The Midnight Oil Summer 2015

The Magazine of the Historic Lighting Club

Issue 91

Featuring contributions from David Burnett, Phil Harris, John Kidger, Neil McRae, Mike Parker and John & Elaine White

LIGHTIN

G

ES

89

HIS T

IC

UB CL

OR

w

TA B

LISHED

19

Committee

THE HISTORIC LIGHTING CLUB To encourage interest in the collecting and restoration of lighting artifacts and the research into and study of the history of illumination

Website: www.historiclightingclub.co.uk PRESIDENT Ian Caunter Tel & Fax: 01752 783565 caunteris@aol.com

CHAIRMAN Ian Smith Tel: 01279 651405 iansmith6666@btinternet.com

HONORARY PRESIDENT David Denny

VICE CHAIRMAN

TREASURER & MEMBERSHIP SECRETARY

Dave Horrocks Whitewall Cottage Milbury Heath, Wotton-under-Edge, Gloucestershire, GL12 8QL Tel: 01454 281095

Mike Parker Tel: 01386 881863 mike@parkers-paraffinalia.co.uk PUBLICATIONS OFFICER John Kidger Tel: 01242 236794

The Midnight Oil Summer 2015

Issue 91

johnkidger@talktalk.net

davidwhorrocks@gmail.com NOTE: We have combined the role of Treasurer & Membership Secretary to streamline member communications, save costs and reduce duplication, with Dave Horrocks assuming the extra mantle.

Membership

Article Submissions

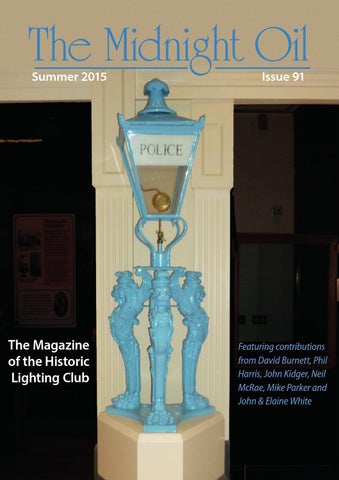

Annual subscriptions are due in November of each year. The current subscription rate is £20 per annum. Those members who live outside the European Union can if they wish pay a higher subscription rate of £25, which will ensure that they receive their copies of The Midnight Oil by airmail. Subscriptions should be sent to the Treasurer, and cheques (in UK £ only) should be made payable to The Historic Lighting Club. Members should ensure that they inform the Membership Secretary of any changes in contact details etc. Please send all material for inclusion in future issues of The Midnight Oil to Mike Parker Email: mike@parkers-paraffinalia.co.uk Front cover: Leamington Police Lantern. Courtesy of Leamington Spa Art Gallery & Museum (Warwick District Council) Editors for Issue No. 91: David Burnett and Mike Parker. All material © 2015 HLC

CONTENTS A note from the Editor A pewter pump lamp Lamp with dual fuel/light source Wrigley unmasked Army & Navy recreated Conference Report A pre-war Super-Aladdin lamp Coleman: the hydro-carbon years A Kinslow Oil advert Joseph Hinks exhibition

Mike Parker John Kidger John Kidger David Burnett J & E White Phil Harris Phil Harris Neil McRae Mike Parker Mike Parker

4 5 7 8 11 12 16 18 21 22

HLC meeting dates for 2015 21 June: Uffington

18 October: Tuddenham

13 September: Wythal

22 November: Uffington

17 October: Wheels by Lamplight

March 2016: Wythal

W.A.S Benson lamp (with reproduction Vaseline shade)

A note from the Editor

A pewter pump lamp

Welcome to Midnight Oil Magazine, issue 91. We are now settling into the new routine of members receiving two magazines and two newsletters a year, all arriving on your doorstep prior to each of the four, more centralized of our six National meetings. As the year progresses you will notice that we have brought forward the publication dates for the rest of this years publications, leaving our copy dates the same. This is to enable MO 92 to include any up to date news about a rather busy October schedule. Our club members have been invited to display their lamps at the “Historic lighting event” at the Black Country Living Museum, Dudley 10th and 11th of Oct 2015, as outlined in our March Newsletter. For any more info please contact: John Kidger, Tel: 01242236794 or email: johnkidger@talktalk.net. Many members will be attending Wheels by Lamplight on the 17th October, followed next day by our North Tuddenham meeting on the 18th October. The Historic Lighting Club is mounting an exhibition at the Leamington Spa Pump Room to commemorate the career and achievements of Joseph Hinks, the Birmingham manufacturer, who was Mayor of the town and lived nearby. This will take place on the week-end of 30th, 31st October and 1st November. The magnificent picture of the Leamington Spa Police lantern on our cover has been provided courtesy of the Museum. More details on page 22

