57 minute read

Swisslog Middle East

In the forefront of equipping and energizing logistics automation and materials handling

Swisslog demonstrates leadership in logistic-related systems, new solutions and innovation

Swisslog’s robot-based solutions combine KUKA robots and Swisslog’s intralogistics knowhow. They are designed to reduce operational costs and improve warehouse efficiency.

Swisslog delivers datadriven and robotic solutions for logistics automation alongside reliable, modular service concepts whilst collaborating with forwardthinking companies, as a testimony of its commitment to setting new standards in warehouse automation to provide future-proof products and solutions, affirms Alain Kaddoum, General Manager, Swisslog Middle East, in an exclusive interview.

Headquartered in Buchs-Aargau, Switzerland and with a local office in Dubai, Swisslog with its strong Swiss roots and legacy, is a subsidiary of the German robots manufacturer KUKA which has a workforce of more than 14,000 people working across the globe.

Swisslog’s range of services includes consulting, concept studies, project implementation, customer service, cuttingedge technologies and software, all tailored to the specific requirements of a business. We stand for innovation, quality, industryleading software and robotics technologies developed in-house.

To obtain insights and get better acquainted on the extent and eminence of its automation products and services quality, Global Supply Chain got close up and personal with Dubai-based Alain Kaddoum, General Manager, Swisslog Middle East, for a wide-ranging interview and the lowdown on the company’s automated solutions in multiple fields related to logistics and supply chain continuum.

Global Supply Chain (GSC): Give us a sense of the size and scale of your current association with the logistics & supply chain industry in the Middle East?

Alain Kaddoum (AK): Swisslog Middle East is actively and intimately associated with several companies in the Middle East

Alain Kaddoum, General Manager, Swisslog Middle East

Swisslog’s AutoStore technology for RoboStores offers maximum storage capacity, flexibility and scalability for today’s warehouse. Aziz Al-Harbi, COO of RoboStores with Alain Kaddoum.

Accomplishments of Swisslog Middle East during the past five years back, under the stewardship of Alain Kaddoum, General Manager, Swisslog Middle East

• The footprint of Swisslog Middle East has expanded in the region. Leading the

Swisslog team in the Middle East, Kaddoum has to date signed a total of over 15 projects in the UAE, the Kingdom of Saudi

Arabia (KSA), and Kuwait with a value of over US$ 120 million. • Expanded the local business, strategically growing the team and helping more and more businesses take advantage of automated logistics • Driving thought leadership in data- and robotic-driven automation and educating the industry on benefits of future-focused solutions in logistics automation by showcasing Swisslog global solutions at key Middle East industry forums and events, participating at trade webinars in the UAE and across the region being the voice for the industry • We were awarded Frost & Sullivan Market 2019 Middle East Best Practices Award for its transformational growth and leadership across automation in warehouse management • Delivered the latest robot-based warehouse system in retail and e-commerce for Axiom

Telecom in the UAE revealing the project at

Materials Handling 2019 expo • Etisalat, the leading telecom group partnered with Swisslog for the first time at GITEX to physically display its highly efficient robot-based order processing solution ItemPiQ, designed for repeated, reliable picking of a wide range of items to fulfill fast delivery of orders at low operating costs • Swisslog is in the process of delivering a fully automated cold storage warehouse with distribution logistics for Almarai in the Middle East. Warehouse management solutions to fully automate the intralogistics systems and to address the requirements of the F&B and retail market • Swisslog was invited to showcase its latest advanced technological solutions at Dubai’s Museum of the Future preexhibition

– in the UAE and Saudi Arabia but due to confidentiality clause we will not be able to reveal further their identity or the details of the projects. The projects currently in the pipeline are E-Grocery, E-Commerce, Retail and Government sector.

In the last year, we have executed some large-scale projects in the Middle East, such as automation for Almarai and Mai Dubai and a project in the banking sector to name a few that we can talk about. Also, we have successfully delivered robot-based warehouse system in retail and e-commerce for Axiom Telecom in the UAE and installed a flexible and scalable automated warehouse management system to achieve automated fulfilment operations for Maison-B-More and RoboStores, one of the largest boutique fashion retailers based in the UAE.

Maison-B-More and RoboStores is renowned for its expertly edited fashion and stores more than 60 designer labels from across the world, including Roberto Cavalli, Just Cavalli, Dirk Bikkembergs, Philipp Plein, Iceberg, Escales Paris and many more.

To address customer demand, the luxury fashion retailer supply-chain is managed and operated by RoboStores. The company dispatches items daily with stringent cut-off times for morning and afternoon dispatches, even small inefficiency in the process can have a major impact on productivity and on the capacity of RoboStores.

Faced with limited space and increasing inventory, RoboStores needed a way to standardise its day-to-day picking across its warehouse, while ensuring high levels of security, flexibility, and efficiency.

With the complexities of the supply management chain, RoboStores needed a sophisticated automated warehouse solution to match the reputation of its brand – one that could efficiently track, stock, pick orders and increase its distribution volume and the bottom line.

Swisslog’s AutoStore technology came as an ideal solution for RoboStores. AutoStore offers maximum storage capacity, flexibility and scalability for today’s warehouse. The AutoStore warehouse solution implemented is a unique and simple solution that is composed of a structural grid, delivery robots and storage bins to quickly process small parts orders.

It provides better use of available space than any other automated system thanks to its unique design that enables direct stacking of bins on top of each other and storage of multiple SKUs in a single bin.

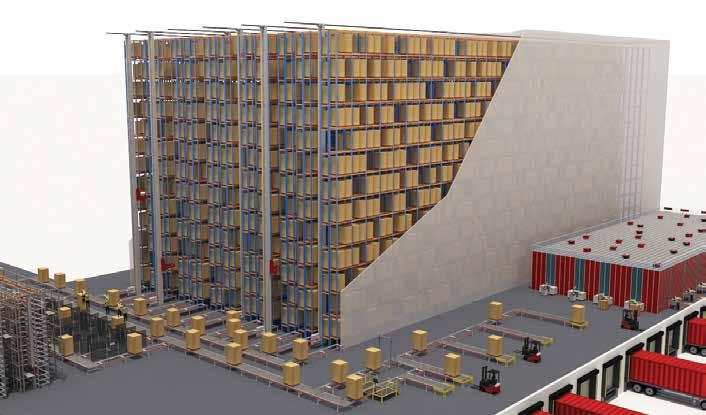

Swisslog’s PowerStore is ideal for manufacturing businesses, especially those in the fast moving consumer goods and food and beverage industries.

What is your outlook for 2021?

AK: Swisslog Middle East has been receiving a lot of enquiries from businesses on how they can integrate automation technology in their existing infrastructure in a very convenient and efficient manner - without disruption to their current business processes, to remain viable and profitable, and ultimately create the future.

These requests are mainly coming from E-grocery and E-commerce sector in the UAE, KSA and Kuwait. The team at Swisslog has been working non-stop consulting with retailers, customizing recommendations for each specific project and implementing automation systems since the pandemic began.

