Material Health Open Innovation Symposium III Proceedings - TABLE OF CONTENTS Designing Safer Indoor Environments, ASU’s Biodesign Center for Environmental Health Engineering……………………………………………………… From ‘impossible’ to everywhere: Scaling up recycled nylon yarn, Interface……………………………………………………………………………………... Material Health Screening with "RoboTox” Feature within the Toxnot Tool, Saint Gobain and Toxnot…………………………………………………….… CVT-B: Increasing Clean Vinyl Technology's™ Bio-Based Content, Len-Tex Wallcoverings…………………………………………………………………… Social Health & Equity - A Manufacturer's Journey with Just, HMTX Industries ……………………………………………………………………………….… Embodied Injustices: Chemical and Environmental Justice Impacts Along Product Life Cycles, Healthy Building Network ……………………………… A Survey of Current Labor Certifications for the Built Environment, CookFox ………………………………………………………………………………….. Incentivize your Suppliers for HPD data using the Toxnot Exchange, Toxnot …………………………………………………………………………………… Sustainable Minds Transparency Report [EPD]™: Integrating EPD and HPD information in one easy-to-understand digital document, Sustainable Minds …………………………………………………………………………………………………………………………………………………………………….. Simplifying Data-Driven Sustainability, ecomedes and Brightworks Sustainability……………………………………………………………………………… Optimizing Material Health and Maximizing LEED Credits, Green Seal…………………………………………………………………………………………. Mission Possible - Healthier Projects using Materials Modeling, Healthy Building Network…………………………………………………………………… 4 16 32 48 62 76 98 130 142 172 190 198

KEYNOTE

Rolf

Designing Safer Indoor Environments

Halden, ASU’s Biodesign Center for Environmental Health Engineering

Rolf Halden, PhD, PE Biodesign Center for Environmental Health Engineering The Biodesign Institute, Arizona State University OneWaterOneHealth.org – ASU Foundation Nonprofit Project AquaVitas, LLC – ASU Startup Company November 15, 2022 Designing Safer Indoor Environments

GOAL: Making the Great Indoors - Safer - Healthier - More productive By reducing : - Hazards - Risks - Exposure - Liability Concrete surfaces 110/133 (83%) Metal Casings and surfaces 32/36 (89%) Finishes : 1008/1202 (84%) Furnishing 459/910 (50%) Wood, plastic and composites 46/73 (63%)

IDEA in the Early 2000s: Anonymous Health Screening Using Wastewater

(Manufacturing) Building

Time It Takes for a Technology to Be Adopted?

Time It Takes for a Technology to Be Adopted?

Anonymous Health Screening Using Wastewater Measure in real- time in sewage in buildings:

Hazards present

•

• Exposure occurring • Exposure level

Now Inviting Early Adopters to Benefit From • Robust hazard assessments • Actual exposure assessments • More robust risk assessments • Observing intervention impacts in real time • Data - driven safety and design improvements • Reduced information uncertainty • Less uncertainty • Smart design • Anonymous • Reduced liability

Acknowledgements

HPDC

Wendy Vittori, Indro Mondal, Nivedita Biyani, many others

Biodesign Center for Environmental Health Engineering, Arizona Sate University

Profs. Rolf Halden, Matthew Scotch, Arvind Varsani, Efrem Lim, Brenda Hogue

Drs. Erin Driver, Simona Kraberger, Adam Gushgari; Devin Bowes, LaRinda Holland, Rafaela Fontenele, Nivedita Biyani, Joshua Steele, Varun Kelkar, Sangeet Adhikari, Kathleen Click, Alyssa Carlson, Allison Binsfeld, Sonja Savic, Jillian Wright, Bridger Johnston, Akhil Mahant, Melanie Newell, Dianne Price, AND MANY OTHERS

City of Tempe Staff

Rosa Inchausti: Director, Strategic Management & Diversity

Wydale Holmes: Project Manager & Data Analyst

Dr. Stephanie Deitrick: Enterprise GIS Manager

William Manning: GIS Staff

Richard Dalton: Environmental Compliance Supervisor

Christopher Garcia: Environmental Compliance Specialist

Andrea Glass: Fire Department

Phillip Brown: Civil Engineer

Hillary Cummings: Tempe Community Council Program Director

AND MANY OTHERS

Contact:

