11 minute read

ASK MATT

By Matt Weber

A table saw often serves as the “flag ship” tool of a home workshop. It can be used for crosscutting, miter cutting, bevel cutting, compound miter cutting, ripping, bevel ripping, rabbeting and

resawing. Since the user guides the stock into the blade, rather than the blade into the stock, a table saw offers superior control and accuracy for a wide range of cutting applications.

DIY'ers can check out these six handy tablesaw tips to cut with more safety and confidence than ever. Note that in the article shown, the blade gaurd is sometimes removed for the sake of photo clarity, but HIR recommends that users at home always operate a table saw using its blade guard.

COUNT ON YOUR SUPPORT

When ripping long pieces of material on a table saw, the workpiece should be always be supported from beneath after it passes the blade. Furniture and cabinet makers typically use a stationary outfeed table for work support, but DIY'ers can rely on a foldaway roller stand to conserve space. A roller stand keeps the workpiece traveling forward smoothly and prevents it from falling off the rear of the table, which can result in blade tearout and impact damage. The height of the adjustable roller should be set at

the same level or just below the surface of the table. We purchased the fold-up model shown from Harbor Freight for less than $20.

To cut sheet goods, arrange a couple of sawhorses as a makeshift outfeed table.

MARK THE KERF

The circular blade of a table saw doesn't cut like scissors but rather removes a line of material, and this line called the "kerf" which refers to the thickness of the saw teeth. The kerf can meaure up to 1/8 inch and should be taken into account when taking accurate measurements.

To make a sight guide for the kerf, position a straight edge flush alongside the saw blade, then use a fine-point pencil to mark both sides of the blade kerf on your saw table. Some manufacturers provide a small window to mark the kerf, but I recommend drawing the lines from the blade all the way to the edge of the table to provide a more useful visual reference. Some carpenters will score this line, but that can get confusing if you use a blade with a different measurement, so we stick with erasable pencil. GRANT AN EXTENSION

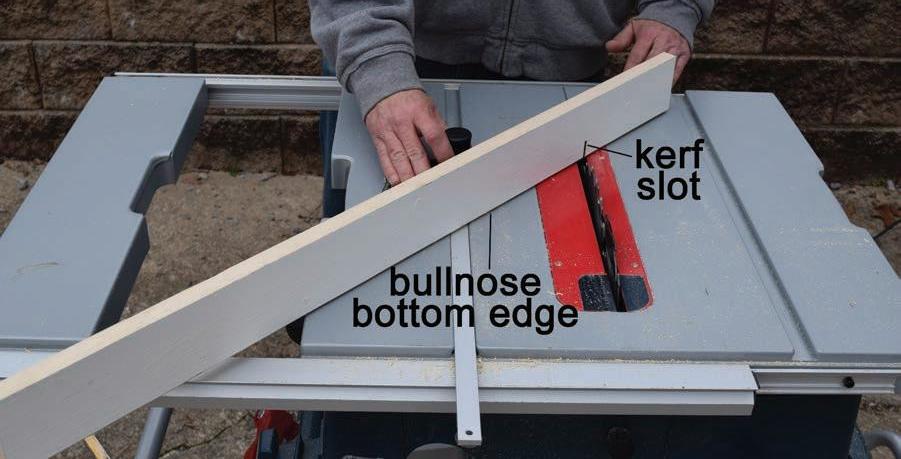

Miter gauges are crucial for making crosscuts on a table saw. Most factory-supplied miter gauges, however, are too small to accurately handle workpieces longer than 2 or 3 feet

because of the workpiece's tendency to pivot on either side of the undersized gauge. The solution: Make the miter gauge larger by adding an extension.

The extension shown was made from a 4-in. wide scrap of painted 1x wood trim screwed to the face of the miter gauge flush with the saw table. I first ripped 1/8 in. off one edge of the trim strip to ensure a straight line, then routed that edge with a 1/4-in. roundover bit. The router gives the bottom edge of the extension a slight bullnose so it will easily slide over the table top without catching or chattering. The length of the extension should span the majority of the workpieces you plan to cut and should reach past the blade kerf. Pass the extension over the blade and cut though it to show a precise kerf location in the extension which can guide your production cuts. The extension not only adds stability and thus accuracy to your cross-cuts, but by backing the workpiece, it also reduces blade tear-out and splintering of the material.

BUY IT

s Companies such as Milescraft offer ready-made jigs and accessories for woodwork, including this double featherboard for large workpieces and resawing applications.

UNDER PRESSURE

A featherboard is a safety device that applies pressure against a workpiece, keeping it flat against the table or fence. Featherboards can very in shape and size, and you can make a simple version with your table saw. Select a straight-grained, defect-free wood board and cut a 45-degree miter on one end. On the mitered end, cut several parallel cuts in the direction of the grain to create fingers or "feathers" that flex in the direction of workpiece travel.

In any cutting operation where the blade guard must be removed because the blade won’t be cutting completely through the wood, “featherboards” should be used for addtional safety. The featherboard prevents the workpiece from being dragged backward by blade friction. Featherboards can be clamped above and to the side of the workpiece to exert pressure until the cut is complete.