This pewter pump lamp is one of the smallest made being only 10 inches (25.5 cm) tall. There is no name plate or cast marks in the base. Typically these lamps were made in France. Patents for these type of pump lamps began to appear shortly after 1800. As the initial photo shows (FIG 1), the lamp resembles a pewter “candle” on a globular pewter base. The “candle” acts as an upper reservoir to feed the oil to the flat wick and the base is the main oil reservoir/font containing the pump. The bottom of the main oil reservoir is concave to centralise/locate the bottom of the pump and thus keep the candle upright. The bottom of the wick holder (see FIG 4) dips into the oil at the top of the “candle”, this in turn, locally warms the oil, reducing its viscosity, and allowing it to “wick-up” slightly higher than when cold and when the oil level drops with the candle. The pewter pump lamp has a large flat flame, set about 25.5cm (10 inches) above a table top, offering light in all directions. Their light output was slightly more than a candle. Their flame stayed at a constant height, unlike a candle. Candles of the day also required trimming of the wick to avoid smoking, and consequently “sooting up” the room. The pump lamp also needed periodic attention to “pump” and maintain the oil at the correct level in the “candle” in order to feed the wick. FIG 2, shows the internal pump details. There was very little to be done to get the lamp functioning. Tapping out the dented base ring over a metal former, tube, and manufacture of a new burner from tin plate (see FIG 4). Luckily the pump cork seal (see FIG 2) was intact and shows us how it was fitted by wrapping round, with an angled slot, at 45 degrees. This angled slot technique is used on modern seals to reduce leakage.

Submitting Material

Image above right: Hinks, small Ruby table lamp, with push-in slip burner

Please don’t think that lamp information which you wish to share, or seek information about, is not suitable for publication. If 50p Parker’s stuff gets in there, your’s can. Even if you are worried about presentation, that’s what we have an Editor for. A gentle editorial nudge towards greater fluidity and use of the spell check can work wonders, if that is what you worry about. We want your personal take on historic lighting, whether it is recounting your lighting related experiences, about your collection, or even seeking to enlighten your ignorance - a regular feature for all of us at some time. Word text and high resolution images are what we are after. Images are ideally sent separate from the text, but with a note within it, as to roughly where you wish the image to appear. Please check that your email program is not set up to automatically reduce image size when sent out. Image resolution should be 300dpi for printing so check your pixel count, ie a 900 x 600 dpi image will print at 3 x 2 inches. If you have any queries please do ring Mike on 01386 881863.

John Kidger

Push down here

FIG 1. The working Lamp

6

A pewter pump lamp

Lamp with a dual fuel/light source John Kidger

Piston tube

Slot In piston cork

Penny valve trapped in tin cage

FIG 2. Lamp stripped down

Feed pipe to the very top

Wick adjusting hole

Many lamps can use different oils, be they vegetable or mineral, of high flash point. Some lamps are designed to accept dual fuel/light sources, usually oil and candle. The second source maybe offered as a standby should oil or candles not be available. FIG 1 shows one such French hand lamp which can use candles or a small oil burner. The lamp is mainly brass and some tin, and is 10 inches tall, less handle, and 3 ½ inches diameter on the base. The top hinges open to clean and the whole top is removed, via two thumb screws, to clean or change the glass. The candle sconce and oil container holder is secured in the lamp via 2 spring brass strips, see FIG 2. The lamp base is stamped LANTERNE MARINE PERFECTIONNEE BREVETE SGDG. Clearly a lamp used on a boat would benefit from a second fuel source as being at sea would limit supplies. FIG 2 shows the candle fitted in the sconce, which in turn fits into the top of the holder on the right hand side. The oil container in the centre also locates in, and sits right down inside, the holder. Therefore by removing the holder from the base of the lamp, either candle or oil may be fitted and used. The enlarged picture of the oil burner shows it is for thicker colza type vegetable oils. The outside wick winder and open wick on the side usually indicate this. This font contained Linseed oil. The wick is 5/8 inches wide. If the more volatile paraffin were to be used the flame would spread down the exposed side of the wick and overheat the winder and burner.

FIG 1. The candle sconce fitted

FIG 4. New tin plate wick holder with wick adjusting hole

FIG 3. feed pipe in candle FIG 2. Candle sconce on the left, oil container and burner centre, holder with spring clips on the right.

FIG 3. The wick winder sprocket is clearly seen and an area of wick exposed

Wrigley unmasked

Wrigley unmasked David Burnett After publication of the MO 90 a number of members commented on the contents. Among these comments was a constructive letter from Mike Bradley reviewing the material in which he pointed out that one of the illustrations in my article ‘Lamping Close to Home’ showed an adapted moderator, a fact which I did not realise for the good reason that I was ignorant of what a moderator might be. The consequence of Mike’s revelation was that I set out to remedy my ignorance, and to find out all I could about these lamps. It didnt take much digging. John Kidger sold me the excellent £1 booklet from the club book list of the Tylor moderators of 1854 (over 60 of the lamps illustrated). The internet provided additional detailed information. In order to chart the probable history of my lamp ‘Wrigley’ (the one in my piece) I made a simple time track, as follows: • 1836: The moderator invented in France. Fuelled by vegetable oil, typically colza, or rape seed oil. Mechanical force feed system with spring and piston to load wick. • 1840s & 1850s: Moderators in widespread use in Europe. British 1854 catalogue of J. Tylor & Sons, a London supplier, lists over 60 examples. • 1860s: Paraffin production in USA develops into major industry • 1865: Joseph Hinks produces the Duplex paraffin lamp, – simpler, cheaper, easier to manage, as bright or brighter than the moderator. Huge factory set up in Birmingham by James and Joseph Hinks for Duplex production. • 1867: Duplex lamp patented in USA. Becomes major export product. Hinks showroom opened in Paris. US paraffin imported into Britain in massive and increasing quantity. Decline and eclipse of moderator. Some moderators adapted to paraffin use by the addition of fonts and burners and later, moderators adapted to electrification. • 1890: Joseph Hinks appointed mayor of Leamington. Among the adapted moderators was my lamp, ‘Wrigley’, originally French, bearing the stamp of Carlian and Corbiere, an upmarket Paris interior decorator with an international clientele. In the Tylor catalogue mentioned above a moderator is shown on page 19 (No. 58) which resembles the original Wrigley.

