2 minute read

Furnaces

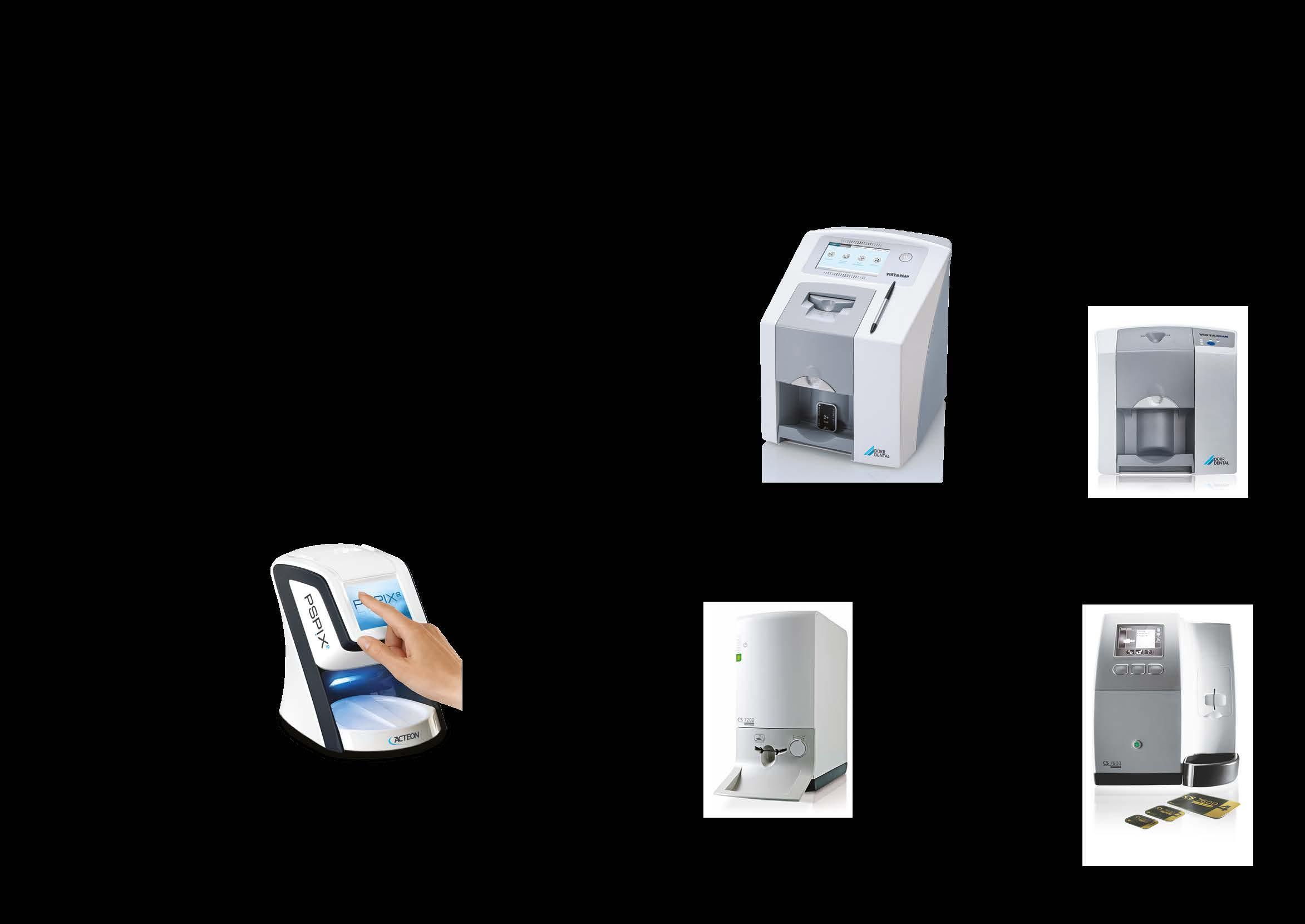

Programat CS series

The ideal ceramic and crystallisation furnace for dentists CEREC® SpeedFire

Advertisement

Sintering and Glazing Zirconia

Programat® CS2

The device has been specially developed for the crystallisation of IPS e.max CAD restorations. The Programat CS2 is easily operated by means of the new colour touch screen and the proven membrane-sealed keypad.

The QTK2 muffle technology is responsible for even more homogeneous heat distribution in the firing chamber, leading to optimum firing results and a prolonged life cycle of the heating element. Additionally, the new vacuum pump control system with double valve technology ensures noiseless and power-saving operation of the vacuum pump.

Benefits at a glance

• Colour touch screen and proven membranesealed keypad. • QTK2 muffle technology with SiC bottom reflector.

• Easy operation; specially developed for use in the dental practice. • Automatic double-range temperature calibration (ATK2).

• Remote diagnostics via Internet, e-mail and data log files.

Click here to find out more

Programat® CS3

It has been especially developed for the crystallisation of IPS e.max CAD restorations. The furnace is operated via the 7-inch colour touch screen with a specially developed operating concept for the dental practice and the well-proven membrane-sealed keypad.

The proven QTK2 muffle technology ensures an even more homogenous heat distribution in the firing chamber. Optimal firing results are achieved and the life cycle of the heating element is prolonged. The new vacuum pump control system with double valve technology ensures noiseless and power-saving operation.

Benefits at a glance

• Firing and crystallisation The furnace furnace with integrated

DSA function for the for dentists digital analysis of the with high tooth shade. standards • Colour touch screen in combination with the proven membrane-sealed keypad. • QTK2 muffle technology with Click here to

SiC bottom reflector. find out more

Programat® CS4

Compact furnace that allows full-contour zirconia restorations to be sintered and completed directly in the dental practice in a single visit. Fast sintering processes result in restorations that are ready to be placed in the patient’s mouth straight away.

Open system of the furnace includes individual programs to allow the processing of a variety of materials. Also suited for glaze and crystallisation firing procedures. High-quality lithium discilicate restorations can be created in a comparatively short time in a single session and then placed in the patient’s mouth.

Benefits at a glance

• Stand-alone furnace without compulsory tie-in to

CAD/CAM so the user can remain independent. • Fireproof, robust housing to ensure maximum safety and long service life. • High temperature accuracy of the heating elements, which is essential for obtaining beneficial shade and material properties when crystallising restorations.

Click here to find out more CEREC® SpeedFire is one of the smallest and fastest sintering furnaces on the market and can sinter a crown in typically 10-15 minutes. The strengths of full contour zirconia can thus also be used for chairside treatment. If required, a glaze can be applied with the CEREC® SpeedGlaze that can be fired in just a few minutes in the CEREC® SpeedFire. Then the restoration is ready to be placed into the patient’s mouth. Partner glass ceramics can now also be processed in the CEREC® SpeedFire with IPS e.max CAD (Ivoclar Vivadent) and Suprinity PC (VITA Zahnfabrik).

Benefits at a glance

• Orders sent automatically – CEREC® Software sends the order with all the necessary information to the furnace. • Induction Technology – allows unparalleled short sintering and firing times. • Just 10-15 minutes – the typical time a full contour zirconia Click here to crown takes to sinter. find out more