A modular robotic automation system can be deployed in 8 to 12 months for small to medium size solutions, delivering a fast return on investment and a longer useful life due to their ability to adapt to change; taking a modular approach to roll out automation can provide important gains earlier and ease the impact of transition – this is our main focus of support to customers now – helping them adapt and be future-ready.

The Middle East is gearing up to take advantage of digitization in a big way, and we are seeing companies in the region making real investments for real results

today. Swisslog’s aim will be to continue with its efforts to help businesses address the strong need to shape the future development of logistics automation.

The time is ripe for automation in the Middle East. Multinational companies in particular will now further improve their supply chain management and establish robust disaster management mechanisms.

GSC: What are Swisslog’s short and longterm expansion plans for the region?

AK: Swisslog will continue to demonstrate leadership in new products and innovation aimed at embedding efficiency, intelligence, and competitive advantages into warehouse logistics operations, especially for businesses that operate in retail, e-commerce, e-grocery, pharmaceutical, F&B and governmental industries.

The ease with which our solutions can be implemented without affecting the existing infrastructure is one of our major USP’s and it will definitely help us expand into various regions in the Middle East.

GSC: What are the opportunities in store and challenges confronting Swisslog in the region going forward?

AK: Covid-19 dramatically changed customer behaviour and has presented a new set of challenges for the supply chain

Using the Smart Glasses, service engineers in a centralized service center can connect with on-site engineers and perform diagnostics and troubleshooting through the eyes of the on-site personnel.

industry.

Today a lot of businesses suffer from many challenges. Rising costs, changing consumer habits, increased operating expenses, loss in sales due to limited fulfillment capabilities add greater pressure on businesses. Though many businesses understand that, not many invest in changes. Reports show that a lot of companies are still afraid of using the latest technologies in their business operations as they assume, they are too expensive but soon this perception is going to change.

A recent survey by PwC indicated CFOs across various sectors are increasingly focused on the benefits of automation within supply chain functions as they exit the initial shock period of the coronavirus pandemic and plan forward to diminish

disruption from future crises or even subsequent waves of Covid-19.

The automation market across the region is set for a paradigm shift due to digitalisation initiatives by end-user industries and the global warehouse automation market is set to grow more than 2x from 2019 to 2025, on the back of strong macro and industry growth drivers of e-commerce fulfillment and increasing warehousing labour costs.

Not surprisingly, automation is central to several GCC countries’ future development plans as the region’s logistics market is set to grow at a rate of 7.3% CAGR to a value of $66.3 billion by 2020.

GSC: How is the surge of E-commerce impacting your business?

AK: Small and big attainments in automation have made e-commerce of 2020 unrecognizable from the ecommerce of 1991. E-commerce is the fastest growing segment in the global economy. According to a recent report by Adobe Analytics, online sales this November and December are forecast to surge 33% year over year to a record US$ 189 billion.

While this means tremendous opportunity for both multi-channel retailers and pureplay e-commerce companies, competition has never been more intense. Meeting the challenges of omni-channel fulfillment operations is compounded by consumer expectations for speed, individuality and convenience, forcing retailers to rapidly adjust their supply chain concepts.

Rapid growth in e-commerce is expected to increase the demand for modern warehouses with advanced IT and digital solutions. Moreover, an increasing number of FMCGs, which are typically a significant contributor to economic growth in the region, are expected to increase the demand for modern warehouses. This is likely to transform warehousing services in the region, specifically in areas of inventory management, cargo loading, order picking and real-time monitoring of stocks.

Some of the other trends we are witnessing are robotics; focus on supply chain visibility and orchestration; and smart last-mile fulfillment. Technology will continue to be a truly disruptive force in how the modern supply chain is shaped, defined, and explored.

From basic improvements like streamlining operations and increasing

Swisslog’s WMS SynQ covers the full spectrum of your organization’s supply chain needs to optimize your warehouse operation in the era of Industry 4.0.

process efficiency to fully automating delivery trucks, technology is enabling much smarter, simpler supply chain management. In the future, companies will leverage new and innovative technologies to create a self-orchestrated supply chain and previously unimaginable efficiencies

The flexible and modular technologies and software in Swisslog’s Retail & E-Commerce portfolio are specifically designed to meet the dynamic needs of retail, e-commerce and multichannel logistics.

Retailers can increase the speed of order fulfillment, improve order accuracy and effectively manage an ever-increasing number of SKUs with Swisslog’s automated systems for e-commerce. Order fulfillment rates can be up to five times faster than manual systems.

Integrating automation technology and by using robots to pick and pack online orders, e-commerce retailers can bet lower prices and faster fulfilment, in turn result in accelerating demand for online shopping and creating meaningful opportunities to take market share from their competitors.

Swisslog wins Award for ‘Digital Transformation & Innovation Solution’

Company recognized for its SynQ Software VR Training App at Seamless Middle East 2020

Swisslog recently won the prestigious award at Seamless Middle East in the category best Digital Transformation & Innovation Solution of the Year for its SynQ Warehouse Management Software (WMS) Application: Virtual Reality Training Manager.

The announcement was done as part of 2020 Seamless Awards, which coincides with Seamless trade expo and took place virtually this year.

SynQ stands for Synchronized Intelligence and is a modular, service-oriented software platform for warehouse management and material flow orchestration. It provides precise functionality needed to optimize warehouse operations.

The Virtual Reality Training Manager has been implemented to overcome the onthe-job training required for pickers within a warehouse environment by moving the training process into a virtual world.

“Ready-to-use innovation is the backbone of our operations, and the Seamless award is a testament of our commitment to continuously innovate competitive technology to meet the demand of today’s omni-channel storage and distribution,” explained Alain Kaddoum, General Manager, Swisslog Middle East.

Picking and palletizing is one of the most time-consuming processes and accounts for up to 60% of the operational costs in warehouses and distribution centres. The Swisslog VR Training Manager application introduces a new approach to training for CarryPick solutions, which increases the efficiency of workers in warehouse picking operations.

The Swisslog Virtual Reality Training Manager provides two additional key advantages to customers who are either just starting with SynQ as their WMS solution, or for existing SynQ customers who have new or seasonal staff that need to be onboarded quickly into a live warehouse environment, a press communiqué concluded.

AK: Automation processes can be devised to tackle a lot of challenges caused by Covid-19. For example, during the pandemic the local grocery stores are witnessing rapid surge in e-grocery sales and the industry is throttled by persistent labour shortages, traditional fulfilment models, and last-mile delivery challenges. Automation can help grocers monitor the inventories in real-time and automatically notify customers once the product is back in stock.

The automated warehouse solutions and the right automation technology can help grocers move their e-grocery fulfilment beyond manual picking. Other important benefits during such challenging times is energy-saving options for businesses, smart execution of processes with higher efficiency but less spend on utilities and other crucial elements for any business.

Automation solutions for grocers can and should be customized for each business to fit their e-fulfilment strategy in the best way. When every second is valuable, such a modernization project can be actually executed on a side without disruption to the main operations, which allow business to continue its work upskilling at the same time.

Automation has proven to be a sustainable and future-focused solution and it is becoming a competitive differentiator that can help companies uplift their operations without affecting business continuity while offering the smooth and organized experience for customers.

GSC: Explain the Swisslog-KUKA association with regard to ownership and shareholding?