rolf.halden@asu.edu

CASE STUDIES

MATERIAL HEALTH INNOVATORS

Mikhail Davis, Interface

–

From ‘impossible’ to everywhere: Scaling up recycled nylon yarn

Davis, Director of Technical Sustainability

From “impossible” to everywhere: scaling up recycled nylon yarn

Mikhail

Carpet Tile Cross - Section

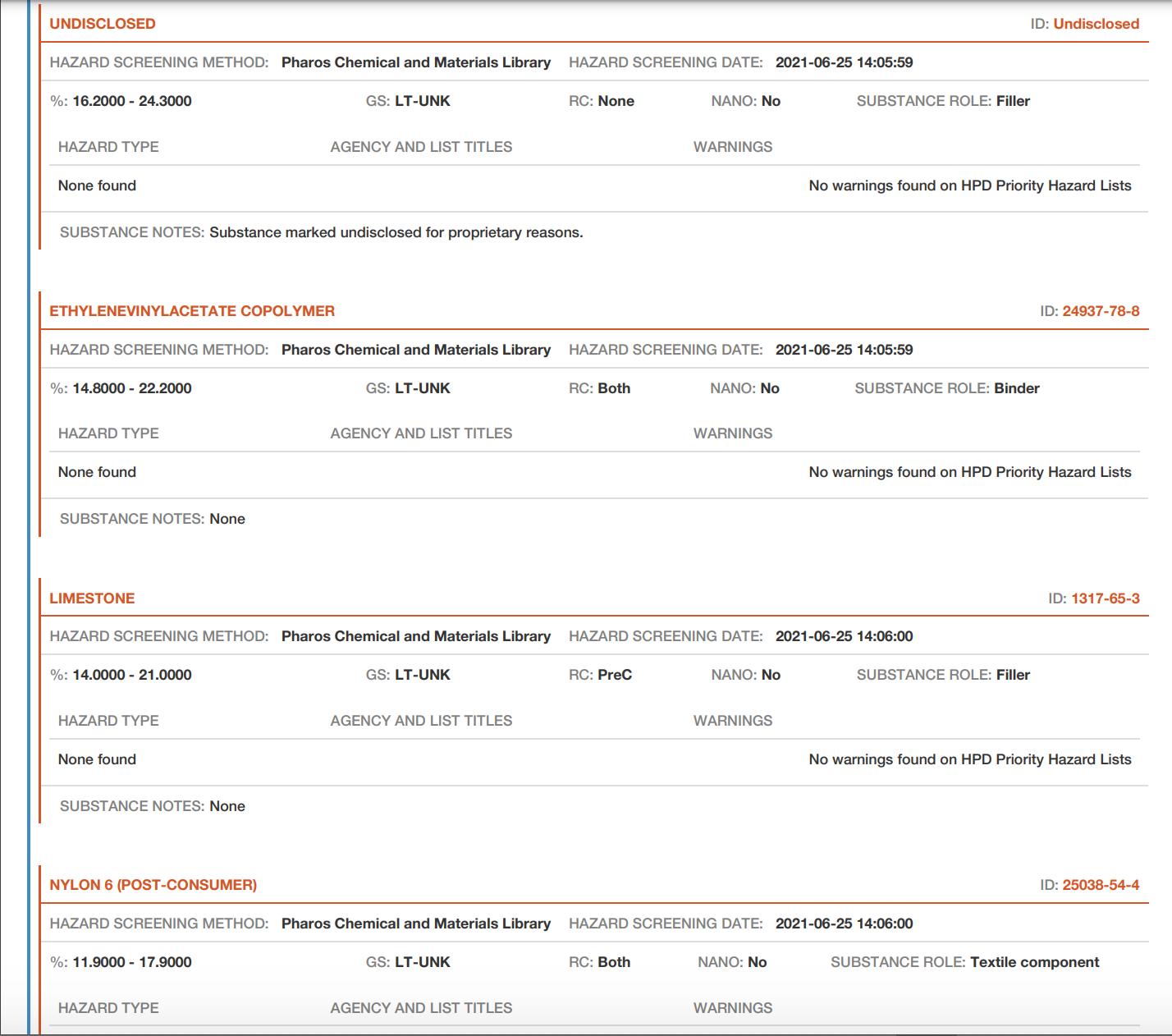

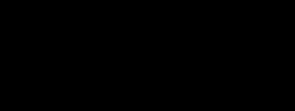

What is Interface’s non-vinyl CQuestBio carpet tile made of?

Yarn / Pile: 75-95% total recycled content, PCR content (50% standard) from sources like fishing nets and old carpet

Primary Backing

Latex: 82% recycled (post-industrial limestone and recycled & virgin VAE plastic w/ carbon capture content)

Thermoplastic Composite: 83% recycled or bio-based limestone filler, bio-resin, EVA plastic, bio-oil and bio-filler

Fiberglass

Thermoplastic Composite (see above)

Certified at least 65% Recyclable

recycled or

content

content

77-84%

bio-based

with 1-18% post-consumer recycled

47% USDA certified bio-based content

2022 Data

High-Impact Materials Predominant building materials with high-impact potential for emissions reductions Carbon-Smart Materials Low carbon/carbon sequestering materials materialspalette.org

USE PHASE MATERIALS PRODUCTION RECYCLING DISPOSAL TRANSPORTATION MANUFACTURING RAW MATERIALS EXTRACTION Life Cycle Impact

A lifecycle

view of green chemistry: plastic feedstocks and intermediates Refining and Synthesis Petroleum and Gas Extraction

Typical petrochemical pathway to make nylon6 (polyamide 6)

Chemical Footprint of virgin nylon 6 (polyamide 6) Raw material source Base chemical feedstock Monomer feedstock 2 Monomer feedstock 1 Monomer Polymer End of Life (combustion products) Crude oil Naphtha or pygas Benzene Cyclohexane, Phenol, Cyclohexanone Caprolactam Nylon6 Cyanide gas, ammonia, acetaldehyde Raw material source Base chemical feedstock Monomer feedstock 2 Monomer feedstock 1 Monomer Polymer Recycling by-products Nylon textiles, fishing nets and carpet yarn Caprolactam Nylon6 Food-grade catalyst, dyes and additives in wastewater Chemical Footprint of 100% recycled nylon 6 (Aquafil)

wants to climb Mt. Sustainability with us?”

“Who

From one Interiors brand, to dozens

And hundreds more in Apparel, etc.

Lessons for scaling healthier materials • Partners, not merely suppliers, are required to innovate at scale • Short-term incentives AND longer-term strategies must be aligned Capital investment in new technology and supply chains is required to move beyond expensive “green” materials • Building the right capital infrastructure creates the right incentives • Legislation can also create incentives and moderate investment risk • If things go well, you will not have an exclusive for long on the material (but that’s the idea) • New models for investment and collaboration are require to scale nontoxic, low carbon footprint, circular materials faster

Annmarie Ott, Saint Gobain

Evelyn Ritter, Toxnot

Feature

CASE STUDIES – MATERIAL HEALTH INNOVATORS Material Health Screening with "RoboTox”

