applications •Wide or standard track axles feature optimal wheel cut angles for a shorter turning radius •Mono-leaf or taper-leaf front springs rated from 8,000 up to 20,000 lbs. •Rear suspension available with a taper-leaf or air leaf suspension rated from 12,500 to 40,000 lbs. depending on a single or tandem drive configuration •AWD option features an offset bowl design for the lowest possible cab height www.forconstructionpros.com/21563513

Miller Electric EnPak A60

The redesigned EnPak A60 power system features Advanced Auto-Speed technology, which automatically adjusts engine speed to match compressed air, battery charge and weld demands.

•Integrated multi-process welding provides up to 325 amps at 100% duty cycle •Available integrated hydraulic pump offers up to 16-gpm hydraulic output •Rotary screw air compressor delivers 60 cfm of uninterrupted airflow •Provides up to 150 amps of DC power for 12/24-volt battery charging and up to 300 amps for crank assist •7,500-watt generator delivers continuous 120/240-volt, 60-Hz power •Includes Auto Start/Stop, Power Priority and Chassis Power features www.forconstructionpros.com/21563121

— Sami Atiya

ROBOTICS Offer Potential to Improve Productivity, EFFICIENCY AND SAFETY

Robotics and automation will increasingly be used to address the skills shortage and improve safety on jobsites.

Shown is a mesh mold and in situ fabricator at ETH Zurich.

In a global survey of 1,900 large and small construction businesses in the U.S., Europe and China, commissioned by ABB Robotics (ABB), 91% of respondents said they will face a skills crisis over the next 10 years, with 44% indicating they currently struggle to recruit for construction jobs. Although only 55% of companies in construction say they currently use robots — compared with 84% in automotive and 79% in manufacturing — 81% indicated they plan to introduce or increase the use of robotics and automation over the next decade.

“With so few construction businesses using automation today, there’s huge potential for us to transform the industry through robotics,” says Sami Atiya, president of ABB’s Robotics & Discrete Automation Business Area. “Unlike building cars or assembling electronics, many techniques used in construction haven’t changed for generations, so we are developing new solutions to address key industry challenges.”

Forecasts for the total value of the global construction industry predict it will rise by 85% over the next decade to $15.5 trillion by 2030. ABB’s internal analysis of the market potential for robotic automation in the industry is for high doubledigit growth in key sectors of construction, including prefabrication and 3D printing.

ABB believes robotic automation offers potential to enhance productivity, efficiency and manufacturing flexibility throughout the industry, including automating the fabrication of modular homes and building components off site; robotic welding and material handling on building sites; and robot 3D printing of houses and customized structures.

The company also believes robotics will make the industry safer and more cost effective, improving sustainability and reducing environmental impact by enhancing quality and cutting waste. It’s estimated that up to a quarter of material transported to a building site leaves as waste, according to the UK Department for Environment, Food and Rural Affairs. Using automation and digital solutions, builders can design waste out at the beginning of a project through effective building design and construction processes.

ROBOTS FACILITATE A NEW APPROACH

In the U.S. alone, the Associated Builders and Contractors estimates that 430,000 more construction workers still need to be hired to

Spatial timber assemblies utilized at ETH Zurich.

BAM Weber Saint-Gobain

Shown is a 3D Printing Powerpac.

meet demand. With younger workers “put off construction careers by perceptions that it is a dangerous occupation,” the industry labor shortage will continue to be a growing issue on a global basis, ABB forecasts. So, it’s not surprising that 42% of survey respondents ranked improving worker health and safety on building sites as a priority.

The International Labor Organization reports construction workers account for around 30% of workplace injuries and are up to four times more likely to be involved in a fatal accident compared to other industry sectors — with an estimated 108,000 fatalities globally each year.

ABB believes robots can make construction safer by: ˜ handling large and heavy loads ˜ working in unsafe spaces ˜ enabling new, safer methods of construction

It argues that the use of robots for repetitive and dangerous tasks means automation can help support the industry’s labor and skills crisis and make construction careers more appealing to young people.

“A new focus on health, safety and sustainability are catalysts for investment in robotics, while the shrinking pool of skilled labor means the construction industry needs robots to help keep pace with the challenges of urbanization and climate change,” Atiya asserts.

Companies such as ABB can provide automation solutions for faster, more affordable and sustainable construction, while helping to address the industry’s labor shortage.

AUTOMATION ALREADY IN USE

Pilot projects are taking place with automation solutions in various parts of the globe. For example: ˜ the automated fabrication of timber roof supports with Autovol in the U.S. ˜ the robotic installation of elevators with

Schindler Lifts ˜ the robotic automation of Intelligent

City’s production of prefabricated modular homes, which has increased production efficiency by 15% and speed by 38% and reduced waste by 30%

In addition, Skanska Construction’s robot welding application has improved quality, employee productivity and safety by automating the fabrication of steel reinforcement baskets on site, ABB notes. It has also reduced the cost and environmental impact of transporting bulky finished reinforcement baskets to building sites.

