4 minute read

3. Precautions

(1) Protect bodywork and interior and exterior fittings

Bodywork can be smudged and scratched during body repair work. Prevent this by protecting the area around the work site. Use a sheet or a special protective cover.

1) Prevent dust when sanding using a sander, etc.

Prevent areas beside the repair site from being dirtied by dust generated when sanding paint or body filler. Be particularly careful with regard to the passenger compartment and engine bay. Protect the surrounding area using sheets, covers and masking materials.

2) Prevent interior fittings from getting dirty

Prevent dust from adhering to the seats, steering wheel and other parts of the passenger compartment by protecting them with plastic sheets and covers.

3) Prevent sparks during welding

Protect the vehicle body from sputters and sparks during welding by covering it with fire-proof sheets (cloth and paper).

4) Protect the surrounding area when making body repairs and treating the substrate.

When making body repairs or treating the substrate, protect the surrounding area by attaching masking tape or plastic tape so that the sander does not damage the pinstripe or other nearby parts.

(2) Prevent fires and explosions

Many pieces of equipment used for body repair can easily catch fire or explode. Be extremely careful when handling such items.

1) Gasoline

When siphoning gasoline, be sure to comply with fire regulations. Work in an area with good air flow and warn nearby workers. Do not use a plastic pump or tank that generates static electricity when siphoning or for storage. Store the siphoned gasoline in a specified safe storage place. If gasoline leaks onto the floor of the workshop, do not leave it but wipe it up straightaway.

2) Paints

With the exception of water-based paints, most paints are flammable. Store them in a specified place and do not leave them lying around elsewhere. As an environmental protection measure, always secure lids and caps to prevent the evaporation of volatile organic compounds. Also be careful when disposing of leftover body filler, cloths containing organic solvent-based degreasing agents and used paint cans, as there is the risk of spontaneous combustion.

* Volatile Organic Compounds

3) Gas cylinder

Be careful when handling acetylene gas, oxygen gas, carbon dioxide gas, argon gas, etc used when welding and also watch out for hose deterioration and the aging of equipment.

4) Naked flames and other fire sources strictly prohibited

Welding sparks can cause flammable gases to explode when gases reach a specified concentration within an enclosed space. Therefore, do not bring any fire sources into the workshop, except those required for work. Smoking is prohibited while working. Use a specified smoking area.

n Many pieces of equipment used for work are highly dangerous

Carbon dioxide gas

Gasoline Paint

Acetylene gas

(3) Health and safety related to body repair

1) Body repair work

Body repair and welding work are highly dangerous tasks. Body repair work can cause serious damage or injury due to the heavy items and large force handled. Pay attention to the following to prevent serious damage or injury.

À

Á

Securely fasten bolts, nuts etc on repair equipment and check they are not loose. When pulling, be prepared in case the clamp should come off by staying out of the area where the chain or clamp is likely to land. Attach a safety wire so that the clamp is restrained if it comes off. Follow instructions for the use of jacks and hoists carefully, and when going under a vehicle always support the vehicle securely with rigid racks, etc.

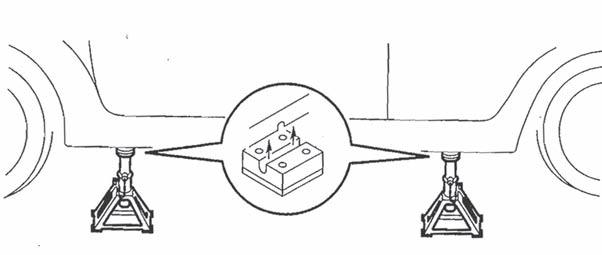

2) Using jacks

When jacking up a vehicle or supporting a vehicle with rigid racks, follow the instructions and weight limits in the service manual. Check carefully to see whether the vehicle is stable or not. When jacking only the front or rear, make sure that the wheels are locked. Do not leave a vehicle in a jacked up position.

n Vehicle is jacked using rigid racks

3) Welding work

Providing that there is nothing wrong with a welder it will not cause electric shocks or catch fire. However, regular checks are essential. Pay attention to the following when welding.

À

Á

Gas produced when welding is toxic so wear a protective mask. Looking directly at a flame when welding can, at worst, lead to the risk of blindness. Always wear a welding helmet or safety glasses. When using an oxygen or acetylene gas welder, check there are no flammable items in the surrounding area, as these welders produce naked flames.

4) Electrical work

When doing wiring or other electrical work, make sure the ignition switch is turned off and remove the connector to the negative terminal on the battery. If there is a risk of the generation of static electricity, do not touch the control unit, connector or other similar parts. Either use an anti-static electric cord or start work after removing the static electricity by touching earthed metal.

n Remove the connector from the negative terminal on the battery before starting work

(4) Health and safety related to painting work

1) Body filler

Coming into contact with sanding dust produced when applying body filler after body repair harms respiratory function, causing pneumoconiosis etc. Use a dust mask when applying body filler. Also use a sander that collects dust. However, since the use of a dust-collection sander alone will not completely take care of the body filler dust, work in a place with a dust collection system that suctions dust from the floor and wall surfaces. When cleaning after sanding, wear a dust mask and lower the pressure of the duster gun used for blowing so that the dust does not scatter over a wide area.

n Be careful with dust when using body filler

Dustcollection sander Dust mask

Dust-collection hose

Grating of dust-collection device