The base containing the spring mechanism stands on a metal plinth of mythical winged beasts (are they griffons? Somebody will be able to enlighten me). It could be that Wrigley (which has a Hinks burner) was adapted to paraffin at the Hinks Birmingham factory, or by the Hinks Paris showroom. At some point, somebody brought Wrigley to England, either before or after modification. So much for that. You may be puzzled by the final entry in my time track. Why mention the apparently irrelevant fact that in 1890 Joseph Hinks became mayor of Leamington? This is surely a blind alley in a discussion of moderators? Well, as a matter of fact, it isn’t and here is why: the time track reveals that the year 1865 was a crucial moment in the history of lighting. Hinks’ Duplex paraffin lamp was invented. At the same time in Leamington, not far from the Birmingham factory, a young lady named Adelaide Pountney was keeping a diary of her daily life in a series of drawings; tiny pictures which showed interior and exterior scenes in amazing detail. In 1997 a member of Adelaide’s family, a retired doctor, found the diaries in her attic when she moved house and she showed them to me through a mutual friend with a view to publication. In 1998 The Diary of a Victorian Lady, 1864-1865, was published with some success. Long out of print now, the book came to mind when I realised the importance of 1865, and the Leamington connection with Mr Hinks. There were a few copies in my bookcase still, and I turned to the tiny pictures in hope that some examples of domestic lighting might be found. The results exceeded anything I could imagine for among the Leamington interiors several lamps were shown, and they were moderators, as John Kidger confirmed. On the following page then, enlarged by the technical wizardry of photographer Malcolm Payne and artfully coloured by illustrator Patrick Benson, are four Victorian scenes from Adelaide Pountney’s diaries for the consideration of members. Here we can see moderator lamps in a contemporary setting, at the very moment when Joseph Hinks was about to consign them to the scrapheap. As a matter of interest, Adelaide’s drawing from October 20th 1864 shows very precisely one of the Tylor moderators (No. 66 or 98). Her accuracy, when working on such a tiny scale is remarkable. The quest to find out about moderators, fired by Mike Bradley, has led me on a fascinating adventure of discovery. It is now on the cards that we will mount an exhibition in Leamington Pump Room in the autumn which will need the support of all Hinks collectors and scholars in the club.

9

10

Wrigley unmasked Four scenes from Adelaide Pountney’s diaries feature gas and Moderator lamps

Army & Navy recreated John and Elaine White

September 3 1864 3 arm gas chandelier, open flame.

October 8 1864 Moderator with conical shade. It appears this is a different Moderator with a different shade in a smaller room. This pattern of shade is shown in the club reprint of the 1854 Moderator catalogue.

October 20 1864 Moderator with globe, supported on a base.

October 27 1864 Moderator, no globe or chimney fitted, no base. Adelaides brother, Arthur, is home on sick leave. The Moderator appears to be under repair or missing upper parts.

I like to have a theme for my table at meetings and the November meeting was no different. Initially I intended to display a variety of candle lighting applications it was the receipt of the latest MO which changed my approach. The back cover of the improved MO featured a page from the 1937-38 Army and Navy Stores catalogue and much to my surprise I found that I had most of the items there presented! This left me thinking I should get out a little more and broaden my outlook on life. I was though inspired to make a display at the AGM meeting based upon the catalogue page. So with the aid of Mike Parker and John Kidger I was able to assemble the majority of the items catalogued for display, the principle exception being the Non-Turnover Night Lamp And Bracket. The great thing about catalogues I find is that they are dated and make you conscious of what was available at the time and the cost of these items. Of the items on the page I am a little surprised to see the availability of the various candle lit items, particularly the hooded candlesticks but specifically the Cricklite Lamp. Most members will be aware that these were manufactured by Clarkes at Cricklewood and would use a palm oil candle with a double wick made of a wood fibre construction so angled to make a single flame. The Shade Support deserves mention as I am of the opinion that they present an option for using a cloth or card shade on lamps instead of a fragile valuable glass shade. Finally the Talc Smoke Consumers I find interesting and provide insurance against a blackened smoke mark on the ceiling! It is the classification as “talc” for the construction of these items as opposed to belief they were of mica construction. Perhaps there is a chemist/geologist in the membership who can educate us on this matter?