“It is increasingly challenging to find people to carry out difficult, time-consuming tasks, which means we must look further afield to find the workers we need,” says Ulf Håkansson, technical director, Skanska Construction. “Allocating these tasks to robots can address this, enabling us to deploy our workers more effectively.

“Automation also suits the experience and imagination of the next generation of engineers, who have grown up with technology and will be invaluable in helping us find new ways to use robots in our business,” he adds. ET

Information provided by ABB Robotics and edited/enhanced by Becky Schultz.

LIFTING SOL UTIONS

SMARTER. BIGGER. STRONGER.

THE NO-WORST-CASE POSITION LIFTING POINT

RUD ACP-TURNADO

NOW IN M36 AND M42 AS WELL AS 1½” + 1¾” FOR LIFTING HEAVIER LOADS.

All images courtesy of Sena Industrial

Bluetooth headsets, such as those using Sena’s proprietary Mesh Intercom protocol, allow hands-free communication across a worksite.

MESH Communication Takes on Radios for Connecting Jobsites

Compare radios vs. new communication headsets and the implications for worker safety and productivity.

Aconstruction site has many moving parts, with active heavy equipment and work vehicles coming and going. Workers want to know that they are heard, seen and safe. This is why worksite communication plays a vital role in worker safety.

Unfortunately, communication between workers is made difficult by the distances involved and a noisy environment. Workers often resort to communicating with a crane operator or backhoe operator via hand signals.

Typically, work crews communicate with operators, drivers and other workers using two-way radios. However, construction company managers are discovering an alternative technology based on long-range Bluetooth signals. This article compares the use of radios with new communication headsets, such as those using Mesh Bluetooth technology, and the implications for worker safety and productivity.

DISTANCE MATTERS — AND SO DOES CHATTER

communication technology, managers should consider range, clarity, worker safety, OSHA compliance and cost.

A jobsite may be miles long. While radios work well over these distances, Bluetooth communications are limited to about half a mile. Mesh Bluetooth technology, on the other hand, enables each headset

Mesh headsets can be worn over the head or attached to hard hats/helmets. New helmets, like this one from Jannatec, have integrated Sena Mesh communication headsets.

to act as a node, relaying the signal to the next headset and extending the range. Mesh network adapters can act as repeaters, extending the range further, and connect to mobile phones beyond the worksite. If a driver leaves the coverage area, the headset will automatically reconnect when the driver re-enters.

While good over distances, two-way radios use air time in a radio frequency band that it is a public band shared with other users. It’s not uncommon to experience cross talk from people outside the team. To avoid hearing the chatter of other users, workers try switching to different channels.

Mesh headsets use a higher frequency band of around 2.4 GHz. While this band is shared with Bluetooth-enabled devices, its use is unlikely to encounter outside chatter. In any case, Mesh technology allows multiple channels of communication, including the ability to set up multiple groups within the network. Workers can have private conversations.

WE KEEP AMERICA

ON TRACK

COME SEE US AT THE UTILITY EXPO! BOOTH E1027

800-365-7260 | morookacarriers.com

Radios are also half-duplex, which means only one person can talk at a time after pushing a button. Sometimes, this can lead to understanding only half of what has been said. A Mesh headset is fullduplex, allowing multiple people to speak at the same time, similar to a phone call. No button pushing is required.

This brings up a safety issue. When traffic is passing at 60 mph, seconds count. The time it takes to push a button on a radio could take too long to warn a coworker. Using a Mesh system, there is no delay. What’s more, workers can continue to use both hands, which is another safety consideration.

CANCEL THE NOISE

Noise is another factor to consider. Communication is hampered by the noise from construction equipment and trucks, and by the sound of passing traffic. Mesh communication headsets offer high-definition sound and noise cancelling, improving the ability of workers to quickly and clearly understand each other.

In addition, earmuff-style headsets are available that provide worker hearing protection. The clamor of concrete saws and jackhammers can be mitigated by 20 to 26 dB at the same time communication is enabled. OSHA guidelines require employers to provide hearing protection for workers exposed to 85 dB over an eighthour workday (or 8-hour weighted time average). Headsets with integrated hearing protection enable companies to be in compliance.

Worker adoption of PPE is an age-old problem. The boss may hand out hearing protection equipment, but it is up to the worker to use it. If workers like using communication headsets, it is more likely they will get the accompanying hearing protection — but even that may not assure adoption.

New safety helmets are emerging that have integrated Mesh communication headsets. Workers don’t have to install the headset on their hard helmets, and there is only one piece of equipment to remember to bring to the jobsite.

COST CONTROL

A final consideration is cost. A construction company must pay for radio air time and sometimes doesn’t want to pay for multiple channels. Instead, managers give workers walkie-talkies purchased at a sporting goods store. These may save money, but they have limited range and quality.

Communications technology impacts cost, safety and productivity. Two-way radios definitely have advantages in terms of range and familiarity. Nevertheless, construction managers are considering alternative technology for connecting the jobsite. ET

ISOtunes LINK Bluetooth Earmuff

The LINK Bluetooth earmuff with SafeMax Technology is suited for the worker who prefers over-ear hearing protection but doesn’t want to compromise their listening experience.

•Reduces damaging noise by 24 dB •Noise-isolating microphone blocks out steady-state noise for clear calls in loud environments •Limits the volume to 85 dB and offers a noise reduction rating between 22 and 29 dB for OSHA and NIOSH compliance •Lightweight and comfortable with a 14+ hour battery life www.forconstructionpros.com/21378144

Iron Capital Rental Purchase Option

Machinery and equipment capital provider Iron Capital offers a Rental Purchase Option (RPO) for contractors needing used heavy equipment, filling a gap between rental and new or used purchase alternatives.

•Fills a need for short-term contracts •Credits a significant portion of the rental payments back to the purchase •Helps eliminate the uncertainty of taking on debt ahead of recurring contracts www.forconstructionpros.com/21563355

The Fleetwatcher Materials Management Solution is a wireless telematics system for paving contractors that uses load cycle analysis to allow users to see where problems are occurring and correct them in real time.

•Enables users to identify traffic problems in real time and reroute trucks on the fly •E-ticketing modules eliminate points of contact •Transponders can be hardwired into trucks or installed via cigarette lighter adapter •Mobile app accessible via cell phone or tablet •Integrates with popular accounting and payroll applications and scale systems www.forconstructionpros.com/12294134

Soil Connect eRegulatory Module

Available through the Soil Connect digital marketplace, the eRegulatory module automatically captures and saves essential truck, load and route data, allowing users to easily share with regulatory bodies and other stakeholders.

•Includes documentation settings for clean fill and contaminated dirt •Turn-by-turn GPS tracking provides an end-to-end record of the truck and material route •Enables contactless e-signatures •Digital database for all manifests provides a record of all routes and deliveries in one place •Information can be easily shared with local regulatory bodies as a standard PDF www.forconstructionpros.com/21521485

HeadLight Photo-based Inspection Technology

Designed for infrastructure construction professionals, this photo-based inspection technology allows construction teams to capture, share and act on data from the jobsite in real time.

•Provides a total and accurate picture of progress •Monitor what’s happening as it occurs to ensure the highest quality of work, even when working remotely •Easy to use user interface and proven deployment process •Virtual and in-the-field training programs available www.forconstructionpros.com/21319313

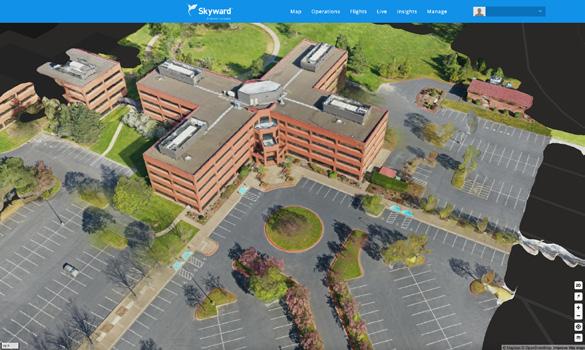

Skyward Mapping & Modeling with Pix4D

Skyward Mapping & Modeling, powered by Pix4D, enables customers to create, view, measure and export 2D orthomosaic maps and 3D photogrammetric models right from the web app.

•Plan flights, receive approval to fly in controlled airspace with LAANC, fly with the InFlight ground control station and process data using Pix4D from within the Skyward platform •Offers access to business-ready data sets through a seamless plan, fly, process workflow www.forconstructionpros.com/21563134

John Deere Slope Control for K-Series Dozers

This factory option provides an entry-level integrated grade control solution for the 450K, 550K and 650K dozers.

•Operators can view real-time cross-slope and main-fall slope percentages through the in-cab monitor •Grade to desired slopes by adjusting the blade manually or through the system’s automated control •Can be set up in Target Mode to enter a specified target slope into the monitor, or Joystick Mode so slope is maintained based on the last joystick input •Includes Flip Slope for seamless turnarounds before starting the next pass and Integrated Increment and Decrement to adjust cross slope or main-fall slope target value on the fly www.forconstructionpros.com/21563110