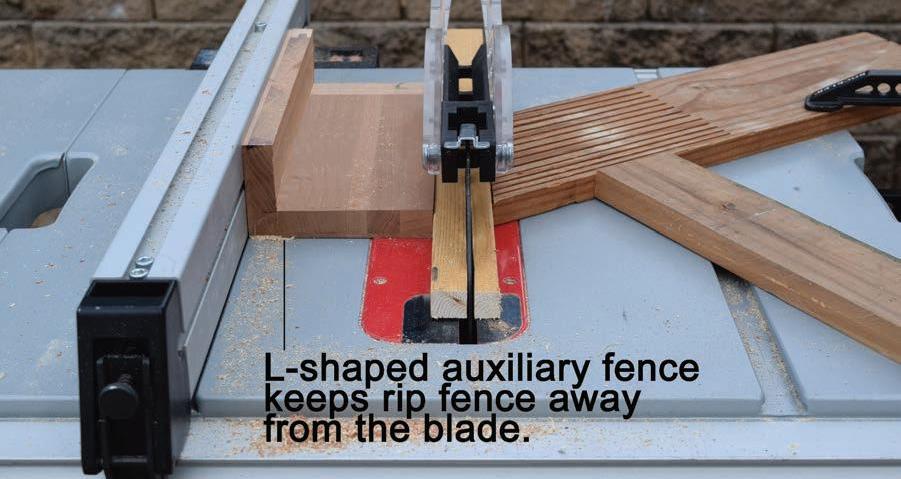

AUXILIARY CLUB

In some cases of very narrow rips, such as less than 2 inches wide, the blade and fence can get dangerously close, impeding visibility and making it difficult to use a push stick. In such a case, you can build an L-shaped “auxiliary fence” about 5-1/2 inches wide and 12 to 22 inches long to fit your table surface. The rectangular sides must be straight and parallel. The L-shaped lip aligns with the rip fence, and the lower side of the auxiliary fence acts as an extension of the rip fence, only with a lower profile to guide the stock by sliding beneath the guard for closer proximity to the blade.

AHH... PUSH IT

When ripping narrow stock, another useful table-saw tool is a push block. Like a push stick, it's designed to spare your fingers as you push a workpiece into the blade. A push block, however,

NEW JOBSITE TABLE SAWS

The new portable jobsite table saws are designed for DIY’ers who use a table saw for a little bit of everything, and carry it everywhere. I only have room for one large table saw in my workshop, but I also need to transport it from job to job, where I might use it to help install flooring at one house and trimwork at a different one. To make this happen, I need a quality saw with a reliable rolling stand. SAWSTOP JOBSITE PRO

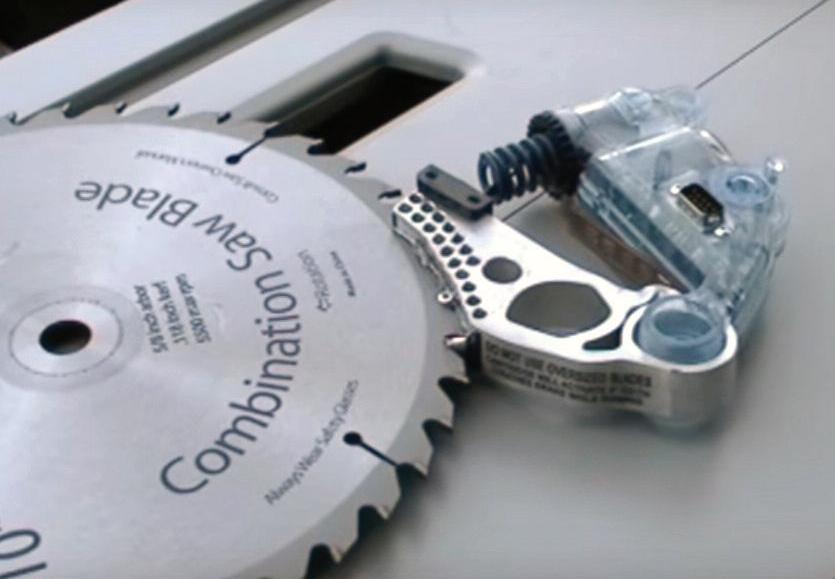

With the push of a simple foot lever, the new Jobsite Pro Table Saw from SawStop will easily set up from rolling cart position or break down again with one fluid motion. In working mode, the stand is sturdy, and the saw motor operates smoothly by starting with a handy paddle switch.

The company earns its name from SawStop's finger-saving, flesh-sensing technology. As a stand-out safety feature, the Jobsite Pro detects contact with skin on the blade, and stops and drops the blade in less than five milliseconds. Note: We've tested this feature on a hotdog, and the wiener barely had a nick!

Several key features of the SawStop’s legacy saw are included in the new model, such as a blade-lift handle with One Turn Elevation (other saws required over 25 turns), which is the snappiest way to set blade height we've ever seen on a table saw. The new model also includes a beefy T-style rip fence with push-button operation for a firm lockdown. The fence even has a

Set up the rolling cart for work in seconds. s

s The saw’s premiere safety feature is its flesh-sensing technology that stops the blade in milliseconds.

