13 minute read

A Window Into Aluminium

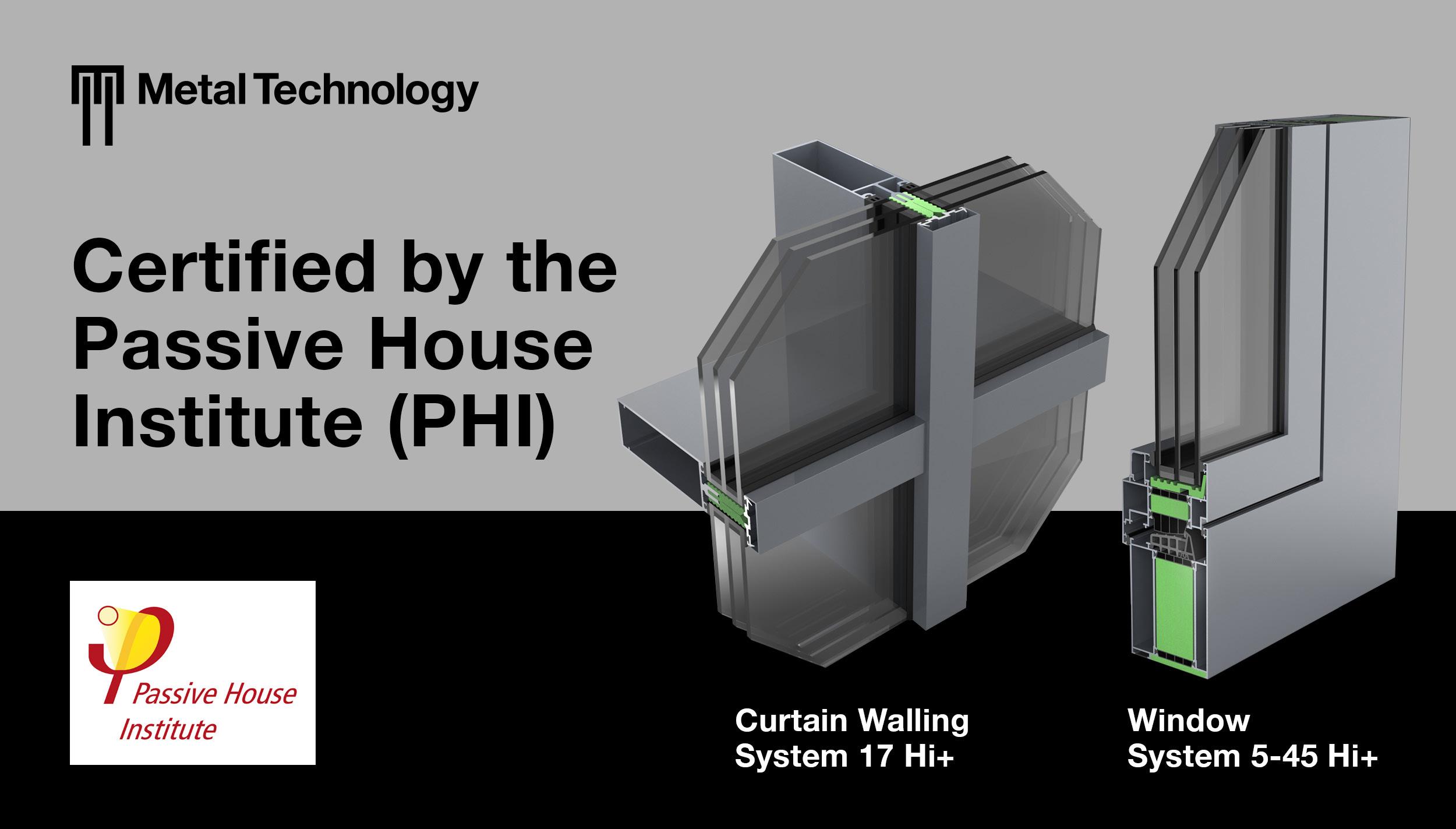

METAL TECHNOLOGY SYSTEMS ACCREDITED BY PASSIVE HOUSE INSTITUTE

Metal Technology’s System 17 Hi+ Curtain Walling and System 5-45 Hi+ Window have been certified by the Passive House Institute, recognising that our products meet the required energyefficiency criteria. Furthermore, System 17 Hi+ curtain walling has been awarded with the highest ranking of A+.

