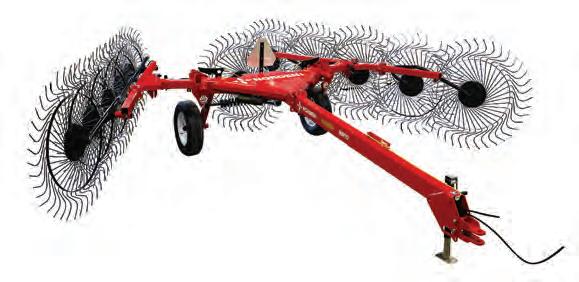

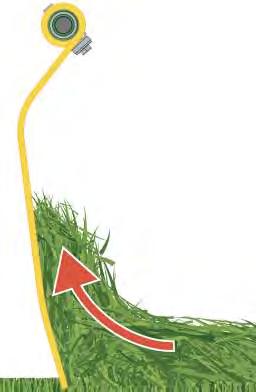

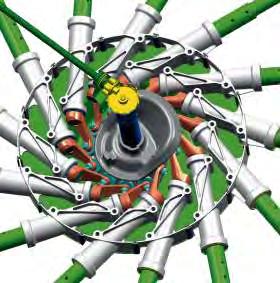

The MM 01 Series twin and triple Merge Maxx® hay mergers are unique in the industry and unmatched in their simplicity of operation, durability and merging capabilities. These machines offer pickup widths of 24’, 36’ and 42’ and complement the 30’ pickup of the existing MM 890 in our commercial merger lineup.

All KUHN’s 01 Series models now include easy to use technology and software. The IntelliMerge™ system allows an operator to run, adjust, and receive machine diagnostics and feedback on an intuitive color display. The OptiSense™ belt stall system (optional on MM 701) alerts the operator to when the belts start to slow down when approaching the capacity of the merger.

Durable, yet gentle, crop handling provided by high-capacity pickups

Multiple options to merge left, right, split or either wing raised

In the midst of acquiring ownership of a dairy farm in Claremont, N.H., Baird Swift is refining his own management style while honoring the original owner’s ideas about forage and milk production. 14

Alfalfa qualifies for conservation payments

Sixteen states have accepted alfalfa as a shortterm perennial option for NRCS conservation crop rotations.

Where is the best cow-calf country? It just might be this region where year-round grazing is often possible.

MANAGING

EDITOR Amber M. Friedrichsen

SENIOR EDITOR Michael C. Rankin

ART DIRECTOR Todd Garrett

EDITORIAL COORDINATOR Jennifer L. Yurs

ONLINE MANAGER Patti J. Hurtgen

DIRECTOR OF MARKETING John R. Mansavage

ADVERTISING SALES

Kim E. Zilverberg kzilverberg@hayandforage.com

Jenna Zilverberg jzilverberg@hayandforage.com

ADVERTISING COORDINATOR

Patti J. Kressin pkressin@hayandforage.com

W.D. HOARD & SONS

PRESIDENT Brian V. Knox

EDITORIAL OFFICE

28 Milwaukee Ave. West, Fort Atkinson, WI, 53538 WEBSITE www.hayandforage.com EMAIL info@hayandforage.com PHONE 920-563-5551

Gary Wentworth helps bale a third cutting alfalfagrass mix on Wentworth Farms near Cambridge, Minn., last summer. His son, Josh, now owns and operates the farm that produces and sells about 20,000 small square bales and 700 round bales per year. A bale bundler that trails the baler has been a game changer and also provides a unique photographer’s perch. Read more about the operation on page 24. Photo by Mike Rankin

S A naïve twentysomething getting settled in the real world, it’s hard not to compare myself to others and question if I’m doing the right things. Should I buy a house? Not with those interest rates. Should I learn a new skill? Pickleball seems to be all the rage. Should I invest in the stock market? I wouldn’t even know where to begin.

The grass isn’t always greener. Sure, I get it. It’s important to be content with what we have, and that sentiment rings truer to me every day. But I have a bone to pick with the old adage. It’s simply too passive; it’s not actionable. I think a more inspiring message would be that no matter the shade of green in our proverbial pastures, we should commit to stewarding the grass well. The grass is greener where you fertilize, if you will. By the time this magazine hits your mailbox, I will have wrapped up my winter travel to the conferences and trade shows Hay & Forage Grower regularly attends. It’s at these annual meetings that farmers have in-person access to the minds and marketing of field experts and industry people. A wealth of information is exchanged during speaker presentations and breakout sessions, as well as through conversations at trade booths and across the dinner table.

There’s a reason these meetings are often held during the colder months, especially for organizations whose membership comprises those from regions where hayfields have gone dormant and winterized equipment is parked in the shed. The winter is a slower season with more elbow room for off-farm events — bonus points if meeting venues are located in tropical climates. Even with a more flexible schedule and the incentive to sit poolside at a resort hotel, though, attending industry meetings isn’t always an easy decision.

Traveling to sometimes days-long events can be tricky for farmers, especially livestock producers who don’t have the same luxury of an offseason as their commercial hay-producing counterparts. That’s not to say the latter party kicks their feet up for a three-month vacation. Quite the opposite, as the winter is often spent selling hay, maintaining machinery, and crunching numbers for next season. But coordinating care for animals and stepping away from the herd requires another level of planning.

Farmers don’t have time for continuing education — they make time. And for that, I commend

them. They know the way to move their operations forward is to keep a thumb on the pulse of the world of agriculture. This includes staying up on advancements in equipment, technology, marketing, and policy. It means learning about new findings from research plots and assessing how updated recommendations can be applied in their own crop systems.

The relay of information from field specialists to farmers is great, but a trend I have noticed at recent symposia is a session dedicated to open discussions about current issues; an hour or so carved out of the program agenda for attendees to ask questions to the experts in the room. I would argue these conversations spark the most intriguing takeaways from an entire event. They are unique opportunities to study the gap between science and practice and troubleshoot what’s really happening on-farm.

Another type of interaction I’ve observed at these meetings is the camaraderie among farmer friends. There is a special connection between fellow members and their families who see each other but once a year, no matter the scale of an organization — regional, state, or national. The close-knit bonds are tight enough to stay tethered over decades, yet loose enough to thread new names into the fabric. As a relatively new addition on many attendee lists myself, it feels good to be invited in and accepted by a larger group.

Achieving greener grass in your own pastures can be accomplished by continuing education, accessing novel products and ideas, and establishing a network of like-minded peers. These interactions, in particular, can plant the seeds for grass of the greenest shades that grows into lifelong relationships. Day to day, farming can seem like an individual sport, but it’s important to know you have others on your team.

As for my own pursuit of greener pastures, I think I will relax into the growing season I’m in. Over time, I trust that interseeding my current stand with new knowledge, experiences, and connections will result in better yields. But for now, I’ll turn my focus away from what is growing on the other side of the fence and toward the field that I am standing in. •

by Amber Friedrichsen, Managing Editor

WHEN John and Beth Haynes bought the family dairy from his parents in 1981, they probably didn’t anticipate that four decades later a pink and orange Dunkin’ Donuts sign would be within eyeshot of the milking barn. But sure enough, there it was.

As the couple planned to retire, they wanted to ensure their farm on the outskirts of Claremont, N.H., would continue to exist instead of being swallowed up by urban sprawl. In addition to putting a conservation easement on their land to protect it from commercial development, they proactively pursued a beginning farmer to take on the dairy as a turnkey business, which is how they met Baird Swift.

At the time, Swift worked for a heifer raiser but had his eye on establishing his own farm. Upon meeting the Hayneses, Swift soon started working on the dairy and moved to the farmstead with his family shortly after. He was intrigued by the organic grazing system and no-till farming the couple had been implementing since the 1970s. By milking cows twice a day and taking on harvest responsibilities, Swift sowed

the seeds for the partnership the two parties have today.

That was five years ago, marking the start of their seven-year plan to transfer farm assets. By caring for cows and managing forage, Swift has paid for the majority of the herd and field equipment so far. In two more years, the men will begin the transfer of land ownership from the Hayneses to Swift. An incremental transition was the best way for them to minimize debt and ensure the passing of the torch was a smooth process.