within the Toxnot Tool

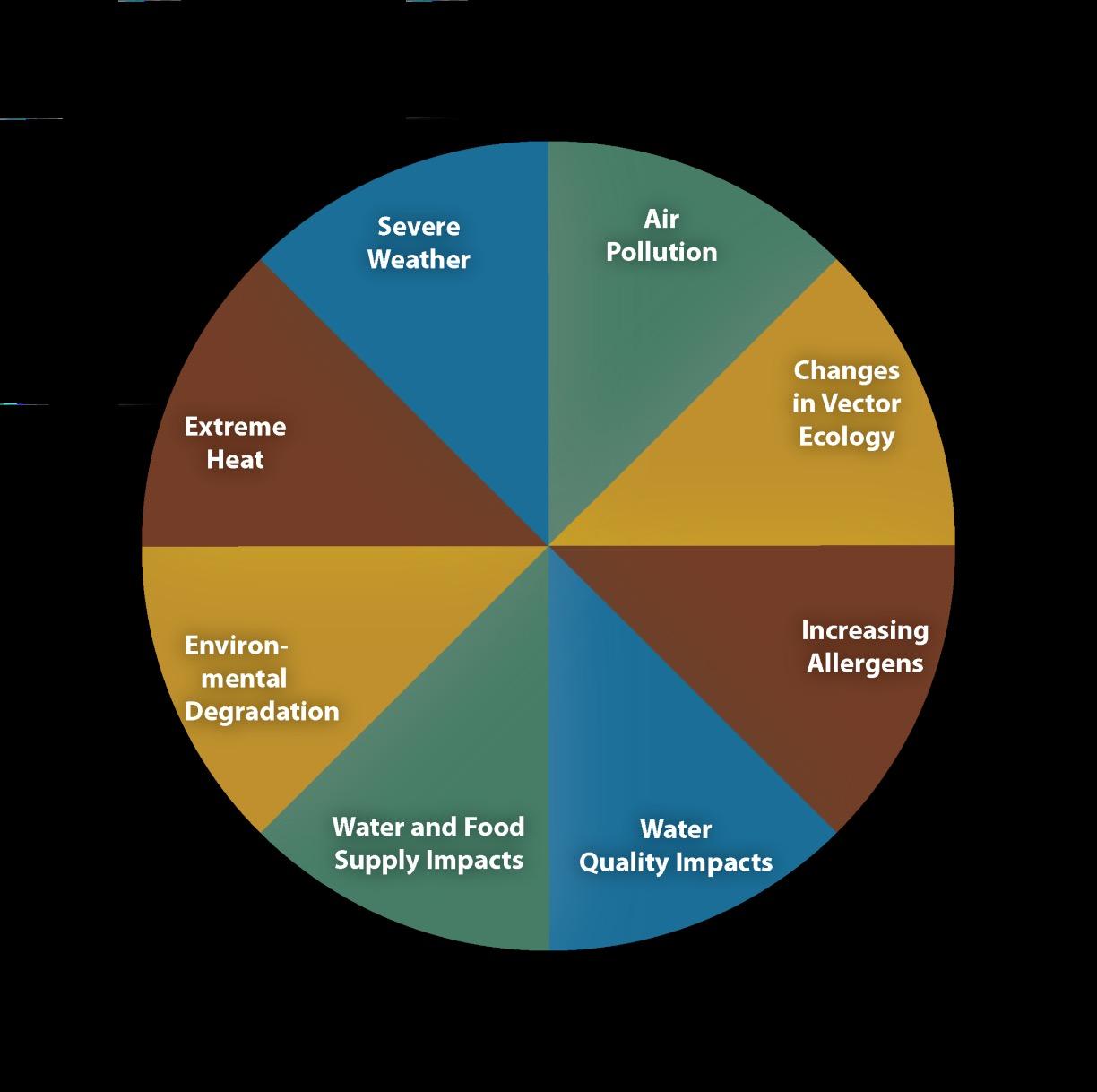

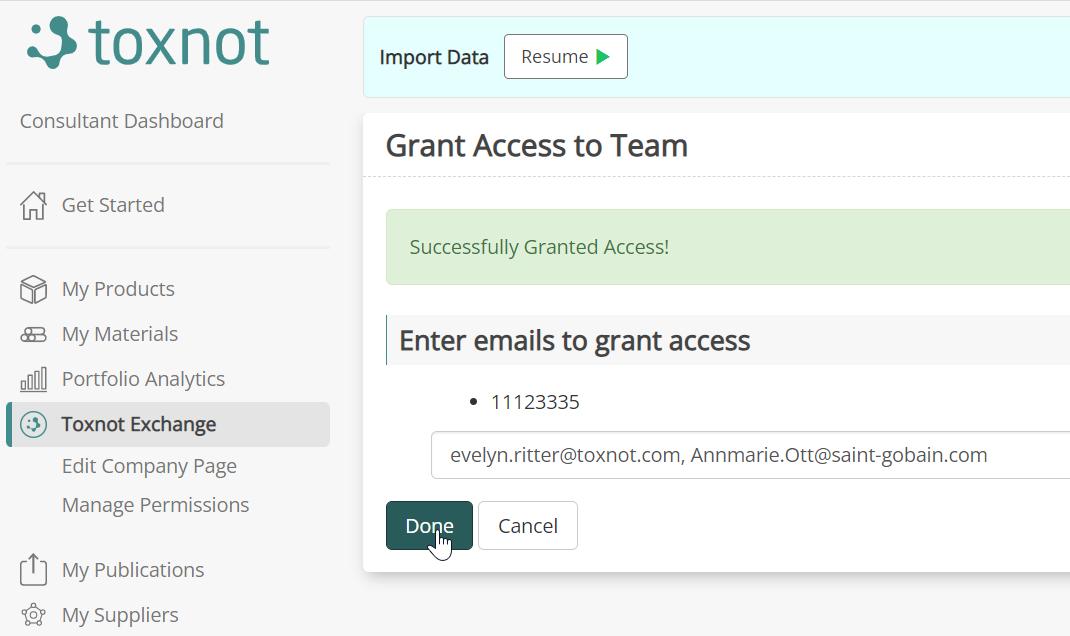

Material Health Screening with “RoboTox” Feature within the Toxnot Tool Evelyn Ritter and Annmarie Ott Material Health Open Innovation Symposium III: November 15, 2022

1 2 3 4 5 QUESTIONS

OVERVIEW

A STRONG GLOBAL GROUP

4 5 4 | The Saint-Gobain Group 2 SAINTGOBAIN AT A GLANCE

sales outlets Around employees More than Approximately years ago Founded over Commitment to achieve carbon neutrality in 2050 World or European leader in most of our businesses countries Locations in cross-business R&D centers Saint-Gobain Research manufacturing facilities around the world

4 5 5 | The Saint-Gobain Group 2 SAINTGOBAIN AT A GLANCE Office new build Multi-family home new build Multi-family home new build Single-family home renovation Multi-family home renovation Single-family home new build Green mobility Glass furnaces School or hospital renovation Renovation and light construction in Europe Construction in emerging markets Construction in North America Industry decarbonization

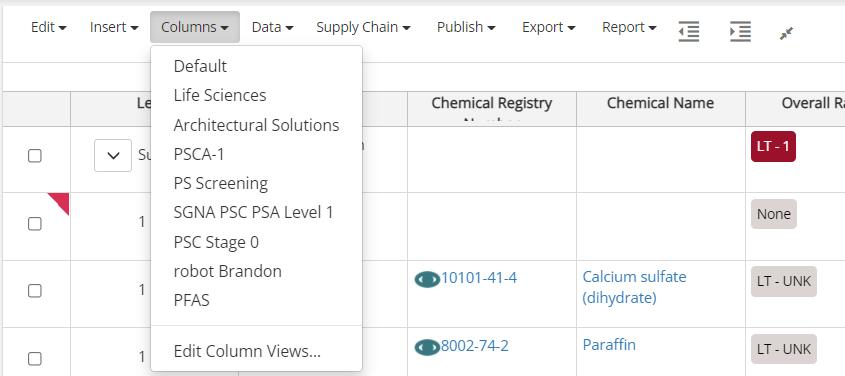

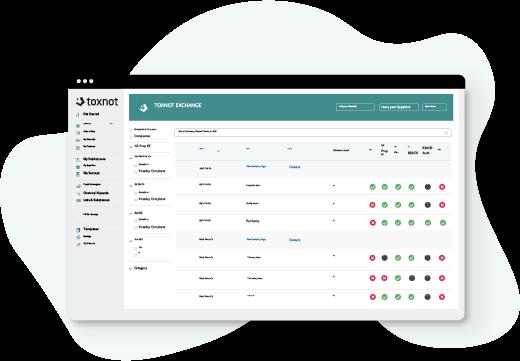

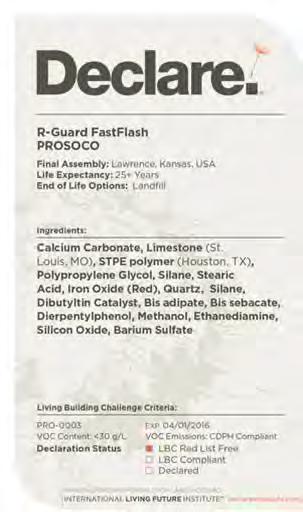

Multiple Business Objectives. One System. Sustainability Reports Screen for Hazards Collect Supplier Data Optimize Materials Analytics Sustainability Objectives • Declare Labels • Health Product Declaration (HPD) • LEED v4 • Red List Free Letters • Product Circularity Data Sheet • Publish to Mindful Materials • Hazard & Safety Screenings • Carbon Emissions & Water Use Compliance Objectives • CA Prop 65 • EU REACH & SCIP • EU RoHS • Conflict Minerals • 110+ other Regulations & Hazard Lists Make the most of your data collection and drive multiple outcomes with the same data all in the same place.