AK: In December 2014, KUKA, a leading global supplier in the fields of robotics, automation and systems engineering, acquired Swisslog. Since August 2015, Swisslog is operating as a separate business unit as part of the KUKA Group. KUKA Aktiengesellschaft is an international group and its shares are traded on all German Stock Exchanges.

GSC: As General Manager, what is your long-term vision for Swisslog in the region? Where do you hope to take the company hereon?

AK: My aim is to continue the efforts to help businesses address the strong need to shape the future development of logistics automation and also to strengthen further the local presence in order to meet our customer expectations and be geographically closer to them.

GSC: Briefly, what are key takeaways and broad observations of the fallout of the ongoing Covid-19 pandemic for Swisslog?

AK: With halted supply chains and blurred production timelines, the outbreak presented several challenges for companies across the globe as consumers prepared themselves for stocking up. Lack of staff due to the quarantines, isolated periods and shortage in transportation also led to serious issues that many labor-intensive companies struggled with their operations, particularly in the distribution and fulfillment centers.

The negative effect to the global flow of goods also bothered many organizations, especially industries where suppliers and distributors rely on single source markets which led to high risk of operations for them.

GSC: How is the onset of the pandemic impacting your local and regional operations?

AK: The team at Swisslog worked round the clock to support our customers as they push the limits of their supply chains to provide needed medical supplies, maintain the food supply and meet the demand for other important sectors.

Globally, over 70% of our staff is engaged in mission-critical business and are working diligently through this time of crisis, to meet the demand of our customers and our communities.

Vectura is a multitalented and energy efficient high bay warehouse pallet stacker crane used in more than 2,000 customer projects.

Autostore

We are also addressing queries from new companies on how they can integrate automation technology without disruption to their current business processes, remain viable and profitable, and get new automation systems installed and operational.

While the front-line team is supporting the customers, they are being backed by our global technical support team and supply chain. Our manufacturing sites remain open to meet the demand for new automation systems also ensuring spare parts are available when needed.

GSC: Have your priorities been rearranged and what kind of new demands / pressures are being put on your business now?

AK: Since the requests from e-Commerce and e-Grocery businesses are on the rise, we are working with a lot of companies in this sector to understand their needs and recommend solutions. At Swisslog we were able to develop off the shelf solutions that can be deployed pretty fast especially to cope with the surge of fulfillment needs during the pandemic. However, every warehouse automaton project remains unique – each system should be customized to the individual customer’s business needs and the priority of our business is to help them make the transition at the soonest possible smoothly.

GSC: How can the Logistics Services Providers such as Swisslog better contribute to ensure more streamlined and speedy transportation and availability of badly needed pharma and protective supplies?

AK: With our solutions portfolio, Swisslog is proud to offer companies with innovative data-based services to optimize their warehouse. For any business including pharma, whose number-one priority is to achieve maximum productivity with reduced costs and minimum downtime, we provide consultation and a detailed analysis with an effective throughput services strategy and recommendations to help ensure their business’s growth, profitability, and success.

The implementation and set up depends on the complexity of solutions chosen, but many can be set up within few months and, most importantly, without disruption to the current business operations.

GSC: What measures has Swisslog taken to better equip its team and maintain a safe environment for the employees?

AK: The team has been supported with protection material and is taking all the necessary precautionary measures advised by WHO and local public health authority. We are all in this together and we all have to do our part. For some, that means staying home. For us, it means keeping our customers’ supplies chains going. The world is now depending on supply chains and their supply chains depend on our technology.

Our Global Help Desk employees are working from home using VPN technology to continue to support our customers.

Rest assured, the health and safety of our customers and employees is our number one priority and hence we are committed to maintaining safe environments for each and every member on the team and for that we have numerous processes and procedures developed to ensure smooth and, most importantly, safe execution of tasks for both our staff and customers they serve.

GSC: Do you see ‘green shoots’ emerging and how is the industry adapting to the changing landscape?

AK: Swisslog has a comprehensive program called GreenLog for improving supply chain sustainability through our solutions and business practices. With GreenLog-branded products, businesses get the most energyefficient solutions for their supply chain.

Swisslog’s portfolio of data-driven, flexible and robotic material handling solutions enables increased productivity, shorter order cycle times and faster response to change. Those same qualities, supported by an engineering focus on sustainability, enable a range of environmental benefits.

Enhancing supply chain sustainability requires collaboration across the industry. We work closely with our customers throughout our solution development process and participate in various certification programs and environmental organizations. All of our facilities are ISO 9001:2015 certified and many are ISO 14001 certified. In addition, we are actively involved in EcoVadis and SEDEX.

These initiatives focus our development efforts on areas where we can have the greatest impact on our customers’ businesses and set new standards for the industry.

GSC: How important is technology in the new normal scheme of things and how is it enabling and empowering operations at Swisslog?

AK: In our opinion, businesses should invest in technology that can help them cut costs and improve their bottom line. Some businesses have limited spaces, and automated solutions can help them utilize them in the most efficient way scaling up their storage capacities, others are challenged by slow operations and number of errors, which as well can be easily solved with the engagement of advanced technologies. The technology is mature, scalable, and cost effective.

SOHAR Port and Freezone’s contribution to Oman’s GDP valued at 2.8%

Since the establishment of the Port sixteen years ago, and the establishment of the adjacent Freezone ten years ago, SOHAR has attracted a total of over OMR 10.4bn (US$ 27bn) worth of investment, valued as of mid-2020, the company indicated in a recent major report on the occasion of the Sultanate of Oman’s milestone 50th Golden Anniversary National Day (18 November 2020).

This was a positive reflection of the company’s contribution towards achieving the Sultanate’s development goals and economic diversification efforts within the industrial and logistics sectors. These sectors are considered vital for the growth of the national economy, in addition to its pioneering role in generating more local job opportunities.

Unique Competitive Advantage

SOHAR Port and Freezone key advantage is its strategic location at the heart of global trade, acting as a gateway to the main shipping routes between East and West. It facilitates quick and easy transportation of goods to serve the demands of fast-growing markets, with a consumer reach of over 2.2bn across Africa, Asia and the Middle East.

SOHAR Port is one of the few global ports equipped with natural deep-water jetties of approximately 25m in depth, capable of handling the world`s largest cargo ships of up to 362m in length and over 400,000 tonnes.

The existing road network links the Port and Freezone to neighbouring countries, including the UAE, and will soon provide direct connectivity to the Kingdom of Saudi Arabia, one of the largest markets in the GCC. SOHAR provides unequalled access to the fast diversifying economies of the

Mark Geilenkirchen, CEO of SOHAR Port

Gulf States without passing through the congested Straits of Hormuz.

The Port receives over 3,000 vessels annually and handles an estimated 1.5mn tonnes of cargo each week, with the capacity to handle more than 2mn TEUs per year.

Premier Gateway

SOHAR Port is the main gateway for import and export in the Sultanate, with over 60% of the Sultanate’s imports entering through the Port. This is in addition to over 40% and 80% of exported and re-exported goods, respectively.

The Port and Freezone play a vital role in connecting Oman to markets around the world, thus contributing to a stable supply of commodities to the local market, while providing local businesses with global outreach.