The History and Impact of Natural Gas

CONFERENCE REPORT -

The History and Impact of Natural Gas Phil Harris This excellent conference was organised and hosted by the Black Country Living Museum in Dudley, West Midlands and took place over two days in October 2014. Being a volunteer at the Museum, I got the opportunity to attend. Fellow HLC member John Kidger also exhibited a fine collection of early and unusual lamps as part of the associated exhibition, which also included a wide range of lamps, mantles, books, gas appliances and documents from the collections of Sugg Lighting, the National Gas Museum, Tipton Gasworks, the Black Country Living Museum and the Stationary Steam Engine Society as well as a number of the presenters. John also contributed the concluding parts of this report. David Eveleigh, Director of Collections, Learning & Research at the Black Country Living Museum, welcomed delegates and introduced the first speaker. Dr Leslie Tomory from McGill University in Canada argued that the gas industry led the second industrial revolution between 1850 and 1920, based as it was on the three principles of science, technological scale, and multinational corporations. After outlining the discoveries made by the likes of Priestley, Lavoisier, Boyle, Stephen Hales, Joseph Black and Cavendish, Dr Tomory explained Bolton and Watt’s involvement in selling the first gas lighting plants to factories and mill owners. The first public gas lighting scheme was installed in 1815 by the original Gas Light & Coke Co in London. At this stage the incandescent mantle was still to be invented, and open flame burners were the norm. By 1850, the gas lighting industry had matured and become multinational, with British engineers installing British gas lighting technology throughout Europe. David McDougal, Museum Consultant, then gave us a working demonstration of various restored gas lamps including various open-flame and mantle lamps plus an Argand burner. His talk was illustrated with numerous historic images of gas lamps and burners in homes and public places, together with catalogue extracts and adverts for Welsbach, Block, Bray, Veritas, Sugg and other products. David has produced some replica upright mantles, using a modern mantle stretched over a mould, and mentioned that the compact inverted mantle only appeared in the 1890s, when gas pressures were more reliable and self-governing burners had been invented. Dr Chris Upton, Reader in Public History from Newman University, Birmingham, described the establishment of the first gas works in Birmingham by John Gosling in Gas Street, and its subsequent compulsory purchase by the City, under the Birmingham Corporation Gas Act of 1875. From then on, Birmingham Corporation’s gas operations produced

a healthy profit of £785,000 in its first ten years of operation and expanded across the city, firstly to theatres; public buildings and factories where gas lighting provided a reduced fire risk compared with candles and oil lamps and helped keep insurance premiums down, and later to pubs and private houses. Lighting of streets was a major contributor to the reduction of crime. The industries of Birmingham and the Black Country responded to demand for gas appliances, examples being Cannon and Tangye, but iron founders and metalworkers were also involved. George Demidowicz, Honorary Research Fellow in the Department of History at the University of Birmingham, gave a talk on Boulton & Watt’s Soho Foundry, the first factory in the world to be lit by gas. This was largely due to the efforts of Boulton and Watt’s employee William Murdoch, who was permitted to experiment and perfect his equipment for producing gas from coal. With the aid of maps and historic documents, George described his detailed investigation and research into the location and design of the gas lighting plant at the factory. The first gas lamps were lit in 1805 and the system expanded and developed until 1836. Professor Jennifer Tann, Professor Emerita of Innovation at the University of Birmingham, described how the famous steam engine manufacturer Boulton & Watt developed the ideas of William Murdoch into commercial gas lighting plants for industry in the period 1805 to 1814. Gas lighting was cheaper to run than tallow candles or oil lamps and was far safer from the fire risk viewpoint, but the capital costs were high and tended to limit the take-up to the largest and most profitable firms. By 1815 the company had effectively solved most of the early engineering design problems of local gasworks, but they pulled out of gas lighting, and it was left to other companies to continue the development of public gas supply. Toni Demidowicz, previously a Conservation Officer for Birmingham City Council, described the original Gas Street retort house building and the process involved in its protection and registration as a Grade 2* listed building, being the oldest known surviving retort house in the country. Built originally in 1818, the Gas Street gasworks was extended and altered until 1838 but gas manufacture had ceased there by 1848, although the gas holders continued in use until the 1870s. Toni described the detailed investigation, and the preservation works carried out by the City Council to ensure the building’s future. The first day of the Conference concluded with an evening tour of the Black Country Living Museum by gaslight. Delegates were able to see several examples of outdoor and indoor gas lights, from individual lamps in shops and houses to street lamps, including a rare Webb Sewer Ventilating Gas Lamp from the 1890s which was designed to create a negative pressure within the sewer to extract foul smells. A single Webb column could ventilate three-quarters of a mile of sewer. Other notable lamps included a cornermounted lantern with fishtail burner, several Size 3 mantle lamps in the shop premises, and the four 3-mantle lanterns on the canal bridge which have recently had replacement curved glass panes fitted. A casting demonstration in the brass foundry and a period of