In-House Compliance and Toxicological Analysis – Simplified! • Import and automatically extract data • Read directly from an SDS -> HPD + more • Toxnot handles list updates for you!

DEFINITIONS

Material Health – as assessment of how the materials used in product can affect human health and the environment, with an emphasis on how avoiding or eliminating toxic chemicals while taking action to choose safer materials.

Product Stewardship - is the act of minimizing the health, safety, environmental, and social impacts of a product and its packaging throughout all lifecycle stages, while also maximizing economic benefits.

9 | 1 HIGH PERFORMANCE SOLUTIONS 4 The Saint-Gobain Group

ROBOTOX = Material Health + Product Stewardship

ROBOTOX STEPS

10 | The Saint-Gobain Group 4 5 1 A FORWARDLOOKING GROUP 1 2 3 4 5

3 4 5 11 | 1 A COMMITTED AND RESPONSIBLE GROUP The Saint-Gobain Group

3 4 5 13 | 1 A COMMITTED AND RESPONSIBLE GROUP The Saint-Gobain Group

3 4 5 14 | 1 A COMMITTED AND RESPONSIBLE GROUP The Saint-Gobain Group

15 | A COMMITTED AND RESPONSIBLE GROUP The Saint-Gobain Group Select lists based on manufacturing and distribution regions and regulations that are applicable to your industry

.

Content Aine Hardaker, Len-Tex Wallcoverings

CASE STUDIES – MATERIAL HEALTH INNOVATORS CVT-B: Increasing Clean Vinyl Technology’s™ Bio-Based

Áine Hardaker, MSL Sustainability Coordinator, Len-Tex Corporation

CVT-B: Increasing Clean Vinyl Technology's™ BioBased Content

Vinyl Wallcoverings Durability Cleanability Color and Design Surface Texture

The Wallcovering Industry

Suppliers Manufacturer Distributor Public Customer

Credit: Slidesgo and Freepik

Clean Vinyl Technology™: A Brief History

Chemical Component Common Use Health Risks Len-Tex CVT Component References

Phthalates Plasticizer/ softener in Film and Inks

Classified as endocrine disruptors; exposure to phthalates has been reported to result in increased incidence of developmental abnormalities Eastman DOTP, Citrate plasticizer

https://www.epa.gov/sites/production/files/201525/documents/biomonitoring- phthalates.pdf https://www.cpsc.gov/Newsroom/News-Releases/2011/CPSC-Adopts-TestingRequirements-for-Phthalates-in-Childrens-Toys-and-Child-Care-Articles-Stayof- Enforcement-for-Testing-Until-December-31-2011 https://www.epa.gov/assessing-and-managing-chemicals-undertsca/phthalates http://www.eastman.com/Literature_Center/Internal/L243.pdf

Barium Film Stabilizer May cause gastrointestinal problems and muscle weakness Calcium

Antimony Film Fire Retardant

Arsenic Biocide/ Anti- microbial

Carcinogen under CA Prop 65; linked to skin and eye irritation; Inflammation of the lungs bronchitis, emphysema Aluminium trihydrate (ATH)

Recognized Carcinogen and Development Toxicant (CA-P65) linked to cancer, gastrointestinal effects, nervous system disorders and skin irritations UltraFresh®

https://www.atsdr.cdc.gov/toxfaqs/tf.asp?id=326&tid=57 http://www.pvc.org/en/p/calcium-zinc-stabilisers

http://oehha.ca.gov/proposition-65/proposition-65-list https://www.epa.gov/sites/production/files/2016-09/documents/ antimonycompounds.pdf

https://www.epa.gov/sites/production/files/2014-03/documents/ arsenic_factsheet_cdc_2013.pdf http://www.ultra-fresh.com/ultra-fresh/

http://www.healthybuilding.net/uploads/files/formaldehyde-found-inbuilding-materials.pdf https://www.epa.gov/formaldehyde https://www.scsglobalservices.com/files/standards/IAQ_GUI_F-Free_V10_011510.pdf

Phenol

https://www.epa.gov/sites/production/files/2016-09/documents/phenol.pdf http://berkeleyanalytical.com/lab-services/voc-emissions-testing http://www.chps.net/dev/Drupal/node/445

Preservative in Inks and Coatings Linked to eye, nose and throat irritation; wheezing and coughing; fatigue; skin rash; allergic reactions Formaldehyde-free inks and coatings

Formaldehyde

(Volatile

Film Stabilizer May cause irritation to the skin, eyes and mucous membranes Ultra-low-emitting

Organic Compound)

stabilizer system

Len-Tex’s Product Certifications

Clean Vinyl Technology™

Certified Environmental Facts®

Len‐Tex Corporation

Clean Vinyl Technology Wallcoverings with Non‐Woven Backing

Facility Location: North Walpole, NH

Certification Period: August 1, 2020 ‐ July 31, 2023

Certification Number: 20‐0192

Product Specific:

Total Recycled Content1

Company: Product: 3% 3% 0%

Pre‐Consumer Post‐Consumer

Carbon Footprint (kg CO2 eq/m2)2 2 Biobased Content1

Take Back Recycling Program1

Published Environmental Product Declaration (EPD)3

NSF 342 Certification Low‐Emitting Materials4

SCS Global Services5 CA Prop 65 Compliant Material Ingredient Reporting: Health Product Declaration (HPD)6

Indoor Advantage Gold Yes

Len‐Tex Corporation

Clean Vinyl Technology Wallcoverings with Woven Backing

Facility Location: North Walpole, NH

Certification Period: August 1, 2020 ‐ July 31, 2023

Certification Number: 20‐0191

Product Specific: Carbon Footprint (kg CO2 eq/m2)1 2.0 Biobased Content2

Take Back Recycling Program3

Published Environmental Product Declaration (EPD)4 NSF 342 Certification

Low‐Emitting Materials5

SCS Global Services6 CA Prop 65 Compliant

Material Ingredient Reporting: Health Product Declaration (HPD)7

Yes Yes 8% Yes

Baseline Period: 36%

Evaluation Period:

and v4.1.