Apart from its prime location, the Port comprises of a large area of 21mn sqm, in addition to 45 million square metres of development at the Freezone, and offers the availability of renewable energy and cool water sources at competitive prices.

Clean energy

The Port management is also looking into alternative energy sources, such as green hydrogen, as part of its strategy to diversify its energy sources and reduce carbon emissions. Green hydrogen is a key component in global efforts towards renewable energy transition and is one of the alternative fuels that holds immense potential for future energy applications.

An Integrated Industrial and Logistics Hub

Both the Port and the Freezone are managed under a singular entity, making SOHAR the only complex of its kind in the region and enhancing its competitiveness in attracting foreign investments and companies in the industrial sector.

Vale Oman, a Brazilian multinational corporation engaged in metals and mining,

is a tenant of the Port and imports ore from Brazil to convert into pellets at its iron ore pelletising complex.

Industrial Clusters Structure

SOHAR Port and Freezone is structured in innovative clusters, with companies and factories distributed amongst clusters and in close proximity to each other to facilitate accessibility and flexibility of operations.

The food cluster covers an area of 400,000sqm and has its own dedicated agro bulk terminal, unique to the region, to handle bulk food commodities.

Potential Expansions and SOHAR 2040 Vision

SOHAR Port and Freezone aims to position itself as an integrated logistics hub that offers the latest global technologies, while maintaining the highest standards of sustainability for all its activities. This makes it aligned with Oman’s Vision 2040 and the Oman Logistics Strategy 2040 (SOLS 2040), which is supervised and implemented by ASYAD Group, Oman’s integrated logistics provider.

Phase 1 of the expansion was completed by the end of last year and 500,000sqm was leased out. Work is in progress on Phase 2, which will see the addition of 2mn sqm.

At SOHAR Freezone, the first phase has been developed, with over 63% of the 5mn sqm leased out and home to warehouses, office spaces, industrial and logistics service providers, as well as cold-storage solutions to serve food exporters and importers. There are currently 44 industrial projects at the Freezone, encompassing various sectors.

With Phase 2 of the expansion recently launched by the Freezone management, the area will see an additional 5mn sqm of land ready for lease. For the upcoming years,

Omar Mahmood Al Mahrizi, CEO of SOHAR Freezone and DCEO of SOHAR Port

the primary focus will be on onboarding companies within the plastic and food industries, as well as those involved in mining, iron and steel, vehicle spare parts and renewable energy projects and activities.

Contribution to the National Economy

SOHAR Port and Freezone has contributed to supporting the national economy through various means. Since its establishment, the Port and Freezone have been able to provide over 24,000 direct and indirect job opportunities. The contribution of SOHAR to the national GDP was estimated to be over 2.8%, and valued at OMR 773mn (US$ 2.008bn) in 2017, as per the latest statistics from NCSI (National Center for Statistical Information).

Mark Geilenkirchen, CEO, SOHAR Port and Omar Mahmood Al Mahrizi, CEO of SOHAR Freezone and Deputy CEO, SOHAR Port, sent messages of congratulations and commitment to growth on the occasion of the Oman National Day.

Airlines in turbulence with plunging revenues, passenger numbers and profits The Emirates Group reports H1-2020 losses, but holding up and well-insulated for the future with reserves, financials and workforce trimmings

The group is positioning itself to play a vital role in the global pandemic recovery, having established the world’s first and largest dedicated air cargo hub for Covid-19 vaccines at Dubai World Central, writes Orkun Altintas, Director Consulting-Aerospace & Defense Practice, Frost & Sullivan, Europe, Middle East, Africa and South Asia.

The Emirates Group has announced losses for the second time in its 35 year history with H1 2020 revenues plunging to US$ 3.7bn, down 74% versus last year (vly). As the biggest part of the group, Emirates Airline has seen a 75% revenue decline vly, at US$ 3.2bn.

From an operational perspective, Emirates carried only 1.5mn passengers in H1-2020, a figure it would have achieved in just over nine days of normal operations pre-Covid. As another arm of the group, dnata has not fared better with revenues down by 67% to US$ 644mn vly.

With airline groups announcing losses of similar magnitude as a result of the devastating impact Covid-19 on the global airline industry, the Emirates Group is by no means alone in announcing results of this significance. Competitors such as Air France-KLM Group and Lufthansa Group have seen revenues plummet by 73% and 76% respectively within the same period.

Chinese airlines have fared little better

Orkun Altintas

with two of the three largest carriers in China, namely Air China and China Eastern, seeing declines of 56% and 57% respectively, which can be attributed to an earlier recovery phase for the country.

Domestic services restarted in April and May showing a steady recovery in traffic levels due to not only aggressive pricing by airlines to attract customers coupled with a strong demand for domestic travel. This does not apply to Emirates as its business model is based on ‘Dubai as a destination of global connectivity’ through its hub.

Cargo revenues on upswing

A rare area of improvement that airlines have seen has been in cargo revenues, as a direct result of an increase in demand for air freight during the pandemic period. Dramatic reductions and often complete halt of passenger services has increased cargo capacity demand due to the loss of belly capacity on passenger aircraft.

This increase in demand covered not only pure freighter aircraft but interestingly in an industry first, the conversion of a large number of passenger aircraft globally to serve as temporary freighters by removal of passenger seats in the cabins.

Emirates itself has seen an increase of 106% in cargo yields, despite suffering a decline in its cargo tonnage by 35% vly. However, while vaccine centric supply chain logistics will help support this increased demand for cargo capacity, the revenue significance of air cargo is expected to reduce as passenger aircraft with suitable belly capacities return to the skies.

Despite the bleak financial results, the Emirates Group has been proactive in trying to safeguard its future. The group’s efforts have covered a range of areas from cost base reduction to operational planning to meeting existing demand while also positioning for a post-pandemic recovery.

While a return of traffic to pre-Covid levels is not expected before at least 2023, several areas of concern remain for airlines globally from which Emirates too is not immune: • Varying levels of travel restrictions, changing by country • Restrictions on passenger load factors that may be applied by relevant authorities • Speed of traffic recovery with an emphasis on higher-yielding business travel • Dependence on regional and global traffic flows • RevenueYield performance • Optimized network and fleet to meet the new market conditions

$21.7

US$ Billion $14.5 $15.9

$12.8

$10.2

-74%

$3.7 -73%

$4.3 -76%

$5.2 -75%

$3.2 -56%

$4.5

Emirates Air France KLM Group Level Lufthansa Emirates Air China

Revenues based on combined Q2 & Q3 performance of comparison airlines Emirates FY Apr-Mar, Comparison Airlines FY Jan-Dec $17.3

$9.1

-57%

$3.9 -85%

$2.6

China Lufthansa

Eastern Airline Level $7.3

-67%

$2.4

Turkish Airlines 2019-20 H1 Revenue US$ Billion

2020-21 H1 Revenue US$ Billion

Source: Various sources and Frost & Sullivan Analysis

Employee reduction of 24% to an overall count of 81,334 at group level

Conversion of B777 and A380 aircraft as temporary freighters to support its existing 11 strong dedicated B777 freighter fleet Launching the world’s first and largest dedicated air cargo hub for Covid-19 vaccines at Dubai World Central

Emirates resilience

Despite the turbulent times brought on by the pandemic, resulting in more than 40 airlines globally either suspending operations or ceasing altogether, the Emirates Group appears to be wellarmoured as covered below, to weather through the current crisis: • Remaining strong cash reserves of US$ 5.6bn, despite a reduction of US$1.4bn in

H1-2020 • A supportive ownership structure with

US$ 2bn secured as equity investment during H1-2020 • Steady recovery of operations with the airline already operating to 104 countries, albeit at lower frequency and aircraft sizes • A leaner organization with a reduced cost base

Furthermore, the group is positioning itself to play a vital role in the global pandemic recovery, having established the world’s first and largest dedicated air cargo hub for Covid-19 vaccines at Dubai World Central.