One-turn operation sets the blade height in no time.

A handy paddle switch starts the motor for normal operation or bypass mode.

The sturdy rip fence includes a hidden work-support shelf.

s

s

thin hidden shelf that flips out to support the end of a workpiece when the table is extended.

With the new Jobsite Pro model, the redesigned rip fence has an additional feature—an adjustable high/low capability for performing cuts close to the saw blade.

Further upgrades of the new Jobsite Pro model include a deeper work table and an active dust-collection blade guard. The saw includes an on-tool storage cabinet, which stows away accessories including the miter gauge and push-stick right beneath the work table.

s A shelf for accessories is hidden beneath the work table.

The downside of the Jobsite Pro is the high cost of the saw, but if it saves your fingers, it’s a bargain! One note about the safety technology: To cut electrically conductive materials without triggering the safety mechanism, the saw must be operated in “bypass” mode, which requires an extra step. So, if your work requires cutting a lot of conductive materials (including treated lumber still wet from the plant), then this saw might not be the best choice for you. Visit www.sawstop.com.

METABO HPT MULTIVOLT TABLE SAW

The new MultiVolt Table Saw arrived at HIR headquarters just in time to make this issue. The saw had been on backorder, meaning this is a very popular new tool. The MultiVolt is a cordless/corded hybrid and the first high-powered 36-volt 10-in. table saw on the market. When you’re near an outlet, plug it in. If you’re working somewhere without an AC power supply, use the battery as backup.

The MultiVolt operates with a powerful brushless motor, and because this is the first 10-in.

The new Metabo HPT MultiVolt is the first hybrid corded/cordless table saw available with a 10” blade. s

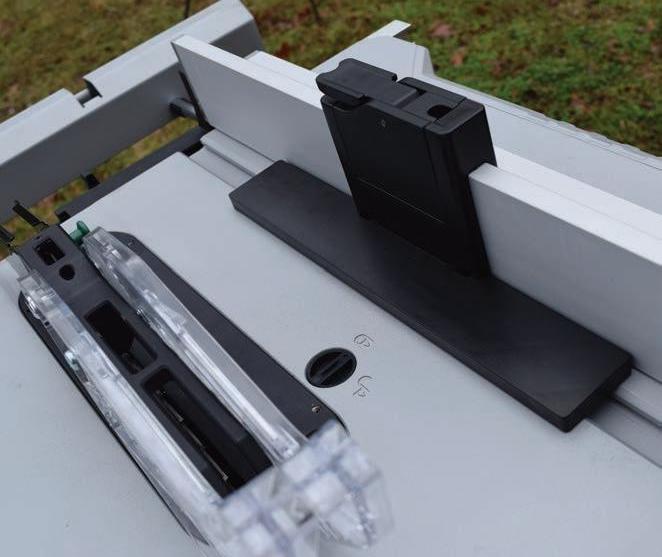

s s Switch from corded AC power to cordless 36V battery power with no drop in performance. The Metabo HPT 36V MultiVolt Table Saw offers best-in-class 35-in. rip capacity. Plus, check out the cool work support bar that extends from the back of the table.

cordless saw available, we’ve yet to fully realize its battery-powered versatility but can certainly see the potential. When powered by the 36V battery, the saw shows no decline in cutting performance, so this new hybrid capability will open a whole new dimension regarding where and when this saw can be put to use.

Standout features include a rack-and-pinion fence adjustment mechanism and an expanding table top that offers the highest rip capacity for a cordless table saw at 35 inches. An accessory fence helps with making thin cuts, and an on-board outfeed support bar extends out the back to help carry the workpiece. Blade

s The rack-andpinion rip fence adjustment ensures easy and accurate control.

tilt allows bevel cuts from 0 to 45 degrees, and an electric brake stops blade rotation within seconds.

Note that we didn’t have the opportunity to test the folding saw stand, but Metabo HPT does have one available for the MultiVolt (Part # 374769). Visit www.metabo-hpt.com. s The rip fence includes an auxiliary attachment for making narrow cuts close to the blade.

H

BOSCH 4100 WITH GRAVITY RISE STAND

The most shining endorsment I can give to the Bosch job-site table saw is that fact that I’ve used some version of this saw for the last 14 years. (I suddenly feel very old). The company’s most recent iteration is the Bosch 4100XC-10. From ripping and resawing to cross-cutting and everything in between, the Bosch job-site table saw has been my partner on many remodeling projects, and it shines as an all-around workhorse. I love the SquareLock Rip fence, the wheeled, go-anywhere Gravity-RIse Table Saw Stand, and the dual-arm Smart Guard blade cover. As far as improvements I'd like to see on future models, some solid-core wheels would be nice so I don't have to keep reinflating the tires, and I wish the under-carriage of the folded stand was more contoured to make it easier to drag over my tailgate into my truck bed. Visit www.boschtools.com.