4. Collaborative for High Performance Schools Product.

5. This meets the requirements of LEED v4 and v4.1 EQ Credit: Low‐Emitting Materials.

7. All reductions benchmarked to production.

Waste Diversion from Landfill10 August 2015 ‐ July 2016 Evaluation Period: August 2018 ‐ July 2019

Yes Conformant Certified 6%

Manufacturing Specific8: Carbon Footprint Reduction9 1% Waste to Landfill Reduction

hazardous and

2 emissions only. Yes Indoor Advantage Gold © Copyright 2020 by GreenCircle Certified, LLC

Credit: Slidesgo and Freepik

Yes

Manufacturing Specific7: Carbon Footprint Reduction8 1% Waste to Landfill Reduction Waste Diversion from Landfill9 August 2015 ‐ July 2016 August 2018 ‐ July 2019 For more information on the Certified Environmental Facts of this product, please contact: info@GreenCircleCertified.com. www.GreenCircleCertified.com

9. Includes both hazardous

hazardous

and non‐

material streams.

Yes Yes 12% Yes 6% Conformant Certified © Copyright

by GreenCircle Certified, LLC * Attributes in green contribute to LEED v4 and v4.1 credits. 1. This meets the requirements of LEED v4 and v4.1 MR Credit: Sourcing

Raw Materials. 2. The value

a Len

Tex specific EPD. Scope is cradle‐to‐gate. Based on a 20oz backing. 6 Thi meets he requ rements o LEED v4 and v4.1 MR Credit: Building Product Disc osure and Optimization ‐ Material Ingredients. This attribute contributes one product under LEED v4 and v4.1. 8. Scope 2 emissions only. 3. This meets the requirements of LEED v4 and v4.1 MR Credit: Building Product Disclosure and Optimization ‐ Environmental Product Declarations. This attribute contributes one product under LEED v4

2020

of

is taken from

‐

10. Includes both

non

7. This

LEED

and v4.1 MR Credit:

Product

For more information on the Certified Environmental Facts of this product, please contact: info@GreenCircleCertified.com. www.GreenCircleCertified.com ‐

‐hazardous material streams.

meets the requirements of

v4

Building

Disclosure and Optimization

Material Ingredients. This attribute contributes one product under LEED v4 and v4.1.

9. Scope

* Attributes in green contribute to LEED

and

credits. 1.

value

2. Style

6. This

EQ Credit:

8. All

3. This

Credit:

Raw

4. This

Credit:

Baseline Period: 36%

v4

v4.1

The

is taken from a Len‐Tex specific EPD. Scope is cradle‐to‐gate. Based on a 20oz backing.

3446 does not contain bio‐based material.

meets the requirements of LEED v4 and v4.1

Low‐Emitting Materials.

reductions benchmarked to production.

meets the requirements of LEED v4 and v4.1 MR

Sourcing of

Materials.

meets the requirements of LEED v4 and v4.1 MR

Building Product Disclosure and Optimization ‐ Environmental Product Declarations. This attribute contributes one product under LEED v4 and v4.1. 5. Collaborative for High Performance Schools Product.

Certified Environmental Facts®

Company: Product:

Clean Vinyl Technology™

Backing Adhesive All product types contain a citrate-based adhesive Non-Woven Backed Products: Cellulose Based Woven Backed Products: Cotton Based

Credit: Slidesgo and Freepik

Clean Vinyl Technology™- Bio Based

Certified Environmental Facts®

Certified Environmental Facts®

Len‐Tex Corporation Clean Vinyl Technology Wallcoverings with Non‐Woven Backing

Facility Location: North Walpole, NH

Certification Period: August 1, 2020 ‐ July 31, 2023

Certification Number: 21‐0590

Company: Product: 3% 3% 0%

Product Specific: Total Recycled Content1 Pre‐Consumer Post‐Consumer Embodied Carbon (kg CO2 eq/m2)2 1.9

Biobased Content1 Take Back Recycling Program1 Published Environmental Product Declaration (EPD)3 Yes Low‐Emitting Materials4

SCS Global Services5

CA Prop 65 Compliant6

Material Ingredient Reporting: Health Product Declaration (HPD)7

Indoor Advantage Gold Yes

Manufacturing Specific8: Carbon Footprint Reduction9 1% Waste to Landfill Reduction Waste Diversion from Landfill10

Baseline Period: 36%

Evaluation Period:

August 2015 ‐ July 2016 August 2018 ‐ July 2019

For more information on the Certified Environmental Facts of this product, please contact: info@GreenCircleCertified.com. www.GreenCircleCertified.com

* Attributes in green contribute to LEED v4 and v4.1 credits.

1. This material meets the requirements for LEED 4.1 Sourcing of Raw Materials: Bio‐based materials. It is valued at 50% of cost multiplied by the biobased content.

2. The value is taken from a Len‐Tex specific EPD. This is global warming potential for cradle‐to‐gate life cycle stage (A1‐A3). Based on a 20oz backing.

3. This meets the requirements of LEED v4 and v4.1 MR Credit: Building Product Disclosure and Optimization ‐ Environmental Product Declarations. This attribute contributes one product under LEED v4 and v4.1.

4. Collaborative for High Performance Schools Product.

5. This meets the requirements of LEED v4 and v4.1 EQ Credit: Low‐Emitting Materials.

6. Testing conducted by SGS to verify compliance with US California Proposition 65 ‐ Lead and Phthalate Content.

7. This meets the requirements of LEED v4 and v4.1 MR Credit: Building Product Disclosure and Optimization ‐ Material Ingredients. This attribute contributes one product under LEED v4 and v4.1.

8. All reductions benchmarked to production.

9. Scope 2 emissions only.

10. Includes both hazardous and non‐hazardous material streams.

Len‐Tex Corporation Clean Vinyl Technology Wallcoverings with Woven Backing Facility Location: North Walpole, NH

Certification Period: August 1, 2020 ‐ July 31, 2023 Certification Number: 22‐0422

Product Specific: Embodied Carbon (kg CO2 eq/m2)1 2.0 Biobased Content2 Take Back Recycling Program3 Published Environmental Product Declaration (EPD)4

Low‐Emitting Materials5 SCS Global Services6 CA Prop 65 Compliant7

Material Ingredient Reporting: Health Product Declaration (HPD)8

Indoor Advantage Gold Yes

Company: Product: Yes

Manufacturing Specific9: Carbon Footprint Reduction10 1% Waste to Landfill Reduction Waste Diversion from Landfill11 August 2015 ‐ July 2016 Evaluation Period: August 2018 ‐ July 2019 For more information on the Certified Environmental Facts of this product, please contact: info@GreenCircleCertified.com. www.GreenCircleCertified.com

Baseline Period: 36%

* Attributes in green contribute to LEED v4 and v4.1 credits.

1. The value is taken from a Len‐Tex specific EPD. This is global warming potential for cradle‐to gate life cycle stage (A1‐A3). Based on a 20oz backing.

2. Style 3446 does not contain bio‐based material.This material meets the requirements for LEED 4.1 Sourcing of Raw Materials: Bio‐based materials. It is valued at 50% of cost multiplied by the biobased content.

3. This meets the requirements of LEED v4 and v4.1 MR Credit: Sourcing of Raw Materials.

4. This meets the requirements of LEED v4 and v4.1 MR Credit: Building Product Disclosure and Optimization ‐ Environmental Product Declarations. This attribute contributes one product under LEED v4 and v4.1.