With two-thirds of the world’s population being within an eight-hour flight time from Dubai and the airline’s freighter fleet of B777 aircraft capable of carrying more than 100 tons of cargo over 10 hours of flight time, the group aims to be a critical link in the global pandemic recovery efforts.

Vaccine breakthrough

With the announcement of new vaccines by Pfizer-BioNTech and Moderna in November and other potential vaccines in development, there is hope that the first signs of recovery will be felt in 2021. This was confirmed by airline stocks rallying by 12% in expectation of stronger future bookings following the announcement by Pfizer and BioNTech.

In the meantime, Covid-19 is leading to calls to explore more agile itinerary management for the Aviation and Tourism industries, with them asking, could this push us towards an‘Amazon model’of high adaptability, accommodating the changing choices and needs of customers and hosts, Why not?

(Report by: Orkun Altintas, Director Consulting-Aerospace & Defense Practice, Frost & Sullivan, Europe, Middle East, Africa and South Asia.)

Etihad Airways announces shakeup at top management

New streamlined structure is leaner, flatter and scalable to support organic growth as air travel resumes

Etihad recently announced a new role of Executive Director Guest Experience, organizational structure that will Brand & Marketing. position the business to deliver on its Duncan Bureau, Senior Vice President mandate in the wake of the pandemic Sales & Distribution, will also be leaving and meet the challenges of the global Etihad. Reporting directly to Al Balooki, downturn in aviation head on. Martin Drew will take on Duncan’s portfolio

The restructuring sees the airline alongside his current responsibilities as continuing its transformation into a mid- Managing Director for Cargo & Logistics. sized, full-service carrier concentrating on Following the departure of Akram its fleet of wide-body aircraft, with a leaner, Alami, Chief Transformation Officer, the flatter and scalable organizational structure Procurement and Supply Chain department that supports organic growth as the world and Transformation Office will move under returns to flying. the leadership of Adam Boukadida.

“The first stage of this is an operational Ibrahim Nassir, Chief Human Resources model change that will see us restructure & Organizational Development Officer, will our senior leadership team and our have an additional responsibility for the organization to allow us to continue Asset Management department. delivering on our mandate, ensuring long- Finally, Mutaz Saleh will be leaving term sustainability, and contributing to the his position as Chief Risk & Compliance growth and prominence of Abu Dhabi,” Officer, after which Henning zur Hausen, explained Tony Douglas, Group CEO, General Counsel, will take on additional Etihad Aviation Group. responsibility for Ethics & Compliance,

The new operational model will while Risk and Performance reporting will result in a number of changes to the move under Adam Boukadida, forming part executive leadership team to streamline of a new Corporate Strategy team. the organizational structure, a press Business Continuity will transfer communiqué indicated. . to Ahmed Al Qubaisi, Senior Vice

Robin Kamark, Chief Commercial Officer, President Government, International & has decided to leave the business, and Communications. following his departure, the business units Chief Digital Officer, Frank Meyer; Chief within Commercial will be separated and Engineering Officer, Abdul Khaliq Saeed; transferred under the joint leadership of and Chief Investments Officer, Andrew Mohammad Al Bulooki, Chief Operating Macfarlane continue in their respective Officer; Adam Boukadida, Chief Financial positions, also reporting to the Group Chief Officer, and Terry Daly, who will assume the Executive Officer.

The global pandemic is prompting companies to accelerate digital transformation to help drive economic resilience and competitive endurance, leaders from Philips, Etihad Aviation Group, and Al Dahra discussed at the recent ‘Procurement Reimagined’, an SAP SE virtual event for procurement, supply chain, and external workforce management professionals.

Etihad Aviation Group, incorporating the United Arab Emirates (UAE)’s national airline Etihad Airways, adopted SAP Ariba solutions to consolidate procurement operations in an effort to reduce negotiation cycle time, improve user experience and introduce e-invoicing with suppliers.

“The recent global pandemic accelerated execution of our digital transformation strategy to support our growth, enhance resilience in our supply networks, and advance our social and environmental agendas,” observed Cassie Mackie, Vice President of Sourcing and Procurement, Etihad Aviation Group.

“With SAP Ariba our suppliers became more equipped to use the platform. It’s a great way to ensure governance, and it enabled us to adjust to working from home from day one without impacting the business,” remarked Mohamad Saker, Chief Corporate Services, Al Dahra.

dnata rolls out just-in-time freight handling platform in Dubai

dnata has further enhanced operational efficiency by launching a smart, just-in-time freight handling platform across its Dubai operations.

A cloud-based platform, Appointment and Dock Management (ADM) ensures improved planning, efficient processing and end-to-end transparency of the entire cargo journey, delivering significant benefits for all freight forwarders. The innovative solution is provided by Siemens Logistics, a wholly owned subsidiary Siemens Digital Logistics.

ADM enables freight forwarders to book an appointment with the cargo terminal to deliver and pick up consignments. The system considers multiple parameters – such as shipment characteristics, flight details, vehicle types, and other business-relevant factors to determine the optimal slot for delivery or acceptance of goods.

A unique feature of the digital platform is its capability to intelligently predict the duration and suggest an appropriate slot based on the historical behaviour of the forwarders and the flight schedule.

Speedy processing

ADM has reduced the average freight handling time at dnata’s cargo terminals by more than 60 percent to an average of 30 minutes, meeting the industry’s needs for planning and transparency to avoid costly idle time for carriers, freight forwarders and terminal operators.

Furthermore, the platform allows terminal operators to see demand in real-time, enabling them to plan the required resources and serve customers just in time.

“ADM is a crucial element in our digital transformation programme. It seamlessly integrates into Calogi, our existing trading platform for the air cargo community, which connects over 800 supply chain partners with 2000 users,” remarked Bernd Struck, Senior Vice President, UAE Cargo and DWC Airline Services, dnata.

“We offer innovative applications for increasing efficiency in freight and cargo process management. Our new platform in Dubai has improved our customer’s business processes,” commented Michael Reichle, CEO of Siemens Logistics.

As one of the world’s leading cargo service providers, dnata handles 700,000 metric tons of cargo per year at the two Dubai airport airports, Dubai International (DXB) and Dubai World Central (DWC). The ADM integrates around 800 freight handling agents and manages already more than 600 appointments per day, whereby the system is capable of even more.