The PHI is an independent research institute that has played an especially crucial role in the development of the Passive House concept - the only internationally recognised, performance-based energy standard in construction. Following an extensive R&D and technical development process, these products can be integrated into Passive House projects, to assist in providing the overall requirement of Passive House criteria.

Metal Technology has been appointed to supply its ‘next generation’ Passive House systems for one of the world’s largest Passivhaus buildings, at 26,666m2 – St Columba’s RC High School and Woodmill High School. This is part of a 55 acre, circa £220m development for the Dunfermline Learning Campus, comprising these two high schools and a new college for Fife Council and will accommodate up to 2,700 school pupils and 2,500 college students. Metal Technology have also played an intrinsic role in the design process of Scotland’s first Passivhaus Primary School, which is being built in North Perth to replace the current North Muirton and Balhousie Primary Schools and the £29m South West College in Enniskillen - Northern Ireland’s first Passivhaus Premium Plus education facility. Metal Technology’s product system manuals and Logikal estimating and production software have been updated to allow pricing and manufacturing. Please speak to one of our sales representatives in relation to any current projects that require design or pricing assistance.

For further technical information please contact our technical department by emailing sales@metaltechnology.com or visit https://www.metaltechnology.com/passive-house/

Artist’s impression of St Columba’s RC High School + Woodmill High School - Part of the new Dunfermline Campus

South West College, Enniskillen, Northern Ireland

INTRODUCING THE NEW

Silka Super-Slim

INTRODUCING THE NEW A-Rated Aluminium

Window System Silka Super-Slim

A-Rated Aluminium The first window in the industry to have foam filled frames with Window System u-values as low as 0.94w/m2k. The fine powder texture is available The first window in the industry in dual colour and is the perfect to have foam filled frames with partner to the Silka Composite Door. u-values as low as 0.94w/m2k. The fine powder texture is available in dual colour and is the perfect To discover more call 0345 672 9333 or email sales@apeer.co.uk partner to the Silka Composite Door. apeer.co.uk

apeer.co.uk

A STELLAR CHOICE FOR PALATIAL DOMESTIC PROPERTY

Stellar aluminium windows and doors have been installed in a palatial refurbishment project in Gerrards Cross, South Buckinghamshire. The attractive five-bedroom detached property was fitted with 25 Stellar aluminium fully flush casement windows and five sets of Stellar flush doors. The products were manufactured by Epwin Window Systems’ fabricator Capital Windows of Uxbridge, Greater London and fitted by Absolute Windows in Buckinghamshire.

The stand-out residential home is set in a desirable location and exacting standards were needed throughout the whole renovation, including the choice of windows and doors. Stellar was selected due to the system’s high-end flush aesthetics which were important to the homeowner. Richard Embleton, Owner of Absolute Windows, explains: “The homeowner was looking to refurbish their property with products that aesthetically replicated the original timber window and doors that were previously fitted. Stellar’s flush detailing on both the internal and external faces delivers the sympathetic aesthetics this project demanded and was the perfect product solution for this high-end job.” He added: “The windows and doors were manufactured with a black external face to replicate the traditional charm with a

clean white internal face to complement the interior decor. The use of leaded lights to the glass units also helped to replicate the original window and door features.” The project also included the manufacture and installation of a 4.2 metre high, three section bay window to the front aspect of the property. Richard said: “The large-scale bay window is a dramatic focal point on the house and the slim sightlines of Stellar were perfect to maximise this large, light filled space.” The multi-award-winning Stellar aluminium window and door system was purposely designed to give the domestic market the best in cutting-edge aluminium windows and doors. Neil Smith, Head of Sales (Aluminium) at Epwin Window Systems, said: “Stellar’s flush aesthetics on the internal and external faces are unique to the aluminium market and present a visible point of difference especially within the domestic sector. As this project confirms, Stellar offers the credentials that give consumers the aesthetic differentiation they are looking for especially as the market continues to shift towards higher value, traditional flush products. In Stellar you have a range of aluminium windows and doors that gives installers an opportunity to secure business at the highest level.” Buckingham-based Absolute Windows has been fitting Stellar aluminium products since the system came to market in 2019. Richard concluded: “We work closely with Capital Windows as their product quality and attention to detail is excellent. Stellar is an easy product to install but most importantly, its unique flush aesthetics are next-level and never fail to impress the homeowner.”