5. Collaborative for High Performance Schools Product.

6. This meets the requirements of LEED v4 and v4.1 EQ Credit: Low‐Emitting Materials.

7. Testing conducted by SGS to verify compliance with US California Proposition 65 ‐ Lead and Phthalate Content.

8. This meets the requirements of LEED v4 and v4.1 MR Credit: Building Product Disclosure and Optimization ‐ Material Ingredients. This attribute contributes one product under LEED v4 and v4.1.

9. All reductions benchmarked to production.

10. Scope 2 emissions only.

6% 11. Includes both hazardous and non‐hazardous material streams.

© Copyright 2022 by GreenCircle Certified, LLC

Yes Yes 25% Yes

Yes Yes 38% Yes 6% © Copyright 2022 by GreenCircle Certified, LLC

Credit: Slidesgo and Freepik

Clean Vinyl Technology™- Bio Based

Plasticizer

Backing

In addition to the naturally based backing and citrate based adhesive, CVT-B products now use a bioplasticizer that is soybean oil based.

Adhesive

Credit: Slidesgo and Freepik

Why

- Polyunsaturated vegetable oil - Renewable Raw Materials - Non-Toxic Alternative - Bio-Based and Biodegradable - Low volatility

Soybean Oil? https://www.aidic.it/cet/14/37/101.pdf

Looking into the Future for

CVT-B and Beyond

Biophilic design and product material transparency Health Continue to have open communication with our suppliers Innovation Recycled Content Increasing the recycled content in our products

Credit: Slidesgo and Freepik

Thank You! aineh@lentexcorp.com 603-445-7821 https://www.linkedin.com/in/ainehardaker

CASE STUDIES – MATERIAL HEALTH INNOVATORS

Social Health & Equity - A Manufacturer's Journey with Just

Arthur Clarke, HMTX Industries

Social Health

Equity

a Manufacturer's

TEKNOFLOR ® PROUD MEMBERS OF THE HMTX FAMILY

Health Product Declaration Collaborative’s Material Health Open Innovation Symposium III

&

-

Journey

WHAT IS JUST? Program Developed & Administered by ILFI Focuses on Social Health & Equity Gauges Depth & Effectiveness – Policies & Programs Roadmap to Improvements & Enhancements

How Does it Work? Applicant (company / organization): Gathers Data & Documentation (D&D) Submits D&D to ILFI Through Online Portal Pays Program Fees Receives Initial Assessment from ILFI Submits Additional D&D to ILFI (as needed) Receives Just Label

2018, JUST 1.0 Pursued for primary factories in Familiarity with Other ILFI Programs Assess Social Health & Equity Equity Built Into Fee Structure Manufacturing in China Existing Transparency with Factories New to Just Data / Documentation - Lack of Availability (depending on Communications Just Standard - U.S. - Centric

2018, JUST 1.0

JUST labels issued for factories in China (and all of First JUST labels issued to a flooring manufacturer First JUST labels issued in Chinese (i.e. in addition to original labels in English)

Benefits Identified areas of excellence & areas for / means of improvement Helped lift stigmamanufacturing in China Familiarized HMTX with Just Means of distinguishing HMTX from competitors (sales/marketing) Instilled pride - factory workers

First

Primary

2020, JUST 2.0 - Pursued for staff / operations in the United States. Encompassed: • Aspecta N.A. • Halstead • HMTX Industries • Metroflor • Teknoflor - Challenges: • Data / Documentation - Lack of Availability (depending on metric) • Different Team • Updated Just Standard

Just 1.0 vs Just 2.0

2020, JUST 2.0 - First JUST 2.0 label issued to a manufacturer (in any industry) - First JUST 2.0 label issued to a company in the flooring industry (resilient or otherwise) - Primary Benefits • Familiarized new team with Just • Means of distinguishing HMTX from competitors (sales/marketing) • Served as pre-cursor for ESG Report • Identified areas of excellence & areas for / means of improvement

2022, JUST 2.0 Achieved improved scores: 9/22 metrics Training/Education (Level 1→4) Volunteering (Level 1→3) Family/Medical Leave (Level →2) Retirement Provision (Level 1→2) Full-Time Employment (Level →4) Gender Diversity (Level 3→4) Gender Pay Equity (Level 1→3) Well-Being (Level 1→2) Local Communities (Level 1→2) 2020 2022

Future of HMTX & JUST - Facilitate new enhancements & improvements; Team includes staff from - STIC - People & Culture - Executive Team - Obtain JUST 2.0 labels for HMTX’s staff / operations in Europe & ASIA - Continue work with ILFI on thirdparty verification pilot program for Just 2.0 - Obtain JUST 2.0 labels for primary factories in China

TEKNOFLOR ® PROUD MEMBERS OF THE HMTX FAMILY Contact Us to Learn More! Arthur Clarke Director, Sustainability & Impact P: (762) 204-6035 C: (203) 561-9722 E: ac@hmtx.global W: hmtx.global

Embodied Injustices: Chemical and Environmental Justice Impacts Along Product Life Cycles

Stamm, Healthy Building Network

ECOSYSTEM PROGRAMS – SOCIAL EQUITY

Rebecca

Embodied Injustices: Chemical and Environmental Justice Impacts Along Product Life Cycles

Rebecca Stamm Senior Researcher, HBN

All

people and the planet thrive when the environment is free of toxic chemicals.

