MAGAZINE ISSUE 46 IS DEDICATED TO THE LOVING

MEMORY OF

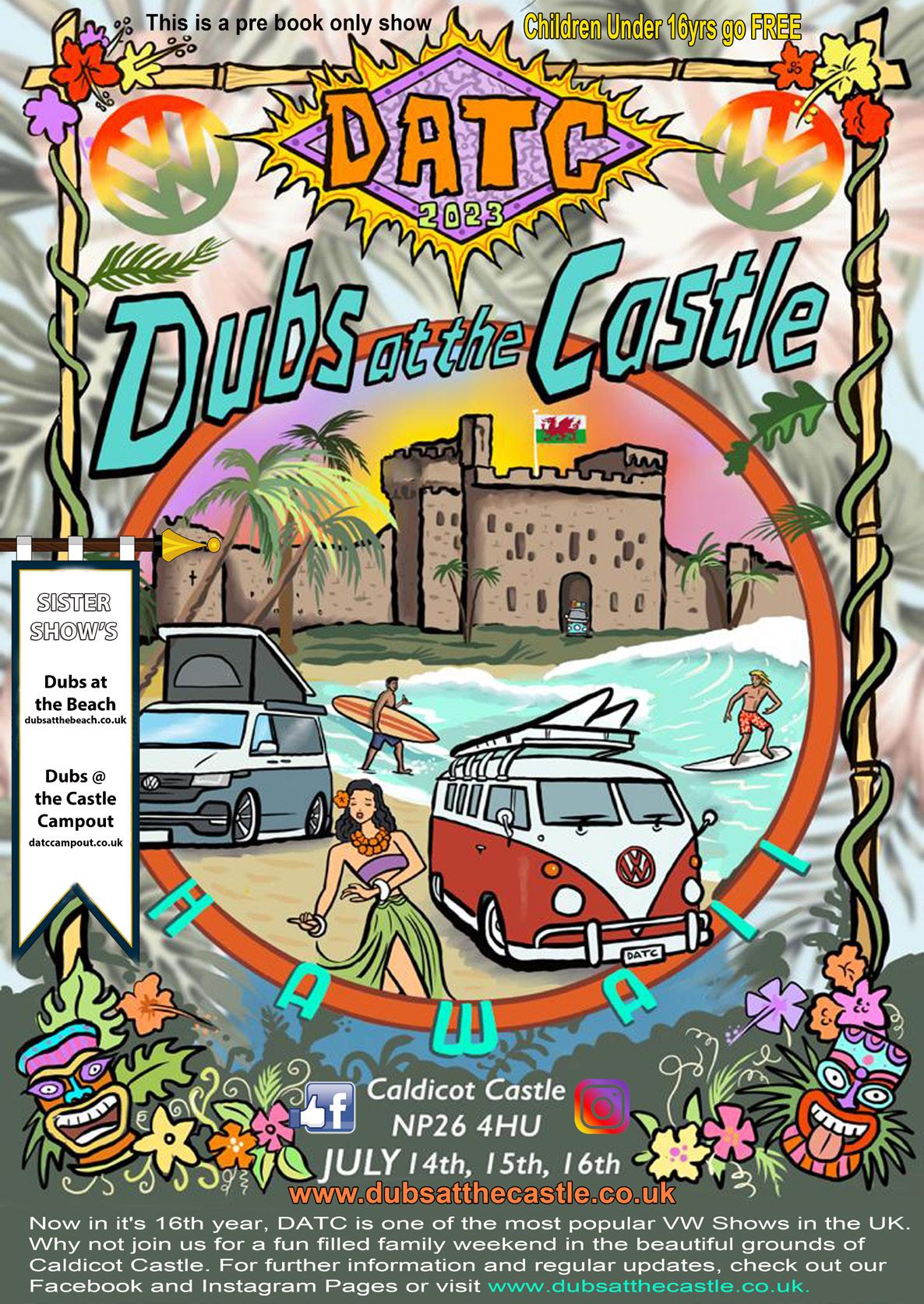

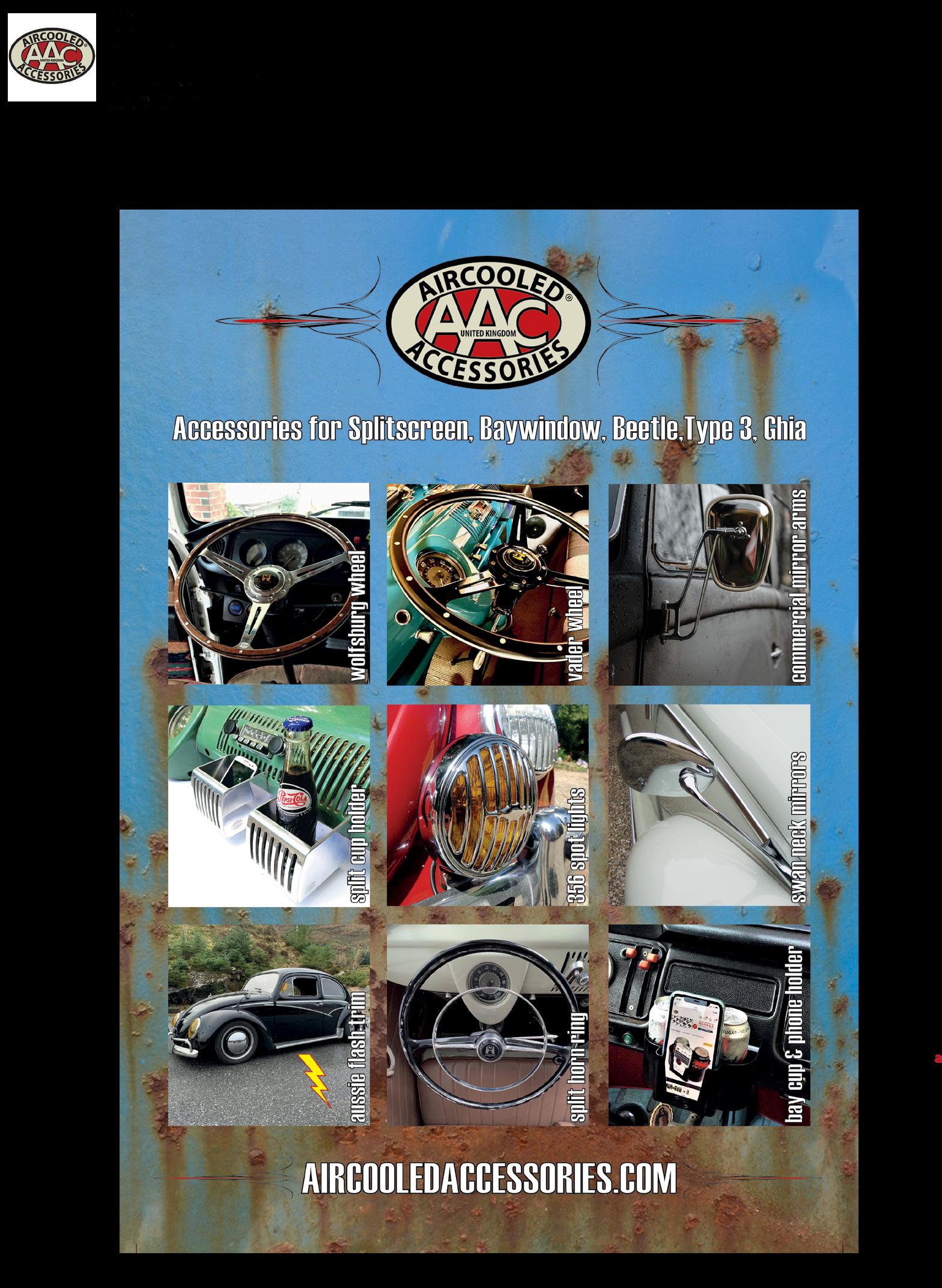

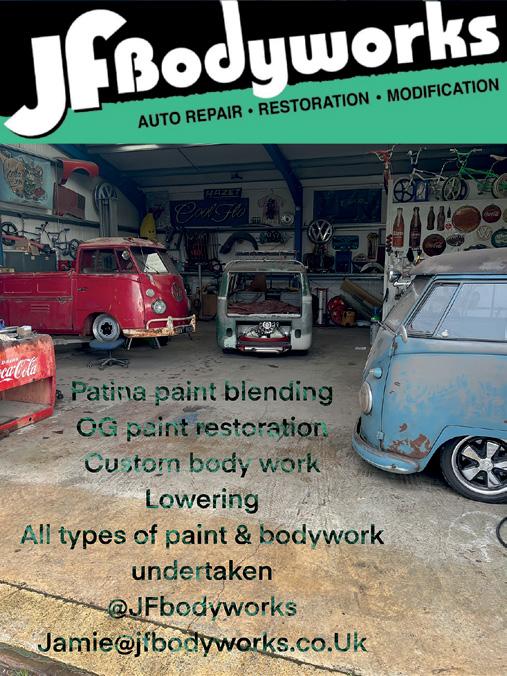

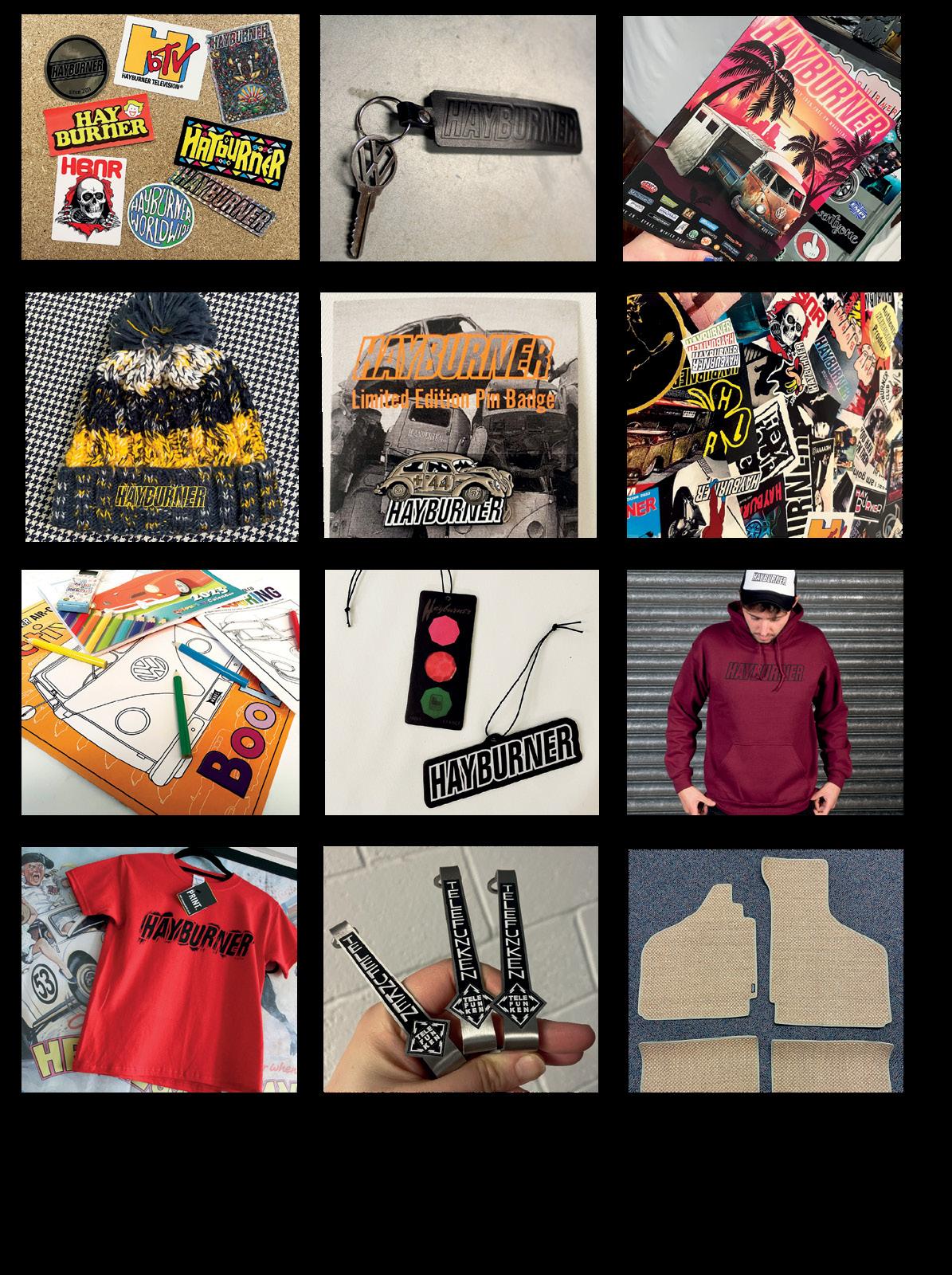

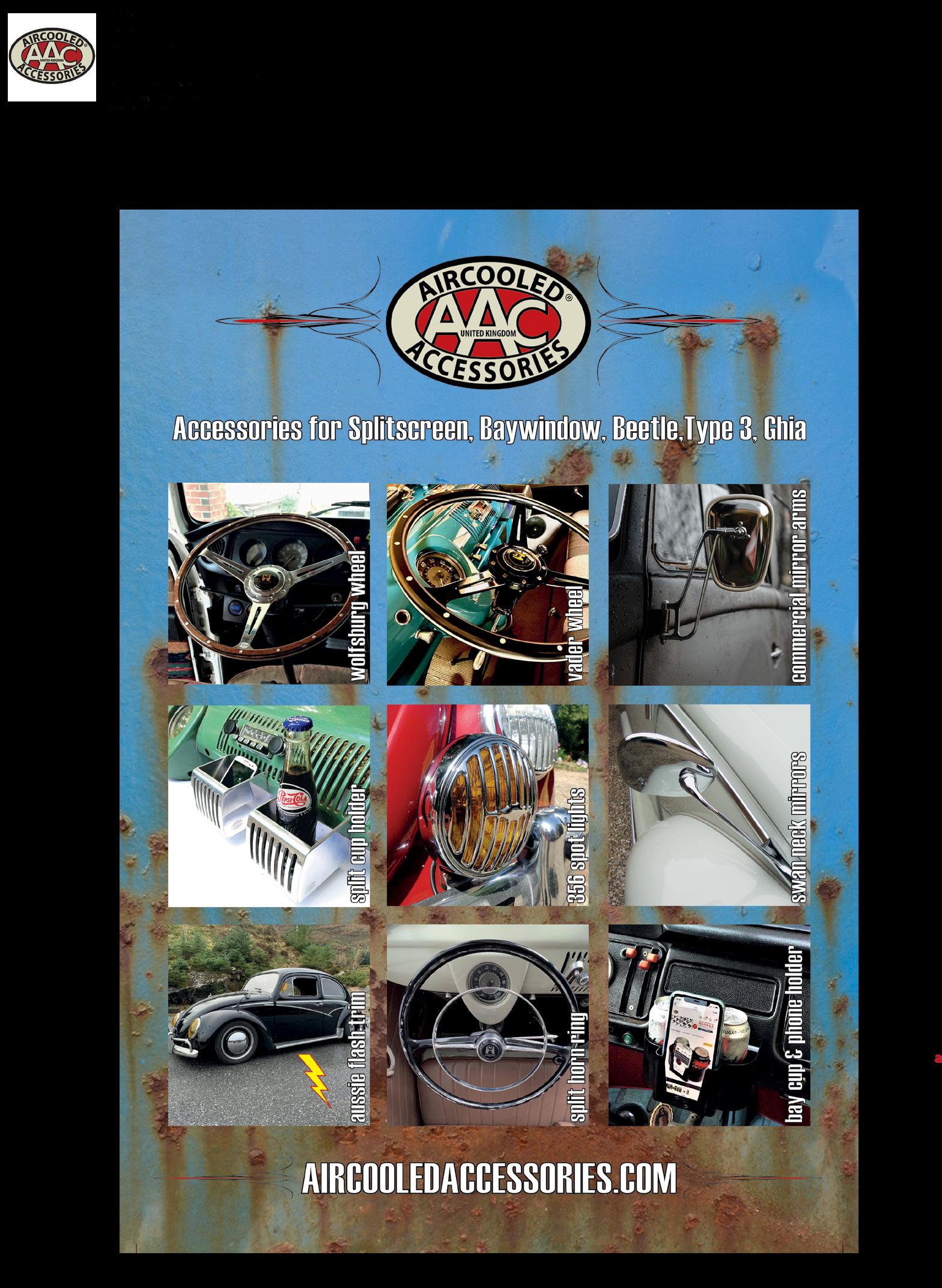

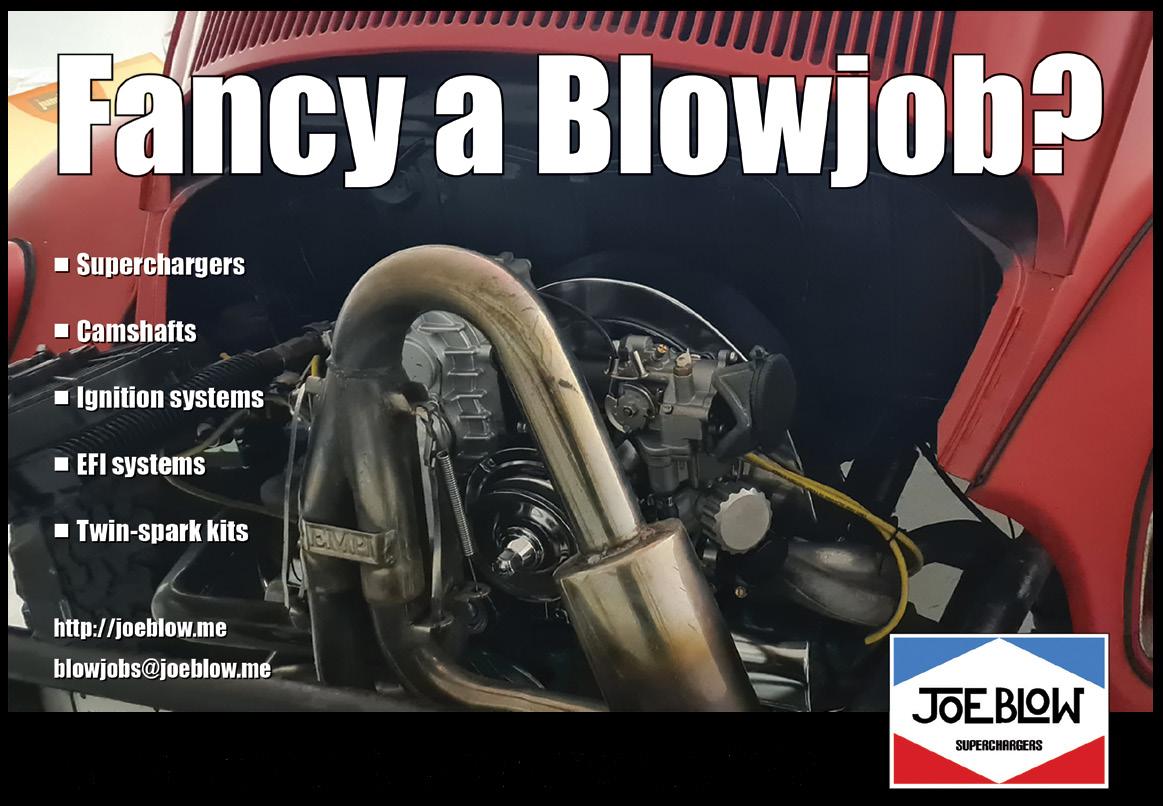

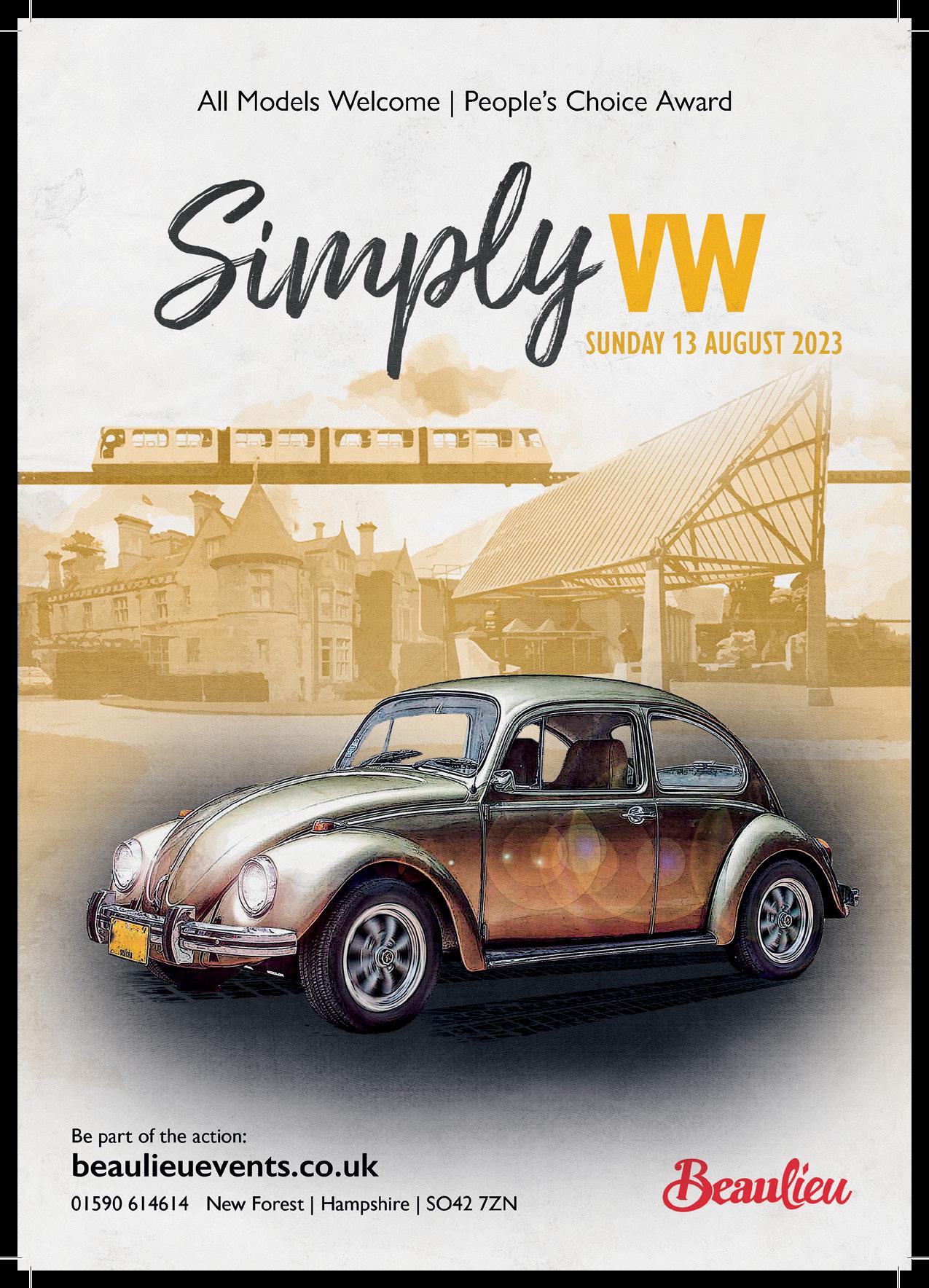

ShaunRees &RichardButolay Butty’s Bits SJ Bowles Coach Trim Sticker Blimp Mad Matz Paruzzi FiftySixDelux Muddy Fields MCJ Es Autos AircooledAuto Elec Oil Can Stickers Deluxe Resto Retro Classic Clothing Wonky Donkey Emporium VW Aircooled Works Concept Poptops Evil Bens German Junkies Aircooled Accessories Outhaus Growl & Grandeur Rarebreed Photography Beetlelink Border Restorations Camper Revamper Geek Shack Peak Van Conversions Rack Shack OB1 Clothing Johnson Autoworks Rusty Lee The VW Engine Company Absolute VW Joe Blow Central England Automotive Autowares Delilah’s Garage 87 SGS Aircooled CohPro Europl8 N2 Engineering Kinky Mick BusOK 94 Bruce Rusty’s Garage Empi US Adrian Flux Dub Fab VW Trends JP Group JF Bodyworks VDub Radio Winner Winner Comps Rooftent Utopia ReCoventry Ltd. Funky VW NL Kompressorhaus R3 Garage Robertson Restos Autocraft Doncaster VW Show Dubs at the Castle RetroDub Suffolk Wilton Bradley VW Whitenoise VDub at the Pub Renegade Brewery Kent VW Festival Beaulieu - Simply VW BRITISH BUILT ELECTRIC B KE E-CHAMP TECH II

c u s t o m a n d c o m m e r c i a l . c o m customandcommercial.com Suppliers of VW parts for your Beetle, Split, Bay, Ghia, T25, and T3 info@customandcommercial.com Wholesale Orders Welcome Unit 31, Bookham Industrial Estate, Church Road, Great Bookham, Surrey, KT23 3EU *ON ALL UK WEB ORDERS OVER £50 * exclusions apply FREE DELIVERY Handle set with one locking cab door handle Bus 1/61-07/63 B a l l j o i n t u p p e r o r l o w e r i n c n u t 4 r e q u i r e d p e r b u s 6 8 -7 9 Brake shoe set 30mm front or rear Beetle or Ghia 49-10/57 Genuine VW insert cap for hazard light switch knob 8/67-79 B33922 Handle set on one set of keys Bus 65-66 S37688 S73893 Double cab front doors & side door handle set with 2 keys 9/68-79 Handle set on one R code key 72-74 S48733 Handle set on one R code key 9/68-71 S23989 S26390 Handle set on one R code key Double cab Bus 72-79 Handle set on one R code key Double cab Bus 9/68-71 S67571 Handle set with one locking cab door handle single cab 59-61 S23999 Handle set without slide door barrel on one R code key 74-79 S67569 Handle set double side door 2 locking cab handles Bus 59-61 Handle set double side door 2 locking cab handles Bus 01/61-07/63 S67570 S45698 rack rod end outer Right hand thread 68-79 S01464 CV boot kit including bolts clamps and grease Bus 68-92 S01778 Genuine VW rear light housing 8/71-79 Sun visors in off white 68-79 S02133 Genuine VW Heavy duty side gearbox mount T1 10/52-7/72 T2 3/507/67 Outer scraper with chrome moulding Right 47-8/64 SKF front bearing kit for Drum & Disc brakes Beetle & Ghia 65-79 B00003 Heavy duty Heater channel Left 8/67-79 B97826 Rear wheel cylinder T1 47-57 BERU spark Plug 1200cc-1600cc W8AC Battery clamp 67-79 Chrome headlamp rim Ghia 56-74 G38524 S45897 B01358 S45688 S45689 complete rear corner Left Bus 64-67 B43221 S02289 B21883 complete rear corner Right Bus 55-63 Orange front indicator lens Right 73-79 S23985 S01818 Window winder handle black 4/68-91 G55691 Chrome rear luggage rack Ghia 56-74 B11175 S02387 Genuine VW glove box hinges Ghia Complete roof skin inc the gutter Bus 68-79 Inner arch fixing nut 47-79 S02250 B39989 S37547 S45697 Handle set with one locking cab handle Bus 59-61 Chrome rear Volkswagen script Bus 55-79 G53992 S37699 Complete set on one set of keys Bus 1967 OEM B03884 We have it all LOCKED up C&C Bus handle sets 1955 - 1979 HOLLAND w w w c a n d c - h o l l a n d n l germany w w w c a n d c - g e r m a n y d e FRANCE s e r i a l - k o m b i c o m Classic wood steering wheel T2 457mm E34567 Complete deluxe internal door handle kit plastic cover surround for handbrake release gloss black 68-79 S73101 S32543 S28149

customandcommercial.com info@customandcommercial.com info@customandcommercial.com Wholesale Orders Welcome Unit 31, Bookham Industrial Estate, Church Road, Great Bookham, Surrey, KT23 3EU Cab door seal kit Grey main door seal for both cab doors 55-67 Modern style safari window seals for both front window 50-67 Stainless steel mirror clamp Bus 55-67 Accelerator push rod to floor seal Bus 3/50-2/72 Brushed stainless steel dash knob for wiper switch 55-65 S00328 S39230 S00867 S00786 S00827 S45699 Made BY w w w . c u s t o m a n d c o m m e r c i a l . c o m S23635 S29938 Side pop out window seal kit with anodised frame 55-67 S00627 Interior light unit Bus 50-67 Accelerator pedal hinge on floor Bus 55-79 S00869 S23584 Heater leavers OEM colour Red & Blue 68-7/73 Fuel filler flap return spring 67-7/71 S73229 Elephant ear mirror arm in stainless steel 8mm 55-67 S00332 Deluxe dash grab handle ivory with chrome ends Bus 55-67 S27719 Locker door & engine lid hinge 3/557/76 Rubber knee protector in grey 