One Cargo

In addition to ADM, dnata has also launched One Cargo, an innovative cargo management system that steers all processes and manages all air cargo operations on a single technology platform. One Cargo has eliminated all redundancies and manual check sheets and simplified dnata‘s operations, significantly improving operational efficiency at both Dubai airports.

Most recently, dnata has been focussed on enhancing its pharma handling capabilities. The company has been using the latest technologies and global best practices to ensure that every pharma and vaccine shipment is handled in compliance with the highest international standards, according to a press release.

— Eugene Mayne, CEO, Tristar Group. Resilience, fortitude and foresight have been the hallmarks and defined Tristar Group’s operations under the stewardship of Eugene Mayne, Founder and Group CEO, at the helm.

The continuing Covid-19 pandemic, the company is coping with the new normal experience some segmental challenges devastating and unrelenting operational environment and staving off due to the overnight crash in oil prices and has challenged companies and challenges wrought by the pandemic that the measures adopted by governments economies, both national and global, has befallen the globe. to contain the pandemic, but we did not for their very survival in 2020. The Global Supply Chain (GSC): This year experience a material disruption to our Tristar Group, has demonstrated remarkable 2020 has been like no other—unusual, operations. buoyancy to buck the downward trend, challenging and volatile to say the least. We did see a slowdown in our crosssuccessfully navigate the turbulence that is Briefly provide us your general introductory border logistics movements due to impacting many companies and operations comment/s, observations and assessment of mandatory quarantining of drivers at and emerge strong despite the demanding the current landscape with regard to multi- border crossings; however, our fuel storage landscape. modal liquid logistics services? business was hardly impacted thanks to our

In an exclusive, expansive interview with Eugene Mayne (EM): Fortunately, we take-or-pay contract models. Global Supply Chain, Eugene Mayne, CEO, have not experienced a major setback in Our remote fuels business supports Tristar Group, spoke expansively about his 2020, despite the Covid-19 pandemic, and peacekeeping and humanitarian missions, company’s encouraging performance in a in fact, expect to end the year on a positive which have not been curtailed. There are of new post-Covid business ecosystem; how note as our business grew in 2019. We did course some limitations in the movement

of troops and flights which have resulted in the reduction of aviation fuel volumes. However, we expect aviation operations to normalise once the pandemic is under control.

On the maritime front, our business has grown, and as we expand our operations with new long-term contracts with oil majors, we expect it to grow further.

GSC: How has the Tristar Group performed to date in 2020 and how do you propose to close this year?

EM: Our greatest achievement this year is having successfully navigated our business through the pandemic without having to implement extreme measures such as laying off staff. Our resilient business model underpinned by long-term contracts with our investment grade customers has ensured that our revenue streams remained stable without the pressure of cancelled contracts or price negotiations.

We expect to close 2020 in a stable position, building on the resilience of our business model.

GSC: How have the working and professional environments changed at the Tristar Group post-Covid 19 and the new protocols in place?

EM: This year has been a challenging year for all industries, particularly with the transition to remote work. However, our company has been able to showcase a resilient business model through effective business continuity plans and due to our people-led approach to business.

We have chosen to find solutions to mitigate the negative impact of Covid-19 by staying focused on reducing service disruptions to customers rather than reducing our workforce. We have set up a Crisis Committee which meets weekly even now to review and monitor the health of our employees and potential disruptions to our services across the 21 countries we operate in.

Astute management of our business continuity plans with day to day oversight by the committee has ensured minimization of disruptions and has ensured that the arrangements for employee testing, isolation and treatments are well.

We organized Covid-19 testing for all our employees and proactively implemented several preventive measures to enable our employees to keep themselves and their families safe during these unprecedented times.

We also provided regular operational updates on emerging situation to our customers, which have been well received as it mitigates the risk of disruption to their individual supply chains.

We continue to check in on our employees, to make sure they are doing well both mentally and physically during these tough times.

GSC: What are the Group’s current and future expansion plans?

EM: For the short term, we will focus on strengthening our integrated logistics model by looking for key acquisitions in our areas of interest and ensuring our organic business continues to grow annually in double digits.

Despite the pandemic, our integrated business model is resilient as it has been built on long-term contracts. We will continue to develop and grow this model – a strategy which has worked well for us over the last 20 years.

In terms of next steps and the future, the integration of technology is very important to us and we are constantly working to find the newest technology that is both efficient and cost effective for our current and future projects.

At the moment, we are looking at Robot Processing Automation and Artificial Intelligence solutions to help with predictive maintenance and forecasting analysis which will ultimately increase performance and efficiency. We are also looking at smart ship technology to better improve operating costs on our marine assets.

Overall, we are growing in our core markets and beyond. We are operating soon our India fuel retail business which is a new market for us and look forward to exploring more opportunities there.

GSC: The Tristar Group recently launched a cryogenic liquids transportation service. How is the division doing?

EM: While our organic growth strategy is to widen our client base, we also aim to deepen our service offering in parallel, and therefore branching out into the movement of cryogenic goods by road is a natural diversification for our road transport business, as handling and movement of extremely low temperature liquids and

gases requires a high level of specialised training and safety in operations and is a good fit for our high HSE standards.

The division is doing well, and we look forward to building a GCC wide network for movement of cryogenic gases and liquids.

GSC: Bring us to current on the construction of storage tanks for JAFZA Chemical Terminal?

EM: We began construction of 10 new storage tanks for our chemical terminal in Jebel Ali Free Zone (JAFZA) in July 2019 and aim to finish the project by May 2021. We acquired this facility from one of our customers as they used to own and operate the facility.

Initially, we bought the chemical terminal from the customer in order to lease it back to them, and the next step was to expand the facility in order to leverage the storage space for other clients as well. We are currently working on increasing the capacity of the terminal from 5,000 cubic metres to 25,000 cubic metres. Next year, 75% of the facility will be completely ready to use, a great achievement for our business.

Other upgrades to the JAFZA chemical terminal that will be constructed in due course include: n A second loading gantry with 10 dedicated pipelines that can accommodate four road tankers simultaneously, n Three more new stainless-steel lines from jetty (receipt from ship) to terminal n Ten drumming lines for flammable liquids, n A nitrogen generator within the terminal n A 100-ton capacity weigh bridge and n A two-story office building with a data acquisition (PLC / SCADA) control room n Upgrading the fire-fighting and fire alarm system as per latest NFPA / UAE fire code standards

GSC: Comment on your JVs and contracts with Shell and Linde-Sigas?

EM: Earlier this year, our joint venture United Stars in Saudi Arabia signed a fiveyear contract with Linde-Sigas, a majority owned subsidiary of Linde in the Kingdom, a leading manufacturer of industrial and medical gases. This was a great partnership for us as we have a diverse portfolio of clients in Saudi Arabia with our depots in Dammam, Riyadh and Jubail.

As for our long-standing partnership with Shell, in 2018 we signed a longterm contract to charter six IMO2 25K Chemical Carrier vessels, and we recently inducted four of the six IMO2 25K chemical carrier vessels we ordered from Hyundai Mipo Dockyard, South Korea’s premier shipbuilder.

The new vessels feature Tier III engines which will reduce emissions and operate in an eco-friendly manner. We have worked with Hyundai for many years, as the we previously received six 50K DWT MR tankers from the dockyard in 2016 for US$ 200million.