13

14

The History and Impact of Natural Gas operation of the steel rolling mill concluded the tour, after which delegates repaired to the candle-lit Bottle & Glass Inn for pre-dinner drinks followed by the formal Conference dinner in the Workers Institute Hall. The second day of the Conference began with David Eveleigh’s presentation on the development of the gas cooker. Prior to 1880, for around 70 years gas had only been used for lighting, but there were early examples of the heat from gas light flames being used for heating drinks and cooking. Fifty years later, 90% of British households were cooking by gas. A gas cooker was instant and did not require the lighting of a fire prior to cooking. David explained how this rapid increase in popularity of gas cooking occurred, largely driven by commercial co-operation between the sellers of gas and the makers of gas appliances to advertise the benefits of gas cooking. Gas cookers were made available on rental, gas cooking demonstrations were organised, and in the 1890s the penny-in-the-slot pre-payment gas meter was invented. Gas cookers became cheaper and lighter, and manufacturers emphasised their fuel economy. Between 1900 and 1910 gas cooker sales boomed, and in 1919 the Radiation “New World” cooker was launched with the first thermostatic oven temperature control known as “Regulo” which continues to be used to this day. Chris Sugg then presented the History of William Sugg & Co, lavishly illustrated with images of the company’s works in Westminster and their products such as burners, lanterns and lighthouse lamps including a colossal double-Argand lamp. Steatite, an early form of naturally-occurring ceramic material, was machined into burner tips. The earliest burners were all open-flame types and William Sugg pioneered the self-governing burner which could cope with fluctuating gas pressure and maintain a steady flame. Many of Sugg’s street lamps were converted to incandescent mantle burners from 1910 onwards. Chris’s presentation concluded with numerous excellent images of Sugg gas lamps and appliances. William Thomas Sugg died in 1907 but Chris, William’s great-great-great grandson, was instrumental in resurrecting the company as Sugg Lighting Limited. Chris Hodrien, an International Consultant and ex-British Gas engineer, in a highly technical presentation described the development of gas production, beginning with the earliest simple retorts and describing alternative systems including producer gas, water gas and synthetic natural gas. Chris explained the mechanisms for removing impurities such as ammonia, sulphur and phenols from coal gas, and showed how gas production had expanded to large scale industrial plants. Many modern, low-carbon alternatives to coal gas were developed in the UK by British gas and other researchers at great cost, but largely abandoned after the coal industry was effectively run down. The technologies are still viable but are now in other countries. Professor Rex Harris, Professor of Materials Science at the University of Birmingham, gave a stimulating and wide-ranging presentation centring on hydrogen gas and the role it could play in the future energy market. After reviewing the science of climate change and anthropogenic carbon dioxide emissions, together with the likely release of methane due to thawing permafrost and the resulting potential rise in sea-levels, Professor Harris

The History and Impact of Natural Gas considered possible mechanisms for improving the situation, and concentrated on hydrogen. Ultimately, it should be technically possible to generate hydrogen from the electrolysis of water using solar energy, preferably on a localised basis. Hydrogen can serve as a gaseous fuel, to produce liquid synthetic hydrocarbon fuels such as would be needed for aviation, or to produce electricity using fuel cells, which is the most efficient form of energy conversion. Ultimately, hydrogen could provide energy storage, filling the gaps between peaks of renewable electricity generation and grid electricity demand. A key part of Professor Harris’s topic involved the Neodymium-Iron-Boron (NdFeB) or ‘rare-earth’ permanent magnet which can be incorporated into wind turbines, wave-power generators and electric motors, to create electrical machines of higher efficiency. The presentation concluded with a description of the first hydrogen fuel cell-powered electric narrowboat, the ‘Ross Barlow’ Protium Project, driven by permanent magnet DC motors using NdFeB magnets. The boat was moored in the Museum canal basin and delegates were invited to inspect the hydrogen and fuel cell installations. The closing lecture by Des Correia, Director, Energy: Unconventional Hydrocarbons at Ove Arup & Partners in Birmingham, summarised the Conference proceedings and noted the contribution that gas had made to society over the past 200 years. However, natural gas from unconventional sources may present a real possibility as a transitional fuel in the short to medium term. Des works with Cuadrilla a UK company based in Staffordshire. Their focus is on bringing together experts to recover natural resources, such as those found in Lancashire. Cuadrilla is aiming to be a “model company” for unconventional exploration in the UK. Des advised it is acutely aware of the responsibilities this brings, particularly with regard to safety, environmental protection and working with local communities. Although exploration for natural gas from shale is still in its infancy in this country, the Government believes that the UK is well placed to become the leading player in an emerging energy industry. Natural gas from shale could increase the country’s self-sufficiency and secure investment and jobs for local communities across the country. Cuadrilla has a production site at Elswick which has been generating electricity from natural gas since 1993. David Eveleigh, summed up the conference and thanked the speakers, exhibitors and attendees. He concluded gas had a great part to play in our future. For reference: National Gas Museum, 195 Aylestone Road, Leicester, LE2 7QH Dr John Beckerson, Curator. Open: Wednesday, Thursday and Friday – 1pm to 5pm. Internet: www.nationalgasmuseum.org.uk Email: nationalgasmuseum@gmail.com Tel: 0116 250 3190 or 07757 612340