Manufacturing Installation Use End of Life

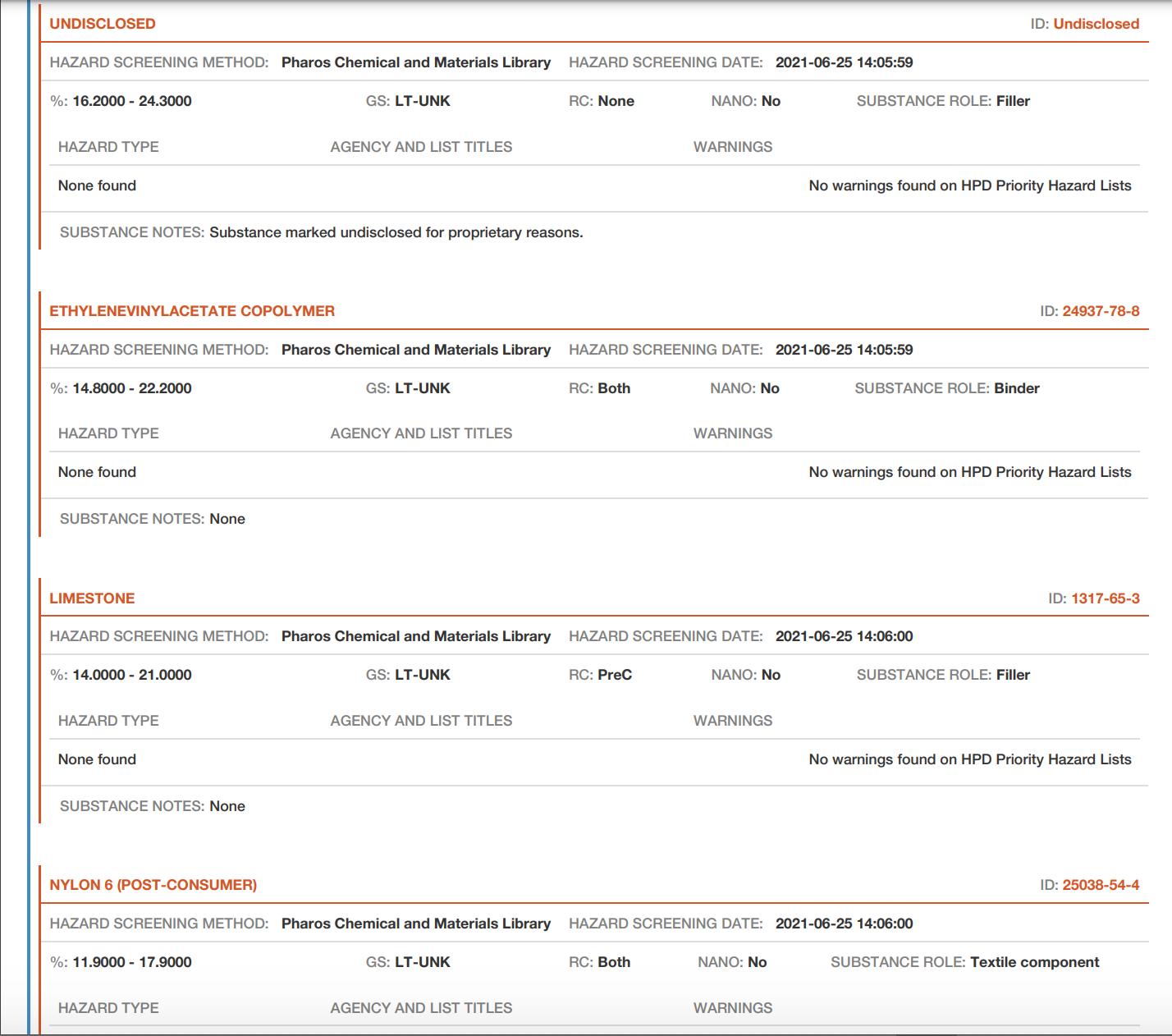

Principles of green chemistry Principles of environmental justice

Environmental equity: Poison people equally

Environmental justice: Stop poisoning people, period.

http://www.ejnet.org/ej/

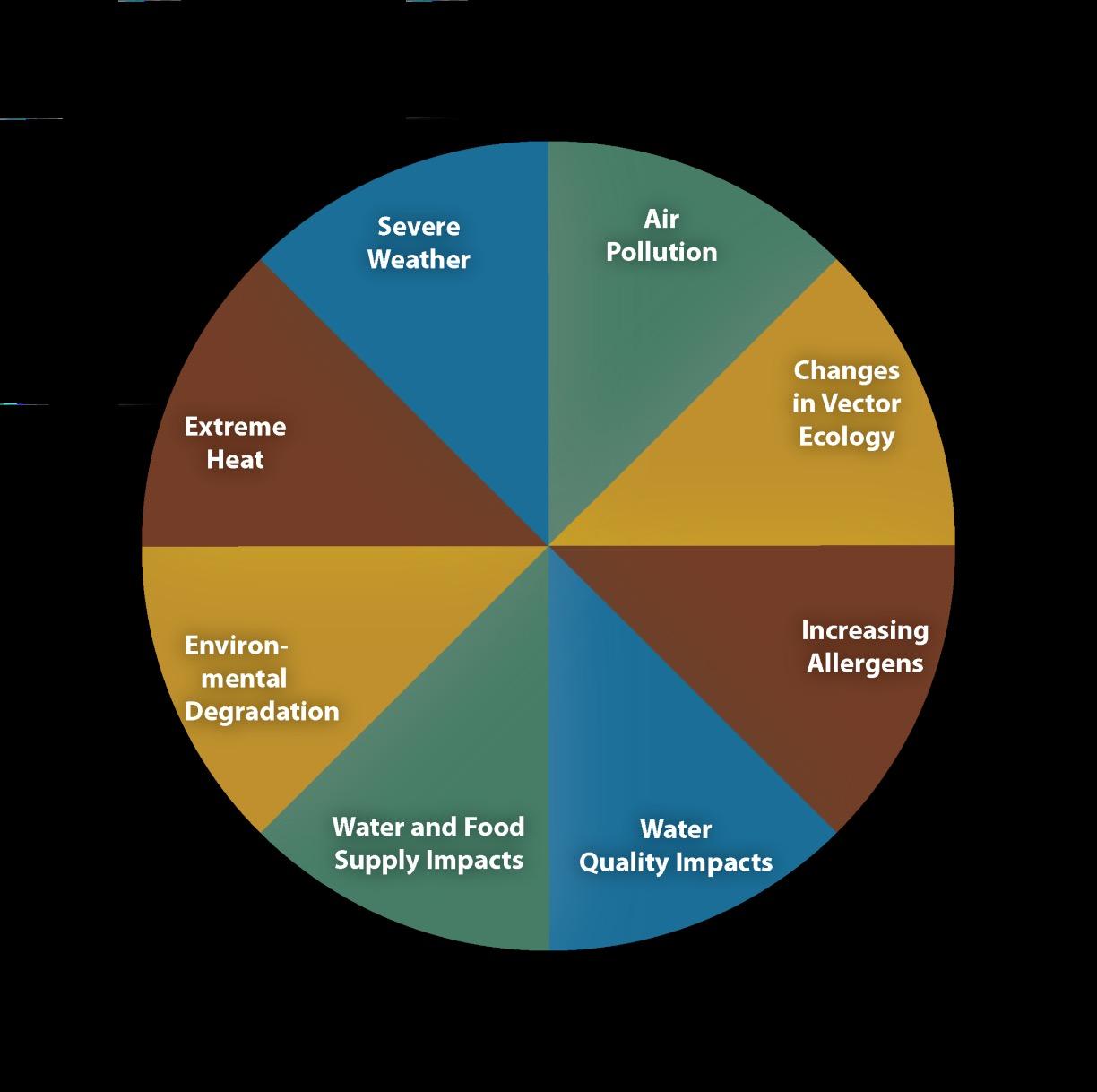

Framework

Criteria for Research and Analysis

“universal protection from toxics for all peoples”

Case Studies for Insulation

Applying the Framework

Production Inputs

Glass fibers

Isocyanates

Comparative Results:

Location Specific Analysis

Identifying Manufacturing Facilities

22 fiberglass facilities, 4 manufacturers 4 isocyanate facilities, 4 manufacturers

Comparative Results:

• Overall, glass fiber production generates much less hazardous chemical waste and releases

Average annual hazardous isocyanate- or glass fiber-related chemicals released to air and water or disposed of as waste for the facilities studied, 2015-2019

• >90% of isocyanate-related waste is released or disposed on site, versus <1% for glass fibers

Comparative Results:

Half of the isocyanate facilities and 14% of the glass fiber facilities had significant violations of EPA regulations for all 12 quarters of the past three years.