GSC: How are your Duqm (Sultanate of Oman) operations faring?

EM: We first established our presence in Muscat, Oman in 2002 and we are proud to say we are now a key transporter for the major international and local oil and gas companies in the Sultanate. In January 2020 we acquired more than 11,000 square metres of logistic land in the Port of Duqm where we had constructed our 3,048-square-metre covered warehouse with a capacity of 5,000 pallet positions and an open yard for future expansion. The warehouse project will offer 3PL and 4PL services.

GSC: The comprehensive Tristar Group Sustainability Report is published annually. Briefly summarize your findings and your initiatives in conjunction with your stakeholders in this area of the 8th 2020 Edition?

EM: The 2019 Sustainability Report was developed in accordance with the globally recognized GRI standards and covers our stakeholder engagement initiatives. The report highlights our key Environmental, Social and Governance (ESG) achievements in line with the UN Sustainable Development Goals and UN Global Compact Ten Principles.

With the aim to protect environmental resources, Tristar achieved a 22% reduction in water use per employee and paper consumption. We also offset 25% of 2019 group carbon emissions using the UNFCCC program. Our JAFZA Warehouse in UAE received the prestigious US Green Building Council LEED Gold Green Building certification.

In partnership with RTA and Dubai Chamber, we conducted road safety campaigns for the community and expanded our educational initiatives. Additionally, as part of our commitment towards gender equality, we signed the UN Women’s Empowerment Principles.

I was also elected to be one of the Board members of the UN Global Compact UAE Local Network last year.

GSC: You have been known to be a strong advocate of and deeply concerned about

sound mental health among seafarers? Tell us more about this endeavor and the Group’s other CSR programmes?

EM: Tristar integrated its Corporate Governance and CSR objectives to create a broader Environmental, Social and Governance (ESG) Framework, as a holistic approach to the planning, monitoring and execution of all activities which support our Sustainability Goals.

As a responsible business operating in the logistics industry, we anchored our sustainability strategy with the adoption of the ESG framework in line with the UN Global Compact (UNGC) Ten Principles and UN Sustainable Development Goals (SDGs).

At Tristar, we have adopted several initiatives of our own to ensure the safety, and more importantly, the happiness and mental wellbeing of our crew and seafarers. When the pandemic first began, we organised three online Psychological First Aid workshops for Vessel Masters and Senior Officers, which had over 90 participants.

The workshops were conducted through video conferencing, to shed light on human behaviour, the signs and symptoms of a person struggling with mental health, and included situational role play to equip Senior Officers with the skills to best deal with these symptoms.

Last November 10, 2019, we hosted our first ever ‘Safety at Sea’ conference with the intention of drawing attention to the number of deaths due to suicides at sea in the maritime world. It was well received and attended by all our customers and other stakeholders from the industry including more than 500 seafarers who watched virtually in India and the Philippines.

We are scheduled to host our second ‘Safety at Sea’ conference this December 9 via webinar and going forward we are committed to making this an annual event.

We have also contracted the Sailors’ Society to set up a 24/7 dedicated confidential helpline for all officers, crew and their families. The services include crisis response assistance, counselling through various channels such as email, WhatsApp and other social media chat platforms, and making appointments with counsellors on behalf of the seafarer in accordance with the ports they will visit during their contract.

GSC: What are the opportunities and challenges for the Tristar Group going forward?

EM: We are excited about the future. At the moment, we operate in 21 countries and we’re looking to increase our footprint,

expanding with our existing customers while also looking for new opportunities and acquisitions.

The integration of technology is important to us and we are constantly working on finding innovations that will be efficient and cost effective for both our current and future projects; for example, Robot Processing Automation and Artificial Intelligence, in addition to smart ship technology.

Last year I participated in a panel discussion at the Future Blockchain Summit in Dubai where I discussed our digital strategy and pioneering work with Blockchain in the region and how we aim to leverage technology to provide world-class services to our customers.

We were recognized for being the first logistics company in the GCC to have a fully live Blockchain platform, which provides our customers with real-time oversight of our warehousing and transportation processes, so I can confidently say that innovation and technology will be a key area of focus for us going forward. I look forward to participating in more events in the future and establishing ourselves as a key player in the integration of technology in the logistics services industry.

We also look forward to strengthening our ESG programme and implementing sustainable practices across all our sectors. Our commitment to being a strong advocate of the United Nations Sustainable Development Goals (UN SDGs) will continue unabated as we strongly believe that as a private sector company we should lead the way for the business world to pay attention to the health and well-being of people, which will be a top priority for all of us after the pandemic.

In terms of challenges, of course the global pandemic has had an impact on oil prices and the slowdown in cross-border logistics movements due to mandatory quarantining of drivers at border crossings. However, we are hopeful by 2021 that the situation will improve, and government regulations will ease. Our priority is for everyone to stay safe and healthy, and we look forward to a safe future.

GSC: The Tristar Group recently won an award by Arabia CSR Network for its Health and Safety Programme. Expand on this recognition as also the Group’s support of the UN Sustainable Development Goals (SDGs).

EM: In October we were honoured to have been awarded by Arabia CSR Network for our Health and Safety Programme, particularly for our Safety at Sea initiatives. The health and safety of our employees is our top priority, especially now during the pandemic. Seafarers can be particularly susceptible to mental health issues, as they are often far from home, with little contact with family and friends.

Whilst we are all encouraged to talk about mental health, it seems that it is still a taboo subject amongst seafarers and as a result they are missing out on vital support and treatment at the early stages of a severe illness.

The initiatives we have put in place are small steps as part of a wider movement to address these issues and ensure adequate support is provided to our most valuable asset – our people.

I’m honoured that Tristar has been recognised for its work in this space, and I look forward to celebrating many more successes with the team in the future.

For the past nine years, we have been a signatory of the United Nations Global Compact with compliance to the Principles of Human Rights, Anti-Corruption, Labour and Environment.

One very important initiative for us, is providing access to education for all as per UN SDG No 5. We have made some progress towards this goal, particularly in Africa. Over the past few years, we have supported the funding and development of two local schools in South Sudan, to help enable access to basic education.

In 2018, we established a Computer Lab at the Gabat School in Juba, South Sudan, making it the first primary school in the country to offer computer classes. We are extremely proud of the success of this development as it has provided an

Tristar Group donates to Al Jalila Foundation to combat Covid-19

Group supports UAE Government’s medical initiatives to counter the pandemic

Tristar Group has donated AED 600,000 (US$ 166350) to support the Al Jalila Foundation’s Covid-19 research. Since 2016, Tristar has supported Al Jalila Foundation in its research efforts to bring global best practices together with regional expertise to solve the region’s biggest health challenges.

Al Jalila Foundation, part of the Mohammed Bin Rashid Al Maktoum Global Initiatives, invests in research and healthcare programmes to position Dubai at the forefront of medical innovation. To date, Al Jalila Foundation has invested more than AED 28mn in grants awarded to UAEbased researchers working in the areas of diabetes, obesity, cardiovascular diseases, cancer and mental health, and more recently, Covid-19.