EPWIN WINDOW SYSTEMS EXTENDS ITS STELLAR ALUMINIUM PAINT PLANT

Epwin Window Systems has just completed a sixteenweek, six-figure investment in an extension to its Stellar aluminium powder coating plant. Phil Parry, Business Development Director at Epwin Window Systems, said: “This new extension increases our powder coating footprint by 40% and allows us to keep pace with growing demand. It’s a powerful reflection of the way the industry has embraced what our Stellar Aluminium Window and Door System has to offer.”

The meticulously planned build was phased over a sixteen-week period with no impact on production output or supply. The new extension maintains the exacting quality and state-of-the-art standards for which Stellar is known.

Martin Westwood, Production Manager at Epwin Window Systems, said: “The emphasis we place on quality was always evident in our facilities and was central to us achieving our QUALICOAT licence. Our commitment to quality has continued in this new extension.”

The new powder coating line is a continuous looped track system that delivers a high level of consistency through the powder booth and oven. When combined with the improvements to the pre-treatment seven-stage bath/tank system, Epwin Window Systems has significantly reduced scrap levels, while maintaining the same high standards throughout the process. Martin commented: “As an example of the consistency of the operation, we recently ran 700 Stellar parts through the system with zero scrap, which is great from an environmental and a waste management perspective.” The extension to the powder coating facility reflects Stellar’s increasing popularity. Aluminium systems are increasingly popular in domestic projects and Stellar was designed to give fabricators and installers a competitive edge by setting a new standard for the sector.

It offers outstanding aesthetics thanks to its slim sightlines. It is also the only system on the market to offer a genuinely fully flush option thanks to the patented reverse butt joint that means there is no need to use dummy sashes or reverse rebate adaptors. As well as state-of-the-art production facilities, every component is also visually inspected at a distance of one metre rather than the industry standard three metres. This ensures the level of quality today’s consumers expect. Phil concluded: “Epwin Window Systems is committed to continuous investment in its plant and processes to ensure we deliver the excellence our customers have the right to expect. This investment in our Stellar Aluminium powder coating plant is the perfect example of this commitment in action.”

Tel: 0845 340 3968 www.epwinwindowsystems.co.uk

EPWIN WINDOW SYSTEMS ACHIEVES QUALICOAT STANDARD

Epwin Window Systems has announced it has received its QUALICOAT licence, which means all its Stellar aluminium products are now QUALICOAT-approved. Martin Westwood, Production Manager at Epwin Window Systems, said: “We are delighted to become a QUALICOATlicenced powder coat applicator. We have always adhered to the QUALICOAT specification because it ensures the high level of quality we deliver with Stellar, but having the official seal of approval was always very important.”

Angus Mackie, Chair of QUALICOAT UK and Ireland, commented: “We warmly welcome Epwin Window Systems into membership of the Association. Gaining a QUALICOAT license show a real commitment to powder coating to its highest quality and ensuring that the most up to date coating technology is followed.” Fewer than 25 businesses are QUALICOATlicenced, which reflects the demanding nature of the specification. It is more wide-ranging than BS EN 12206 (coating of aluminium and aluminium alloys for architectural purposes) and requires twice yearly, unannounced, third party accreditation visits. Martin commented: “I am very proud of the hard work our team puts in every day to ensure that we meet the exacting QUALICOAT requirements.” The licence process took around 18 months to achieve and was delayed by the COVID pandemic. The first audit was pre-arranged with the final unannounced audit taking place in late September, after which the team found out they had passed. Martin said: “The QUALICOAT specification is often a requirement for commercial projects and it’s a specification that’s increasingly requested in the retail sector too which gives our customers a competitive edge.” The license reflects the quality of the Stellar system that is evident at every level. As well as meeting the requirements of the QUALICOAT specification, every product is visually inspected at one metre, rather than the industry standard of three metres. Martin said: “Stellar was always designed to be second to none, which means there’s no room for compromise. Excellence comes as standard.”

