2 minute read

Milling

20% off the PrograMill range Up to £5,000 Ivoclar milling consumables FOC

Powerful and unrivalled

Advertisement

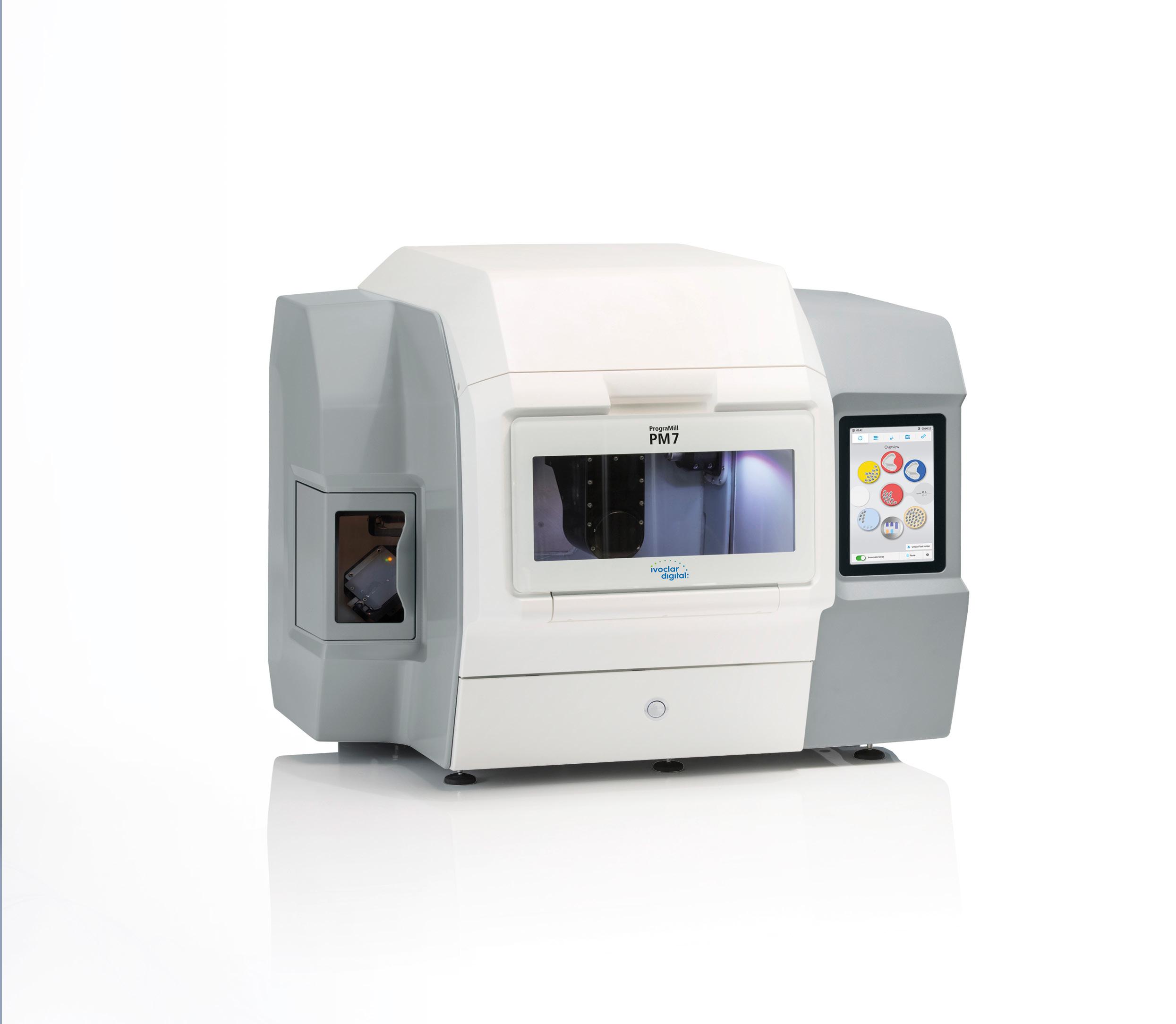

PrograMill PM7

PrograMill PM7 sets new industrial standards for the digital production of restorations in the dental laboratory. The powerful performance and dynamics of this unit make it a highlight in the PrograMill portfolio. The high-power machine is capable of processing a variety of materials in wet and dry mode and is suitable for a wide spectrum of indications. The high dynamics and efficiency of the machine result in precise and fast production results. The 5-axis machining process is controlled via the integrated PC with touch-screen monitor. The good cooperation of material and tool changer allows independent and consistent production. The central management of max. 8 discs / 48 IPS e.max blocks in the material changer and up to 20 tools in the magazine ensure that the right, individual processing strategy is used.

Click here to watch the video

Contact us for the latest offers on the PrograMill range

Flex lease monthly cost of £691.22 for 4 years †

Click here to watch the video

VHF S5

£27,930

VHF S5

The S5 is a highly versatile dental milling machine. It has five simultaneously operating axes, a blank changer for eight blanks and is designed for both dry and wet machining. With the optional wet grinding module, you can grind all common types of glass ceramic. 8 Discs, 24 Blocks, 48 Abutments

Five simultaneously operating axes

• The second rotary axis (B axis) with a tilt angle of up to ± 30 degrees enables the precise milling of undercuts.

Non-stop machining

• Thanks to the eightfold blank changer, you get performance that won’t stop. The changer can be loaded with blanks via a small flap in the front and the correct blank for your milling job is then automatically inserted into the clamping device when needed. As a result, you can mill around the clock.

Wet grinding option

• The S5 can be equipped with a wet grinding module. Liquid nozzles are already mounted to the spindle to cool the tool during grinding. This module allows you to grind materials such as glass ceramics.

More efficiency and comfort

• With the three integrated ionizers, users of the S5 considerably reduce their cleaning effort, as static charge of acrylic chips, such as PMMA, is neutralized largely. Air nozzles distribute the ionized air in the working area for excellent results.