“This donation towards research ties in with our efforts to support the UAE government as it marches forward in the fight against Covid-19,” affirmed Eugene Mayne, Group CEO, Tristar Group.

“Now more than ever, we are counting on scientists and doctors to come together and develop diagnostic testing and treatments to gain a better understanding of the SARS-CoV-2 biology and combat the pandemic,” observed Dr Abdulkareem Sultan Al Olama, CEO, Al Jalila Foundation.

opportunity for young children in Sudanese communities to pursue higher education and build a brighter future.

GSC: Any imminent mergers or acquisitions on the cards?

EM: All our expansion plans, whether organic or by acquisition, will have our end customers’ interests in mind.

GSC: Any plans for the Tristar Group to go public / IPO issuance?

EM: It is part of our longer-term growth strategy. We will provide updates in due course.

Join NAFL / FIATA to get connected for networking and business opportunities

Membership open for 2021

TRAINING

Most powerful network in the world for freight and logistics SCHOLARSHIPS FOR DESERVING UAE NATIONALS

Here’s why you should consider being a member: International Benefits:

+ The FIATA member certificate + Use of the Fiata logo + Entry in the FIATA members directory & networking events + Advertising in the FIATA members directory, review and information (FIATA e-Flash) + Special Rates for FIATA publication and articles + Access to secretariat›s assistance + FIATA arbitration code + Use of FIATA documents + FIATA worldwide member connectivity + Talent Connect Worldwide, E-Learning

National Benefits:

+ The NAFL member certificate + Use of the NAFL logo + Free access to networking events + Discountes rates in participating in global and regional conferences + Asssistance in case of legal advocacy + Discounts for cargo/logistic events and exhibition stands + Discount training for NAFL members + Training/Certification for regional/international courses + Insurance at discounted rates (cargo/liability/medical) + Complimentary internship, Skill upgrade and Mentoring & Innovation ideas + Discounted supplier rates for industry products

Be the Industry voice, protect yourself by STC, Insurance and maritime advice, network B2B, B2C

ACCREDITATIONS

National Association of Freight & Logistics the global voice of freight logistics FIATA LEARNING ACADEMY

Cloud WMS coupled with automation key to Warehouse Operations Optimization

Vishal Minocha, Sr. Director, WMS Product Management and Go to Market, Infor.

By adopting cloud WMS, warehouses can also improve staff efficiency and mitigate challenges around training, affirms Vishal Minocha, Sr. Director, WMS Product Management and Go to Market, Infor, the New Yorkheadquartered multi-national enterprise software company and a global leader in specialized business cloud software.

He spoke recently to Global Supply Chain in an exclusive interview.

Global Supply Chain (GSC): What are the biggest challenges in the warehousing sector amid Covid-19, and how can technology help?

Vishal Minocha (VM): Based on

Cloud WMS becomes even more powerful when combined with automation.

conversations with a lot of global warehousing customers around the world including in the Middle East, the biggest issue customers are facing with their warehouses is capacity disruption.

Major ongoing trends such as e-commerce are having a significant impact on warehouses and the way they manage their capacity, while Covid-19 has forced many warehouses to handle a sudden rise in volume and throughput for certain types of product, such as masks and medical supplies, and a decline in others.

Looking at e-commerce in more detail, in some industries it was there for a long time but that trend has accelerated, and even sectors such as grocery and packaged food – which did not have e-commerce as their normal channel – are being forced to adapt to e-commerce.

From a warehousing perspective, the way e-commerce and traditional orders are handled is completely different. E-commerce orders are typically smaller, whereas traditional store fulfillment orders are larger but less frequent.

The way warehouses process these in terms of the allocations and the picking is completely different. If a warehouse is handling both e-commerce and traditional orders from a single facility, it needs a flexible WMS system which can handle both, and we have that flexibility in our WMS.

With respect to the capacity issue, one of the major advantages of using a cloud WMS is that is allows for rapid up-scaling and downscaling of computing warehouse capacity. With cloud WMS we don’t have to go through the traditional deployment and procurement of the hardware: It is already provisioned and deployed on the cloud. This means that provisioning for a new customer takes days rather than weeks or months.

Cloud WMS becomes even more powerful when combined with automation, which allows your computing capacity to auto scale as per capacity demand, which keeps the warehouse running at an optimum level.

By adopting cloud WMS, warehouses can

also improve staff efficiency and mitigate challenges around training. If a warehouse is using traditional WMS, with various components from different vendors, it can create challenges in terms of ensuring sufficient staff are trained to use the various systems.

If someone is off sick or on leave, a warehouse can easily find itself in a situation where there is nobody on-site with the know-how to use a certain piece of software. Conversely, with an intuitive WMS, it is far easier to have a large pool of staff trained and able to use the software.

GSC: What specific requests have customers made during Covid-19?

VM: One of the main things we’re helping customers with is the ability to cope with extra volume. If they’re cloud customers we can spin off an environment quickly for them, and in 2-3 days they can have an environment up and running.

GSC: Will the pandemic speed up digital transformation? If so how?

VM: I believe it will. From the warehousing perspective we are already seeing the impact of digital transformation. It’s an enabler that benefits all areas of a business, from the operations to customer experience, and warehouses are no different. E-commerce itself is a result of digital transformation and it will keep growing at a massive rate, especially during the pandemic.

For warehouses this means increased volume, and this is likely to encourage some warehouses to look at adding some degree of automation to their warehouse to augment their workforce, helping them to perform essential jobs such as picking more efficiently.

In this industry, speed is of essence, and solutions that give you an edge are important. But warehouses must also be able to cope with black swan events such as Covid-19.

As mentioned, we are seeing disruptions in supply chains due to the pandemic and some warehouses need some level of new functionality. Tomorrow there might be another black swan event, so how do customers ensure that their warehouse management system keeps up with disruptions that might happen in the future.

The only way to keep up with all the disruption and change that is happening in warehousing is with cloud WMS. With this we provide continuous innovations every four to six weeks, which are all updated automatically. This is a big value proposition for customers.

GSC: What savings can be made by a warehouse typically?

VM: It really depends on the starting point. We have seen customers get as much as 20-30% productivity improvements by adopting cloud WMS. This is mainly due to the faster time to value because it’s much easier to deploy in the cloud with our agility and implementation methodology, as opposed to 12-18 months for implementation of tradition on-site systems involving hardware and software.

We use an agile implementation method with more of a continuous delivery type approach, so we go live in phases allowing the customer to start reaping the benefits of their investment sooner. We aim to get 60% of functionality in a matter of weeks. The next 30% is about fine-tuning, optimizing the warehouse and ensuring we are doing warehouse transactions in the optimal way.

GSC: What are some of the obstacles to customers adopting cloud?

VM: The warehousing sector was relatively late in moving to the cloud and remains at a nascent stage. One of the big reasons for this is that some warehouses are in remote locations and there was concern about the connectivity and bandwidth to public cloud providers. This was a big hindrance, but it gets better every year.

Cybersecurity was also perceived as a challenge, but with the amount of investment the public cloud providers are putting into security, and the investment we are making, it is no longer an issue to deter warehousing companies from migrating their management systems to the cloud.