As Swift acquires more authority, he has begun to button up some aspects of the operation. Managing pastures, securing more land, storing more feed,

and shifting the milking schedule has trimmed the fat of farm expenses to boost margins on the organic dairy. In every decision to do something different, though, Swift maintains the sustainable principles that Haynes Dairy Farm was founded on years ago.

The pastures at the home farm are anchored in orchardgrass and clover with some reed canarygrass and timothy. Swift recently began frost seeding clover in a few of his fields, but for the most part, the grazing acres have been intensively managed and effectively maintained for multiple decades.

“We operate on all grass, no tillage,

and with native species. I’m really not introducing anything; I’m not reinventing the wheel,” he said. “When John was in charge, he was clearing the land and improving the pastures so that all of our pastures can also be hayfields.”

An emphasis on no-till is attributed to the landscape of Swift’s eastern side of the Granite State. Tilling fields and seeding new forage would likely encourage erosion on the rolling hills and sandy loam soils.

Clearing the land, on the other hand, was a necessary step to clean up field perimeters and maximize available acreage that otherwise would have been surrounded by trees. With those improvements established, Swift can navigate fields more easily when he cuts hay. “I do take a first cutting, but the name of our game is to graze,” he said.

The grazing game, according to Swift, gets a quick start out of the gate when forage grows rapidly in the spring. He rotates cows to new paddocks several times a day to keep up with the flush of grass when the grazing season begins. Then, as the growth curve slows heading into the summer, he uses polywire fence to divide pastures into fourths and gives cows a quarter section after each milking. “When I set up the grass, I envision the cows need to eat five round bales of forage,” the dairyman said. “If I were to come mow that and rake it up, would I get five round bales? That is what I am asking myself every day.”

In the fall, slow forage growth isn’t as much of a limiting factor as freezing temperatures and snow. Swift said the first frost tends to fall around the middle of September, and by early November, underground water lines will be frozen. At that point, he relocates cows to the barn and feeds them baleage throughout the winter.

In addition to the home farm in Claremont, Swift has also formed an agreement with Carl Phitzer to make baleage on his 90 acres in Vermont. Those hayfields abut the backyards of large vacation homes in a small ski community nearly 40 miles north. Swift said he pursued this partnership on a whim. “I found it on a Craigslist ad,” he shrugged.

One downside of the deal, though, is that it takes Swift over an hour and a

half to drive to the Vermont farm, negotiating the twists and turns of the mountain roads. He originally hired a custom harvester to bale hay there, but after crunching the numbers, he determined it would be cheaper to do it himself.

Last summer, Swift squared away first cutting in Claremont and waited until the grazing season was underway before tackling hay harvest in Vermont. Then, he drove back and forth between mowing, baling, and hauling hay to the home farm one load at a time where he wrapped bales and put them into storage. It may seem like a roundabout way to secure feed supplies, but for a beginning farmer who is left to his own devices, it’s worth it.

“John and Carl have taken me under their wings, but they haven’t given me anything. I’ve had to pay my own way; I’ve had to earn it,” Swift said. “I bought all of my equipment, I bought all of John’s cows, and I have been able to acquire the land that Carl has used his whole life.”

Even though these extra acres are exclusively used for baleage now, Swift would like to work them into his grazing rotation someday. In addition to cutting equipment costs by letting cows harvest grass themselves, Swift said doing so would create another outlet for manure.

Despite a forage-centric diet, Swift does offer his 60-cow milking herd organic ground corn to incentivize their walk from the pasture to the parlor and to supplement their energy intake. At one point, he experimented with a 100% grass-fed diet, but without easy access to a target market, it wasn’t a profitable practice.

“Historically, the cows have never eaten a lot of grain, and when I bought them, I went to no grain. For two years, they just got hay,” Swift explained. “But I’m not getting a premium for grass-fed milk because that truck won’t come out here to pick me up. I’ve gone back to feeding ground corn again to make sure I’m not missing out on energy, so I’m organic, but I’m not completely grass-fed.”

The ground corn comes at a cost that Swift often contemplates and compares against the cost of feeding more hay. However, low commodity prices have kept this expense at an affordable level, and with a purchase of ground

corn, his supplier offers discounts for other ingredients he buys in bulk for weaned calves. As much as he dislikes paying a grain bill, he admits it is a good management tool.

Another tool to optimize milk production has been the introduction of Norwegian Red cows into the mostly Holstein herd. Swift said these cows maintain body condition on grass and respond to a high-forage diet better than more conventional dairy breeds. With that said, milk production in an organic system will never match that of a conventional one.

Opting for once-a-day milking when he took over the farm has also tugged on average production per cow. Even so, Swift said the decisions to let go of existing employees and establish a more simplified system were partly made for personal reasons, but also to streamline the economics of scale at the small dairy.

“I don’t like telling people what to do — the boss role just didn’t work,” Swift admitted. “When I bought the cows, there were four full-time people manag-

ing the same number of cows that I’m milking now. Granted, the milk volume was different. But I’m really pushing for simplicity with haying, with my cows, and by bringing them home once a day.”

For these reasons, he has no intention of expanding the herd, nor does he intend to diversify his operation. While many other New Hampshire farmers

tap into local markets and seek out direct-to-consumer sales, Swift prefers the routine of selling organic milk on the truck as a commodity. Even with the pink and orange Dunkin’ Donuts sign within eyeshot of his milking barn, he appreciates the freedom and privacy that the farming lifestyle has afforded him and his family. •

by Alan Franzluebbers

IS IT safe to assume that we all look forward to a bit of spring green up? While writing this story at the beginning of winter, it is difficult to know if it will be a typical winter with freezing overnight temperatures or if one of those unusually warm periods occupies some or all of January and February again this year.

In either case, spring green up gives me an opportunity to describe some peculiarities between soil organic matter and nitrogen. Soils with low soil organic matter concentration can limit the supply of nitrogen to plants. If soil is low in organic matter, then external nitrogen inputs would likely be needed from either synthetic nitrogen (like urea, urea ammonium nitrate, or ammonium sulfate) or organic nitrogen sources such as composted yard waste, poultry litter, or dairy effluent. These external nitrogen sources would be necessary to meet the high demands and ability of forages to grow rapidly when exposed to abundant sunshine and precipitation in the spring. Without sufficient nitrogen, forages may grow slowly and not accumulate much biomass. They may also lack sufficient green color, which can be indicative of protein deficiency.

In general, soils with high soil organic matter concentration can supply a robust quantity of nitrogen to forages over the course of a growing season or even on an annual basis. This statement assumes some conditions are met, though.

For nitrogen to be released from soil organic matter, soil microorganisms must be actively decomposing organic substrates. These tiny organisms that are classified as innumerous species of bacteria, fungi, archea, and actinomycetes require a microscope to be seen. They can be found in soil, on plants, and in animals all around the world, yet they are most abundant wherever organic resources are present. Although we may consider some of these organisms pests, parasites, or disease-causing (as some are), the vast majority of

soil microorganisms are beneficial, and many even directly assist plants in their development.

The conditions that favor soil microbial activity are warm temperatures and soil pores with a desirable balance of water and air. When overnight freezing temperatures give way to mid-morning warmth after some winter snow or rains have occurred the week prior, cool-season forages are activated, and so are soil microorganisms. But what if newly emerging grasses or abundant residual forage mass cover the ground completely and the warmth of the sun doesn’t penetrate into the soil? Or what if the days are sunny but the soil doesn’t break free of its frozen condition?

These early spring growing conditions can limit the activity of soil microorganisms feeding on the abundant resources of soil organic matter present in a well-managed pasture, which may give rise to the notion that all pastures need to be fertilized in the spring to make sufficient growth for grazing livestock or making hay.

Sufficient time is necessary for soil microorganisms to consume soil organic matter and excrete enough nitrogen to feed a robust stand of forage. Therefore, if time is needed, then patience will also be needed. Even more time may be needed to accumulate sufficient biomass for grazing livestock on highly enriched surface soil that is full of organic nitrogen developed from a long history of good grazing management. If you were to wait another week or two, the growing forage will almost assuredly show you that nitrogen was being released from organic matter into the plant-available inorganic forms of ammonium and nitrate that are rapidly absorbed by the actively growing roots of the forage sward.

When you don’t have the patience to wait for nature to keep its balance, applying readily available inorganic nitrogen to an emerging forage sward can jumpstart the stand and allow for

an earlier stocking time or hay cutting. Indeed, nitrogen is needed by growing forages. The issue becomes when and how much nitrogen is supplied either by nature or by you, the land manager.

To illustrate the point of nitrogen availability from soil organic matter, consider the results from a trial on a farm in Haywood County, N.C. Surface soil samples collected in September indicated about 50 pounds of inorganic nitrogen per acre and 300 pounds of potentially mineralizable nitrogen per acre with a high level of biological activity shown on the soil test.

Fall stockpiled tall fescue mixed with other cool-season forages did not produce enough additional forage with urea application at the end of summer to justify its application compared to forage with no nitrogen fertilizer. With that said, plots with urea applied did produce forage with a statistically greater crude protein (CP) concentration, which was 14.7% CP versus 13.5% CP without amendment.

When plots were harvested again six weeks later, there was an additional 1,400 pounds of forage per acre. With the original fall nitrogen application, forage yield in the second harvest was, again, not statistically different from forage yield without nitrogen applied. Crude protein was still greater with urea (21.9%) than without nitrogen applied (20.6%).

Was external nitrogen needed? If CP was the indicator, then the answer might have been yes. If forage dry matter yield was the indicator, then the answer should have been no. Relying on the supply of nitrogen from organic matter mineralization is possible. However, it might be important to know how much nitrogen can be released from soil organic matter over time and if that is within your comfort zone. •

ALAN FRANZLUEBBERS

by

MANY of us use the weather as an ice breaker to start a discussion. This is partly due to the fact that the farming community is directly impacted by when the first and last frosts will occur as well as the frequency and amount of rain that falls across the agricultural landscape.

The weather is so important to our daily lives that the national news dedicates air time to cover local weather; there are even stations that only cover weather-related stories. Technology has put up-to-date weather information in the palm of our hands through apps on our smartphones.

Much of the United States remains in the grip of dry conditions. Upon writing this column, the Drought Monitor Map released on November 27 showed 74% of the United States being listed in the abnormally dry through exceptional drought categories, with 41% of the country experiencing some degree of drought. This was similar to the fall of 2022 in which more than 75% of the United States was experiencing dry conditions. Areas most affected by low precipitation last fall were in the Upper Plains states and the Midwest. The East Coast was also shown as being very dry.

I also took a look at the precipitation data from the Kentucky Mesonet website spanning 2019 through 2023. Any weather sites with incomplete precipitation data were removed from the data set. The number of weather collection stations included in the data set ranged between 66 in 2019 to 75 for 2023.

As shown in Figure 1, average annual precipitation has declined over this five-year period. The annual precipitation received in 2023 was 16 inches less than in 2019, which is approximately a 25% reduction. This information simply illustrates annual precipitation has been less in recent years, leading to challenges in managing pastures as

these dry conditions can impact forage production and persistence.

On the other hand, temperatures seem to be climbing some, but when looking at the data, it appears to be a small

spike of around 1ºF on average. Figure 2 compares the average July temperatures for the Bluegrass State for the time frames between 1981 through 2010 and 1991 through 2020. The trend suggests slightly warmer summer temperatures. As most pastures in the area are dominated by cool-season species, though, warming during the summer months may have a greater impact on production of these forages. Combine warmer temperatures and less precipitation and one can expect changes to occur in our cool-season pastures.

For several years we have noticed common bermudagrass encroachment in the southern edge of Kentucky. This past year, I was on a few farms in southeast Kentucky where dallisgrass was found in the fields. Johnsongrass has also been a burden for our alfalfa producers, and it seems to be becoming more prevalent. Given these trends in warm-season forage growth, this past summer, Katie VanValin with the University of Kentucky and our crew looked at the issue a bit closer.

We visited seven farms across the state to collect botanical composition data. Using a grid sampling approach, we estimated botanical composition for 18 fields on these farms. Since tall fescue is the dominant forage in our pasture systems, I did a quick tally for just tall fescue. The lowest percentage of tall fescue in a field was 5%, and the highest prevalence was 94%.

Interestingly, the average percentage of tall fescue for the fields was only 62%, while the median was 76%. Clearly, we were not dealing with straight tall fescue pastures; however, it is too early to get a deeper look into this information. Intentional practices, such as interseeding clover, may have contributed to some of this difference in stand composition. However, we need to appreciate the diversity of plant species in our pasture systems and that this diversity may be changing over time. As we move forward in stewarding our grazing systems, keeping an eye on botanical composition changes will be of value. The more information we have on what species are in our pastures, the better we can manage forage production. Change is not always bad. Many of our warm-season forages are high in quality and provide growth when our

cool-season forages are not as productive. However, loss of desirable forages to unpalatable or toxic plants as a result of overgrazing during drought conditions is not ideal. Take the time to learn how to assess your pastures for cover and botanical composition. Monitor your grazing areas and note the changes that are occurring. Then develop a plan to encourage this shift

or change the course if undesirables are encroaching. Happy grazing! •

JEFF LEHMKUHLER

The author is an extension beef specialist with the University of Kentucky. 5 1/2

We run out of creek water about June 1, and Macbeth still kicked out the tons. We had to raise the swather to get through it! Of the five meadow bromes on the market, Macbeth is the only one that excels on dryland or low water. A meadow brome will always be your highest yielding grass! Macbeth will have leaves about as wide as barley.

WHEN hopping into my light duty diesel truck and heading to a meeting, I’m cognizant of the distance to empty. I tend to run hard, as many do in agriculture, leaving only a few minutes to spare in between meetings. Thus, needing 10 to 15 minutes to fuel up is not ideal, so the distance to empty (DTE) estimate is always up on my truck’s dashboard.

The DTE is determined by the amount of fuel on board and the current fuel conversion efficiency, measured in miles per gallon. The fuel conversion efficiency is akin to feed conversion efficiency in that it is affected by various factors and current conditions. For example, when driving into a strong headwind, the miles covered per gallon of fuel is dramatically reduced. Similarly, forage quality needs are greater when feeding cattle in freezing conditions.

This is the point to latch onto in this month’s column — not necessarily the energy consumed in different conditions, but an interaction between conditions and feed quality. There are many interactions between forage and grain to account for that affect feed energy value, ration performance, and feed conversion efficiency.

With dairy or beef nutrition, these interacting factors can be categorized into several areas. To break them down, consider fiber and grain particle size, nutrient content, nutrient digestibility, and feed hygienic characteristics as separate categories that interact with one another in the ration. Each of these interacting factors can be affected by seed genetics, agronomic practices, harvest management, and growing conditions. The first three of the four are under your control, and we’re going to talk more about the harvest management factor here.

Factors like growing conditions, soil fertility, and kernel processing seem to have fueled a higher feeding value for 2024 corn silage.

In a Hoard’s Dairyman Intel article titled “Grain hardness likely affects kernel processing,” we uncovered an upward trend in both new crop silage starch digestibility (Figure 1) and kernel processing scores (Figure 2). This side by side upward trend in corn silage starch digestibility and processing is notable because I think they’re tied together.

In the article, I referenced a custom harvesting operator who asked me about relationships between corn hybrid and processing several years ago. His experience suggests a strong relationship between seed genetics and harvester processing performance, not to mention diesel usage in his high-powered machine. Building upon this experience, I’m speculating the 2024 growing season likely impacted plant nitrogen use, grain development, and subsequent starch digestibility and kernel or grain processing potential.

To build the case around these interacting factors and outcomes, we should understand plant development. We’ve learned over the past decade that a protein cage in the grain endosperm surrounds the starch granules. This protein cage is called prolamin, and it’s important for grain test weight and density. Pat Hoffman taught me that more nitrogen fertilization and protein equated to harder and denser grain.

We also know that soil-applied nitrogen is mobile with water, and

in some regions, this past growing season offered plenty of rainfall to move nitrogen a bit deeper in the soil. At the same time, the excessive rainfall earlier in the year for many also equated to shallower roots in corn. I believe the outcome was less plant-available nitrogen earlier in the year and fewer plant resources to yield a strong kernel as grain development proceeded during

drier conditions.

Think of this like how a floury mutation in corn equates to a softer and more rumen digestible grain. If the grain was indeed softer, then it also stands to reason that softer grain might process differently, such as what we’re seeing play out in the Rock River Laboratory kernel processing score database.

Tying this all back together relative to the introduction of this column, think about your farm’s interacting conditions last year — growing conditions, fertility plan and management, and kernel processing — like available diesel fuel and fuel conversion efficiency. Then, consider how soil fertility, growing conditions, and harvest practices can ultimately affect silage feeding value.

The 2024 silage grain feeding value looks to be up, which will help offset lower quality fiber in silage that we’ve previously observed and discussed. Take up these talking points with your agronomist and nutritionist as you evaluate and feed out last year’s corn silage. •

JOHN GOESER

The author works for Rock River Lab Inc., the University of Wisconsin-Madison, and is a consultant with Cows Agree Consulting LLC.

Ground squirrels distracting you from your daily to-dos?

Minimize the squirrel moments with Rozol Ground Squirrel Bait.* REGISTERED FOR USE IN: CA, ID, MT, ND, NV, SD, UT, WA & WY

by Amber Friedrichsen, Managing Editor

THE National Alfalfa & Forage Alliance (NAFA) announced last month that alfalfa will now be included as a shortterm perennial option in the USDA’s Natural Resources Conservation Service (NRCS) 328 Practice for Conservation Crop Rotation.

NRCS offices in 16 states have adopted this practice and have released payment scenarios on a per-acre basis for incorporating alfalfa into conservation crop rotations. These payments range from $60.44 to $79.07, depending on the state.

According to NAFA, its representatives have been working on this process for several years and will continue to do so until all states have adopted alfalfa as a short-term perennial option in conservation crop rotations. This is a part of a larger effort to urge NRCS and Congress to incentivize alfalfa integration into NRCS programs and bring awareness of the crop’s environmental and conservation benefits.

Each of the 16 participating states have their own payment scenarios, which can be found on the NAFA website, alfalfa.org. In addition to payment

per acre, of which the full rates are listed below for each state, these documents include a detailed description of the payment scenario, a before situation, and an after situation.

Arkansas – $60.44

Connecticut – $70.39

Kansas – $65.79

Louisiana – $64.36

Maine – $67.52

Massachusetts – $74.26

Michigan – $69.31

Minnesota – $73.14

Mississippi – $63.96

Nebraska – $66.86

New Hampshire – $67.32

North Dakota – $77.47

Rhode Island – $79.07

South Dakota – $64.40

Vermont – $68.98

Wisconsin – $67.90

Before situations: All states define a before situation in which annual crops were being grown on the field with infrequent or no use of cover crops and an absence of perennial crops for at least three years. Erosion, soil quality, and pest management are listed as the primary concerns for conservation management. In Michigan, Minnesota, and Wisconsin, eligible fields must range in slope from nearly flat to C or D slopes.

After situations: These include a list of potential benefits of growing alfalfa

in conservation crop rotations for three to five years. The after situations outlined by each state vary slightly, but mainly include reducing wind and water erosion, building soil organic matter, improving soil moisture retention, and interrupting pest cycles.

Minnesota and Michigan also qualify that providing feed and forage for domestic livestock and reducing the concentration of salts and other chemicals in saline soils can be potential purposes of growing alfalfa as a short-term conservation crop.

While this information has been published by the national NRCS office, as of this writing, the scenario has yet to be offered by many offices at the local level, creating challenges for farmers looking to sign up. Those interested in planting alfalfa in conservation crop rotations should continue to follow up with their local NRCS offices and stay tuned for updated enrollment information. Moreover, if your state isn’t on the list, contact your state’s NRCS conservationist and encourage them to offer the scenario. For additional assistance, call the NAFA office at 651-484-3888. •

by Kathy Soder

ARMERS and farm consultants often seek rapid and inexpensive methods to assess the feeding value of forages in the field to make timely harvest or grazing decisions. However, current methods of forage nutritive value analyses can be expensive, time consuming, and technically difficult without sending samples to a testing lab.

Brix readings can be taken rapidly in the field using handheld refractometers and have been used anecdotally by farmers as a proxy for energy value in fresh forage, but data validating Brix as an estimation of sugar and thus energy content of forage is lacking.

Brix is a unit of measure that has been used in wine, honey, and fruit industries to estimate sugar (sucrose, fructose, or glucose) content. It has been thought that Brix could also be used to estimate the sugar content of forages; however, it was never meant for pasture forages.

The liquid extracted from fruits, such as grapes, is primarily made up of sugars, but this is not the case with forages. Plant liquid can also contain starches, free amino acids, salt, proteins, and pectins.

Brix reads all dissolved solids — not just sugars — in extracted liquids. This is why Brix is used in a number of other industries. For example, the salinity of saltwater in marine aquariums can be monitored using Brix, where there are no sugars, but plenty of salt. A little closer to our agricultural roots, Brix can be used to evaluate colostrum quality by estimating antibodies. High-quality bovine colostrum will have a similar Brix reading to high-quality wine grapes, which demonstrates how Brix can read different components of a solution.

In a solution of dissolved sucrose, a Brix value of 25% means that there are 25 grams of sucrose and 75 grams of

water in a 100-gram solution. This is a true Brix value. However, the same Brix reading in a solution extracted from grass means that there are 25 grams of soluble solids, which may include dissolved solids other than sucrose and may provide an overinflated estimation of the energy value of a forage.

Brix has been touted to provide an idea of nutrient density of a forage, given that the refractometer measures total dissolved solids and not just sugars. However, some of those dissolved solids may not be nutrients, per say, but may provide noise that inflates the reading on the refractometer.

All those other things — pectins, proteins, free amino acids, and more — in the liquid extracted from forages may give a false high Brix reading as the sugars cannot be sorted out from the

rest. The sugar content of most fruits will be six to 10 times higher than the sugar content of forages. Therefore, a Brix reading from fruit is more likely to reflect the actual sugar content of the fruit compared to forages.

Forages constantly react to the environment around them. While it is true that sugars accumulate in forages during the daylight hours due to photosynthesis and are utilized by the plants at night, the process isn’t so simple. Not all sugars accumulate in the leaves — some are stored in the stems and roots. In addition, plant maturity, plant functional group, forage species and variety, and different plant parts can affect sugar accumulation, which can also affect Brix readings.

Environmental factors can also impact plant sugars. For example, if the barometric pressure drops due to an impending storm, plants may send energy to the roots to protect themselves should there be storm damage to the leaves. If the day is cloudy, photosynthesis slows down. Moreover, most of our pastures have many different forage species in them. How will you take a forage sample for Brix testing that is representative of the mixture?

On the other hand, many factors can also impact Brix readings. Human variability is one major issue. As part of the sampling process, the plant part is prejuiced when it is rolled around in your hands. The longer the rolling time, the higher the Brix reading can climb, inflating two- to four-fold. The time between when the liquid is extracted and when the result is read on the refractometer can also alter the sugar content by over 10% due to enzymatic changes. How hard plant liquid is squeezed from forages can impact results as well.

We cannot prepare forage and take Brix readings at the exact same time. Environmental conditions can change from one field to the next — the sun may go behind a cloud and the temperature may change. Dew, soil, and other contaminants on a blade of grass can also affect the reading.

USDA Agricultural Research Service (ARS) researchers in State College, Pa., conducted a study to determine how well Brix readings correlated with actual sugar analysis in orchardgrass and alfalfa via wet chemistry. Samples of each forage were collected monthly from May to August for two years on sunny days with temperatures at 75°F to 80°F.

To minimize human error, plants were not rolled before taking a Brix reading. Plant tissue was crushed with a garlic press and read on a Brix refractometer. The remaining uncrushed forage was frozen in liquid nitrogen to stop all cellular activity and sent to a laboratory for individual sugar analyses.

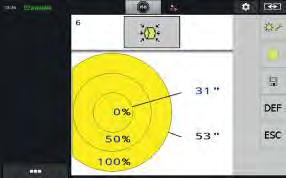

Results showed that the relationship between Brix and forage sugar content was not consistent across species or harvest (Figure 1). We analyzed total sugars as well as several of the major individual sugars, including fructose, glucose, and sucrose.

Bars above the red line in the graph show a positive correlation, which means when sugars went up, Brix readings did, too. The taller the bar, the stronger the correlation. Bars below the red line show a negative correlation, meaning when sugar content rose, Brix readings declined and predicted the opposite of actual sugar values.

Alfalfa showed moderate to strong correlations in May, June, and August. In July, there was a moderate to strong negative correlation, meaning Brix predicted the opposite of the actual forage sugar content.

Orchardgrass was a different story. Positive correlations, when present, were weak to moderate at best in May. In June and July, there were moderate to strong negative correlations, meaning that Brix predicted the opposite of what was true for total and individual sugars — if sugars were higher, the Brix reading was lower.

Taking Brix readings may seem like a practical solution to analyze forage nutritive value in the field, but the reality

is that the science does not support this premise. Even if we could control human and environmental variables that can affect Brix readings, it is still not a reliable method to estimate energy content of forages.

Laboratory forage analysis via wet chemistry or near infrared reflectance spectroscopy (NIRS) is still the gold standard for making forage decisions as they have high repeatability and fewer sources of error. The downside is that these methods take more time and have a higher cost. However, progress is being made in developing technologies that may allow real-time analyses of forages in the field, such as the portable NIRS spectrometers. Science-backed technologies such as these will provide more accurate results than unproven methods like Brix. •

Scan this QR code for more information on the research results and conclusions from the Brix and wet chemistry comparison study mentioned in the article.

KATHY SODER

Soder is a research animal scientist with the USDA Agricultural Research Service based in State College, Pa.

Contributing authors were Eric Billman, USDA-ARS research agronomist, and Jeff Horst and Kristi Balk with AgriKing Inc.

Brand

MIX 25%

“Plowdown” alfalfa with your regular alfalfa seed. Expect a hearty yield increase your “new seeding” first year!

“Plowdown” alfalfa with your regular alfalfa seed. Expect a hearty yield increase your “new seeding” first year!

“Plowdown” is #9 fall dormancy. It is supposed to winterkill, but has often been known to overwinter for a second growing season!

“Plowdown” is #9 fall dormancy. It is supposed to winterkill, but has often been known to overwinter for a second growing season!

You could plant “Plowdown” as a one year only crop. Great for a bean crop, for example, next growing season.

You could plant “Plowdown” as a one year only crop. Great for a bean crop, for example, next growing season.

G RE ENWA Y SEEDS ww w.g reenw a ysee d .co m Alan Greenway Seedsman Over 50 Years Experience! 208-250-0159 (cell) 208-454-8342 (message) “Modern Forages Sold Nationwide and Canada”

G RE ENWA Y SEEDS ww w.g reenw a ysee d .co m

by Jimmy Henning

IT DOES not seem possible that it has been over 38 years since I started my first professional job in forages at the University of Missouri. Forages have come a long way since 1986, yet in some ways, things have not changed at all.

In 1986, we were in the honeymoon days of the endophyte. Forage workers in Alabama and Georgia had conclusively proven the cause of fescue toxicosis to be an endophytic fungus, and grass breeders worked at a frenetic pace to release endophyte-free tall fescues. As a graduate student at the University of Kentucky (UK) in the early 1980s, I remember the excitement surrounding the release of Johnstone tall fescue. In the rush to bring seed to market, some of the first batches were lower than premium quality and had greater than desired levels of annual ryegrass. Lower seed quality coupled with several years of summer drought, especially in Missouri where I was working after graduate school, made for a rocky start for endophyte-free tall fescues. Clearly, science had provided a solution to the fescue toxicosis problem that was ill-timed and possibly oversold. The novel or friendly endophyte tall fescue varieties of today look to be that long-

term solution as a replacement for toxic tall fescue where needed.

Another technology that tracks with my career is the advent and refinement of using near-infrared reflectance spectroscopy (NIRS) to estimate forage quality. The University of Missouri implemented a mobile hay testing program modeled after the Penn State and University of Minnesota programs. I ran the Missouri hay testing program, which meant I took the van to events, processed and tested samples, and then conducted educational programs promoting forage quality.

The NIRS technology has advanced significantly since those mid-1980’s instruments, but the need for education about forage testing and forage quality still remains. I can never forget that in 1986, a survey of Missouri producers found that most beef producers did not test hay because there is no reason to — talk about an uphill battle for a forage extension specialist. Outside of the dairy industry, forage testing is still underutilized, at least in Kentucky. On the positive side, forage quality contests in the Southeast are providing an enhanced emphasis on forage testing.

Rotational grazing was not new in 1986 when I started, but there was a new push

for “intensive” grazing. The popular press was full of writings about the benefits of this new technique. I remember — not fondly — a national columnist who wrote that “intensive grazing would let you double your stocking rate.” Adding fence does not grow grass. I remember thinking those kinds of columns were irresponsible, as anyone who tried it would figure out after one season.

In the 1980s, I was able to watch and learn from Jim Gerrish, who ran the University of Missouri’s Forage Systems Research Center in North Central Missouri. Seeing Jim at work taught me that a motivated and talented forage scientist can have impacts that are almost incomprehensible in scope. In less than 10 years, Jim’s grazing school had brought people from all over the county to that little station, which was not even on a paved road.

Now there is a renewed emphasis on rotational grazing, driven partially by the regenerative agriculture movement. Still, I cringe when I see some of the over-the-top claims emerging on social media and other outlets about grazing and regenerative agriculture. Rather than the “fence will grow grass” of the 1980s, I think a lot of people are hearing the message that rotational grazing will “fix” every issue with a farm, even severely infertile soils. Given enough time and the right management, farms can be fixed. I worry that not much discussion is given to the timeline required.

Another area of great change over my career has been the seed industry and forage genetics. Some advances are easy to recognize, like Roundup Ready or HarvXtra technology in alfalfa. Less apparent has been the almost total shift from university or public to proprietary varietal releases.

Farmers can still find good products to plant, relying on data from university trials wherever possible. But producers will need to cultivate a high trust relationship with their seed suppliers (and vice versa) and learn to read seed tags to ensure they are getting high-quality seed.

In the humid eastern U.S. during the 1980s, your bale package options were two: small square or large round, both tied with twine. Over the years, manufacturers have added net wrap, solid plastic, and breathable wrap binding, all of which reduce storage losses.

Balers have grown in size and sophistication. Now we have mid-size (36 by 32 inches) and large (36 by 48 inches) rectangular balers that bale more tons per hour but require larger tractors. Their rectangular size and greater density allow trucks to trailer maximum legal weights, and they lend themselves well to mechanization. Although the equine sector still prefers the smaller rectangular package, these larger bales are making their way onto horse farms in Kentucky.

Manufacturers have also added labor-saving innovations, especially for small square bales. Bale accumulators, grapples, self-propelled bale wagons, and bale bundlers have allowed the cash hay producer to adapt to the shortage of farm labor and speed up haying operations.

Balers now can be electronically controlled from within the cab. Bale size, density, type, and amount of twine or wrap can be changed from a monitor linked to the baler. Balers are commonly equipped with sensors to continuously monitor moisture. These can be electronically linked to certain hay preservative applicators that will alter the rate of treatment based on changes in bale moisture readings. When I started my career, moisture and forage yield per hour had to be determined manually, which was a slow and inexact process. No-till seeders were available in the 1980s, but they are now more complex and effective. Even the lowly spinner seeder has been upgraded. Seeders now can be quickly and accurately calibrated and will deliver seed by air or using the traditional spinner/spreader.

Arguably, the largest change in making high-quality stored forage was the ability to make round-bale silage. I remember a demonstration of individually bagged high-moisture bales at UK in 1984. High-moisture round bales were sized to fit into individual bags. Oxygen exclusion was attempted by using a shop vacuum to draw most of the air out of the bag, which was then sealed with a zip tie. This silage method was a slow, labor-intensive process and bales were prone to excessive molding. Advances in bale wrapping equipment and UV-resistant stretch wrap plastic has made this process much more efficient, with less risk of failure because of better oxygen exclusion. Making roundbale silage allows farmers to more nearly cut on time, and forage quality of

baleage will often exceed that of all but the best hays. Wrapping equipment is available for rent, making the technology generally available.

One of the most dramatic areas of change has been that of information and communication technology. In 1986, a powerful computer had two 5.25-inch floppy drives, 640 kilobytes of RAM, and cost $6,000! According to the U.S. Bureau of Labor Statistics, this is the same as $17,430 in November 2024. At the time, email was new. To see them, my secretary would have to print them out. There was no Google, and the internet was just beginning to develop.

For information, I relied on my textbooks and a well-stocked filing cabinet from my predecessor. We also had hardcopy journals. In the 1980s, newsletters were hard copy, and information moved slowly. The most high-tech communication method we had was a conference call. I had to go door to door in my building to look for answers, often while producers were on hold! Thinking back, those were stressful days for a freshout-of-school forage specialist.

Today’s pace and scope of information flow makes the 1980s seem like the Stone Age. We are in the time of instant everything. I can access and send all of the publications from any land grant university from my phone. Even though COVID-19 was difficult to work through, it actually accelerated the adoption of technology like Zoom and YouTube to conduct meetings and even larger conferences. Now, farmers have access to information 24 hours a day and seven days a week if they want. There are literally hundreds of hours of instructional video on our UK Forages YouTube site alone.

From a university perspective, forage work has gotten more complex and faster paced, with a much greater reliance on external funding. The availability of technology might lead one to conclude that a forage program can be carried out without ever leaving the office, but effective university forage programs must still have a significant relational component — we have to stay in touch with the clientele. This need is more than just the wistful longing for the “good old days.” I can prove that some of the most valuable and impactful work done by our forage team has come as a direct result of in-the-field farmer discussions. Not

every problem is what it seems in an email, and not every answer is ready for implementation.

There are fewer people overall at agricultural colleges, and that goes for those working in forages as well. One-hundred percent extension appointments were common when I started and almost nonexistent now. These days, extension hires are expected to carry a research appointment and often a teaching appointment. This “multiple-masters” system is often a necessary evil because of fewer people.

When we lost one of our forage faculty at UK, I took on a formal teaching appointment — something I felt was detrimental in the past. Early in my career, I felt like having to be tied down to the classroom was harmful to a forage extension specialist who needed the freedom to be in the field. However, teaching the forages class over the past five years has helped me discover a synergistic relationship between teaching and extension. Teaching made me a better extension specialist. Also, I realize now that I was training the next generation of farmers, county agents, and industry professionals. The new generation of forage workers are some of the brightest and most motivated people I know and are themselves finding the synergy between all three parts of the land grant mission — teaching, research, and extension.

Looking back, we have come a very long way since 1986. Just about the only thing that has not gotten better for the producer is time. For much of the eastern U.S., many forage producers are part time, making it hard to get it all done. In the latter stage of my career, I felt like my job was less about helping a farmer find the right variety, herbicide, or answer, and more about helping to prioritize among tasks.

The land grant system has more ways than ever to stay in touch with clientele and implement good science to solve problems. These are still among our core principles. Thankfully, that has not changed in four decades. Happy foraging. •

360-V Alfalfa will ALWAYS Test Premium (five)

If you knew the breeding of this alfalfa you would buy it immediately! EliminateBuy$3.75/lb.Direct!the Middlemen!

It is common knowledge that you can cut heavier 1st and heavier 3rd or 4th cuts with a class 5 alfalfa, but they usually die out in colder areas. Not so with 360-V!! This unique variety has an unbelievable winter hardiness rating of 1!! (The highest W.H. rating available!) A bigger haystack of 3rd or 4th cutting will make you more money.

“360-V

“360-V has leaves at every inch of the stem, and the stem is very fine. Best alfalfa we have ever planted!”

Fiereira - Cotta & Fiereira Custom Farming, Stockton, CA

“360-V always test premium. It is out best variety on the farm.”

Plant On Dryland

On the Market since 1979 (and still unbeatable)

We are a non-GMO seed house! Never a positive hit for GMO

Plant

Never a Report of Winter Kill

This Alfalfa has been called a tetraploid anomaly by alfalfa breeders. On the market since 1979, and being improved twice, It remains the highest yielding, low water alfalfa on the market!

HERE’S WHAT GROWERS ARE SAYING: (More testimonials available on our website)

When Planting Dryland Alfalfa always use coated seed! (Let us prove it!)

"We run out of water often times by June 1, but the 360-D yielded 6-3/4 tons! We’ve ordered another ton of 360-D"

Jordan Dillon - Rivers Edge Dairy - Hesperus, CO

“In our extremely tough and pure dryland conditions, 360-D has become our only ‘fall-back-mainstay’ variety.”

Max Wilson - Camas Prairie (elev 5060ft) - Fairfiled, ID

"360-D yielded 7 ton under a pivot that only pumped 375 gal./min."

Everett Messner - Salmon Track - Hollister, ID

“We planted 360-D in an irrigated pivot that was very short on water. Side by side was a pivot with normal water. The 360-D yielded with the well irrigated adjacent field! No difference in yield!

Ryan Telford - Richfield, ID

Alan Greenway Seedsman

Greenway Seeds Caldwell, ID

Alan Greenway 208-250-0159 (cell) 208-454-8342 (message)

Warehouses in Caldwell, ID and Deer eld, WI FREE SWEET CORN SEED WITH ORDERS!

√ Will produce AT LEAST 80% of crop with 50% of water

√ Will produce a subsequent cutting after water is gone

√ Plant on dryland/ guaranteed to out yield Ranger or Ladak

√ Plant under pivots that only pump 400 gal/

√ Plant on elds that have only early season creek water

√ Plant under end guns on pivots

√ Plant in the late fall with your dormant seeded grasses

* *Plant in your pivot corners. Two ton bonus per acre per year.

“Modern Forages Sold Nationwide and Canada”

HIGH-quality forages are the foundation of a productive and healthy dairy herd. However, the way feed is managed from the field to the cow is crucial for maximizing a producer’s investment in forages. Regarding feed management, the “three rations” concept provides a valuable framework for solving problems and preventing them before they start. If you have ever taken an animal nutrition course, you have heard about the three rations. For those who have not, the three rations on a dairy farm are the ration on paper, the ration delivered to the cow, and the ration the cow consumes. The ration on paper is what your nutritionist has balanced for you, while the ration delivered to the cow was mixed and dropped in the feedbunk. Ultimately, however, the only ration that matters to the cow is the one she consumes.

Along the way from ration balancing to animal intake, there are many opportunities for error, and the more we can do to minimize this error, the better the ration consumed by the cow. These errors can negate all the care and effort made in putting up quality forages, especially if it means that the cow eats around, or sorts, these forages. A diet built on high-quality forages promotes rumen health and milk fat yield, so it is crucial to consume these forages in a ration as it was balanced.

Sorting occurs when a cow eats the parts of the total mixed ration (TMR) that are appealing to her and leaves the rest. If a TMR is like a salad, sorting would be the equivalent of eating only the things you like in the salad. I leave behind onions when I eat a salad; for others, it might be tomatoes. As humans, we are hopefully eating enough diverse food in our diets that choosing not to eat all of the ingredients in our salad is probably harmless. For the dairy cow that depends on a perfectly balanced TMR to meet the demands of high milk production, this can mess up a nutritionist’s hard work and spell trouble.

So, how do we prevent sorting?

Researchers have given us a few options.

Particle size. Particles that are too long are a major cause of sorting. It is common wisdom to say that the forages in the cow’s diet should be shorter than her mouth is wide; however, growing evidence shows cows can still sort out these particles. Particles that are an inch long are less sortable than particles that are four inches long, and they still provide effective fiber for rumen health.

This is a crucial consideration in dry cow diets, as these are high in lower quality forage. The forage in these diets fills the rumen, which makes the cow feel satiated without

providing much energy, resulting in overconditioning. Additionally, a full rumen around calving may help prevent displaced abomasum, but sorting of these diets can result in metabolic issues around calving.

Liquid feeds. A TMR that is too dry is easier to sort. Adding a little liquid to the diet can help the ration stick together better, especially the small particles that might settle out. This can include the fragile but valuable leaves on forages, which provide highly digestible fiber. It also promotes the consumption of longer, less palatable particles from forages, which provide effective fiber for rumen health.

Adding water to the diet is a simple and cost-effective solution, especially when the diet is overly dry. Other liquid feeds discourage sorting and provide additional benefits, perhaps by including additives for improved

health and production. Molasses, for example, is an excellent liquid feed solution for rumen health. In addition to promoting the consumption of longer, less palatable forage particles, the sugar in molasses provides an energy source for fiber-digesting bacteria, helping the rumen break down forages more effectively and promoting milk fat production.

Feed push ups. Routinely pushing up feed throughout the day not only keeps the diet within reach of the cows and promotes intake, but it will also gently mix the ration. Sorting cows will often push the long particles away and dig to the bottom of the pile for the smaller, more tasty particles. You might notice these “birds’ nests” or holes that cows have dug with their mouths in the feed at the bunk. Pushing up feed covers these holes back up, slowing down sorting and encouraging her to eat the long particles, too.

Measuring sorting. Are your cows sorting in the first place? The Penn State Particle Separator (PSPS or Shaker Box) is a tool that your nutritionist might already be carrying in the trunk of their car or the bed of their truck. Comparing the particle size distribution of a fresh TMR sample to a sample after cows have had a chance to sort through it can show whether sorting is occurring. If the two samples are dramatically different, that is a good indication that your cows are sorting their feed. But don’t just look at how much feed is in each sieve — pay attention to what the feed looks like. Are the particles in the top sieve very long? If so, they are likely to get sorted out, even if they are not a high proportion of the ration.

Good forage management does not stop at harvest. Ensure that your feeding protocols maximize your forage instead of sapping your investments. •

GAIL CARPENTER The author is an assistant professor and extension dairy specialist at Iowa State University.

TIME . . . it’s the one thing we never seem to have enough of. Time on the farm can bring about a totally different outlook. That outlook in the hay business is usually based on the weather forecast. How much time do we have between rainstorms, or what time is the sun supposed to break out from behind the clouds? The stress caused by scheduling your hay operation is largely based on time. So, anything we can do to shorten the amount of time when cut hay is on the ground is always beneficial. Fighting these issues of rain and moisture is nothing new for farmers in the eastern U.S., but Western hay growers also fight the same battle. As many of us start to farm more and more acres, this means we have to get more acres to dry in the same amount of time. To speed the drying in grass hay, farmers often use a tedder, or fluffer, as it’s called in the South. These fluffers do just that — they “fluff”

the hay out to help speed up dry down. They start by scattering out the mowed windrows into an even, fluffy layer. This will enable more air flow through the crop and allow sunlight to evenly dry down all of the crop, not just the top layer of the narrower windrow. The fluffier and wider we can make the crop, the more air will flow through it and over it.

The tedder is not a new piece of equipment; in fact, The New York Times reported on a machine used to scatter out hay in 1868.

These days, tedders have scaled up. Models are available from 6 feet to 60 feet of working width, with the larger units becoming more popular in recent years. You don’t typically see many tedders used in alfalfa production, as they are fairly aggressive and can knock off leaves unless the crop is still high in moisture.

There are some manufacturers that now have models where you can adjust the angle and aggressiveness settings,

so you are basically stirring the hay and not throwing it everywhere. This can be helpful in alfalfa if you get a stray rain shower during the season. Spreading out the windrows will drastically reduce the amount of time before a baler can get in the field.

As working widths have grown, the amount of time spent in the field has declined, allowing for multiple trips to be made if needed. With better time management of the dry-down period, you can justify the extra trip across the field with the ability to cover more acres in the same amount of time.

Whether you use a four-basket or a 14-basket tedder, the end goal is to put up the highest quality forage possible in the shortest amount of time. It’s a tool you might want to consider in 2025. •

by Mike Rankin, Senior Editor

TELEVISION commercials tell us ad nauseam (pun intended) how bundling home and automobile insurance can result in unimaginable economic benefits. For Minnesota haymaker Josh Wentworth, bundling small square bales has proven to have the same outcome.

Wentworth farms near Cambridge, Minn., about 50 miles north of Minneapolis. His parents, Gary and Cyndee, bought the farm in the early 1980s and began row cropping. Their son started purchasing the farm about 20 years ago and took over managing the operation in the late 2010s, transitioning about 250 of the nearly 400 tillable acres into hay.

“The soils here are pretty sandy, so our nonirrigated farm doesn’t make it easy to get top row-crop yields,” Wentworth said. “We still grow about 150 acres of corn and soybeans, but our main enterprise is hay.”

The Wentworths have a family farm in every sense of that overused nomenclature. The management and work get done without any nonfamily

labor. Although Wentworth’s parents are retired, they still help with tractor driving and other jobs during the rush times. His wife, Trisha, has an off-farm job but also helps on the farm as her time allows. In 2024, the farm provided hay to about 100 clientele, putting up nearly 20,000 small square bales and 700 round bales.

With Wentworth doing most of the heavy lifting, he’s had to figure out ways to lighten and quicken the workload. “When I first started, we made hay with a John Deere 328 small square baler and eventually owned 15

kicker-bale hay wagons,” the 44-yearold haymaker explained. “Although we could make a lot of bales in a day without stopping to unload wagons, those bales eventually had to get unloaded by a client or us.”

Wentworth’s haymaking game totally changed a few years ago when he purchased a Massey Ferguson in-line 1840 baler and a Bale Baron 21-bale bundler that runs behind the baler. The bundles of hay are picked up with a tractor and spears and loaded onto one of two steeldeck trailers or a flatbed gooseneck trailer. Some of his customers have their own trailers and will come right to the field and get loaded.

“We use the kicker-bale system as little as possible now,” Wentworth said with a wry smile. “You won’t find 15 kicker bale hay wagons around here anymore. Both my customers and I like the bundled bales a lot better from the perspective of loading, trucking, unloading, and storing.”

Wentworth shoots for a 45- to 50-pound bale, and his bundler will only handle about a 34-inch bale. “Most of our customers don’t want bales over 50 pounds,” he said. “If they’re heavier, they think they’re too wet.”

All of Wentworth’s production is sold by the bale, and 75% to 80% of his hay goes to horse stables or horse owners. Most of the remaining clientele are beef farmers who usually take his round bales made from hay that got rained on or is lower in quality.

Wentworth services both larger horse customers who take between 1,000 and 2,000 bales per year and those who may just own a few goats who only need 20 bales. He delivers many of the larger loads himself, and most of his customers are within the state. Most of the hay produced is marketed during the summer months. “I know we probably lose a little in price versus waiting for winter, but it’s easier than needing to plow snow every time somebody wants hay during the winter,” Wentworth said. “Generally speaking, we’ve got everything sold and out of the barn by the end of November.”

sensors on all of the balers and use hand-held probes to verify. We also have preservative applicators on the balers, but we only use them if absolutely needed,” he asserted.

Wentworth likes to keep the baling moisture under 15% and slightly lower than that for round bales. If there happens to be a bad bale, he makes good on them. “It’s rare that we have a customer who wants to see a hay test,” he said. “Sometimes, a horse customer will want to know the sugar content of the hay, so we’ll run a test, but it doesn’t happen often.”