55-67 S00947 S38221 S03062 OEM style rear light housing 62-7/71 S33003 S35662 Ignition barrel with T code keys 3/55-67 S01530 All red rear light lens 58-61 S00433 S00312 Mirror arm fitting kit Bus 55-67 S27189 Silver wiper arm and blade kit 55-67 T42235 Slide door centre runner wheel T25 8/85-92 Handbrake ratchet T1 5579 T2 50-67 B00756 S00459 Chrome pop out catch Bus 55-67 S00344 S92331 Silicone rocker cover gaskets 1200cc-1600cc Rear jacking point and outrigger combined left Bus 68-79 G00001 Orange front indicator lens Ghia 8/59-63 Short check strap & bracket brown Bus 61-67 Rear backing plate Right Bus 8/67-7/70 S21222 Complete slide door track runner unit right side door LHD Bus 68-79 S73865 Master cylinder dual circuit conversion kit For TRW Master cylinders to fit Splitscreen buses Convertible wiper arms chrome finished stainless steel. plastic cap style Side window jail bar kit for both sides rear side windows 68-79 S00756 Wiper spindle and sleeve complete bus 55-64 Chrome 1/4 light catch with black knob Left Bus 68-79 B89776 Rubber cab floor mat with polypropylene trim LHD Bus 59-67 S27688 S01846 Front shift rod bush Bus 10/66-7/73 Need Parts worldwide? Australia w w w c a n d c - a u s t r a l i a c o m usA w w w 2 c i p 1 c o m JAPAN m y b o w s - d e p o t n e t Correct Fit S38979 Complete samba roof with sunroof hole S49990 S35686 S35969 Complete upper side panel RHD bus Right side 55-07/67 S15897 Rear corner complete right Bus 08/61-12/63 Windscreen full repair frame Bus 55-67 Complete front inner frame assembly LHD Bus 55-67 S12899 Full side panel for non side door side of van Right side RHD 55-62 S00100 Complete bulk head Bus 50-7/62 50-7/62 S66788 Complete cargo floor LHD 55-67 S37994 Complete seat mount panel Left Bus 55-67 Front roof 1/4 Bus 55-67 S00006 Complete cab floor inc handbrake brackets LHD Bus 55-59 A to B pillar connecting repair above cab door Left Bus 7/63-7/67 S63548 S29077

LUXURY SHOES CACTUS PETE’S

When it arrived from Greece it still had shoe boxes, clothes hangers and original 70s Greek dust! There’s even an old faded newspaper on the dashboard.

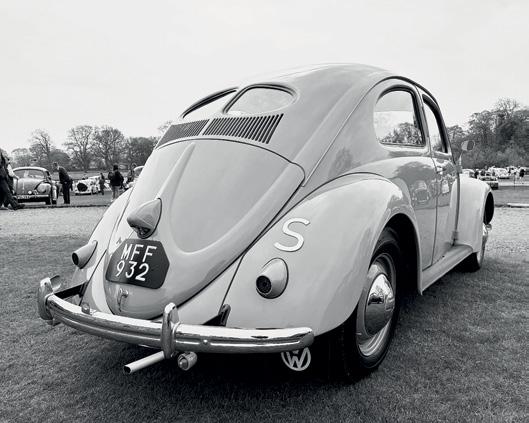

LOWLIGHT

The car had certainly seen some action, including a knock on the front passenger side, and was covered by at least 10 different layers and colours of paint. The project became about paint “restoration”

PROJECT ‘58

I believe the last instalment went a bit like this: “On my still to do list are passenger side signwriting, diesel heater, fit door cards and interior, modify exhaust, and fit door locks and seals.

PROJECT ‘49

Instead of the regular editors letter (which I really don’t want to write anyway) Athis is a chatch up on my own personal project.

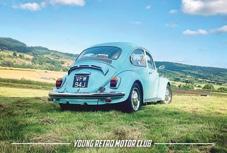

There was something about the Cactus Pete’s bus right from the first time it caught my eye as it arrived at our classic VW show back in 2015/16.

In 1955 agricultural machinery manufacturer Fahr AG, based in Gottmadingen, designed this lightweight utility vehicle. The initial brief specified that it needed to have a gross weight of 1000kg.

VW DO BRAZIL

Brazilian cars sometimes get a lot of heat, don’t they? I’ve heard all sorts of negatives aimed at them for ages, but all of those things come down to pretty much the same thing: “They aren’t real Splits” or Bays or Beetles or whatever.

FLAT FOUR

Adolf Hitler seemed adamant that the people’s car should be powered by a 3-cylinder engine with its cylinders arranged in a radial star pattern.

Copyright © 2023 by Hayburner Limited. All rights reserved. This magazine or any portion thereof may not be reproduced or used in any manner whatsoever without the express written permission of the editor, except for the use of brief quotations. Operations Manager - Vic Faux Editor-In-Chief -& Founding Editor - Ned Faux

FARMOBILE

36 82 * 20 * * 52 170 HAYBURNERPLUS HARDCOPYONLY Subscribehere HAYBURNERPLUS HARDCOPYONLY Subscribehere

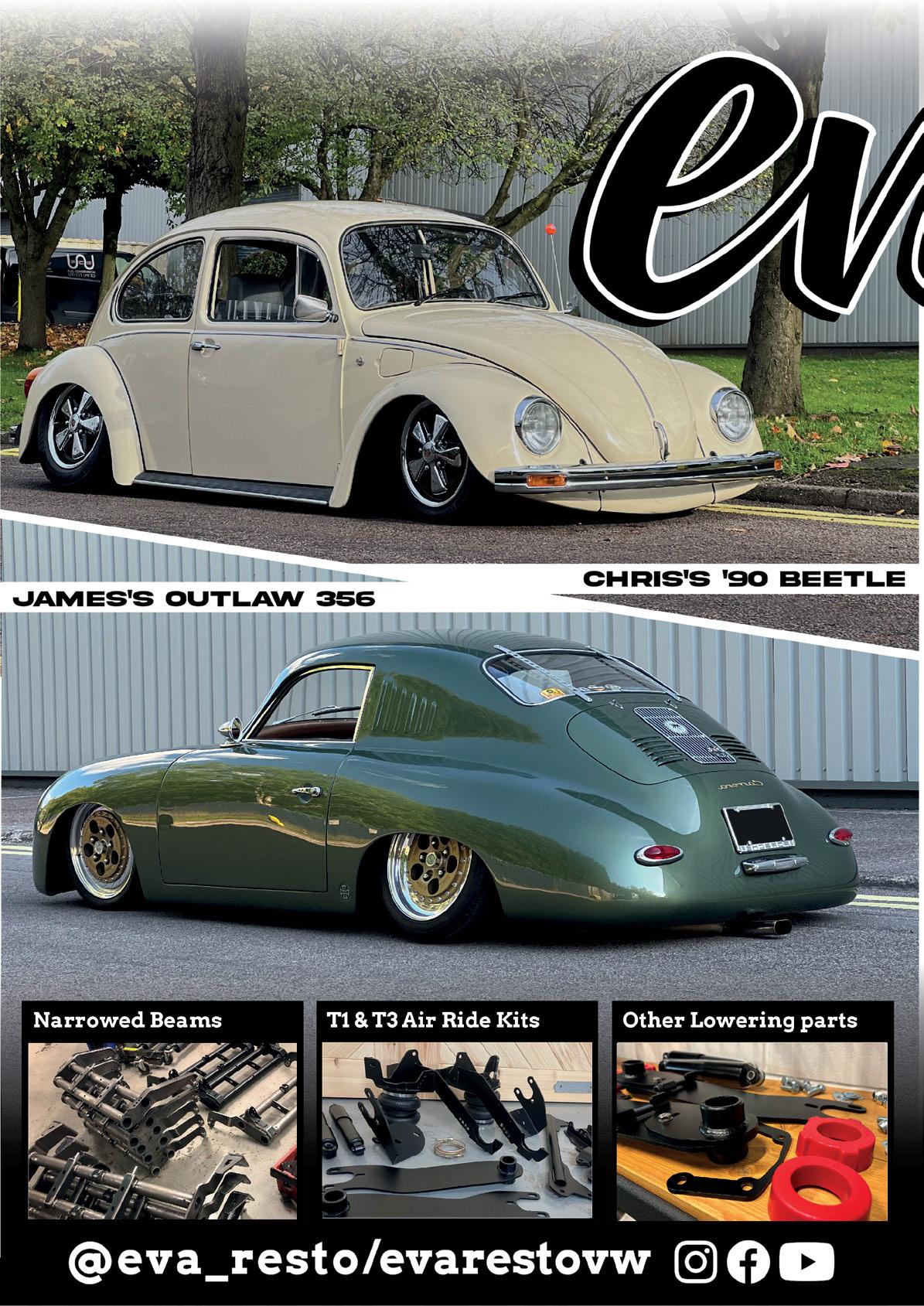

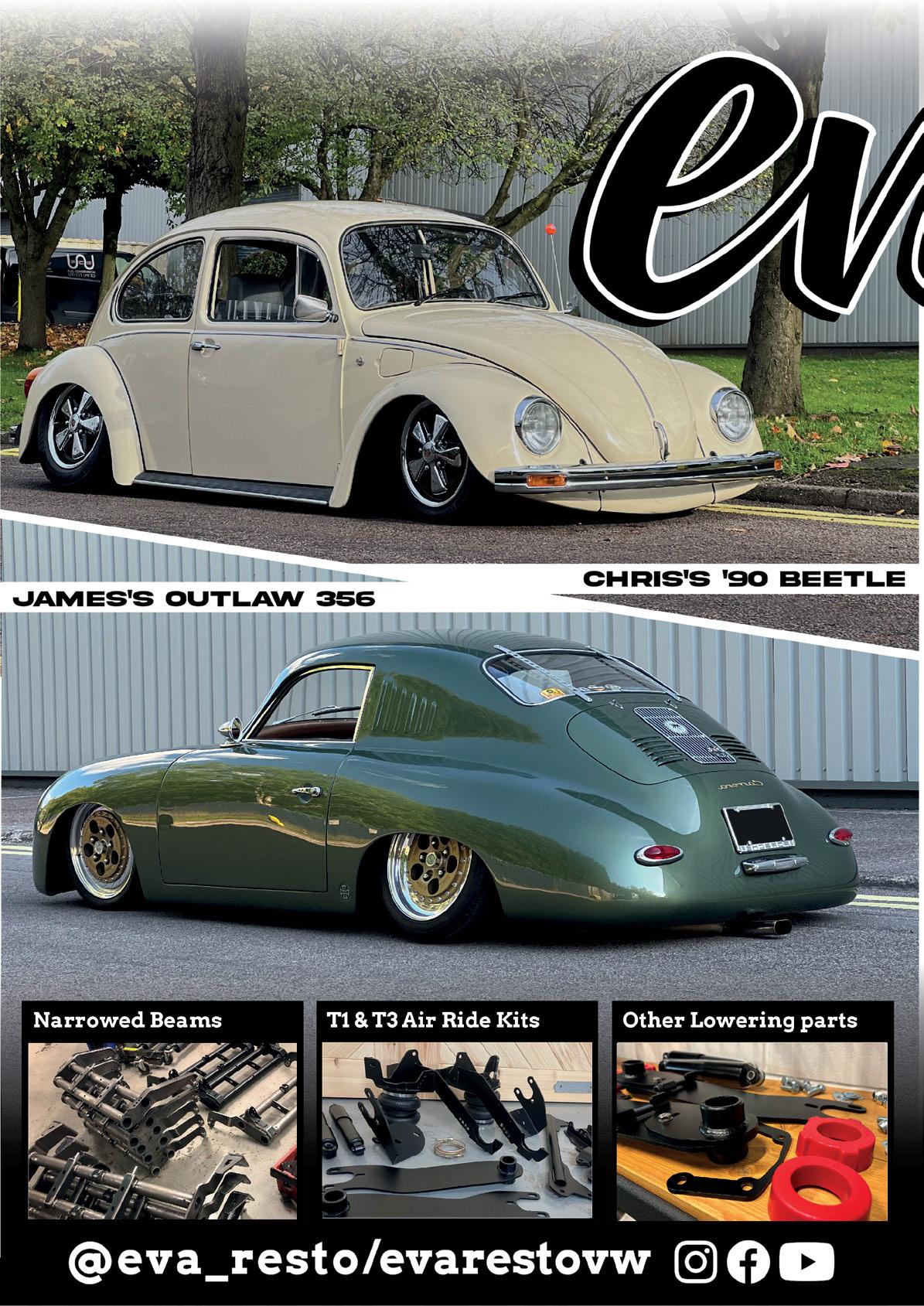

A big deal for 356 buffers, as are some of the features carried over from the previous beehive model (named after the shape of the back lights), which were phased out less than two weeks before this car was born.

1946 – Bill Burke, a young G.I. and keen hot rodder, recovers an abandoned aeroplane fuel cell. He takes a chopped-up Ford Model T chassis and flathead V8, he cobbles it together, and that’s how the legend begins.

There are two kinds of people in the VW scene – those who Mexican and those who Mexican’t. No, don’t go!

History seems to state that the people who bought into the KDF scheme lost everything, but this isn’t entirely accurate. A case was brought before the courts by a large number of Sparkarte holders in 1950, led by a scheme member named Karl Stolz.

I first discovered I was interested in motor cars way back during the Second World War. At the time I lived in Kettering – well, I was born in Kettering and I’m still here. At that time I lived in the north part of the town, and being born in 1932.

Having never left Texas, the overall condition of the van was great, with only a few minor home repairs which Neil rectified and straightened out almost immediately.

Newsstand distribution – www.magazineheavendirect.com The editor or Hayburne LTD gives no warrantees, assurances or guarantees and makes no representations concerning any services or goods advertised or featured in this magazine. Hayburner Plus is Printed in the UK. We hope you enjoy Issue 46 of Hayburner Magazine. SOMETHING ELES

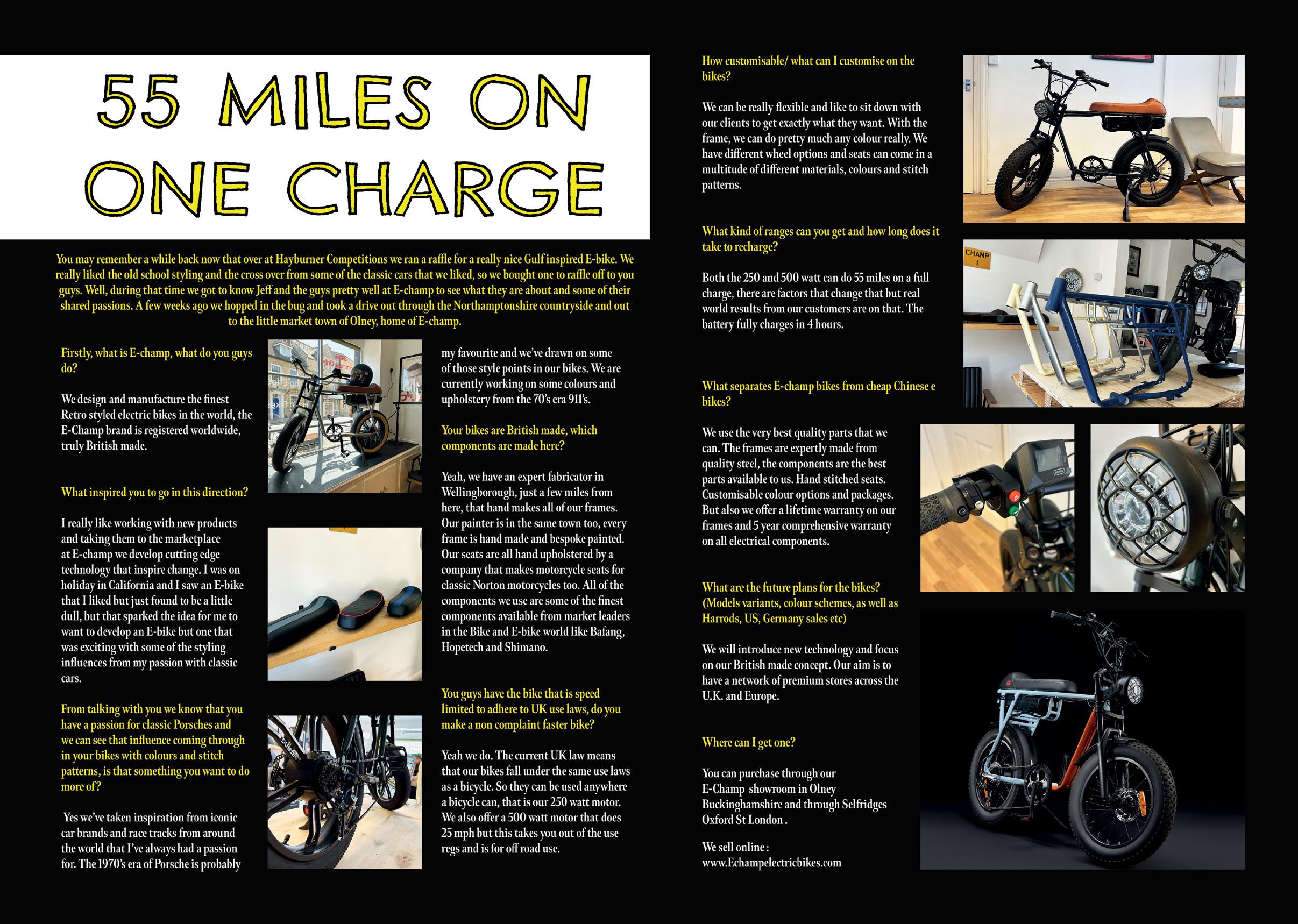

NOTCH PRIDE AND JOY SEASIDE 3X - DOUBLE PHOTOPAGES 52 -BUS SELECTA’S 94 - 99 PROBLEMS 89 - SHOW CALENDAR 70 - AIR-COOLED COLORING 132 - E-CHAMP

356-A BBS 4 EVA

106 62 150 * 126 134 HAYBURNERPLUS HARDCOPYONLY Subscribehere HAYBURNERPLUS HARDCOPYONLY Subscribehere

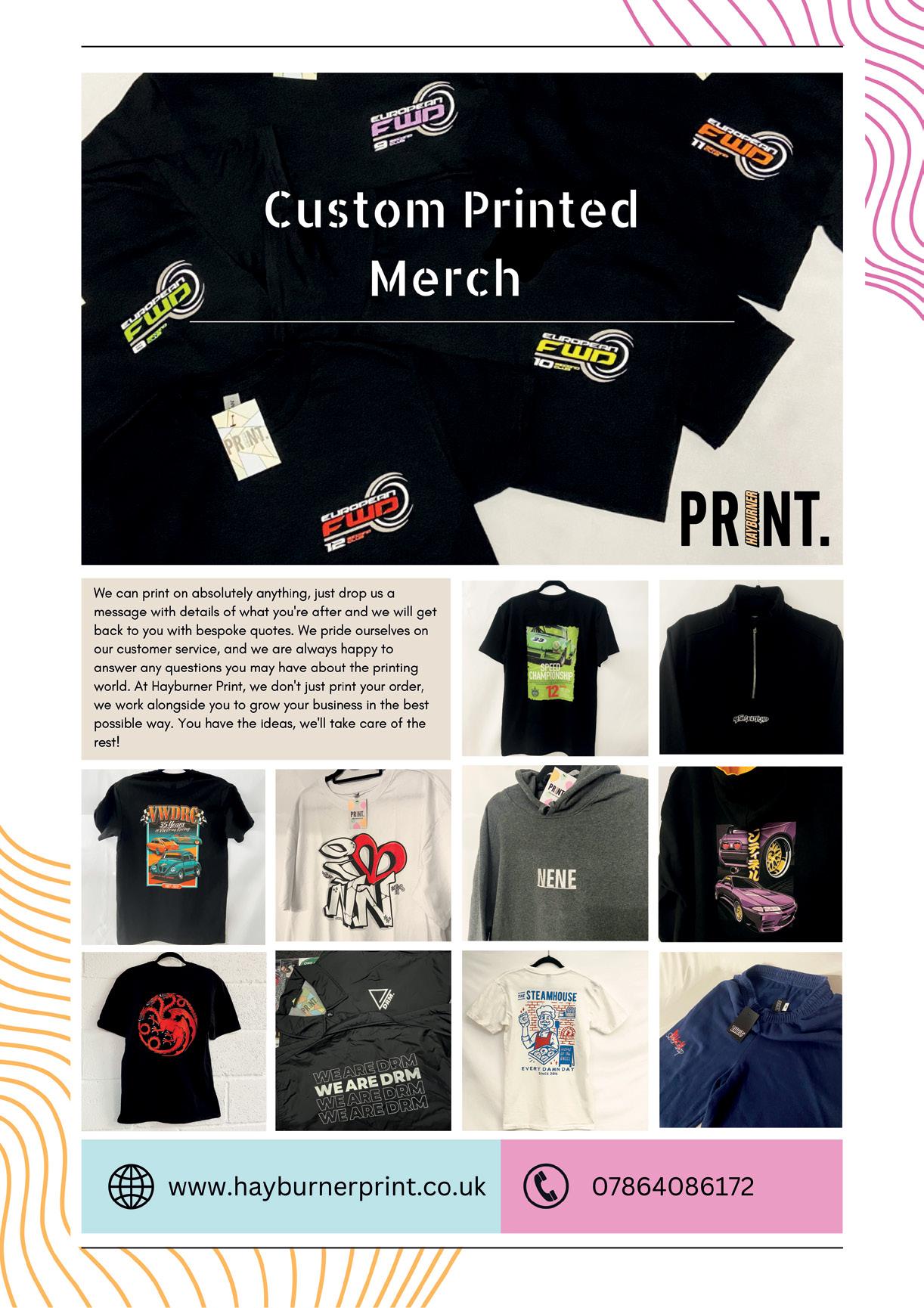

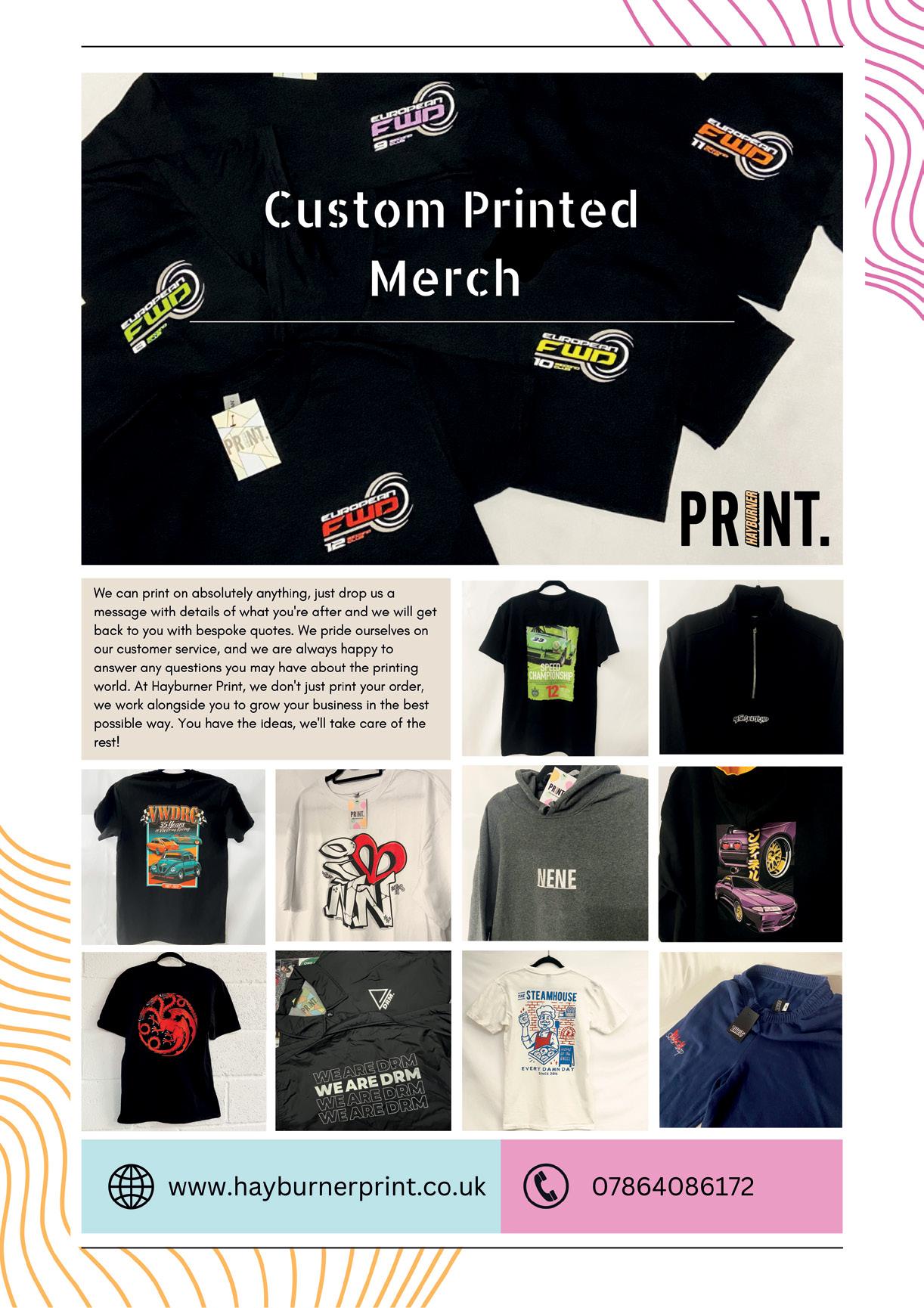

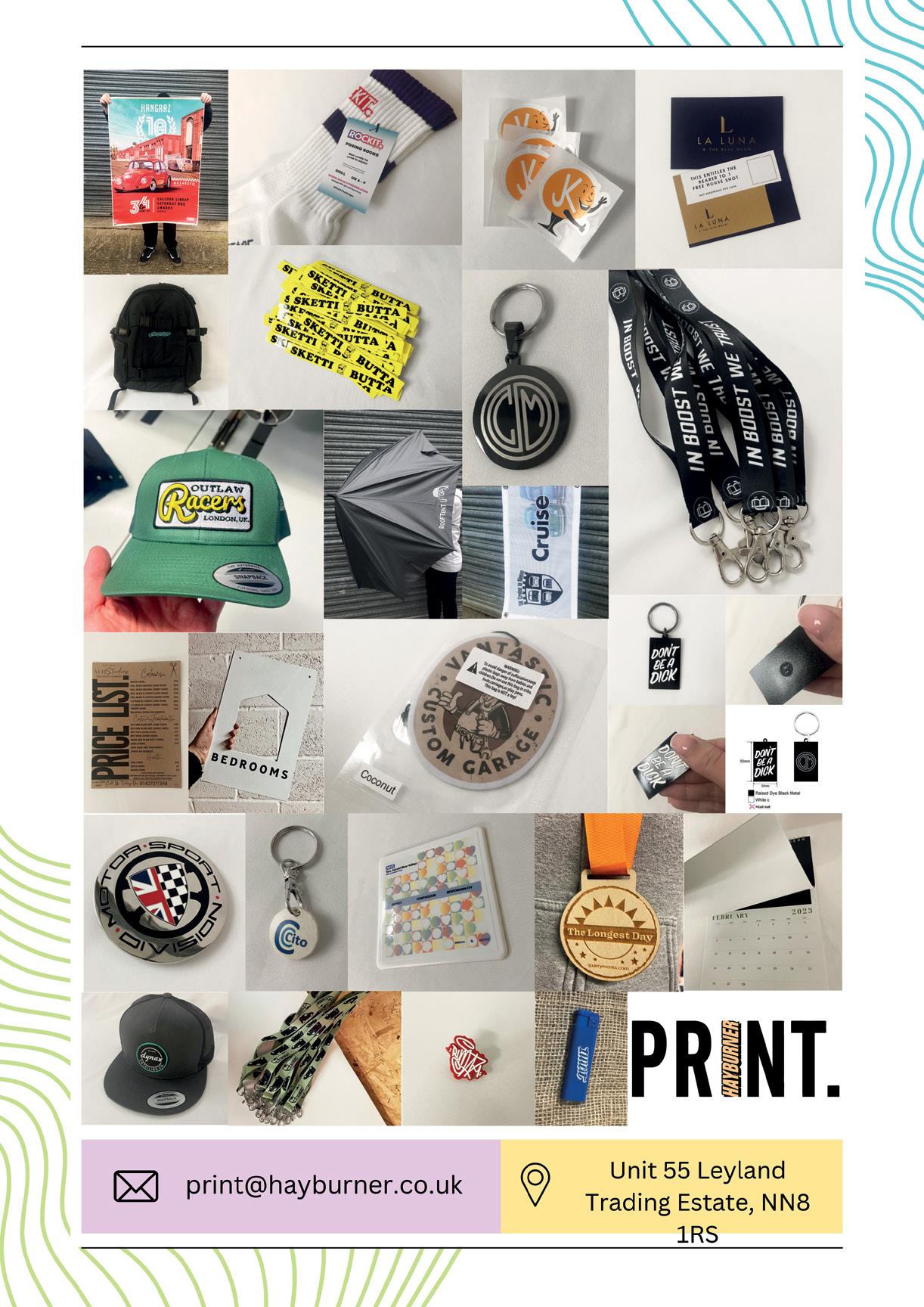

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

20

WORDS BY NED FAUX PHOTOS BY JULIETTA ARDEN TAYLOR

I believe the last instalment went a bit like this: “On my still to do list are passenger side signwriting, diesel heater, fit door cards and interior, modify exhaust, and fit door locks and seals. It’s only a few days’ work but with the mag going to print in a couple of days, Ninove at the weekend and Volksworld the next, I’m really up against it. I’ve

spoken with Ewan, letting him know it’s going to be a couple of weeks yet, and he’s been once again extremely cool.” I guess that’s where I should pick it up.

The bus was back at Hayburner HQ from the epic build-up day at T2D and we were slowly

getting on with it. Ewan and I had originally settled on a finish date of 12 April, but Ewan gave me a call and enquired if it might be possible to get the bus back for his birthday weekend which was 12 days earlier. I knew when he asked that it would be tight, but being a people pleaser and feeling a bit guilty about how long the project had taken anyway, I just replied with “Of course, mate. No problem”. This turned the three weeks I’d planned to finish everything and get some decent road miles on the bus to under a fortnight. I think this turned into the hardest working two weeks

of my life. I know I said that it was just a few bits to finish, but when every single nut, bolt and component has either been replaced or restored on the entire bus you start to find more and more that needs work.

For instance, building up a cab door top – just a couple of seals, right? Na, it never is. They take a full day a side to fit properly and that’s if you already know what you’re doing. I had to call in some help. On and off, Steve Walker, Drummer Mat and even his dad Andrew were coming and going to lend a hand.

22

I even dragged Dan from upstairs in the office to muck in pretty much every day. It felt at the time like everything was a nightmare and nothing was going my way. I genuinely find it hard to think back to what went on that week because it was just so stressful and because of that I sadly took very little in the way of photographs or video. When you’re in a tight space, cursing something that just won’t fit, the last thing you want to do is get out your phone to document your torment or have someone stick a camera in your face.

The DVLA demanded an inspection, which they seem to do so often these days. The inspector came and did his thing. He seemed instantly happy and the reg arrived just in time to have the number plates made up. I then got on with restoring the rest of the sign writing on the other side, while my good friends beavered away on other parts of the bus. Mat was modifying the exhaust to fit behind the ribbed bumper, and Steve was fitting seals. I then started on the door handles which I’d just picked up from the locksmiths. Annoyingly, the cab door handle was

the wrong type, and by the time I’d taken apart three different handles I had in my stash in an attempt to make one work, I just gave up and robbed the NOS handle that I’d treated Shuvarda to the year before and donated it to the cause.

The interior was the most enjoyable job, being such

a simple layout. With all the panels ready cut from MadMatz it was an easy-going rewarding job with everything slipping easily into place. I was made up with the way the cab looks inside. It really is as comfortable as it looks.

After days of stress and hassles it was time to take

24

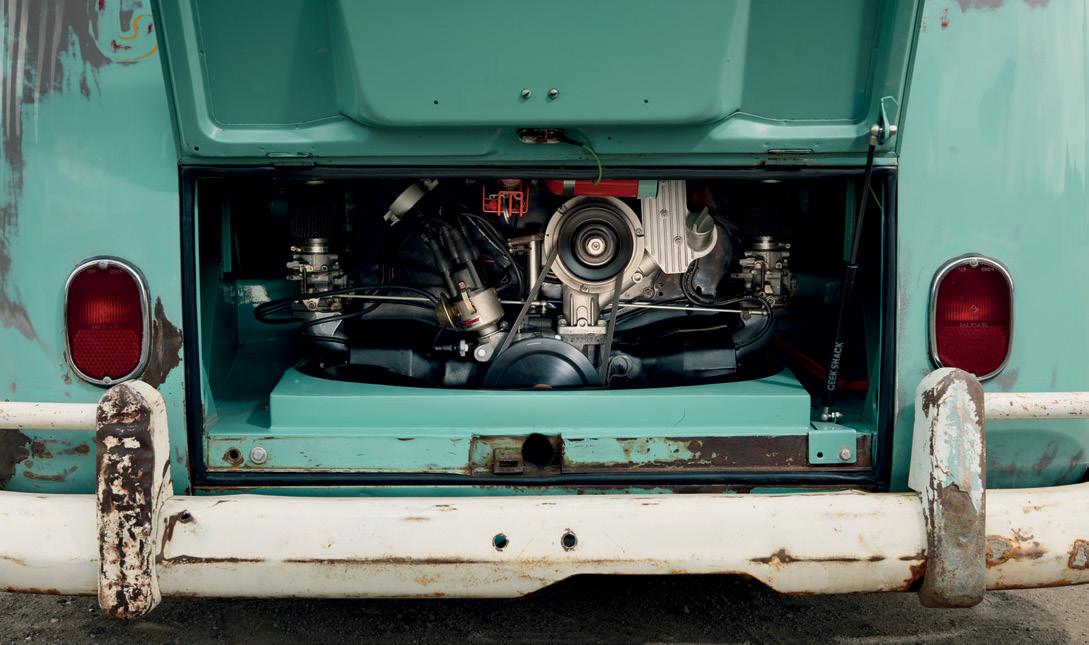

the bus for its first test drive. I was the last one at work and the sun was going down. I left on my own. I only live 20 minutes from the unit and I thought it would be a perfect distance to see what’s up. I drove out of the workshop, left the industrial estate and the heavens opened! It really did get a proper test, seeing as it was its first drive in 45 years. Considering

the conditions, it performed really well. The motor had plenty of power and with the combination of brand new steering components, Bilstein shocks and tall radial commercial tyres it has to be the best handling Split bus I’ve driven … and the brakes! Wow, those discs along with a servo really work. It stops like a new car. The electrical system was

perfect, with every knob switch and dial working as it should.

Before I drove it back to the office in the morning, a friend of mine and Hayburner photographer Julietta came over to do a quick photoshoot on and around my driveway. I then drove to work and Vic got to cleaning it up ready for us to deliver it to Ewan. I really wanted to get some more road miles on it before I delivered it, but the change in date meant we didn’t get a chance to shake it down as I would have liked,

but it seemed everything was in order so I drove along with Vic the 60-odd mile journey to meet up with him and hand over the keys. Annoyingly, it was bloody freezing that day but it didn’t kill the mood. It was great to see Ewan as I’ve not had a chance to visit since before the pandemic. He was over the moon with the bus. I could tell it was overwhelming. When you’ve been watching something being built over a year or so and then have it in front of you, it’s a strange feeling. I was exhausted but at the same time kind of sad it was all over. Talking to someone

in detail a few times a week over a period of time about a project you’re all passionate about becomes something you look forward to, and I started to wonder what I’d do with that time.

After a little Facetime with Lloyd, we said our goodbyes and Ewan trundled off up the road. Watching it drive away made me think how it’s easy to forget just how bad this bus was before it arrived at Lloyd’s and just how far it’s come. I have to say I was pretty nervous leaving the bus with him. I know

everyone who worked on the project is trustworthy, but things can and do go wrong with fresh builds.

I got a call when he got home and all was well. Ewan used the bus over the next couple of weeks and found a few teething problems – nothing major, but things we would have maybe picked up on if we’d had more time with it. The gear shift developed a selection problem, the cargo door latch shat itself, there was a fuel sender issue, and the fresh airbax annoyingly leaked while on a trip back from Scotland.

Ewan did say it was torrential rain for hundreds of miles but still, if it’s set up right it shouldn’t really leak.

Luckily enough, Ewan’s working not far from Chris Riley at Garage 87 and they’ve been looking after the bus to iron out anything that comes up over the first 1000 mile shakedown. I should really take the opportunity to thank Chris and Iain Burns for looking after Ewan on this one at such short notice, and also for being so professional and doing a great job. We know it’s never easy following other people’s work.

Although the bus is with Ewan and is being used, he’s decided it’s a bit noisy to drive, being a completely empty Panel Van. I’m going to drive up at some point

so we can hang out and line the inside, maybe a bit of sound proofing. Now the pressure is off, this is something I really look forward to.

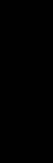

There are a lot of thanks I need to give around this project: all the guys at T2D; Mark at MadMatz; N2 Engineering; the VW Engine shop; Rusty Lee; Radu; Air-cooled Auto Elec; FBI VW; Just Kampers; Rick at Schofields; Steve Walker; Dan Morrisey; Mat Ward; The VW Engine Company; and last but certainly not least, the man that brought it back from the dead, Lloyd Jackson.

28

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

WANT

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

01482 374116 www.kingstownshipping.co.uk 5% VAT Clearance & NOVA DVLA Registration Import / Export Service Marine Insurance Inland Transport

38

WORDS BY PAUL RILEY PHOTOS BY JOSS ASHLEY

Chris has been interested in VWs from a very early age. Having been brought up in a family that regularly attended VW shows and that was involved in all aspects related to the brand meant that he became familiar with all the air-cooled VW range. His very first few words included “Beetle”, as Mum regularly took him out in her 1302S Beetle, one that his dad bought back in 1982 as the “daily”. He would creep into the

garage while his dad was restoring the car a few years later and watch some of the very necessary repairs taking place.

It was pretty much inevitable that he would become interested in cars as he grew up. By the time he left school, Chris had decided he would like to pursue a career that involved working with cars. After a few

years training to become a vehicle technician and working at a couple of local garages, he decided to follow his passion, and set up what is now Garage 87 in Cheadle, Cheshire.

One of his first jobs there was further restoration of that first car that his dad, Paul, bought way back in the early 1980s. He decided that it warranted a full nut and bolt restoration.

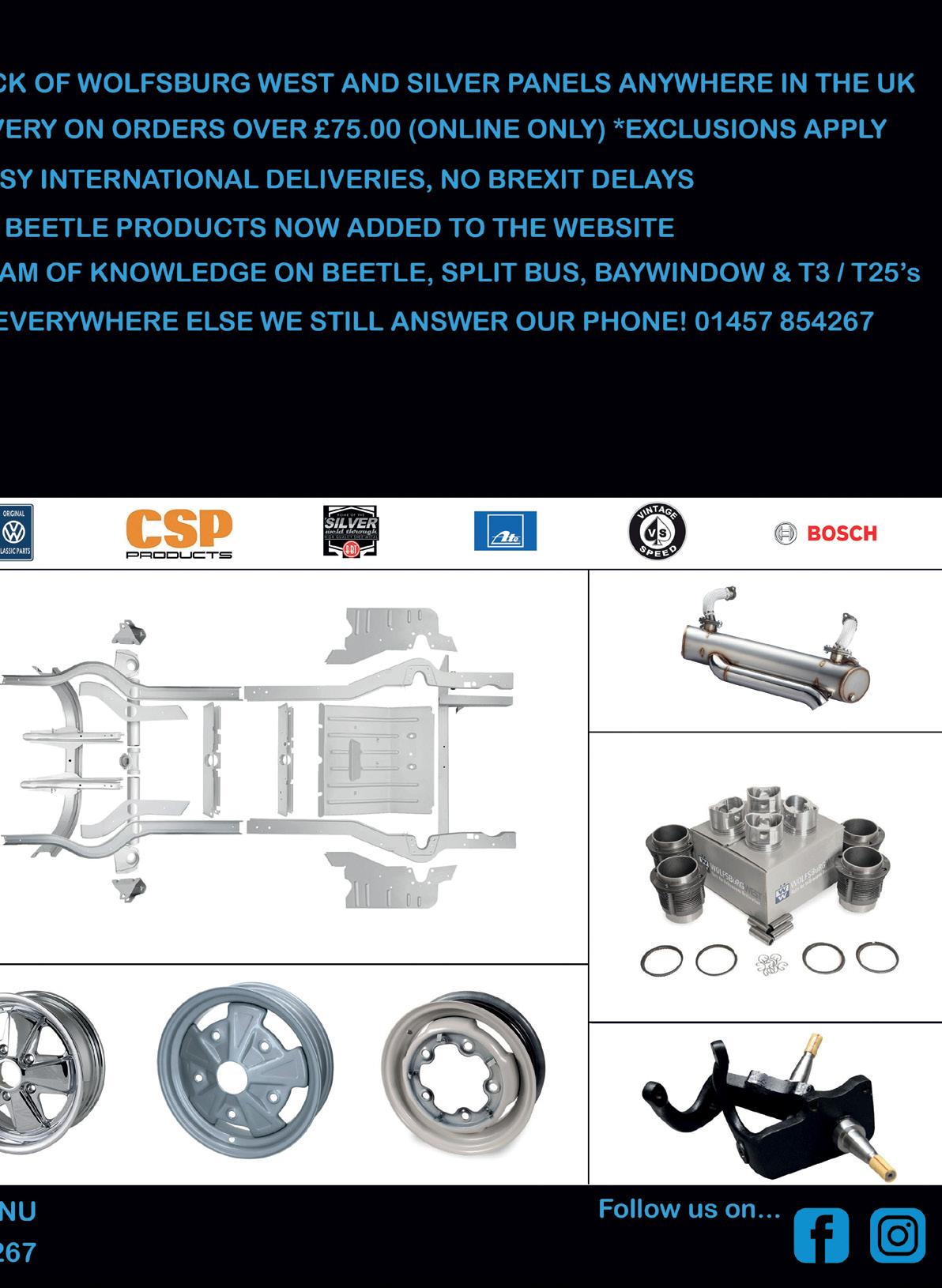

Ever since Chris was old enough to reach into his own wallet, he has continued to buy VWs at an even greater rate than his dad. One such vehicle is the Greek delivery van. While holidaying in Greece, he saw one of the green delivery vans in use and decided there and then that he had to have one.

This van was originally owned by the Kordas family in Louros on mainland Greece, who had a specialist shoe

40

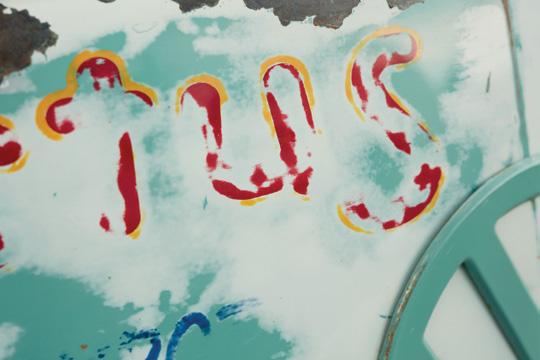

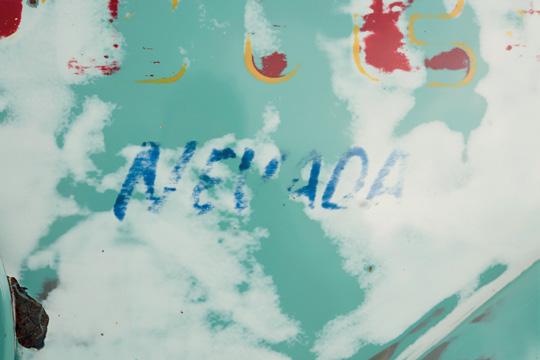

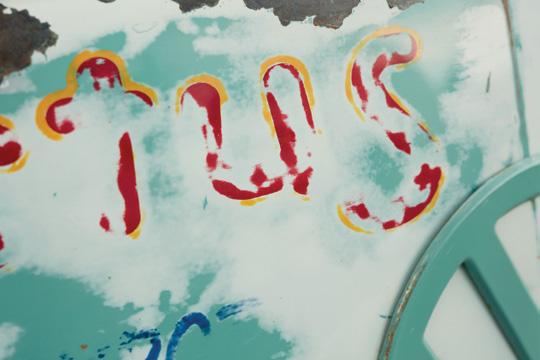

shop, possibly wedding shoes. In Greece in the 1970s all delivery vans had to be signwritten, describing what business it was and what they would be carrying. The lettering says that the van carries “Luxury Shoes and Goods”. While obviously written in Greek, many ask if it’s Russian, German, Arabic or Japanese!

After initially buying a Brazilian Split and having a deal that fell through, Tom Booth was prompted to

secure a deal on the “green van” instead, with money burning a hole in his pocket.

Tom spotted it at the back of the storage unit at M and J VW in Gloucester. They hadn’t even had a chance to clean or prepare it. When it arrived from Greece it still had shoe boxes, clothes hangers and original 70s Greek dust! There’s even an old faded newspaper on the dashboard.

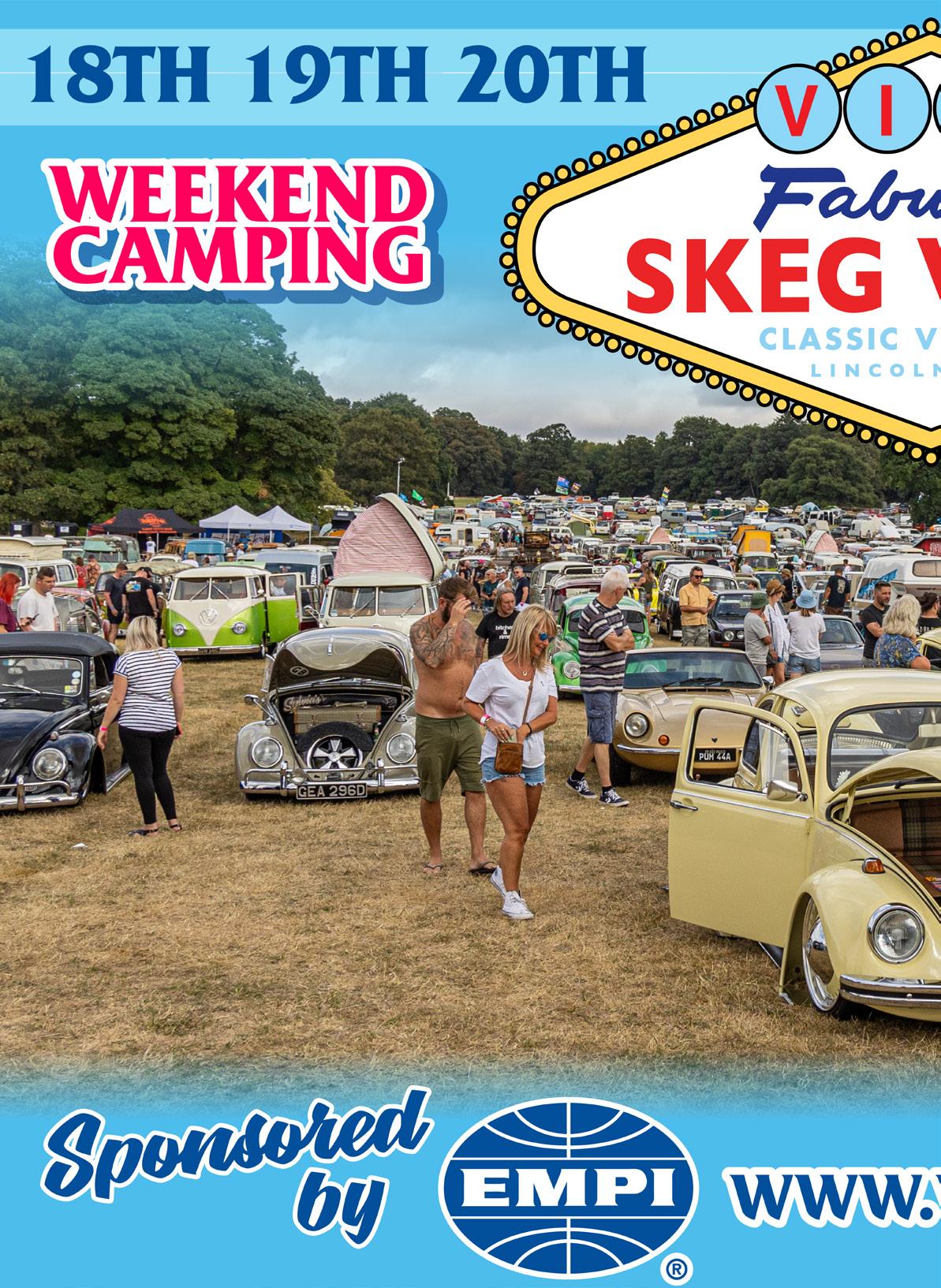

Tom slapped a battery in it and drove the van back home, where he and his friend Austin got stuck into recommissioning it at their business, Waboo Automotive. Through some conversations online they decided on a quick build and slam job with George from Fresh Kustoms in Australia. He would come over

for a couple of weeks, help the guys, and head over to Skeg Vegas in 2016. Work carried out by Tom included 4 inch narrowed and 7 inch raised beam, front tubs, doors tubbed, rear end “notched” and tubbed. The engine and gearbox were raised with a custom fuel tank and filler neck. Tom continued to

42

use the van over the years and carried out more work and more lowering and then attended Ninove in 2018.

Meanwhile, Chris had always kept an eye out for the right van, and having missed out on another similar van he was lucky enough that Tom saw this

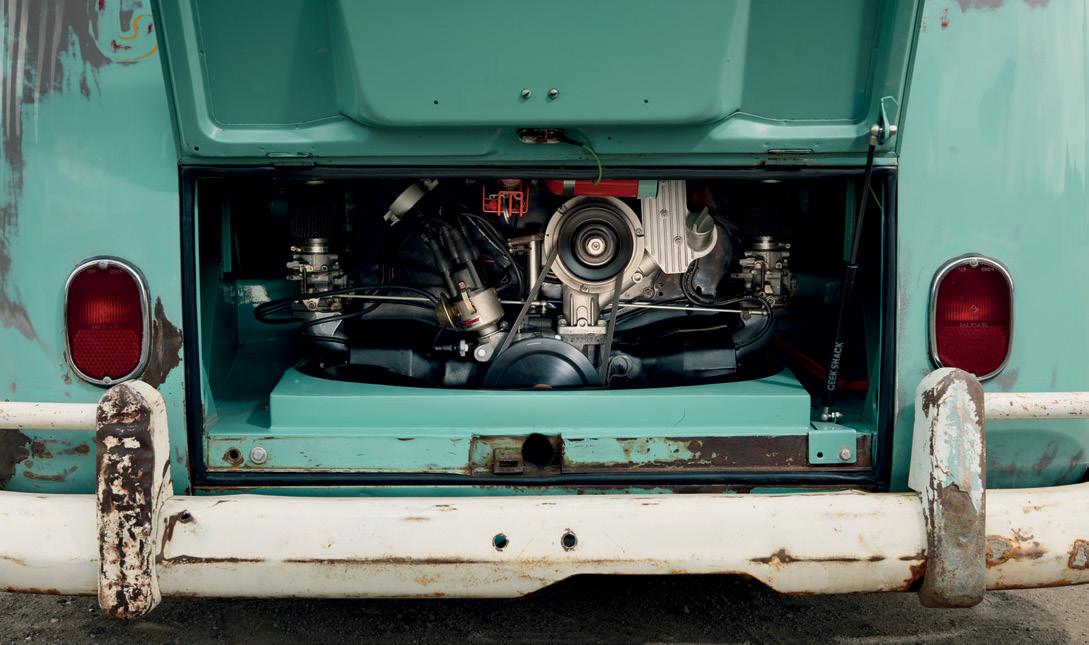

and messaged him an offer on the green van. Tom didn’t want to let it go without completing some underside restoration work. Due to lock-down, the deal continued for a further eight months, meaning that Chris got a completely mechanically restored slammed van to put his own mark on.

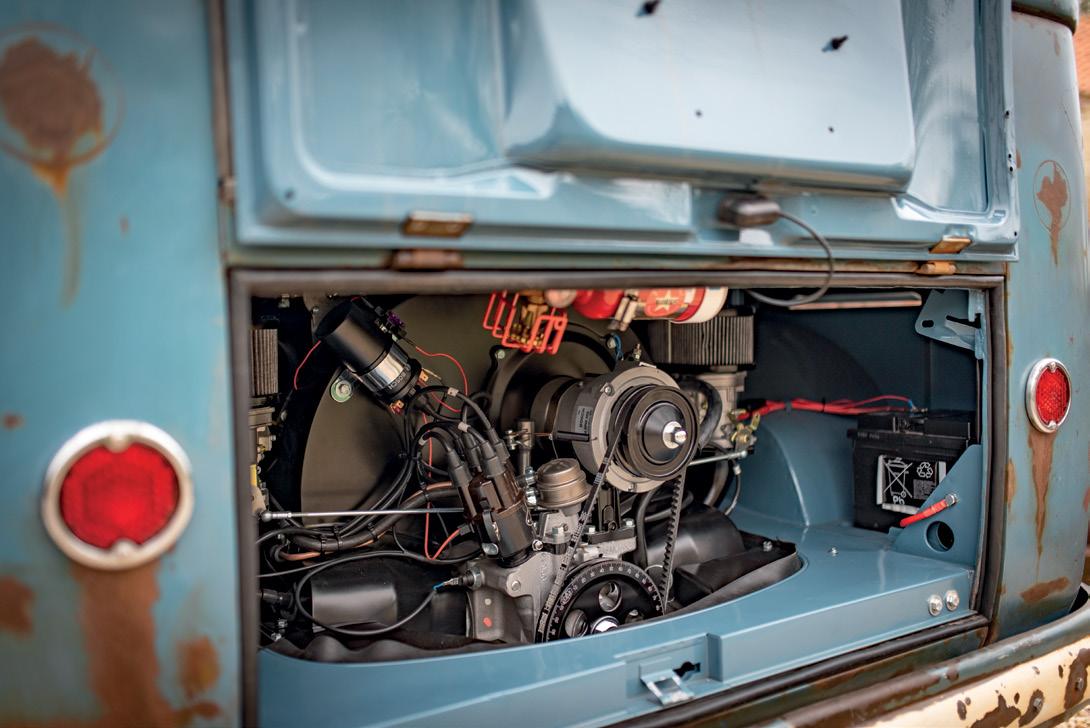

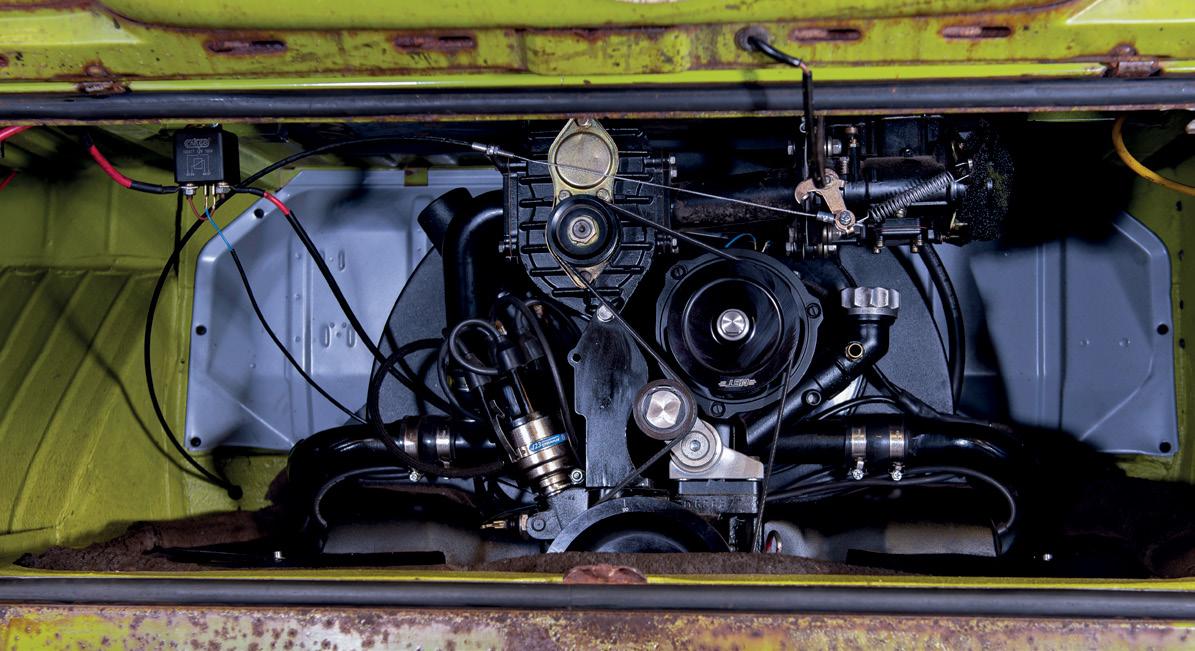

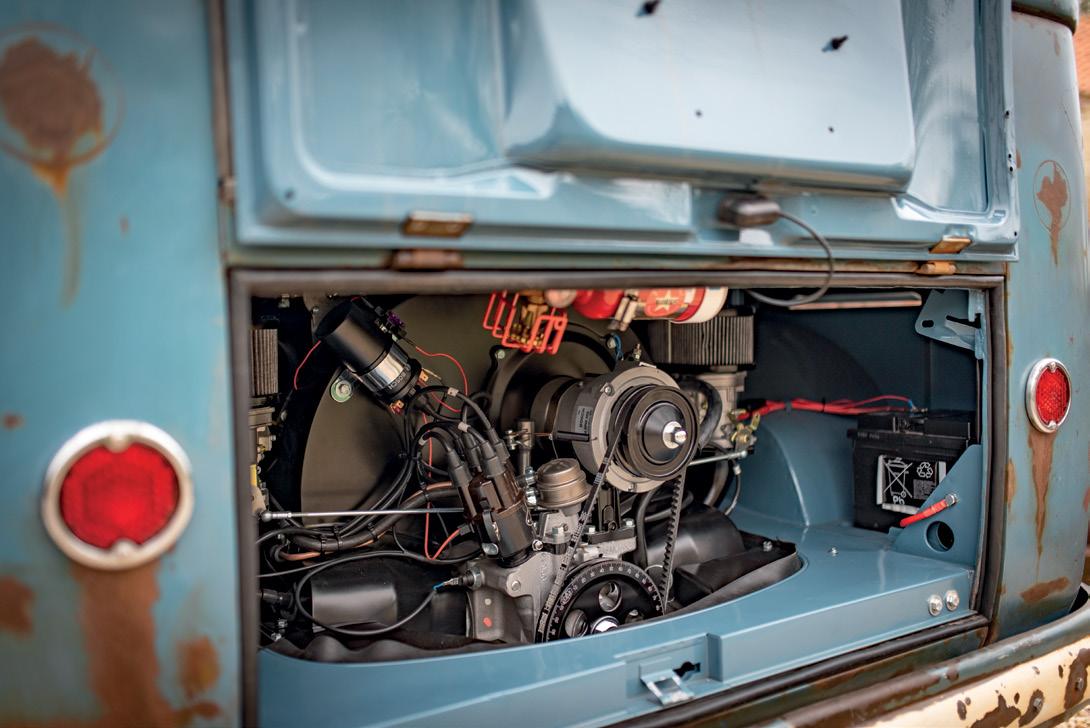

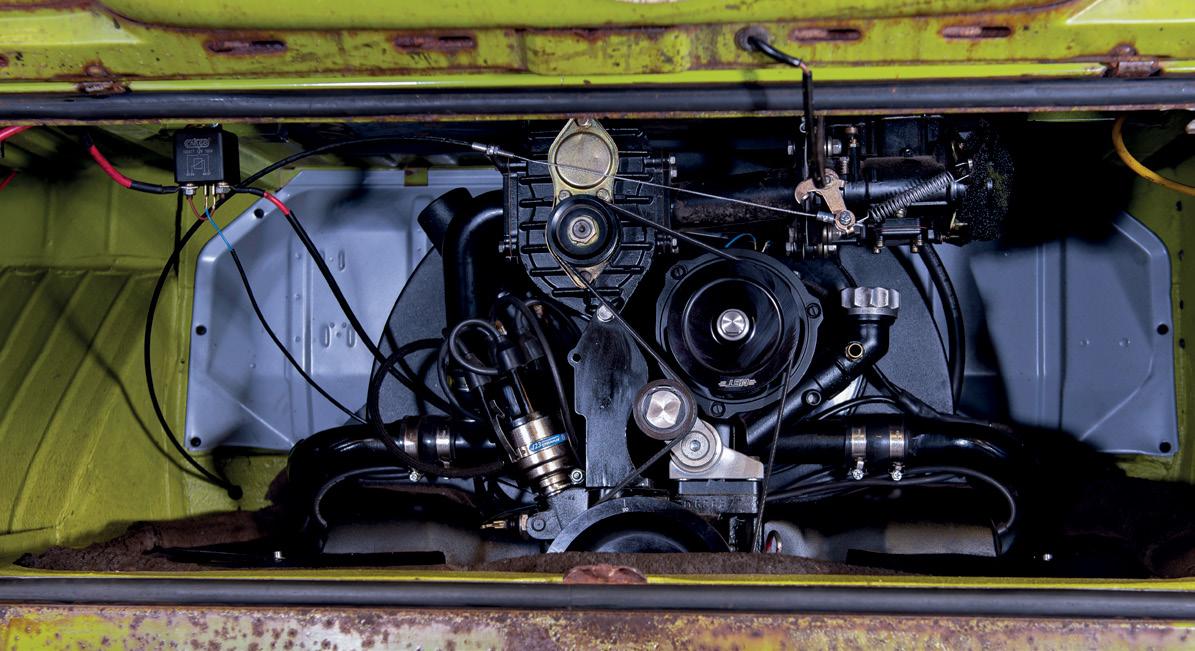

Chris has since treated it to a general tidying up, new interior including a custom “flip” front bench seat and Rusty Lee bed in “Westy” plaid, a sound system, some heating and fresh wiring from Iain Burns. The original engine, albeit reliable, needed some tidying up and oil leaks fixing. It was removed, the engine bay painted, tinware powder coated, and refitted with a Kompressor Haus supercharger kit and Vintage Speed exhaust. Finding the right set of wheels has been a challenge, but Chris eventually

found the 14x7 Gotti wheels which suit it perfectly.

Chris hopes to use it more this year, having started the season by returning the van to Ninove in March 2023. Thanks go to family and friends who continue to support Chris with all his car-related projects – and all those who have helped in some way with the Greek van.

44

TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

WANT

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

WORDS BY NED FAUX

WORDS BY NED FAUX

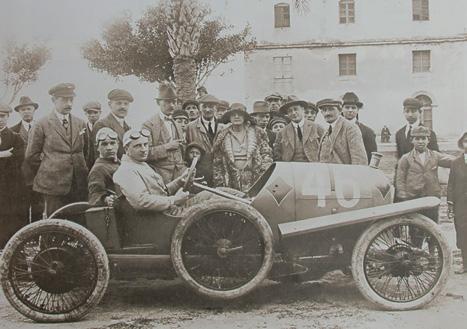

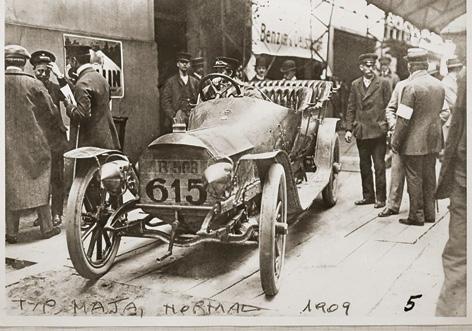

With discussions happening around Europe since the 1920s regarding the concept of a “people’s car”, Porsche had absolute confidence that they were about to win the contract to work on development of the first KDF prototype. The work actually began months

before Ferdinand Porsche or the RDA had signed anything at all. Porsche had already worked on a number of small car designs. In fact his design study was to be one of many compact-style cars which he had been responsible for after the 1901 Lohner-

Porsche Voiturette, 1906 Austro-Daimler Maja, 1922 Sascha, 1926/28 Mercedes-Benz 5/25 PS, 1930 Steyr XXX and two development projects which closely resemble the Beetle – in 1931/32 the Porsche Type12 for Zündaapp and the Type32 for NSU. Although

built by Porsche, the Type12 was the brainchild of Zündaapp’s owner, Fritz Neumeyer. It was similar in dimensions to a Beetle, and also with a rear engine, but with a seemingly troublesome 5-cylinder radial engine putting out 26hp.

1930 Steyr XXX

1922 Sascha

1926/28 Mercedes-Benz 5/25 PS

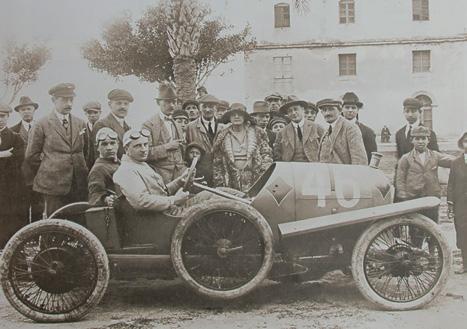

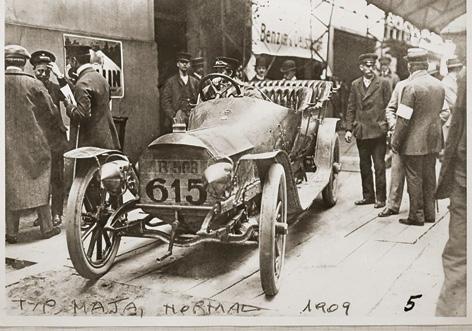

1906 Austro-Daimler Maja

1933 NSU Type 32

1932 Zundapp Type12

1930 Steyr XXX

1922 Sascha

1926/28 Mercedes-Benz 5/25 PS

1906 Austro-Daimler Maja

1933 NSU Type 32

1932 Zundapp Type12

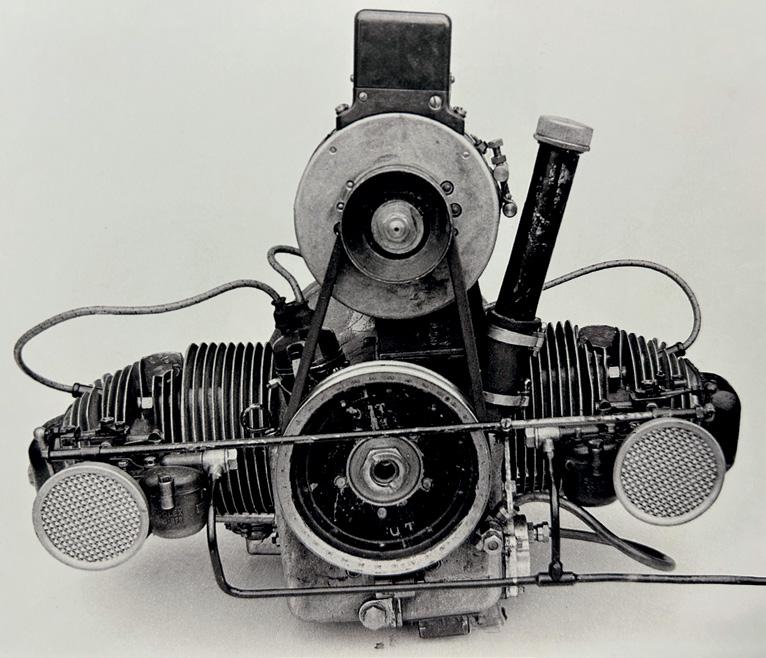

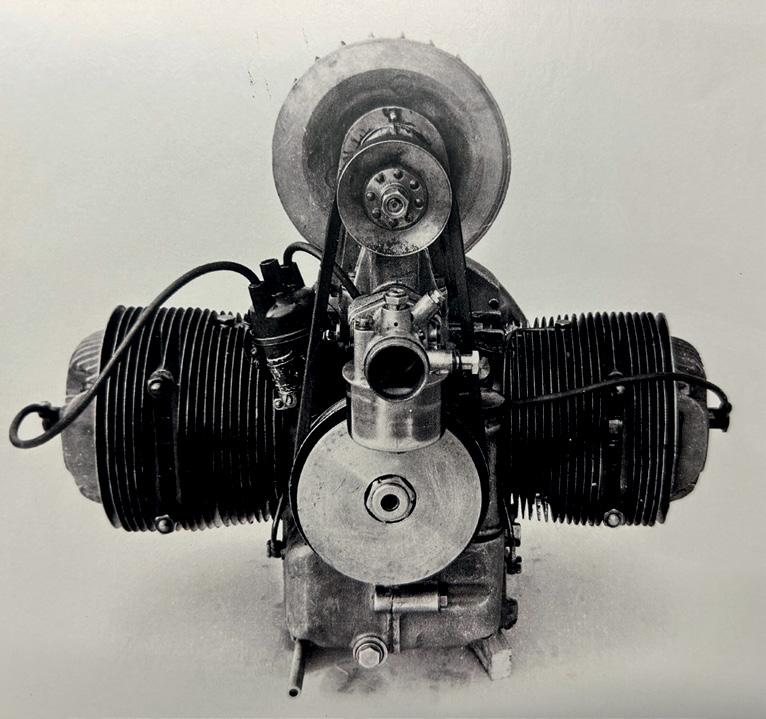

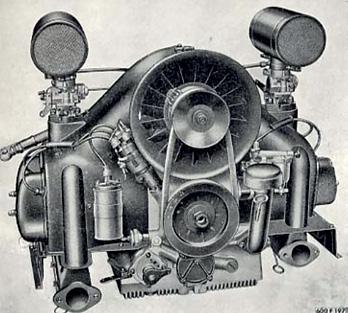

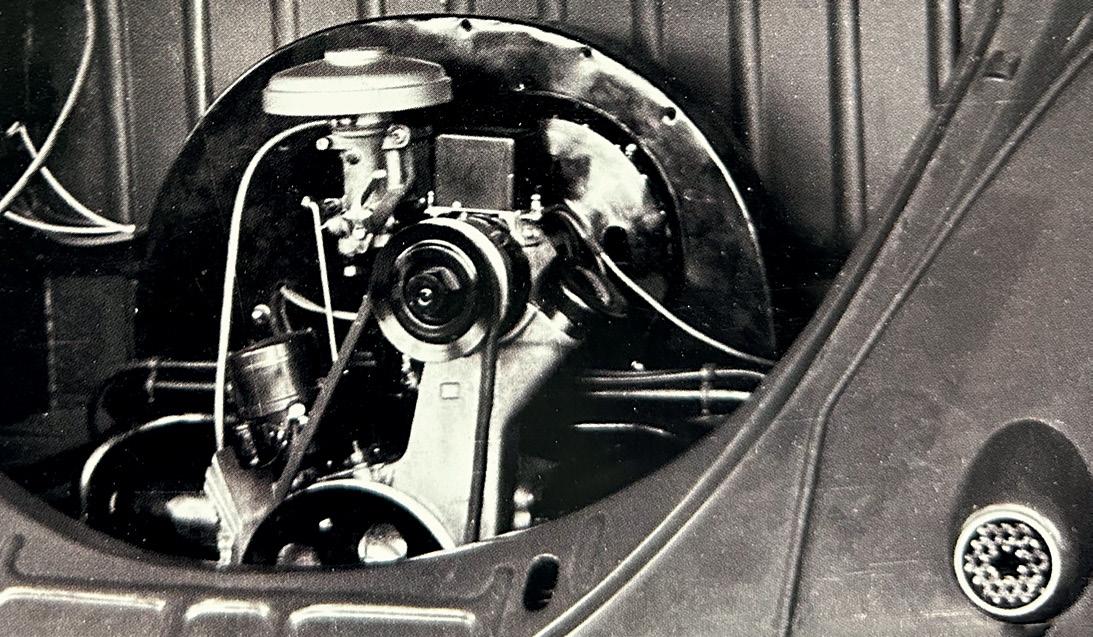

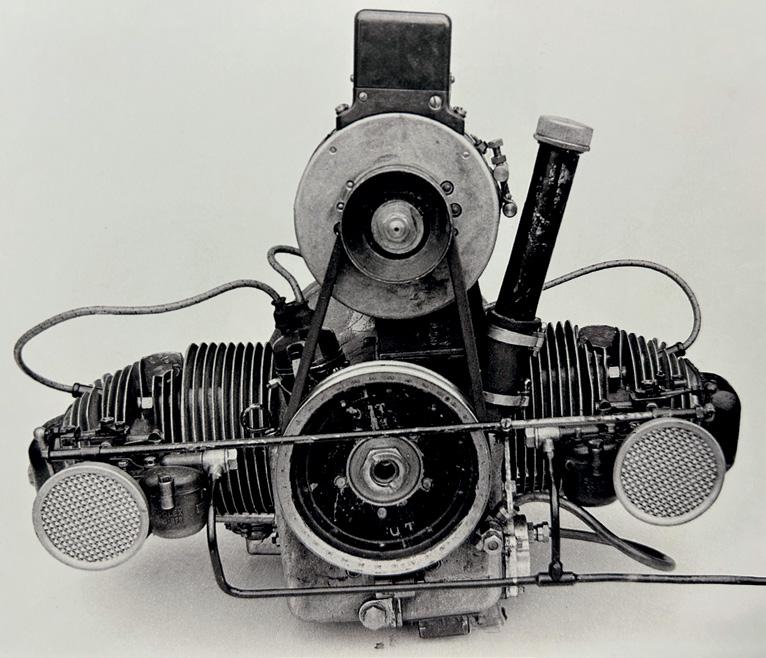

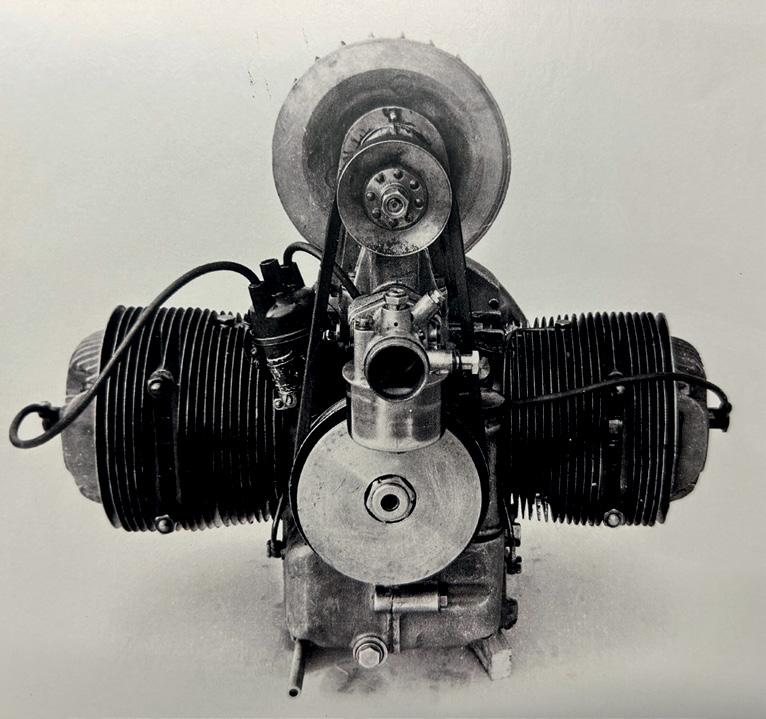

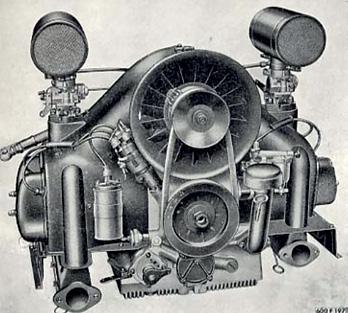

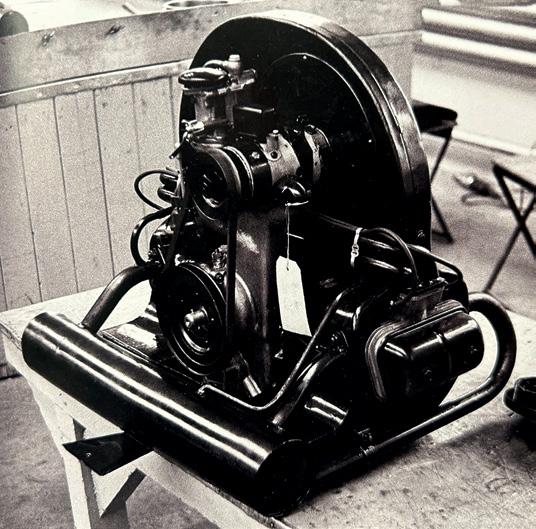

In early meetings regarding their new project, Adolf Hitler seemed adamant that the people’s car should be powered by a 3-cylinder engine with its cylinders arranged in a radial star pattern. Porsche called in his leading engine specialists, Josef Kales and Franz Xaver Reimspiess, to make this happen. Not sharing Hitler’s vision for the 3-cylinder motor, Porsche’s technical team developed a number of engines (all air-cooled) to put forward to power the People’s Car project. There was a twin-cylinder, twin-piston twostroke motor, a horizontally opposed two-stroke twin, a similar four-stroke unit, and a “flat-four” four-stroke engine. None of the two cylinder designs performed in the way Porsche had envisaged for the car: the power output from the four-stroke flat twin was just too weak, and those twinpiston motors turned out to be unreliable.

Even with the low power output, Ferdinand Porsche still favoured the two-stroke engines for many reasons but mainly for the reason of cost. After more testing was carried out it became even more apparent that the flatfour outperformed the others in every way. The engine that shifted Ferdinand’s view was the flat-four four-stroke unit designed by Xaver Reimspiess, although I should probably add that it has been said that the design was his own take on the two cylinder motor built by Josef Kalesan. Xaver Reimspiess was an Austrian engineer born in Wiener Neustadt in 1900. In 1915 he began his training as an engineering draughtsman with Austro-Daimler. Throughout the years he was known for his precise work and a wealth of ideas. He joined the Porsche construction office in 1934. He also had a controversial claim to being responsible for the design of the Volkswagen logo and is documented as receiving a one-off payment of one hundred Reichsmarks for the design.

In case you didn’t already know that the flat-four engine

The Porsche ‘C’ engine, a twin-cylinder two-stroke unit with sleeve valves.

The Porsche ‘D’ engine, a twin-cylinder four-stroke unit.

The Porsche ‘C’ engine, a twin-cylinder two-stroke unit with sleeve valves.

The Porsche ‘D’ engine, a twin-cylinder four-stroke unit.

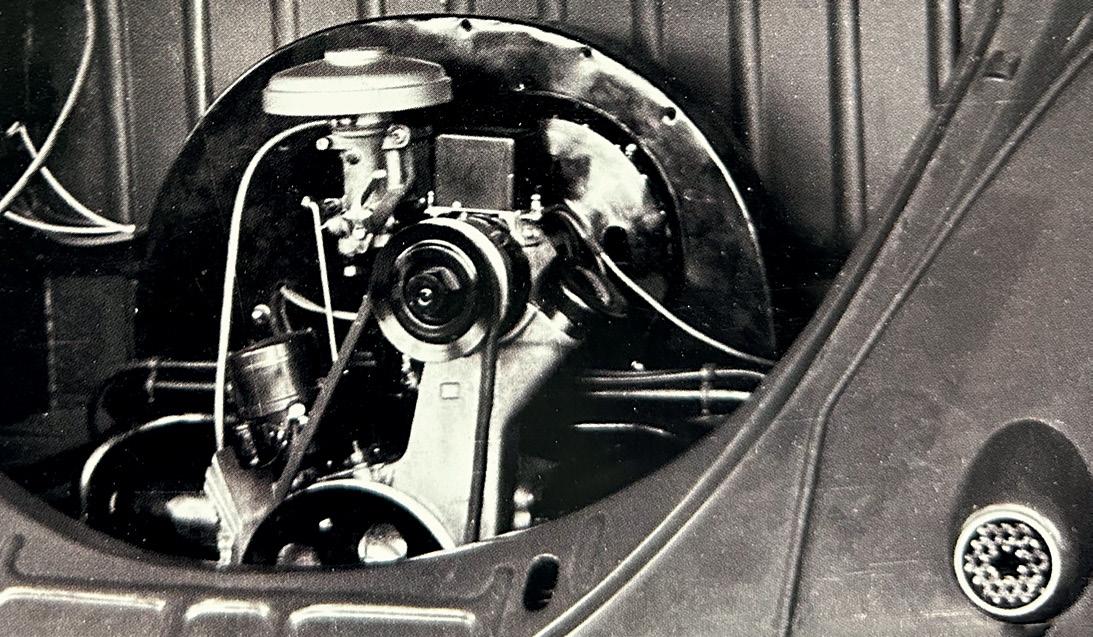

powering your Beetle or Bus is based on Xaver’s design, the boxer engine, also known as a horizontally opposed-four engine, is a four-cylinder piston engine with two banks of cylinders lying on opposite sides of a common crankshaft. Each pair of opposed pistons move inwards and outwards at the same time. The advantages of the boxer-four layout are perfect secondary vibration (resulting in minimal vibration), a low centre of gravity, and a short engine length. The layout also lends itself to efficient air cooling, with the airflow being evenly distributed across the four cylinders. It is also really easy to maintain yourself, something that was very appealing to the handson German citizens of the time. Although the design was different, the concept of a flat-four layout was not unique. Tatra introduced

an air-cooled flat-four in the 1926 T30, followed by many flat-four models throughout the early 1930s.

The motor had a far higher material cost when compared to the other concepts, to the point that other staff in the workshops

54

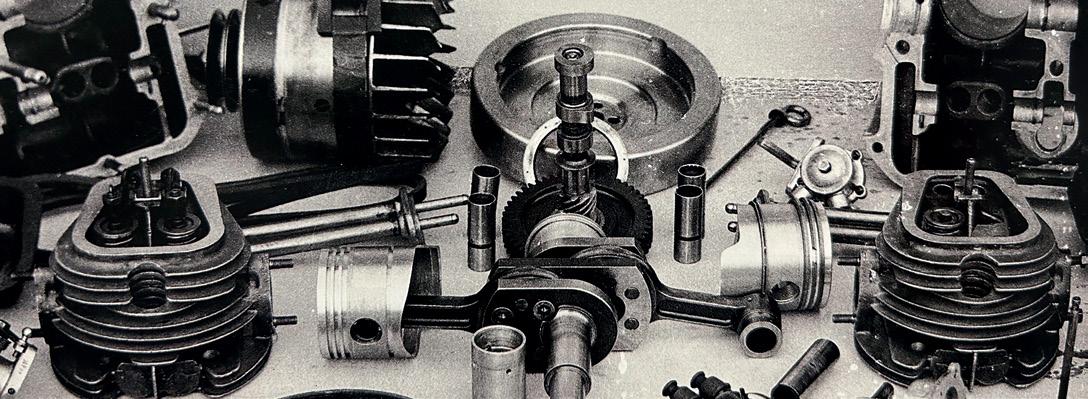

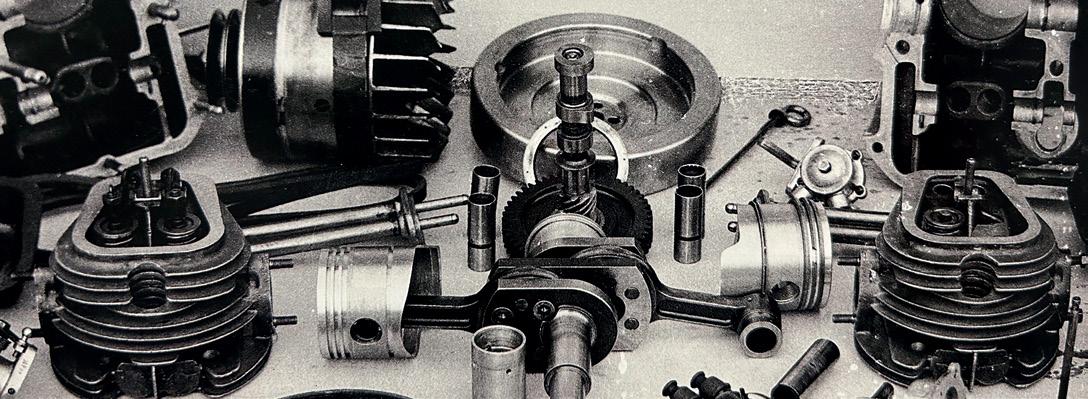

‘D’ Engine components.

Tatra T600 engine.

Tatra T30

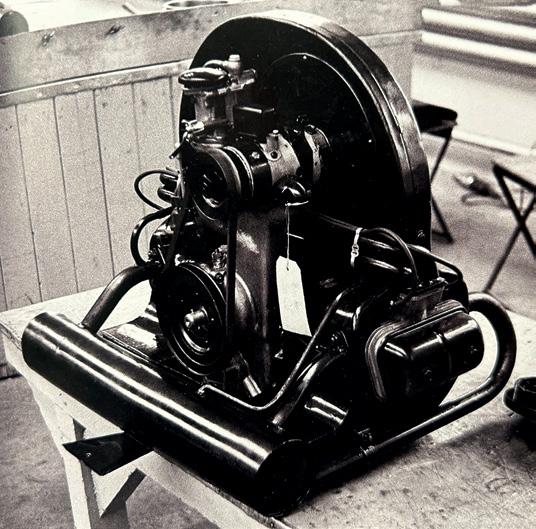

referred to his design as Xaver’s “Rolls-Royce” engine. Ferdinand insisted that Xaver make it his mission to finesse the design and get the costs down. He found that in the end, with the ease of assembling his engine, they would make huge labour savings in the long run, which counteracted the extra material cost. The final prototype was a split alloy crankcase to reduce weight, a cast-iron crankshaft with three main bearings, a single four-lobe camshaft – each lobe operating opposing valves. Each side of the engine had a single, aluminium cylinder head bridging two cast-iron cylinder barrels, the assemblies held in place by studs threaded into the crankcase. The camshaft was located in the centre of the block, gear-driven off the crankshaft. Pushrods were enclosed in steel tubes, pushing against shaft-mounted rockers to actuate the horizontally oriented valves.

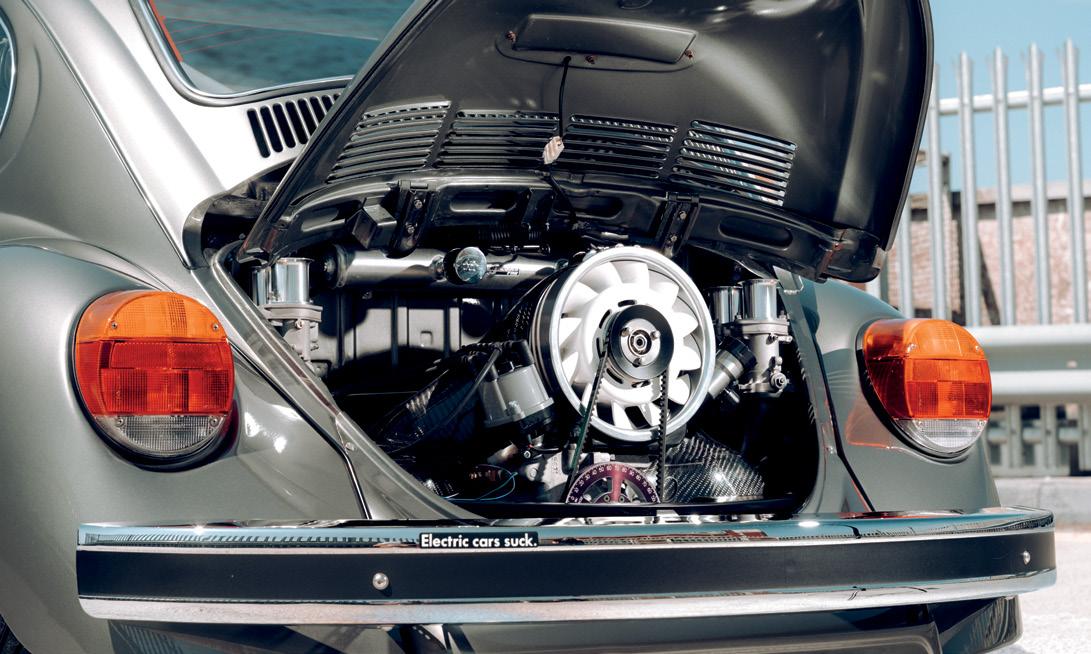

A radial fan, enclosed in a steel shroud, was driven by the generator, which was itself driven off the crankshaft by a rubber belt. The fan forced air down over the cylinder barrels, and across the oil cooler mounted to the fan’s left – so oil as well as air provided the cooling. A long manifold connected the inlet ports with a single carburettor. When crankshafts broke in testing, the

cast iron was replaced with forged steel. It made only 22.5hp at 3000 rpm, but it could run at maximum speed on low-grade fuels all day long.

The original production VW aircooled engine displaced 1100cc and made 25 hp. VW soon enlarged the engine to 1200cc and 36 hp and later boosted the 1200cc engine to 40 hp. In the 1960s, VW went through 1300cc and 1500cc transition models before arriving at the 1600cc single port, and then the 1600cc dual port design at 60

hp. The dual port layout lasted pretty much through the end of production. Fuel injection came in late in the game but had more to do with emissions requirements than performance. Xaver’s design was also used in Porsche 356, 912 and 914 models.

Including their industrial motors, Volkswagen produced well over 30 million flat-four boxer motors. This number is testament to just what a great design it was and puts it up there in the list of the most produced engines of all time.

A freshly built Air-cooled Flat Four engine ready to be fitted in to a W30 after being vigorously teste in the V3 prototypes.

TO ADVERTISE

GET IN TOUCH AT advertising@hayburner.co.uk

FOR YOUR SUPPORT.

WANT

HERE? PLEASE

THANK YOU

62

WORDS BY STEVE WALKER PHOTOS BY PJ GIBBONS

If you are anything like me, you will have given the images on these pages a glance or two long before you settled here. Hopefully you like what you see, and hopefully you have checked the photo credit above. If you haven’t done any of that, now is the opportunity – before we get going in earnest.

All done? Good! It will help as we are going to talk about visual creativity. Not the kind where average blokes like me point our phones and make do, but professionals within the visual media. Freelance photography, videography and graphic design, for example. The air-cooled VW world seems to have a disproportionately high number of creative participants, and here at Hayburner we pride ourselves on working with some of the very best out there. People who make ideas come to life,

have a unique depth of vision, and display a willingness to go the extra mile to bring you stunning locations and strive with us to push the boundaries of boring old car pics a little.

Photographers like PJ, for example, who not only found the amazing Renegade Brewery location, but wangled the photoshoot all clear and kindly parked his own car there for good measure! Now that’s commitment.

The story of this 356A T1 is quite typically missing a massive chunk of information. The vast majority were sent to the US, and as the voracious car culture marched on, the little Porsches fell into the realms of the quirky. As values dropped, so did the maintenance levels,

and you don’t need a diploma to work out what happened next. However, we do know the coupe was built on 11th September 1957, was finished in Ivory 5704, ended up in Carolina, and probably visited California if the ancient window sticker is accurate. While the build sheet is disappointingly blank, it does have one pièce de resistance, as found under the options heading is the word Sunroof. A big deal for 356 buffers, as are some of the features carried over from the previous beehive model (named after the shape of the back lights), which were phased out less than two weeks before this car was born. I guess the

noticeable bits clinging on from the previous cars are the dash-mounted interior light and ashtray position (both of which were lost shortly afterwards), catching up with the raft of changes already introduced for the ’57 model year – ranging from improved locks, exterior handles and seats, to number plate light position, over rider exiting exhausts for increased ground clearance, modified US-spec crash bars, and a whole lot more exciting news in the “we fiddled with them a bit” department.

Fast forward to early 2019, and the car was

72

advertised in the UK on good old eBay. You could easily romanticise about its adventures and pampering over those lost decades, but unless your musings involved a crappy paint job, accident damage and neglect with a capital N you would be way off the mark. I actually went to see it myself, drawn by the lure of the sunroof and some encouraging words. The nicest thing I can say is that the encouraging words bore no resemblance to the car itself, and that was that.

Unbeknown to me, at about the same time, PJ was

having a bit of an epiphany (he called it a midlife crisis, but you decide) and was actually in the process of being a responsible adult and writing a will. He has been into VWs for years and had bought and sold to the point of having three or four genuine keepers, but he realised that if the unthinkable ever happened the logistics would be a nightmare. Rather than thinking which kids would get what Volkswagen, it was now or never, and ever since seeing a picture of a 356A on theSamba years before, the tangible need to own one made selling the VWs relatively straightforward. Obviously, if the unthinkable

happens now there will be a bit of a squabble, but downsizing is good, especially for a dream car. Now it is time to confess that it was around this point that I, amongst others, may or may not have been guilty of a bit of 356 naysaying. I don’t think I said they were crap, but I did advise trying one if possible, as the expectation may be a little different from the reality of a 65-year-old dream car, even if it is a Porsche. From experience, shovelling everything into one previously unattainable fantasy car can be daunting at best. They certainly are a tad strange at first, and a damn expensive mistake if things don’t pan out. And that is even before the rust is considered, and they do like to rust. I suppose I was trying to be kind in lowering expectations, but it plainly didn’t work as PJ and June were soon heading to see the car I

had tilted only a few weeks before. They were not really looking for a project as the Porsche was a non-runner, but felt the need to see what was available and learn in the process. The car required a lot of mechanical work, had the aforementioned accident damage, an uninspiring worn out interior and a few paint coats in a non-original shade – everything the couple didn’t want – but the magnificently scruffy and forlorn car had potential and certainly looked the part even if it was financially out of reach at the price advertised. On the journey home, PJ called his good friend, Si Medlicott, and relayed the bad news. Then, bizarrely, the vendor called and reduced the price dramatically. So much so, the car could now be bought with a healthy budget

24 74

left over to get the thing back on the road, and potentially restored if they wanted to.

On 7th April 2019 the long-term dream became a reality.

I am sure PJ won’t mind me saying that he is way more conversant in the ways of the lens than the spanner, and with wedding car duties looming, the coupe went over to Ian at E’s Autos for a basic assessment, some structural remedies and the motor sorting. While Ian and the team were busy building the soon-to-be 1680cc big bore engine, the car made its way to the epicentre of all things 356. Essex based PR Services went through the car, rebuilding the gearbox and replacing the worn

braking system with a full CSP wide 5 disk upgrade – great quality and way cheaper than original drum alternatives. Things were progressing nicely, but then out of nowhere Covid hit. The world went into limp mode, the 356 became an ornament in Essex, and PJ & June’s wedding was cancelled. For all the setbacks, PJ credits the lockdown period with a personal reset, resulting in a fresh focus (sorry, couldn’t resist) on life, his freelance photography, and a lot of gaming which found him repeatedly piloting a Porsche 718 RSK around the Nordschliefe, hanging onto a burgundy werks steering wheel (a real-life version of which would soon be applied to the 356 using one of KK’s excellent reproductions). Oh, and a little something to share with the group – the highly acclaimed

Classics at the Clubhouse Aircooled Edition VW and Porsche event held at Sandford Springs Golf Club in a lovely setting near Newbury.

Fast forward and back on track, and the 356 was reunited with its now fresh motor and finally delivered back to Berkshire, where an excited PJ was long overdue his first drive, and who now takes up the story.

“After struggling to find reverse, I was ready for my first drive, not just my first drive in this car, but my first drive in a 356. Expectations were high.” Unfortunately for PJ, the naysayers were right, and the car in his own words was “crap”. The motor, box and brakes were lovely, but the car felt loose, sloppy and, as first impressions go, driving and handling like a pregnant cow wasn’t ideal. Deflated and seriously underwhelmed, luck was on PJ’s side as Jack Dudman aka Flat Six Jack had opened his air-cooled

shop very close by. Specialising in Porsches, with a love for the earlier cars, the two became firm friends and PJ credits Jack for not only working out the waywardness the car displayed, but for sharing the processes and thoughts relating to upgrades and tweaks along the way. This has allowed PJ to form a more understanding bond with the car and this evolution is an ongoing thing, with reliability and a bona fide nippy responsive daily driver resulting from essentially replacing worn track rod ends, the zf steering box, adding an uprated PRS anti

roll bar and swapping the tyres for a nice set of Pirelli CN63s.

The ride height has been tweaked a little with the factory installed adjusters, and a set of fresh new Koni shocks completes the transformation. Not much exciting wheel info to share as they are stock steels, but the seats are a pair of PRS (I did say they were the epicentre) supplied Simonson ally Speedster seats, trimmed with some black BMW fabric in the centres for a bit of posterior grip, and with the bolsters matched to the rest of the car. And they are

exciting. Coco mats always lift an interior, as does a twist of the rev counter to show folks it’s a go car not a show car.

As usual I have managed to skirt over some important areas, so for people used to Porsche tales of never-ending welding horrors, relax. While the car was, and is, flying high on the rustic scale, its rust repairs were localised and relatively simple to address. The accident damage was aesthetically taken care of decades ago, so no modern repairs spoil the exterior, and the motor?

Well, I know a 356 motor isn’t much fun to build properly, and not worth lashing together. So I asked Ian Kent, and he told me the basic idea was to build a reliable hot rod style unit that would be hassle free and as happy on the school run as the motorway. The result is a thing of beauty in its own right, and is a testament to the skills and meticulous attention to detail applied to the build. I would literally have it in my house, but as it’s currently housed, I’ll make do with a strange looking dog and keep my options open.

As with any classic car, especially one that was so neglected, the path to reliability and enjoyment hasn’t been straightforward, but it’s fair to say this was and is still PJ’s dream car. He is proud to say it is his car and he loves it exactly the way it is.

I don’t need to point out that this is an unrestored car which wears its age with pride. It is an ongoing project, but just as with any car belonging to a creative owner, it may be subject to changes.

I do need to point out that PJ has a ton of special thanks to Jack, Paul Smith at PRS, Ian Kent and the Renegade Brewery. Without them you would be looking at a blank page or adverts. And not forgetting June and the kids, Si Med, and his parents who encouraged PJ with all his passions from an early age, bought his first camera, and have shared his enthusiasm for anything automotive. Actually I’m going to step in and add Jack again, because his influence and help has been immeasurable, and it will probably make him laugh.

The 356 chronology is a bit weird, but hopefully this helps understand the model change timeline:

Pre-production 48-52 Pre A (or 356), 50-55 356A (T1), 56-57 356A, (T2), 58-59 356B, (T5) 60-61 356B, (T6) 62-63 356C, 64-66

Option 1 - Basic 356A specification rebuild*

Including:-

* Refurbish existing engine case

* New camshaft

* New lifters

* Replacement crank pulley

* Replacement flywheel

* New oil pump

* New oil cooler

* New piston and barrel set

* Reconditioned replacement cylinder heads

* Reconditioned rockers

* Refurbished pushrods

* New pushrod tubes

* All new quality bearing, seals, and gaskets throughout

* Refurbished dynamo

* Replacement dynamo pulley

* Refurbish distributor

* New ignition components (plugs,

leads, points, capacitor etc...)

* New oil filter

* Fuel pump blanking plate**

* Full assembly of turnkey engine

Option 2 - 356SC / 912 complete with:-

As per option 1 but with…

* Replacement engine case

* Counterweighted crankshaft

* Forged con rods with ARP bolts

* Forged lightened flywheel

* Full flow oil filtration

* Upgrade to twin port oil cooling

- includes wider cooling fan, modified stock 356 style tinware, improved aluminium oil cooler, etc...

* Billet stock style crank pulley

* 85mm “big bore” piston and barrel set - gives 1680cc capacity

* Repair and powder coat tinware

* New Weber 40IDF carbs, correct

manifolds, and refurbished linkage

* Modify existing oil filter canister to custom crankcase breather

* Cam burn in process and initial tune on test stand (includes break in oil, filter, etc...)

* The heat exchangers are upgraded by replacing the mild steel tubes (that corrode very quickly) with stainless tube inside original heat pods correct for the 356A/B.

*stainless steel 4 tip exhaust

*oil filter head, Hp1 filter, aeroquip hose and AN fittings

*electronic fuel pump with safety relay, pressure regulator, cohline hoses and correct clips throughout

*modified accelerator cable and linkage

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT. See our Website for further details : TheGermanJunkies.Com Genuine Parts For Fixing Der Kaputt Old-Timer VW • New Old Stock and Restored 40’s 50’s and 60’s VW Beetle and Bus Parts and Accessories VO LKSW A GEN CAMPER VA N SPECIALIST tel 01743 884 655 07977 334 687 restoration restoration.com

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT. Peak Van Conversions www.peakvanconversions.weebly.com See our range of caddy conversions for South West Microcampers at www.southwestmicrocampers.co.uk peakvanconversions@hotmail.com

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT. S.G.S AIRCOOLED Aircooled & Watercooled Classic VW Specialist Unit 3 Woodmans Farm Curdridge Lane Curdridge Hampshire SO32 2BH *Servicing *Repairs *Welding *MOT *Restoration Work *Lowering *All Vehicles *Bosch Diagnosis *Vehicle Recovery www.sgsaircooled.co.uk info@sgsaircooled.co.uk 07814 687725 01489 896488 We still work on all makes of vehicles, new & old.

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

82

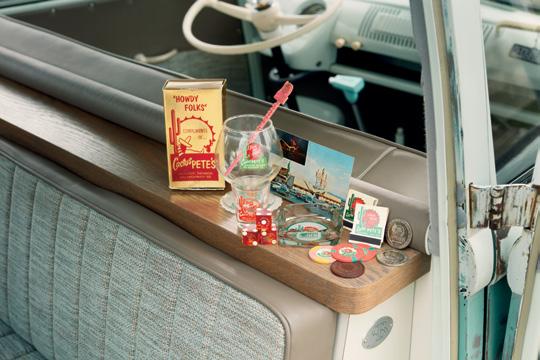

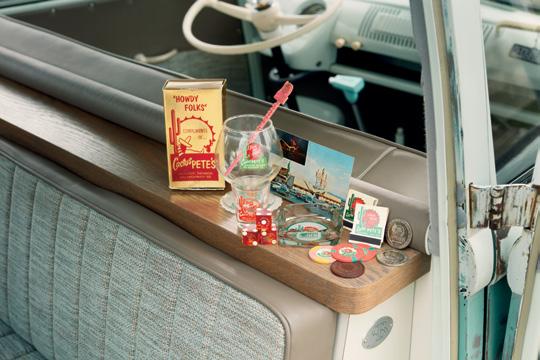

There was something about the Cactus Pete’s bus right from the first time it caught my eye as it arrived at our classic VW show back in 2015/16. Everything about it, that red and yellow sign writing over the L380 Turkis, the ride height, the roof lamp – everything just worked, so much so I’d argue it’s one of the coolest sign written UK buses for a long time. But when you add all that cool visual stuff to the vehicle’s history it gets even better, and it’s this history that drew Hubert Lewczuk-Tilley’s attention – being an amateur poker player, it’s almost like the stars have aligned!

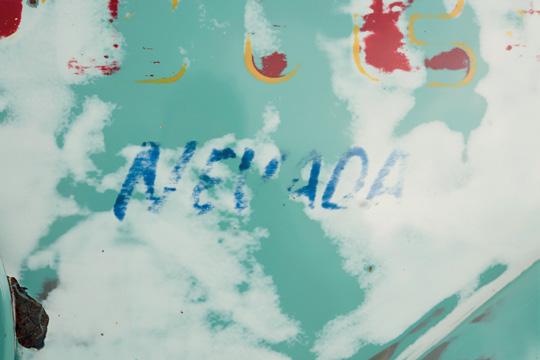

So let’s give you a brief history of Cactus Pete’s. Founded in 1954 as a Desert Inn and Lodge in Mineral Springs, Nevada, it started to lose business to the Horse Shu Club due to its close proximity to the Idaho state line. So in 1956 Cactus Pete’s moved north to Jackpot, Nevada, directly across the road from the Horse Shu, where they both still stand and operate as a casino today. Believe it or not, Cactus Pete’s is 452 miles north of the Las Vegas strip, which is where the majority of us Brits (including myself) would automatically associate any casino.

The bus was originally purchased in 2014 by brothers Lee and Adam Edmonds, when good friend Sam Trigg put them onto it on thesamba.com. This was right when Adam and Lee were starting out in the restoration business with their company Edmonds Classic Restos in Burton upon Trent (check them out on Facebook or Instagram @edmondsclassicretos (07725 180908).

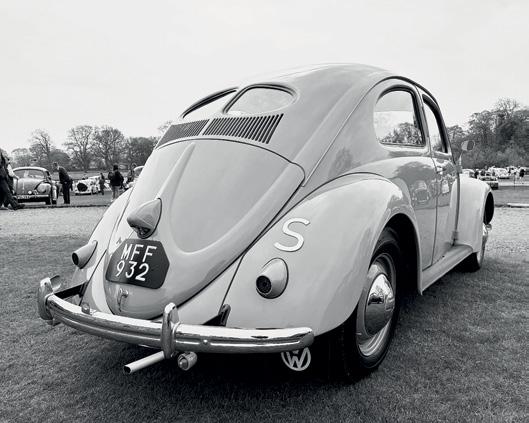

Back then the brothers had no background with VWs really, but were into the classic car and scooter scene. When they went to

see the bus they instantly saw potential and snapped it up. “The more we dug into the history and the more paint we rubbed off, we soon realised how cool this bus was.” Originally shipped to Oregon in 1962 and then first purchased by Cactus Pete’s Casino to be used as their airport shuttle bus for VIP guests, the bus was used by the casino for ten years between 1962 and 1972. In that time it was sign written twice on the lower body. It was blue letters first, then

the amazing complementary red and yellow letters secondly. (If you look closely you can make out the larger first logo under the last one.) A working searchlight was added to the roof by the casino and is still present – it’s visible in some ’60s photos of the bus. This would have been used to help guests at the airport in the dark. It’s a modified searchlight that would have been found on police cars of the day.

84

The bus was sold to a local man in 1972, who painted it with household paint and used it until the engine gave up in the late ’70s, when it then sat in an Idaho field for 20 years until it was found by @zvwbus. It then sat in his yard another 10 years. It then sold to @funkstown who cleaned it up and stripped the house paint off.

This is where Lee and Adam took over. It was a little

too rough in areas for their liking, so they added a new small panel and various other localised repairs to make it really nice and solid while retaining as much of the original paint as possible. The underneath and inside restorations were carried out to a very high standard. The brothers were starting out and learning new skills, but also wanted it to reflect the level of work they could actually carry out and showcase their new business.

As they were learning with the VW there were a few things that bugged them, like the massive rear camber on it and the front wheels going forward too much when lowering. So they lifted and notched the front chassis 2”, added a 4-inch narrowed beam with dropped spindles, and also lifted the engine and box up 2” while lifting the fuel shelf too, such a neat and subtle trick. Adding to that the standard approach of front and rear tubs along with a

steering box raise meant Adam and Lee had achieved the stance they wanted while retaining a really nice ride quality.

All repairs and modifications were painted the Turkis body colour, which makes everything look super clean. The outer floors and inner arches were also finished in Turkis. For the sign writing, as Adam comes from a design background, he drew up a vector

of the logo and laid it over the bus digitally to come up with the final scale, etc. of the letters. “There were enough existing letters, etc. on the bus to give clues to how it once looked.” It had been sign written up numerous times because of repairs, etc., but the brothers went with the red and yellow as that’s what was seen

86

most on old postcards. The boys did a fantastic job with the paint/ logo blends and the final look.

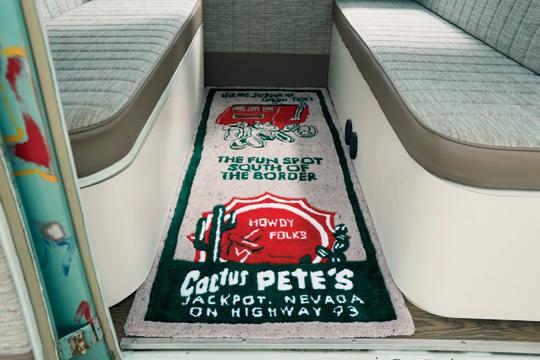

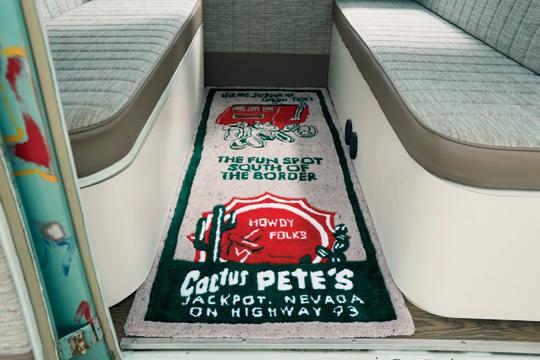

Once the bodywork was complete, they sent the bus off to Ken’s Customs for the interior upholstery. Sam Trigg was a big part of this bus and wanted to make sure the inside was perfect, and let’s be honest, they knocked it out the park. Subtle hints of body colour with light browns and

greys in the cotton tuck and roll seat pads and door cards with light brown vinyl look awesome against the freshly painted L289 Blue White dash and wool cloth headliner, etc. Also the amazing addition by previous owner Rob Hines added the commissioned floor rug of an early casino advert which looks fantastic between the two bench seats which also incorporate a Rusty Lee rock and roll bed. Rob also added the custom Gene

Berg shifter, another great touch. Richard Booth Design made the cabinets, again a good friend of the brothers who went above and beyond with the build.

Hubert purchased the ’62 from Rob in 2023 and has now started

to make his own mark on the bus. Being an amateur poker player, Hubert was already familiar with the actual casino, which as we mentioned earlier inspired him to buy the bus. Having never owned a Splitscreen bus before, naturally this was the right vehicle

for him, especially as he already owns a collection of ’60s Cactus Pete’s Casino memorabilia and collectables, such as poker chips, ash trays, shot glasses, postcards, etc., which obviously he has added to since owning the bus. Hubert has fitted an autotherm diesel

90

heater system, with the controls hidden behind the radio panel. This is connected to the original heating system up front so it comes through the original pipe up the centre and to the windows. It also diverts into the rear out of the seats.

Hubert has raised it a little so he can refit the US-spec bumper overriders. He has also fitted a leisure battery system to connect over and to allow the bus to be used for more overnight camping off grid.

The bus is still running drum brakes at the minute, but he plans to go for discs shortly. Also a custom diesel tank is being made and powder coated in Turkis. This will sit in the engine bay to fuel the heater which is currently a plastic tank.

This isn’t his first air-cooled VW. Hubert’s first car was a Beetle because insurance was cheap. As a matter of fact, he is keen to buy that car back. He has checked the DVLC database and it’s still on the road, so if you own or know reg NMD 638L, get in touch and we

will pass on your details.

We love seeing this bus evolve as each owner makes their mark and we can’t wait to see what Hubert has planned for the future of Cactus Pete’s. You can keep up to date, as the bus has its own

Instagram page. If you would like to see more historic photos of the casino and the bus from its inception to future progress, go give @cactus_petes_vw a follow.

Saturday morning and I’m in the workshop. It’s a beautiful sunny day. It really does feel like summer is here and not a moment too soon. Summer never feels like it’s long enough for me, so best make the most of it before it’s gone. Looking around the place, it’s clear that we have a load of work on and as usual a yard full of cars. I think I’m finally getting used to the process of ordering parts and waiting for them to be delivered by a courier. It’s a big change from the three vans a day that used to bring all my parts from Northampton, but I think I now have the hang of it. It must be said that I do like to call up my suppliers and have a conversation with a human rather than wash my oily hands and search the web to make orders, but this seems to be how the world is set up and I have no option but to go with it. I do miss making personal connections with the people I spoke to every day on the phone, people who knew exactly what I wanted and who could give various options and opinions on the parts I was ordering, but those days are gone and I’m embracing the new digital reality.

I wrote a while back about the 1956

WORDS BY CHEZ WILLIAMS

WORDS BY CHEZ WILLIAMS

right-hand drive Oval which Glen Lucas has had in his possession since 2003. It’s a beautiful Horizon Blue (L331) car and I really like it. The mission is to get it back on the road with a strong but sympathetic restoration, keeping as much originality as possible but tackling all the bits that need attention so that when it gets on the road it will stay on the road, being used for a long time. Well, as ever it’s tricky to assess how much welding something needs until you hit it hard with the wire wheel on the angle grinder. The Oval stood up to this quite well, but we did also find extra areas that needed attention. They were the usual places, but they looked fine until we went at it with the abrasives and ended up with a big pile of rusty dust on the floor. We started very careful surgery on the car and as I said we want to keep as much good original metal as we can, but also want this car to be out on the road for years without needing any more welding. It’s always a tricky balance, but Glen pops into the workshop on a regular basis and has been a great help with making decisions on how far to go with things. Glen does not want to paint the car, which I’m really glad about, but we are going to have to get very

creative with how we blow in the areas that do need paint.

The wiring loom is the one that came with the car in 1956 and is in fairly good condition and has not been hacked about too much. Glen has been busy soldering and extending the wiring around the headlights and cleaning all the fastenings and threads so it should all go together well when we get to the point of screwing everything back together. We have dry fitted the wings several times and have had to adjust quite a lot to make everything fit with nice gaps. Over the next few weeks we will have the whole car welded and painted underneath ready to have the beam and gearbox reinstalled. I’m really looking forward to firing up the newly rebuilt 30HP engine. The rebuild went well and the engine looks lovely and stock. We will try and get it on the test bed for a first fire up as soon as we can; then it should be a case of fit it and away we go. We are going to convert the brakes to a dual circuit system and have blasted and painted the backing plates and arms and Glen got new brake cylinders and shoes from the show at Stanford Hall ready to go.

94

Brakes have been a bit of a topic in the workshop over the last few weeks. I have always been a fan of the drum brakes on bugs and buses. They do a fairly good job and when the system is in good working order perform well. Even my big, heavy Kemperink stopped quite well on its standard drums as long as they did not overheat. I have been lucky enough to have a local lad called Charlie Westbrook join our workshop crew over the last few weeks. He is waiting to start an automotive engineering degree and wanted something to do while he was waiting for his course to start. Teaching someone how to go through brakes is nice because you have a side each and just get them to replicate on one side what you have done on the other. So we got a Split bus into the workshop and started on the front brakes. We removed the drums and shoes and went through the cylinders, cleaning and replacing as required. All went well until we came to bleed them – no fluid from one side. This was odd, so I went over to Charlie’s side and looked at the hard brake pipe that connects the two wheel cylinders. Whoever had done this job previously had not routed the pipe correctly and had trapped it between the bearing housing of the brake drum and the spindle/backing plate. It was so crushed that it was never

going to pass a drop of fluid through it. So we removed the pipe and I showed Charlie how to make up brake pipes with the flaring tool, a job I always enjoy and one I doubt he will be taught on his course. The most important lesson is remember to put the unions on the pipe before flaring the ends, which is a lesson he learnt straight away.

A few weeks ago, I came to the workshop slightly late and saw the doors open and the lights on. Loz must have got here before me (not unusual, if I’m honest). I walked into the workshop to be met by a massive barking dog. Yes, sat there snarling at me in my own workshop was a huge Doberman Pinscher. I picked up the broom and read it the riot act, heavily enforcing that it was my workshop and I was not in the mood to be barked at by a massive hound. In walked Loz to inform me that he had come across this dog that had become too much for its owner to handle and that the owner was going to “get rid of it”. Loz, being the soft-hearted idiot that he is, agreed to adopt the dog, who is called Milly, and make her our workshop mascot. She is a beautiful creature and so sweet and soft-hearted, even if she does look like she could eat me in about 30 seconds. It is nice to have a dog in the workshop again

as she is great at greeting people at the door and knocking everything over with her general clumsiness, so anyone who comes to the workshop now has the chance of being met by our newest member of staff.

I have just heard the rumble of a Flat-Four engine coming into the yard. It’s Matt and Sophie in their Bay Window, coming for their first service on the new engine we built for them. They have only done about 500 miles, but if I’m honest I like to get them back in around then to do valve clearances and to check timing. The bus had been sat for about three months without use and started on the button straight away and drove over to me fine. They opened the side door of the bus and out jumped their two Italian greyhounds, the most beautiful dogs I have seen in a long time. I have just finished giving the bus a good once over and now it’s time to take Matt and Sophie and the two dogs to the pub for a well-earned pint in the sunshine. So all in all, the workshop has been about welding Ovals, bus brakes and squashed pipes, but mainly canines taking over everything. I do love how random the universe is…

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

144

WANT

Restoring aircooled VWs since 2001

Servicing, inspections and MOT’s

Lowering and mechanical upgrades

Modification and fabrication

Auto electrics, split charge systems and 240 volt hook-ups

For all air-cooled VW’s and transporter generations

Vehicle valuations

Call for FREE friendly advice

TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

106

WORDS BY RAPH-RATS PHOTOS BY JO MEMORY

1946 – Bill Burke, a young G.I. and keen hot rodder, recovers an abandoned aeroplane fuel cell. He takes a chopped-up Ford Model T chassis and flathead V8, he cobbles it together, and that’s how the legend begins. He is the first to pilot a Belly Tank across California’s El Mirage lake bed. Built in a car port, the rod comes, leaves its mark, and goes, before the emergence of popular enthusiast magazines (Hot Rod, for example, was first published in 1948).

He creates the “Belly Tank”, the only car built in the shape of a drop of water. It drives fast, but only in a straight line. Bill sets some impressive times at El Mirage dry lake, Arizona. Continuously improving his concept, he goes on to build no fewer than 13 Belly Tank racers during the 1940s and 50s.

2010 – Raphaël Vanlathem has taken a trip to the USA. After getting heavily involved in automotive culture from an early age thanks to his father, Raph is in America to immerse himself in US car culture. On this trip, he visits MOON, West coast Chopper, So Cal and Lake Bonneville.

He visits Bonneville in December, sadly not speed week, so Raph is therefore alone on the lake with a rental Mustang. It is there and then that he makes the decision to return, but next time he will be back with a real racing car.

Raph is fully aware that by himself he has neither the budget nor the skills to complete such a project. Luckily for Raph, with his father being involved in original restoration, he has the

contacts. At least ten influential hot rodders in Belgium get the call.

Four people say a solid “yes”, but one of the four insists that it has to be a V8. The budget being zero, he decides to build a “home grown” Belly Tank. The hunt for parts is on. Luckily, Raph wins a hull in perfect condition at auction in the USA.

With Alx, the second of the four, being an industrial designer, he has no problem creating a complete roll cage for the hull. Very quickly the arch is mounted, and the Belly on wheels. However, this is only the beginning of a build that lasts longer than 10 years.

With little budget, Raph contacts several craftsmen to offer them the chance for their seats to be mounted in the Belly. Finally, Blackhands, a Toulouse workshop, manufactures a superb bomber seat which is perfect for this application.

These chance encounters turn out to be very important. Dim, a photographer from the village, offers to document the project. His quality as a photographer and the timeless decor of Raph’s dad’s garage do the rest.

Rumble59 falls in love with what they are trying to achieve with little money, so their sponsorship gives a serious boost to the project. Pascal joins the group, others leave … Everyone believes in the Belly build.

The project is present at many exhibitions and events mocked up with V8, but the engine never actually runs.

During one of these exhibitions, the NBR launches the idea for a race in Ouistreham, France. Raph is thrilled, but the car is the wrong spec and doesn’t correspond to the race’s requirements. It doesn’t matter to Raph, even if they have to start all over again and reverse nearly 10 years of work in only six months. Raph is convinced: he just has to convince the NBR that the Belly can participate, and also his team that it’s going to be worth all the extra work.

The NBR is very quickly convinced. The team is, too, even though months of work will be thrown in the trash.

Grafting in the Chevrolet inline-6 is going pretty well, but Pascal is going mad trying to get brakes, an accelerator and a gear linkage. The exhaust manifold is also a fabulous piece: it’s basically a test manifold, just to see if the engine can run with the lower carb. It does run and the manifold is still fitted.

The Belly is to be finished the weekend before the NBR race. The car is getting plenty of attention, but it isn’t progressing fast enough to hit the tight deadline. At this point Raph doesn’t even want to drive it. He says he doesn’t want to drive to lose. The problem is quickly found – the clutch slips.

2021 – NBR 2. Their desire to win is there, the clutch has been changed to a copper model, and the Belly finally starts like a real racing car. The project that

Raph didn’t really want to see finished, wins! All thanks to Alx, Pascal and Pierrot and more than 10 years of hard graft.

We asked the team whether there would be anything they’d change on the Belly. The answer was clear: “A track long enough to be able to change gears!”

Raph thanks his dad, Alx, Pascal, Julia and the BMG team, for their patience, Dim and Nicole for their images, Rumble59, and the NBR for making them dream.

110

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

WORDS BY ROY SHAKESHAFT PHOTOS BY JULETTA ARDEN TAYLOR

WORDS BY ROY SHAKESHAFT PHOTOS BY JULETTA ARDEN TAYLOR

I first met Roy very briefly a few years back, when he knocked on my front door after being sent by a friend of mine to have a sit in my Karmann Ghia to see if it suited him. I then didn’t see Roy until a couple of weeks back, when he arrived at Hayburner HQ with his particularly interesting 1978 German military spec Beetle. During this visit Roy told me various stories from the past and paid us probably the best compliment the magazine is ever likely to receive, when he

said that after reading motoring magazines for 75 years, Hayburner was his favourite. Well I’ve stayed in contact with Roy (now in his 90s) and he was kind enough to have me round for the afternoon so he could tell me all about his eight decades of classic car enthusiasm.

This is what he told me.

122

My full name is Roy Allen Shakeshaft – a Shake and a Shaft. When I was young, nothing ever happened in my house other than music, so I was always the odd one out because I was interested in motor cars.

I first discovered I was interested in motor cars way back during the Second World War. At the time I lived in Kettering – well, I was born in Kettering and I’m still here. At that time I lived in the north part of the town, and being born in 1932 I was just a boy. Cars were so rare at the time and most people who owned them had to put them away, because the only those connected to essential duties for the war effort could use fuel.

When the war ended in 1945, cars were very expensive, new cars or second-hand. At this time, all I could do was to look at cars and dream about them. That was until 1947 when we were fortunate enough that my father could afford to buy a Standard 8 from the Standard Motor Company in Coventry. This is when my interest in motor cars really blossomed. I was able to get my licence very soon after this and I was allowed to use the 8 once in a while.

Being more affordable, I also bought motorcycles at that time. Then 1949 came along and you had to join the forces in those days. Everybody had to join – well, everyone who was physically able. So I joined the RAF as a musician. I was posted to Henlow and played there for around six months. I then got posted to a flying unit to play in a military band but it wasn’t full time. Luckily for me, I started to learn to fly as it was a flying training school. This took another three years of my life. At that time it wasn’t really an attractive proposition for me to stay in the forces. So I came out and looked around for a job.

I’d already worked at a coach-building firm before I had to sign up. The company is still in existence today. They’re called AE Smiths and they’re still on Carrington Street in Kettering. I was in the trimming shop, only working with material and cloth. I couldn’t stay there long because it was my time to sign up. I enjoyed this sort of work and it always makes me think of one of my only regrets. I probably ought not to say this because I’ve had a wonderful life, but when I came out of the RAF, I met a fellow I’d worked with at AE Smiths, and he said: “Roy, if you ever want to do anything you have to get out to Germany. It’s all happening out there and you can find work, no matter what it is.” But I didn’t, and now I hear the stories of what happened there with the Wolfsburg factory under British management and that I could’ve gone, but I never went. Instead, I stayed in Kettering, and met a girl (Mary) who I married and started a family.

Luckily, when you’re in the forces all your accommodation and living expenses are covered. I had accumulated a little money so I could buy a car. It was a 1932 Morris 8, an eye doctor’s coupé. A most unusual coach-built car, I still have a photograph of it to this day. Having a wooden body covered in cloth, I remember cleaning this car with black boot polish. If you rubbed the polish into the fabric it came up with a beautiful shine. This car was mine and my father still had the Standard, but

this was my own car.

Then the bubble age came along and it was all mini cars which suited me just fine. I bought a Bond. I think this was in the early 60s, because I got married to Mary in 1954 rather than going to work in Germany. Then our children came along and I bought a Comma van. I converted it into a family vehicle by removing the floor and fitting seats. I could also fit the old-style pram in the back.

I was still playing as a musician at this time before I spent most of my working life in textiles. I still work with fabric, as I kept a couple of sewing machines back from the factory. The last job I did was repair my pyjamas. When I was playing, one of my band mates had a Morris Oxford, so when I needed to take a car for a holiday, I could pay him to use it. Soon after I sold the Bond and bought myself a Triumph Herald, which at the time was quite a revolutionary car. I bought it because we couldn’t afford to go on holiday and stay in hotels so we decided we’d go camping. One year of camping was enough for us, so the next year I found a caravan in the local paper. Well, it was a Friday night and I had my wages in my pocket so I went to see it and stuck a deposit on it. I came home and told the family that we’d bought a

caravan! This was in July and we had a holiday booked in a week’s time, so I stuck a tow-bar on the Triumph with its 800cc engine and, believe it or not, that thing pulled the caravan with four of us in the car. I had to use the gears sparingly, but in those days 30mph wasn’t really frowned upon. We took it all the way to Felixstowe, perhaps a little faster downhill and a little slower up, but we still made it.

As I grew older I got more and more interested in Mercedes cars. There was and still is a chap in Rushton who has a field full of classic Mercedes. He goes by the name of Albert Lock – notorious for not wanting to sell anything. I visited regularly and he eventually decided to sell me a 1965 SEB 220. It wasn’t roadworthy at the time, but Lock managed to get the engine running along with everything it needed to get back on the road. It was a wonderful car and I owned it for 23 years.

By then I’d joined the Mercedes Club and I’d been offered a seat in a 230 SL Pagoda, a fantastic American car with no hood. It was to do a rally to Salzburg, and the owner, Nick Mitchell’s wife could not attend so I got the job of navigator co-driver. This was approaching the end of the century and we had to do nearly 1000 miles in one hit. When we arrived,

we missed the bus that was taking all the participants to the hotel. We arrived at an important celebrity dinner. Everybody else had time to shower, shave and change their clothes and we turned up in shorts and as sweaty as muck. We had to stay there till after one o’clock in the morning and then be up at six o’clock for breakfast and to receive rally instructions. On this trip, I saw some of the cars and just realised what wonderful motors they were. I still had the SEB, which I loved, but I started to look in newspapers at prices of older models and I happened upon an advert for a W18 290 limousine. It was in Ireland and needed a lot of work. Well, to cut a long story short, I went over with a friend and ended up buying it. It took me over 10 years to rebuild and restore this car. That’s the car I sold to bring home my pride and joy, the Mercedes I showed to Ned earlier.

Currently, I have mostly Mercedes cars in my collection, but a few others. I think they’re all rather special. I love the history, see.

Let me tell you how I ended up with this Beetle. Firstly, why the interest in Volkswagens? Well, one of my sons owned a Beetle and I drove the car regularly and got to know it well. Durability was the thing that struck me.

No matter what happens, you can still make it home. I know this because my son was driving along one day, when he looked out of the side window and saw a car’s wheel overtaking him. When he went to turn, he realised the wheel was from the front of the car he was driving. The Beetle skidded along the ground

with no nearside front wheel and ground to a halt. He then got out of the car, retrieved the wheel, removed a wheel bolt from each of the other wheels, lifted the front of the car up, put the wheel on and off he went home. My son was only around 20 at the time. He’s now in his 60s. He had found his love for the

Beetle while working in Antwerp and when he returned home he just had to go and buy one.

For many years on 1st January, I visit Stony Stratford. They have a classic car show in the town and there are a lot of military vehicles. I got chatting to

some of the owners and I found everything about them just so interesting. This was probably around seven years ago. I know I couldn’t do with one of those big lorries I’d been looking at. I can’t do with climbing up those steps and finding a place to put it. But still I was searching eBay for anything interesting with a military history. I just wanted something different, something interesting. This is when I came across this Beetle. I found it for sale in Canterbury. I went to see it with my friend but the car was in such a state. My friend insisted that the Beetle would be a liability, so we told him we were not going to have a car and we left for home. Strangely enough, two or three weeks after that I got a phone call from the seller, saying he’d bought a Land Rover that was local to me and he offered me the car at knockdown price and it could be delivered. I’ve restored cars pretty much on and off all my life in one way or another so I wasn’t afraid of taking on the project and we came to a deal.

The car arrived at my house and the chap drove the Beetle straight off the trailer and into my garage. I thought to myself, it can’t be all that bad. Soon after, I took it for MOT and then I really found out what was wrong. The lower door hinge was completely detached because it was so rotten. The chassis were solid, but it was the bodywork that was an issue: around the fuel cap, two front quarter panels supporting the bonnet were rotten. Body wise it had lots of dents. It even had wood spacing out the front bumper to put it into the correct position. When I looked the bumper irons they were buckled so

it could have it been in an accident at some point in its life. I took it to Gary Tunn in Finedon for the work and he did a great job.

I know my friend told me not to buy the car, but I had a drive when I went and looked at it that first time, and it gave me that old Volkswagen feeling I remembered from all those years ago and I love left-hand drive. I find with my stature I can see the road better and I can see around vehicles on the inside.

I like that I don’t have to turn up at Stony Stratford to see my friends in a civilian vehicle any more. I thought it was the only late-model military Beetle in the UK. That was until last week when I went to Hinton and Moss in Bishop Stortford, a top motor dealer who do restoration work. Official Mercedes-Benz send vehicles to them for restoration. All their vehicles are top notch and rare and very expensive, most in the hundreds of thousands of pounds – a bit rich for me, you know –footballers’ cars. I got a tour of the workshops and ended up speaking to a stranger. I told him I owned a Volkswagen Beetle and the type and he said, “Oh, I know of another one.” His name was Roy Wilson and he’s been a Volkswagen engineer all his life. He has a company just outside Stratford Bishop Stortford. You never know who you’re talking to do you?

My Beetle was made in 1978. I have the bill of sale and its use was for the German allied forces, postwar of course. It was then resold in 1988 by a serviceman. I have an MOT showing

126

his BOR address in Germany. He brought it to England and sold it to his brother. I managed to get the names and addresses of all the owners and have written to each one. One replied. I’ve got all the details of where it went and what happened to it. I did get confirmation from Wolfsburg that it was a genuine military vehicle and it still retains its original engine. The engine sounds very good. The mileage was only 25,000 km when I received it in March. I’ve now switched the speedometer to miles –that’s the only thing that’s been changed from its original specification. It’s so

simple, being a Standard model – no trim and a simple headliner. It’s very basic. When you drive it you really realise how much luxury we take for granted. I drive it at 50 down the A14, but I know it will do more. I don’t like to push it any harder because of the old-style drum brakes.

I love the car but I also do have an interest in the Type3 Squareback. I may consider selling this at some point and buying that style. I’m attracted to the size, and Ned tells me it’s a lovely driving position and that they come with

the air-cooled feel but with a little more comfort.

Just in case you’re wondering where he finds the energy to still be enthusiastically building cars in his 90s, I’ve already asked Roy this question. It’s all down to beetroot juice – two large glasses a day, apparently.

I’d personally like to thank Roy for visiting us and also for sharing his story. We will definitely be keeping in touch.

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

134

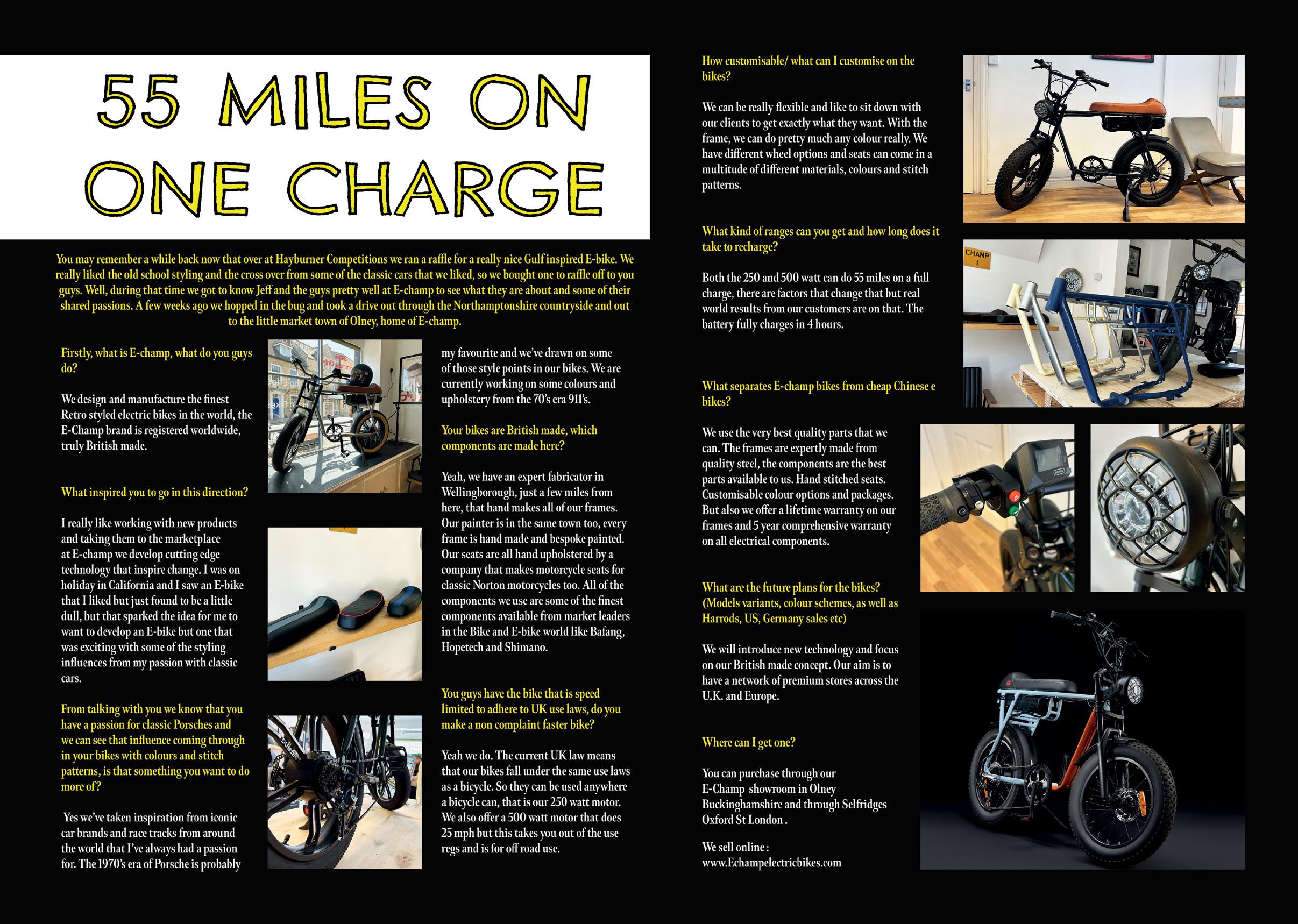

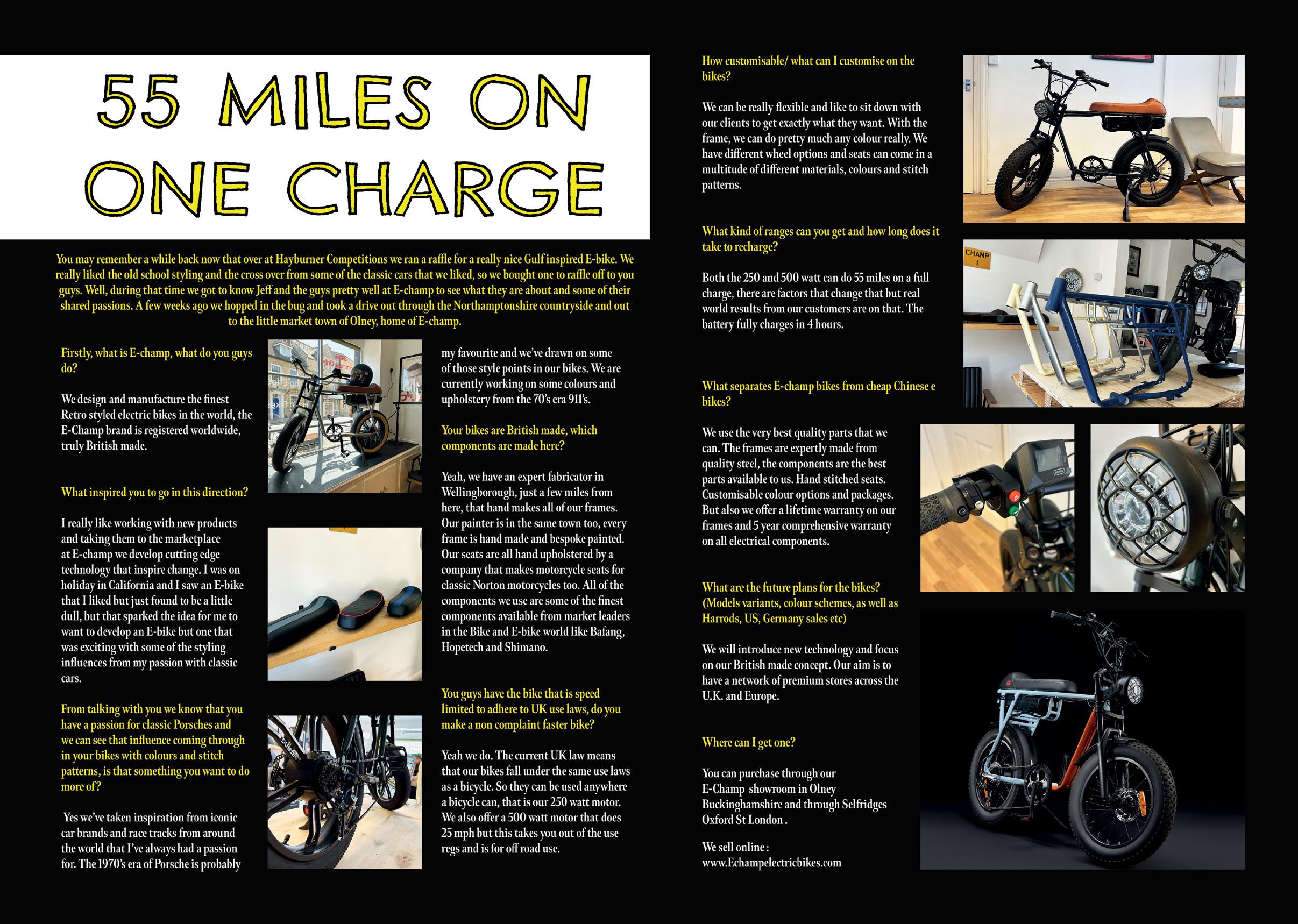

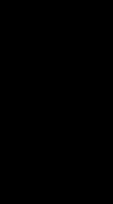

WORDS BY VICTORIA FAUX PHOTOS BY NED FAUX