Stellar has set a new benchmark for aluminium systems. It offers exceptionally slim sightlines and is unique in the industry for having a reverse butt joint that delivers true flush lines inside and out – and means it is as easy to fit as PVC-U. In achieving the QUALICOAT licence, it’s continuing to set itself apart as the aluminium window and door system of choice. Tel: 0845 340 3968 www.epwinwindowsystems.co.uk

INVESTMENT AT FENTRADE SUPPORTS CONTINUED GROWTH

Aluminium fabricator Fentrade has recently invested in new manufacturing machinery to support its continued growth. Chris Reeks, Fentrade’s Director, said: “The new machinery enhances quality and production flow across the board. It also means we can cut a wider variety of shaped profiles, which will help support the growth we’re experiencing in shaped gable frames on residential extensions.”

The company has taken delivery of an Elumatec TS161/21 Table Saw, complete with roller conveyors. It has also added another bead station, which will support fabrication of the newly introduced Reynaers CP130 sliding patio range and the Jack Aluminium SD70 Heritage Door.

The investment in new machinery is being coupled with new staff to help handle the increased demand. Three new fabricators have been taken on in the factory and a part time support role has been created in the office.

Chris said: “Our success has been built on exceptional products backed up with attentive service on reliable turnaround times. These latest investments will enable us to continue to meet these demanding standards, even as we continue to grow.” Fentrade is a young company but one that’s growing fast. This latest investment follows a doubling of manufacturing capacity last year, plus investment in state-of-theart fenestration software.

The company is based in Newport, Wales, and works with trade and retail customers throughout Wales and the West and along the M4, M5 and M6 corridors. It partners with renowned industry brands such as AluK and VBH Greenteq and manufactures a full range of aluminium windows, doors, bifolds, inline sliders, GFT commercial screens, shopfronts and curtain walling products. The product range is supported by a commitment to returning quotations within 24 hours, offering superb attention to detail and ensuring reliable on time, in full deliveries direct to its customers. As Fentrade’s investment shows, it’s an offer that’s proving increasingly popular. Tel: 01633 547787 fentradealuminium.co.uk

FREE TRAINING OFFER FROM EMMEGI (UK)

Emmegi (UK) says user error is now the biggest single cause of machinery breakdowns, with lots of avoidable problems stemming directly from poorly trained operators.

In response, the Coventry-based aluminium machinery specialist is offering a day’s free onsite training for any customer who takes out a new Emmegi service contract. Operations Manager Wayne Hunter explained the motivation behind the offer: “Component failure on a CNC or saw is actually very rare if the machine is consistently operated in line with our training guide. That means always running it at correct speeds, always keeping the cutters sharpened and making sure you avoid collisions which can cause hidden damage. “We see some fantastic examples of customers who have kept their machines running reliably for many years and crucially at optimum performance levels - simply by making sure everyone who operates the machine has been properly trained. “The investment these companies make in training pays for itself just in terms of avoiding breakdowns, but it also means they make the most of their machine’s features and capabilities – and get lots of valuable advice and tips from our experts. “Unfortunately, the trap that too many companies fall into is allowing operators to train each other, which means things are inevitably missed and bad habits get passed on. “We provide operator training as standard when a new machine is installed, but if the product portfolio changes or a new operator takes over, then we always recommend that customers call us to arrange an additional training session as soon as possible. When you compare the cost of that with the cost of replacing a component which has failed because the machine is operating incorrectly, then it’s a pretty simple equation.” Emmegi (UK)’s offer of a day’s free training to customers who opt for an Emmegi service contract for the first time is designed to encourage better uptake of training and demonstrate its ongoing value. The training offer is flexible so customers could, for example, choose a half day of software training and a half day of operator training if they prefer. More details on the offer and on Emmegi (UK)’s training packages are available from the team on: 02476 676192 or via: https://www.emmegi.com/en/location-worldwide/uk.

New challenges, trusted solutions

PURe® is a UK patented range of aluminium windows which features an innovative expanded polyurethane (PUR) thermal barrier to achieve ultra-low U values and outstanding thermal performance.

Window systems

An established aluminium window solution for Part L compliance

*IGU and PSI dependant. ** When calculated as a commercial CEN Standard Tilt & Turn window at 1230mm x 1480mm +25%

Windows that work for you

Our comprehensive window range is suitable for a wide range of projects. Combining sleek and stylish frames with robust durability and exceptional thermal efficiency, our aluminium windows can be powder-coated in a choice of colours and finishes, and are fully compatible with our high-performance aluminium door and curtain wall solutions.

Find out more:

See the complete range at: