7 minute read

Machinery

WHY THE UK WINDOW INDUSTRY’S MOST PROLIFIC CMY BRAND IS UPDATING ITS IMAGE AND WEBSITE K

An announcement that a company is re-branding and launching a new website is hardly earth-shattering news these days, when even the humblest business requires at least a half decent digital face to present to the world. But when a firm that can claim to have its products operating in almost 100% of the potential customers in its sector, it becomes more intriguing.

This is the case with Jade Engineering, a company best known for the machine tools that it manufactures by which the vast majority of the UK’s PVC-U and aluminium windows and doors are manufactured. Jade Engineering’s products are rarely seen although frequently heard. And their brand is well known amongst their core customer base. So why bother now? The response from Sean Mackey, who with partner Adam Jones has taken Jade from back-street metal bashers to become the window and door industry’s de facto engineering partner, offers a simple explanation: “We are an engineering firm in the best traditions of good old fashioned, British metal bashers, even located in a Coventry industrial area that is peppered with references to ‘engineering’ and metals, in the facias of the firms based here,” he offered. “We have achieved success by producing precisely engineered products, consistently well and as and when required. Our tools are specified by every PVC-U systems house and used by every PVC-U fabricator in the UK, and now the vast majority of aluminium brands and frame makers too. But we also make so much more.” And thereby hangs the tale…. “Every fabricator out there knows the name ‘Jade’,” continued Sean. “But we are constantly told ‘I didn’t know you did that!’ from customers who find out about our other products and services, often by chance. So we decided to do something about it.” Paradoxically, the process of re-branding, but especially designing and populating the website, has taken a somewhat lengthy 12 months or so, largely due to the complexity of the company’s product and service offer, explains Adam Jones: “As the new website illustrates, we now define Jade Engineering as three divisions: Jade Tooling, of course; Jade Machines, which includes our single application units such as end millers, corner cleaners and so forth; and Jade Consult, which is a fast growing but otherwise relatively unknown side of what we do. Working with our designers on this project was an interesting exercise not least because we had to define what we do, how we do it, before we could advise our designers. It’s been fascinating and very useful.”

Sean Mackey Adam Jones

For Sean, who trained as an accountant and for engineer Adam, marketing issues can have the substance of mist. But both understood the need for something that communicates everything that Jade offers, especially beyond tooling: “The tools are listed of course – it remains the most significant part of our business,” explained Adam. “And whilst our range of standalone machines are very popular, many of those are unknown, such as the Reverse Butt Weld Cleaner, for example. It’s neat, automates a laborious process and stops bottlenecks. It brings the classic response: ‘I didn’t know you did that!’” The most intriguing facet of the company – and arguably that which is most difficult to communicate – is Jade Consult. Sean steps in: “This division grew from nothing. Whilst chatting with customers they might express a need for something or a problem they were trying to resolve…and we or our engineers would offer a casual solution… which the customer would immediately seize upon…and which we would then design and build for them,” said Sean. “We now design, build and implement whole production lines to order: give us objectives, a budget and we can do the rest.” Jade Consult now includes some of the industry’s most respected brands as customers. The website is able to communicate some of Jade’s success stories through case studies which themselves are illustrated with high quality video and images, in a way only a good website can. As for the new branding? “We needed some new branded shirts and just thought we were overdue for a change,’ said Adam, engineer’s pragmatism clearly never far from the surface.

WORTH WAITING FOR?

Anyone who’s had any building work done on their home or tried to order a new car over the past year or so will be very familiar with the supply chain issues which are impacting the whole of the global economy.

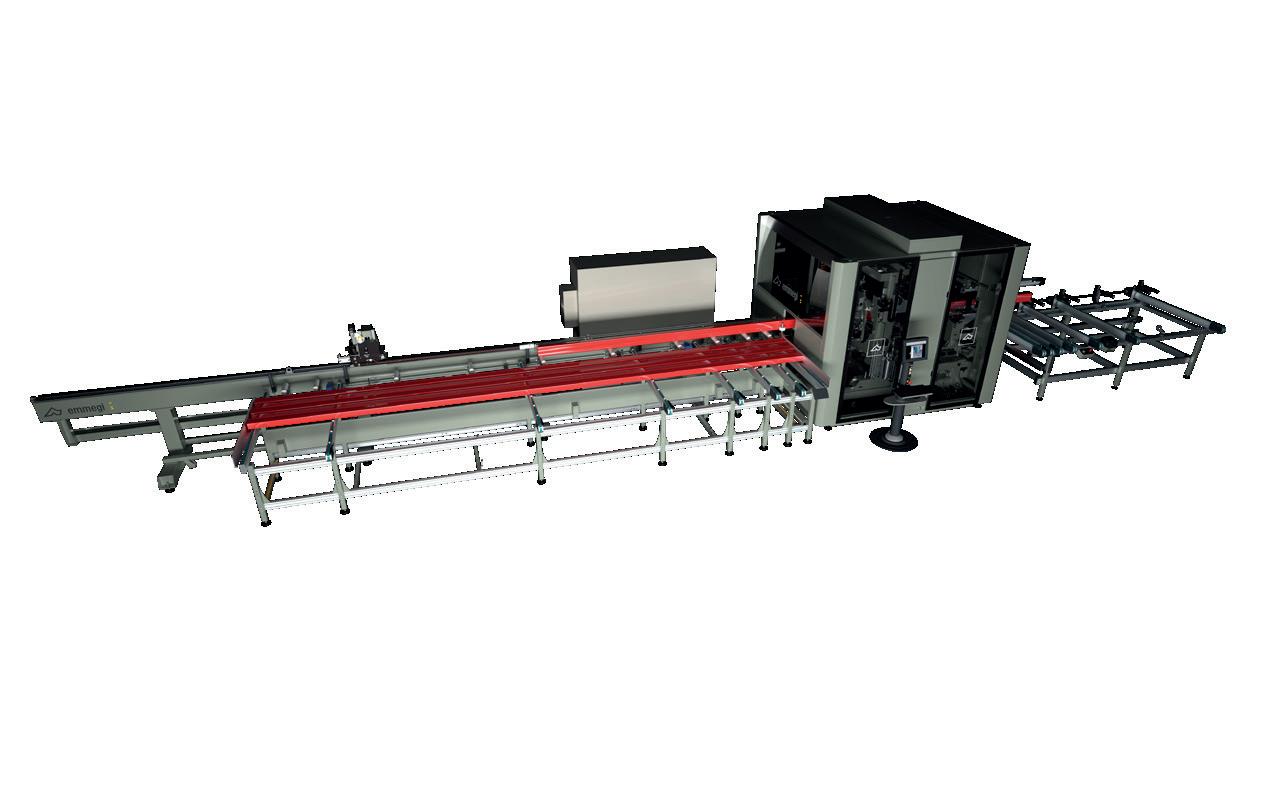

While things have improved considerably, we’re obviously continuing to face challenges in this industry – whether that’s from a shortage of components and raw materials, knock-on effects of the repeated lockdowns in China, the war in Ukraine and the sanctions on Russia, or simply insufficient capacity to respond adequately to the post-Covid bounceback. From a machinery supplier’s perspective, the issues we have faced in terms of extended lead times are similar to those in the motor industry. The surge in retail demand that we’ve experienced in the UK and the savings mountains accumulated by consumers working from home who couldn’t spend their money on holidays or entertainment have been replicated in many markets around the world, and it’s created something of a perfect storm for many global suppliers. When it comes to cars, the fact that it is the most affluent buyers who have saved the most is reflected in the fact that the longest lead times are on some of the most desirable and expensive models. Want a new BMW? According to car leasing specialists Pike and Bambridge, you’ll have to wait for nine months. A Porsche? You’ll wait between 12 and 24 months. And don’t even enquire about a new Range Rover? They are saying it’s a minimum of 2 years. We’re obviously not talking about anything like those lead times on machinery – but it’s undoubtedly the case that our most advanced and prestige models are on much longer lead times than normal. That’s why we’re doing our best at Emmegi (UK) to communicate that to fabricators up front so that they can factor it into their investment plans. If you know it will take over a year for your new Porsche to be delivered, then you’ll obviously place your order much earlier than you would have done previously – and it’s a similar situation for fabricators buying machinery from many of the suppliers into the UK, and not just Emmegi. If you are well aware that the machine you want isn’t likely to be available within just a few weeks, then as long as you place your order well in advance, you should still be able to take delivery at a time to suit you. Apparently, new vehicle stock in the UK is better on more mainstream models from the likes of Nissan and Hyundai, but I doubt there are many Porsche buyers who are going to order a Nissan just because they can get it more quickly, and I think it’s a similar situation with our machines. We don’t think fabricators want to compromise on the quality, durability, or capability of their machines for the sake of not ordering further in advance.

Everyone at Emmegi, both in the UK and at our manufacturing hub in Italy, is focused on increasing output and on bringing lead times back in line with where they were before the pandemic. We are making good progress, and, in the meantime, we are offering certain machines in the UK from stock, including our Comet X6 and Comet R6I 4 and 5 axis machining centres. Because these are stock models, they are not available with the bespoke set-ups that customers might be used to from an Emmegi machine, but they are amongst our most popular machines because they are already highly specced. Our team can obviously give advice on availability for the rest of the Emmegi range and customers can be reassured that they will be kept fully informed about the status of their orders.