15

Restoring a pre-war Super-Aladdin lamp

Restoring a pre-war SuperAladdin lamp Phil Harris

I have been very lucky this summer to have acquired a couple of nice lamps. The first find, a modern 2003 Vapalux M320 pressure lantern in military drab green finish, was complete, new-in-box and cost just £20 from a local steam rally. The second (and last, according to my wife...) was found completely by chance in a junk shop whilst holidaying on the Isle of Wight. I recognised it as some type of Aladdin wick mantle lamp, and on closer inspection it appeared to be complete, with chimney, shade, wick and an undamaged Loxon mantle. I was more than happy to pay the £20 asking price! On getting home and dismantling the lamp in the workshop, under a thick layer of dust the lamp appeared to be in fair condition, apart from considerable staining on the nickel-plated tank and base. This responded remarkably well to liquid Brasso and several hours’ worth of elbow-grease. The fitted Loxon mantle was in perfect condition, and whilst it had clearly been burned at some time, as a thin layer of soot inside the chimney confirmed, I was able to remove it and carefully take off the worst of the dust using a gentle vacuum cleaner and a tiny paintbrush with very soft bristles. The burner and gallery were in very good condition, and apart from removing the accumulated dust, needed only a gentle clean and polish. The wick, however, had at some time been allowed to burn dry, so I used a plastic Aladdin wick trimmer to restore a good tapered charred edge all round. I washed the Loxon-pattern chimney and the shade in warm soapy water and reassembled the lamp. At this point I realised that the three steel arms didn’t hold the shade very securely at all, so I spent some time in trial-and error adjustment to ensure a better fit. In the end I resorted to fitting short lengths of black heat-shrink electrical sleeving over the ends of the arms. I’m not sure if this shade or shade ‘ring’ are the originals; however this style of shade is certainly common on Aladdin lamps. COMPARISON WITH THE FAMOS MANTLE LAMP This is my second wick mantle lamp. I know, I know - one lamp is just a lamp; two lamps constitute a collection... I wrote about my first non-pressure mantle lamp, a Famos 120CP, in MO Issue 88, and I mentioned that I had

fitted it with a new 60CP Aladdin Loxon mantle using one of the HLC’s special adaptors. It’s interesting to compare the performance of the Aladdin with the Famos, although such comparison is completely unscientific and won’t involve any light-meter readings at this stage, as both lamps are of similar brightness. The light from the Aladdin is warmer and more yellow in colour than that from the Famos, despite having notionally the same mantles fitted to each. But I think this is probably more due to the fact that the Aladdin burner is of the side-draught design, whereas the Famos has a centre-draught burner. Then there’s the age of the mantles; I’ve no idea of how old the mantle that came with the Aladdin is, but it’s considerably older than the new mantle I fitted to the Famos, and from my experience with pressure lamps, mantles vary considerably in performance. And there, perhaps, lies another factor for the difference. The Loxon mantle naturally retains its curved conical shape, being supported both by the top ring and around its base by the brass Loxon mantle holder, and the heat of the flame impinges evenly on the mantle. The first time I modified a new Loxon mantle, using the HLC adaptor to fit the Famos lamp, I adjusted the height and shape of the wire support rather by trial and error, and in the end the mantle hangs solely from its top ring, thus taking on a more straight-sided conical shape. Whatever the reason, incandescence is not so even, and whilst the rated 60CP can easily be achieved, the fuel consumption of the Famos is clearly higher than the unmodified Aladdin, detectable by the much greater heat release from the chimney. That’s not surprising either, as the Famos is rated at 120CP; the 120CP Famos mantle is a fair bit bigger than the Aladdin mantle, and would have been quite a sight when lit. I have one original 120CP Famos mantle, but given their rarity I’ve decided not to burn it. HISTORY The history of Aladdin lamps is well-documented elsewhere and I don’t propose to repeat any of it, save to say that the ‘Super Aladdin’ was made specifically for the British market and released in around 1932 as the ‘Cottage model’ originally with an optional fabric, rather than glass, shade. Production continued basically unchanged into the 1950s, and the later Model 14 is similar but apparently more common. Mine seems to have the Model 14 fount and base with the earlier pattern burner. The legend on the winder knob states “PAT. Gt Br and I.F Ste” and I take this latter to refer to the Irish Free State, which came to an end in 1937. The wick winder detail changed to a plainer design in 1938. Finally, the opal shade that came with the Aladdin is known as ‘moonstone’ and I believe this has a special internal coating. In use, the shade does indeed seem to glow most attractively and emits a significant amount of light.

17

The Swiss Connection

Coleman: the hydro-carbon years Neil McRae William Coffin Coleman was owner and president of the Coleman company from its small beginnings in 1900 to 1951 when his son Robert Sheldon Coleman took over as chief executive. Robert Sheldon joined the company in 1925 and worked in the Toronto factory until 1928 when he returned to Wichita. He became influential in improving the company’s fortunes after 1931 when the great depression had hit hard. He became CEO in 1940 and president in 1951. He then took over as Board Chairman after W.C Coleman died on 2nd November 1957. Robert’s son Sheldon Coleman Jnr entered the business in 1981 and took over as CEO after his father Robert Sheldon died 21st September 1988 but his tenure only lasted a few months because, after a hostile take over of the company by Ron Perelman in May 1989, he was dismissed. W.Cs other son Clarence was also an executive officer of the company from the late 1920s until 1955 when he left the company to become a financier although he remained a vice chairman of the Coleman board. So in 1989 after some 90 years the Coleman company passed out of the family’s control. The company has extensive records which have been preserved mainly due to the efforts of Herb Ebendorf and the International Coleman Collectors Club has copies of company magazines which contain much detail. The accepted Coleman history, as told to us by Herb Ebendorf, tells of a travelling typewriter salesman trying to pay his way through law school, William Coffin Coleman, who saw a bright light in a drug store window in Brockton Alabama in 1899 and conceived the idea to sell light instead of lamps and obtained the right to sell the lamps. William bought a stock of 100 Irby Gilliland lamps with $1,000 he borrowed from his sister Evelyn’s husband Judson Wilson and sold the light to the merchants of Kingfisher Oklahoma for $1.00 a week. In 1902 Irby Gilliland offered to sell their lamp business to William for $10,000. After some negotiation William bought their stock and patent rights for $3,000 at $250 a month. He then created the HydroCarbon company in partnership with his cousin’s husband William Covalt and moved the business to Wichita initially having the lamps made by the Edward Miller Company of Meridon Connecticut and then at some time in 1904 started to make an improved version of the lamp in his own workshop in Wichita. What Herb told us was of course correct and we all owe a great debt to Herb for his dedication to the company

Coleman: the hydro-carbon years history but modern internet research allows us to much more easily uncover evidence and this later research into family genealogy, city directories and contemporary newspapers shows that the reality is rather more complicated. This further research was triggered with the discovery by Leonard Johnson of a letter from the Hydro-Carbon company to K.B. Coleman and signed by William Covalt which in the content mentioned Dean who I later found was Dean Coleman. I then started to look hard at these people and the company in the early years aided by Darcy Vantiger who found details of a 1907 court case involving the company and by Dr Terry Marsh who obtained copies of the State incorporation documents. So who were these people and what were they doing in the company in 1906? This was the Coleman company but not K B and who is W Covalt??? Many hours of searching directories and analysing all the info uncovered the answers. William and his new wife Fanny moved to his home town of Wichita in 1901 where his Uncle George was still living. He started the Hydro-Carbon Light Company and in 1902 he is listed as President with William B Covalt secretary and has his niece, William Covalt’s daughter, Margaret Covalt working for him as stenographer. I assume that at the time Coleman and Covalt had both invested cash into the company which was trading as a licenced business but not incorporated by charter from the state of Kansas. William B Covalt was the husband of his cousin Fanny May Coleman. Fanny May was the daughter of W.C. Coleman’s uncle George J Coleman who was a farmer in Labette Kansas. This partnership of William Coleman & William Covalt was formed into a separate company, Coleman and Covalt, which in 1905 is listed as proprietor of the Hydro-Carbon Light Company and this situation was maintained to 1906. The Wichita directories from 1903 to 1907 show two companies with the partnership owning the lamp business. For some years this was a real family affair with two of George Coleman’s sons, Kay Bushnell Coleman and Dean Shepherd Coleman, working for the business. In the office they had two young ladies of the families, Margaret E Covalt, sister of William Covalt as stenographer and Kay Coleman’s daughter Ethel S Coleman as book keeper. In 1904 Charles Wells joined the company. He had been working in a local hardware business as manager/foreman and William Coleman also persuaded Richard King, who owned a local plating works, to move into the company premises. Later that year he also employed Hiram Strong. Hiram had been trained as a machinist and worked for some years as foreman at Walterscheid Bros who were a fair sized local machine shop. I took a snapshot of the 1904 Wichita directory and as far as I can tell there were a total of 11 people working for HydroCarbon Light in Wichita that year although there would have been some agents working out of the state. In addition to those mentioned there were four men in the factory; Curtis H. Beyers, Edward W. Heil, Ralph W. Kenyon and Curtis C. Lewis. These four guys are listed in the 1904 directory as labourers but I suspect they were better than that implies and were in fact capable of repairing and servicing the lamps. This was set to change because with an experienced machine man in Hiram the company was able to change from sales and repairs to

19

20

Coleman: the hydro-carbon years manufacturing. Hiram stayed with the company until he retired in 1945 having been foreman and then factory manager. Hiram was a significant member of the team and involved in the design as well as manufacture of most of the lamps made during that period. Business was doing well but then there was a disaster on the 27th February 1906 when a lamp being operated by company agent John Jamison in the Lawton County Jail Oklahoma exploded killing John and Andrew K Fitzwater who was a 16 year old prisoner. Andrew’s father then sued the partnership for $10,000 damages in the form of an attachment and the Lawton Sheriff took possession of the companies assets in Lawton. The partners were then summoned by publication which meant a notice of the summons was published in local newspapers with a default date after which the petition would be taken as true. I assume this happened and in default the company assets were sold at auction on the 10th August 1906. The sale included 73 mostly new lamps and other supplies. I suspect this sale probably raised about $2,000 but would have effectively ended any Coleman sales in Oklahoma for some time and badly damaged the company reputation. The event was reported in Wichita so reading between the lines the company was in trouble from this negative publicity. I also have little doubt that W.C. Coleman was mortified at the loss of two lives through the failure of one of his lamps. This disaster and subsequent court case must have had a serious effect on the two men and we can assume it cost them a great deal both emotionally and financially. I am sure that one of the consequences was a determination that from then on the lamps would be safe. I don’t know what transpired between William Coleman and his partner William Covalt but the partnership was dissolved in 1907 and William Covalt moved to Oswego that year. The Hydro-Carbon Light Company applied for a charter of incorporation May 3rd 1906. I am sure this corporation was only established because of the deaths in Oklahoma and the subsequent action for damages on 12 April which is 3 weeks before this application and it was an interim measure to protect the company because W.C. Coleman and W.B. Covalt were disassociated from the company. It was so soon after start of litigation that it had to be a quick family rescue headed by George Coleman who was Uncle to W.C, and father in law of W.B. Covalt. It is perhaps significant that neither of the two proprietors are listed as company officers but their wives are and the Company is headed up by George who was an experienced businessman and presumably concerned to help a family business in some difficulty. The applicants were Fanny S. Coleman with 399 shares, George J. Coleman and Margaret Covalt with 250 shares each, Fannie C. Covalt with 100 shares and 1 share with Charles T. Wells. Charles was the only non family member but he had been working for the company since 1904 as Manager/Forman. So we can say that for a few months William Coleman was just another employee of the company with no financial stake. However if we assume that George’s shares were in fact owned by W.C. and of course had his Wife’s 399 shares from the above list, then he was two thirds owner of the Coleman Covalt partnership at the time. This corporation only existed for 15 months and in that time the partnership of Coleman & Covalt seems to have been dissolved and W.C. Coleman became the sole majority shareholder presumably by purchasing the shares held by the Covalt family. William Covalt and his family moved to Oswego Kansas in July 1907. (to be continued in the next issue)

A Magnificent Hinks Enamel Advertising Sign

A Kinslow Oil advert Mike Parker I had forgotten that I had this dinky little advert handout, until it turned up when I was searching for suitable black and white images for the HLC Newsletter. Folded in a square 8 by 8 cms it shows a happy sun mocking and challenging, a single lamp to light up, one presumably filled with Kinslow Kerosene,. The reverse side tells you, in no uncertain terms, why Kinslow Kerosene is a so much better Lamp Oil than other oils and that you should: “Beware of Imitations”. Then Voila! You lift a flap that reaches to the middle of the lamp and you see a sad sun. A sun clouded over in the face of an oil fuelled brightness that could only be responded to in wonder with “Good Gracious”. Reminiscent of snake oil salesmen I thought, and an interesting precursor of the later Guiness advert. Note; the small schooner in the background, quietly taking advantage of that other bountiful and infinite, energy source –wind. Energy with a quality that the sun might envy, with its ability to either fan the flame, or blow it out.

IC

LIGHTIN

G UB CL

Joseph Hinks:

OR

Joseph Hinks – a forthcoming exhibition HIS T

an exhibition at Leamington Spa Art Gallery & Museum ES

89

22

TA B

Following a meeting at Leamington Spa Art Gallery & Museum with Vicki Slade, Senior Curator (Human History) of the Art Gallery & Museum. David Burnett and Mike Parker saw that there was an excellent opportunity for the HLC to mount a static, week-end exhibition about Joseph Hinks; the Birmingham factory, his lighting work, interests and connection to Leamington Spa. David is familiar with the museum because they launched the publication of his reprint of The Diary of a Victorian Lady. There is a strong connection with Hinks and Leamington Spa, he was Mayor and built a house there. David has also made contact with Eve Cox a distant relative who lives in Birmingham and has been researching the Hinks family. The Museum offered the HLC exhibition space in an old Turkish bath building (called the Hammam). The concept is different from what we have been involved with before. A single subject, with a secure display under the museum’s loan arrangements, security and insurance. Dave & Mike talked to our Chairman and agreed the dates October 30th, st 31 and 1st November. The main efforts will be: 1. Planning the display. 2. Delivering the materials: lamps, pictures, advertising signs, computer images, HLC information and application forms etc, and setting it up within Museum standards, in the room they allocate for such events. 3. HLC member’s presence as and when they wish and are available. 4. Removing the materials. These educational week-ends are a regular programme advertised through the Museum’s publicity and website. They include an approximately 20 minute lecture during the Friday before the weekend, on the subject displayed in that particular room. The average attendance is about 40 local history enthusiasts. A great opportunity to spread the word about the HLC and our aims. Late October may seem a long way off as we enjoy the April sunshine but David and Mike, who are coordinating HLC’s contribution to the Exhibition, are already gathering ideas and information about how it might be presented. We already have much material but please let us have access to any research you may have done, or pictures taken. We are particularly interested in burner development over the years, so if you possess any unusual burners or detailed history about them, please let Mike know.

LISHED

19

Look what’s coming in the next Midnight Oil • PART TWO OF NEIL MCRAE’S COLEMAN FEATURE detailing the period after 1907. • JOHN KIDGER’S PENNY BOTTLE LAMP A description of his lamp with rare tin top. • EARDINGTON HALT Phil Harris describes an oil-lit railway station • ANTON KAIM’S WORKING ERA MANTLE BURNER A history of one of the oldest kerosene mantle burners ever made. • TABLE TALK FROM WYTHALL, 22 MARCH 2015 by Phil Harris • A CALL TO ALL MEMBERS – now is the time to be thinking about that gem of an article you know is bursting to come out. If you need technical help or advice we are here for you. Call Mike P.

Veritas Mantles, by John Hassall, famous as the ďŹ rst great illustrator of railway posters