Horse owners are as diverse in their hay preferences as there are spot configurations on an Appaloosa. Wentworth generally targets early bloom alfalfa for his horse customers, although all of what he grows is an alfalfa-orchardgrass mixture that can range from 75% to 25% alfalfa. This wide range enables him to meet about any client’s hay preference.

The Minnesota hay producer establishes his alfalfa and orchardgrass stands using a Brillion seeder. “It’s tough to get the same amount of grass every year with new seedings,” Wentworth noted. “It all depends on the weather at the time of seeding and how much rain we get. With our sandy soils, if we don’t get enough rain after seeding, establishment is often a total failure.”

The price for Wentworth’s hay is staggered by cutting, with each progressive cutting being more expensive per bale. “For those clients who lean on the frugal side, they will take the lower-priced, first-cutting hay, and that’s nice for me because I can move it pretty fast,” he noted. “Other customers are willing to pay a premium for some of the higher quality, softer hay that comes with later cuttings of alfalfa and orchardgrass. When you sell to horse owners, the important thing is to have dry hay that’s not too stemmy and with a good blend of alfalfa and grass. We have moisture

Wentworth used to seed 17 to 18 pounds of coated alfalfa seed and 3 to 4 pounds of orchardgrass per acre, but more recently has started seeding over 20 pounds of alfalfa and 7 pounds of orchardgrass per acre. His observation is that the hay is less course with the higher seeding rate, although yields appear to be similar between the two seeding rates.

A late-maturing orchardgrass variety is Wentworth’s preference because it fits better with spring alfalfa maturity; however, he said that some of the

continued on following page >>>

late-heading orchardgrasses don’t produce very well if the summer is hot and dry. “We’ve tried grasses other than orchardgrass, but none of them seemed to do as well for the growing conditions we have here,” Wentworth said.

Stand persistence hasn’t been a problem for the haymaker who also holds down a side business as a skilled snowmobile mechanic and welder. Wentworth noted that he has stands that are going on 8 years old. “We just don’t see a lot of winterkill with our good soil drainage and snow cover,” he explained.

Wentworth cuts his hay three or four times per year with a New Holland 313 center-pivot Discbine. He also utilizes a double-rotary tedder and two twin-rotary rakes to help speed drying. “We try to finish up making hay by early September; it gets pretty tough to make dry hay after that,” the haymaker said.

his hayfields healthy and free of pests. He applies potassium at a rate of 150

pounds per acre every fall. His fields also receive an application of ammonium sulfate, and because of the sandy soils, 75 pounds of nitrogen per acre is applied in the spring to spur grass growth.

ing and try to keep a close eye on my fields throughout the growing season. If bugs come in, you have to act quickly or it will be too late. In 2023, farmers who didn’t spray for alfalfa weevils after first cutting had nothing. In 2024, we had to spray way ahead of first cutting. Now that we have to spray more often, I’ve been trying to alternate the insecticide mode of action to help prevent resistance,” he added.

Along with Minnesota’s unpredictable humid weather for getting hay dry, Wentworth now counts insect pests as one of his greatest challenges. Even so, he is not deterred. He’s pleased with his relatively new hay bundling system but at this time has no plans to take on more acreage or outside labor. Two daughters also grace the farm, but they are still too young to gauge if haymaking is in their future.

IT SEEMS like many of my columns begin with, “A lot of people ask me . . .”

Well, here’s another one. I often get asked where I think the best place is to be in the cattle business in the United States. I generally take that to mean: “Where is the best cow-calf country?” I answer that question by saying, “If my life’s ambition was to be in the cow business, I never would have left Missouri.” Sometimes, I qualify that answer by saying, “Missouri and the states that touch it.”

Over the last 45 years that I have been working in the realm of grazing, I have had the opportunity to visit 43 of the 50 states that make up this country either in a consulting or teaching role. I have consulted with individual farms or ranches in 39 states plus various Canadian provinces, the state of Chihuahua in Mexico, and a dozen other countries around the world.

Within the U.S. and Canada, effectively managing feed costs is the primary determinant of profitability in the cow-calf business. In much of the U.S. and Canada, it is specifically winter feed costs that are the greatest challenge, which also means they offer the greatest opportunity for improvement.

When I arrived at the University of Missouri Forage Systems Research Center as a young researcher straight out of graduate school, my research assignment was to make beef cow-calf operations economically competitive with soybeans on the highly erodible landscape in northern Missouri.

I grew up as a crop and hog farmer in southern Illinois. I had no association or experience with the beef industry beyond custom hay baling for beef and dairy farmers in our area. I knew nothing about the economics of cowcalf ranching at that time. What I did know was there are only two parameters in the profit equation. That is, revenue minus costs equals profit. In the early 1980s, there were no premiums or value-added programs in the beef sector. It was entirely a commodity business where revenue could only be improved by running more cows or getting a better price for your calves.

I didn’t see any way I was going to affect the revenue side of the equation. I asked our beef ag economist for a sample cow-calf budget. When the top line on the budget was “feed costs,” I knew that was the line item we needed to tackle. Believe it or not, some of the first research I was involved with was hay storage and feeding systems. If hay was the biggest cost, we needed to be more efficient in storing big round bales and feeding them out. Right?

It turned out that was a dead-wrong viewpoint. It didn’t take but a few years to realize the key was not making hay feeding more efficient but rather eliminating the need for making and feeding hay. The research program that followed led to more efficiently managing land to grow more stockpiled forage and managing grazing to more effectively harvest that forage.

What became the Management-intensive Grazing Program at the University of Missouri originated out of winter grazing programs designed to eliminate the need for hay in cowcalf operations. We were actually very successful at winter grazing stockpiled forage both on our personal farm and at the university research center. Once you figure out a few basic principles, year-around grazing is quite feasible in places like Missouri.

That brings us back to our original question: Where is the best place in the U.S. to be in the cow-calf business? The answer is where it is the easiest to consistently graze at least 10 months of the year.

In an earlier “Pasture Walk” column, I had reported that Dallas Mount of Ranching for Profit had stated it is nearly impossible to be profitable in the cow-calf business if you feed hay more than 60 days annually, and feeding no hay is a much better position to be in. Burke Teichert of Deseret Ranches had set the benchmark for those ranches as no more than 15% stored forage in the diet. That is approximately 55 days of the year.

In my experience around the country, I have seen more cow-calf

producers eliminate hay feeding in Missouri and the adjacent states than most other parts of the country. The combination of relatively reliable precipitation with moderate summers and mild winters makes a favorable year-around grazing environment. The ability to grow most cool-season forage species as well as strong native warm-season plant communities make that region productive more days of the year compared to states to the north or those to the south.

For being in the cow business, Missouri is still hard to beat. •

JIM GERRISH

Gerrish is a rancher, author, speaker, and consultant with over 40 years of experience in grazing management research, outreach, and practice.

Hay & Forage Grower is featuring results of research projects funded through the Alfalfa Checkoff, officially named the U.S. Alfalfa Farmer Research Initiative, administered by National Alfalfa & Forage Alliance (NAFA). The checkoff program facilitates farmer-funded research.

RECENT study has provided valuable insights into the optimal timing for spraying insecticides on alfalfa seed fields to minimize harm to pollinators. Kelsey Graham of the USDA-ARS Pollinating Insects Research Unit in Logan, Utah, and Kimberly Hageman of Utah State University sought to balance effective pest control with the protection of these crucial pollinators, which are vital to both crop production and biodiversity. It is generally recommended to apply pesticides in the evening or early morning when pollinators are less active. By avoiding peak pollinator activity during midday, farmers can reduce the risk of pesticide exposure to pollinators while still managing pest populations, offering a more sustainable approach to crop protection. This study tested if and when an evening application would be more favorable than an early morning application.

Funding: $55,107

“We wondered if applying pesticides at night was effective at reducing residue exposure for bees the next day since most pesticides are likely to undergo slow dissipation at night,” Graham said. “Since each type of pesticide behaves differently in the environment, we chose to investigate the behavior of three insecticides used by alfalfa seed growers with the aim of providing tailored recommendations.”

Hageman added, “Not much is known about the timing of adult lygus bug activity or their preferred positions within the alfalfa canopy. This was an important data gap because pesticides