4 minute read

TRAINING SPREADS OUT THE BENEFITS

by Robert Meinen

Legislated mandatory certification of custom applicators in Pennsylvania began in 2006 with a unique five-level educational format. The three levels of manure haulers included:

Advertisement

1. Those that only transport but do not land apply manure (Hauler 1).

2. Those that can both transport and land apply manure under the supervision of an owner or manager (Hauler 2).

3. Those who can perform all duties of the other levels and also supervise other haulers (Hauler 3).

Two manure broker levels were also designated: Those that take ownership and determine the end utilization of the manure but cannot create Pennsylvania’s Nutrient Balance Sheet (NBS) (Broker 1), and those that receive additional certification to write the NBSs (Broker 2). The Pennsylvania NBS determines application rates and setbacks for farms that import manure.

Educational requirements expand with each certification category. Those in the Hauler 1 category complete a verification checklist to ascertain their understanding of important manure transport and stacking principles. A Hauler 2 must study a detailed workbook and successfully complete a proctored certification exam. Other categories require attendance at a certification training followed by successful examination.

A survey of certified commercial manure haulers and brokers in Pennsylvania conducted in 2018 demonstrated that education of industry professionals positively influences worker knowledge. This should, in turn, transfer to field-level decisions that are advantageous on agronomic, economic, and environmental levels. Enabling workers with science-based knowledge can have widespread impacts.

What they learn

All levels except Hauler 1 have a continuing education requirement. Hauler 1s were not included in our results since surveys were distributed at educational events that group rarely attends.

The legislation prescribed certification competency criteria includes:

• Laws and regulations

• Application setbacks

• Rec ord keeping

• Nutrient behavior and management

• Conservation practices

• Ha ndling safety and spill response

• Biosecurity

• Odor and fly nuisance issues

At the time of the survey, a total of 808 individuals were certified in the state. The survey asked about knowledge of key certification components, and 171 acceptable surveys were returned.

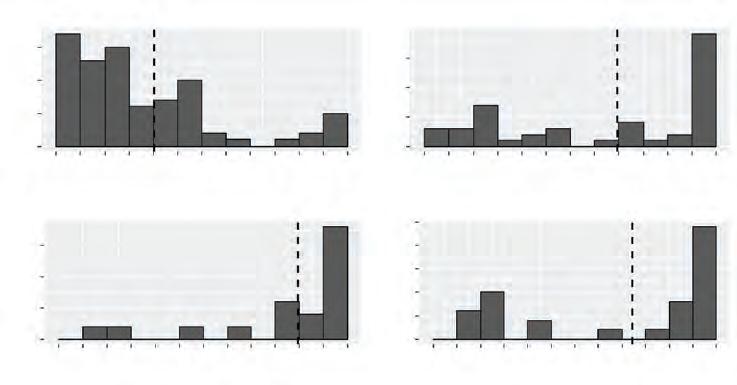

Scores ranged from 28% to 100% correct, with an average across all levels of 78.7% correct. Scores seemed to rise with the rigor of certification education requirements. An analysis of covariance with score as the response and certification level, role (employee or owner), supervision (supervised or supervisor), number of years certified, type of manure worked with, and number of farms worked with annually as factors and covariates demonstrated that certification level was statistically significant (p value = 0.022). Survey results are presented in Table 1. Across all certification levels, the average length of certification was 6.4 years. However, as demonstrated by the dashed lines in Figure 1, Hauler 2s were only certified for about four years on average, while owner/managers and brokers were certified for eight years or longer.

Of all respondents, 84 respondents were supervised by others and 87 supervised others, while 90 identified themselves as employees and 81 as owners/managers. Expected testing scores for those that were supervised was around 76.5%, while expected scores for supervisors were 81%. Similarly, those listing themselves as employees had an expected score around 76%, compared to 81% for those listing themselves as owners/managers. Less experience and slightly lower testing scores of employees is reasonable, if not expected. This highlights the importance of supervisory roles in the industry.

Broader benefits

The table outlines responses to questions concerning whether the individual worked with solid manure, liquid manure, or both. In the Hauler 2 category, 44.3% worked with liquid manure only, which is indicative of services provided to dairy and swine farms. Companies that service liquid systems are more likely to have employees that operate only liquid application equipment.

Just five of 46 Hauler 3s (10.9%) worked only with solid manure. Most individuals that handle only solid manure commercially in the state engage in brokered transfer of poultry or equine manure that is often exported and applied away from the farm where it was generated.

This advanced solid manure brokering industry is highlighted by the 18 of 28 Broker 2s (64.3%) who work only with solid manure. Many of these individuals work with or for poultry farms and provide NBSs to farms that import the solid poultry manures.

The survey also demonstrated that professional manure handlers work across a wide landscape. The average worker serviced 38.5 farms annually. It stands to reason that practical education that empowers individual field-level decision-making, based both on the latest science and state policies, can have far-reaching positive impacts on farm production and nutrient conservation. ■

GEA RELEASES NEW ALLEY SCRAPER

The new GEA ProManure E2191 tilting blade scraper replaces the current 16-degree and straight blade scrapers. It is configurable on-site and adaptable to most barn styles and conditions. Reduce downtime by keeping the limited components necessary for maintenance and repairs on hand.

The E2191 scraper is the latest advancement in the GEA ProManure cleaners and offers versatility, adaptability, and reliability. Learn more at gea.com/dairyfarming.

PIT-KING SUBSCRIBERS GET NEW PRODUCTS

Get the newest manure digestant product shipped directly to your farm. With the Pit-King Monthly Maintenance Subscription Program, farms can choose to have Pit-King sent to them monthly or quarterly at a discounted price. For more information or to sign up for the PitKing Monthly Maintenance Subscription Program, contact your local Agri-King representative or visit agriking.com.

DAIRYPOWER BRINGS ITS AERATION SYSTEMS TO NORTH AMERICA

Dairypower Equipment, an Irish designer and manufacturer of manure aeration and handling equipment, is now serving the North American market. Suitable for the hog, beef, and dairy industries, the Smart Manure Aeration System is designed to keep manure in a liquid, pumpable state year-round. High-volumes of low-pressure air are pumped through the manure from the base of the storage facility to mix the manure, eliminating the build-up of toxic, volatile gases and the need for tractor agitation.

The system creates an aerobic environment that reduces odors and dangerous gas emissions, while increasing manure nitrogen levels by up to 70%. Farmers can purchase less fertilizer, and the manure is ready to pump and spread when they are without agitation, resulting in better air quality and a safer environment. Multiple aeration systems have been installed across North America. Dairypower’s expanding dealer network (including their newlyformed partnership with Agri-Plastics and Agri-Comfort) is ready to help serve and support dairy, beef, and hog farmers. To learn more, go to www.dairypower.com or call toll-free at 888-231-3575.