Cumulative Impacts

ISOCYANATE FACILITY TRI REPORTING FACILITY

• Production and disposal of building materials can impact communities, contributing to environmental

injustice

• Both materials generate toxic emissions and hazardous chemical waste that impact BIPOC and/or low-income communities

• Glass fibers perform comparatively better – still room for improvement

• Principles of green chemistry & EJ can guide actions to reduce and eliminate harmful pollution

Summary

Recommendations

ü Avoid spray polyurethane foam insulation whenever possible.

ü Advance transparency about what is in a product, how and where it is made and hazardous releases throughout its life cycle.

ü Choose materials with fewer hazardous chemicals.

e.g. HBN’s Product Guidance https://healthybuilding.net/products

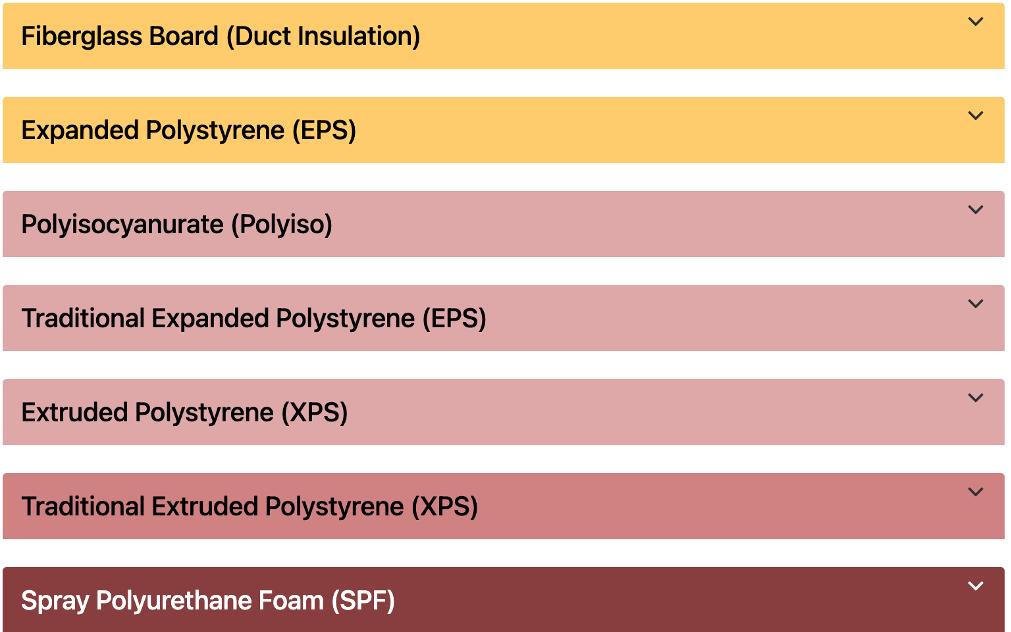

Insulation Avoid, Eliminate, Innovate Prefer, Prioritize, Specify

Preemptive First InformedTM

Coming Soon

https://healthybuilding.net/reports https://healthybuilding.net/products

More information

Thank You

rstamm@healthybuilding.net

A Survey of Current Labor Certifications for the Built Environment

Russell Beaumont, CookFox

ECOSYSTEM PROGRAMS – SOCIAL EQUITY

A Survey of Current Labor Certifications for the Built Environment

Forced labor is “all work or service that is exacted from any person under the menace of any penalty and for which the said person has not offered themselves voluntarily.”

1930 (No. 29)

ILO Forced Labour Convention,

“Design for Freedom by Grace Farms.” Edited by Sharon Prince, Luis C. deBaca, and Chelsea Thatcher. Grace Farms Foundation, October 2020.

Building supply chains areheavily reliant on forced labor.

https://www.designforfreedom.o rg/download-media/design-forfreedom-report

COOKFOX Architects is a member of the Design for Freedom Working Group, which includes 60 experts and leading firms working in built environment industries.

“Design for Freedom by Grace Farms.” Edited by Sharon Prince, Luis C. deBaca, and Chelsea Thatcher. Grace Farms Foundation, October 2020.

As part of our efforts, we conducted a study about labor certifications for the built environment.

https://howmuch.net/articles/modern- slavery- map - 2018 Walk Free Foundation. “The Global Slavery Index 2018,” 2018. https://www.globalslaveryindex.org/resources/downloads/ .

- use

Image from: https://us.fsc.org/en- us/certification/logo

https://www.c2ccertified.org/

https://coppermark.org/

https://cookfox.com/news/surve y-of-labor-certifications-for-thebuilt-environment/

for

Legal and Social context

Methods

Supplier Certification Self - reported information Observation (auditing)

Cradle to Cradle. “Cradle to Cradle Products Innovation Institute.” Accessed February 4, 2022. https://www.c2ccertified.org/.

Cradle to Cradle. “Cradle to Cradle Products Innovation Institute.” Accessed February 4, 2022. https://www.c2ccertified.org/.

Cradle to Cradle. “Cradle to Cradle Products Innovation Institute.” Accessed February 4, 2022. https://www.c2ccertified.org/.

Cradle to Cradle. “Cradle to Cradle Products Innovation Institute.” Accessed February 4, 2022. https://www.c2ccertified.org/.

Cradle to Cradle. “Cradle to Cradle Products Innovation Institute.” Accessed February 4, 2022. https://www.c2ccertified.org/.

Cradle to Cradle. “Cradle to Cradle Products Innovation Institute.” Accessed February 4, 2022. https://www.c2ccertified.org/.

https://sa - intl.org/programs/sa8000/

How do designers create market change?

Steps we can take today: Incorporate certified products into our material library. Include requirements in specifications and client goals. Forge new connections in local building markets. Avoid high - risk materials and products.

Sample specification from the Design for Freedom Toolkit, available here: https://www.designforfreedom.o rg/home/design-for-freedomtoolkit/

https://www.usgbc.org/credits/IPpc144 - v41

Steps we can take today: Incorporate certified products into our material library. Include requirements in specifications and client goals. Forge new connections in local building markets. Avoid high - risk materials and products.

we can create long- term change: Advocate for policies and local building codes that require supply chain transparency and certification. Build and share material libraries . Support research and reporting on the state of forced labor in the building industry.

How

Be familiar with forced - labor certifications and long term goals . Both groups need to be able to educate and support clients and consumers.

Be inclusive. Underlying goal is to make ethical sourcing the norm to reduce human suffering.

How designers and manufacturers can work together: Reward transparency. Help the market realize uncovering high - risk supply chains should initially be rewarded, not punished.

Questions ?

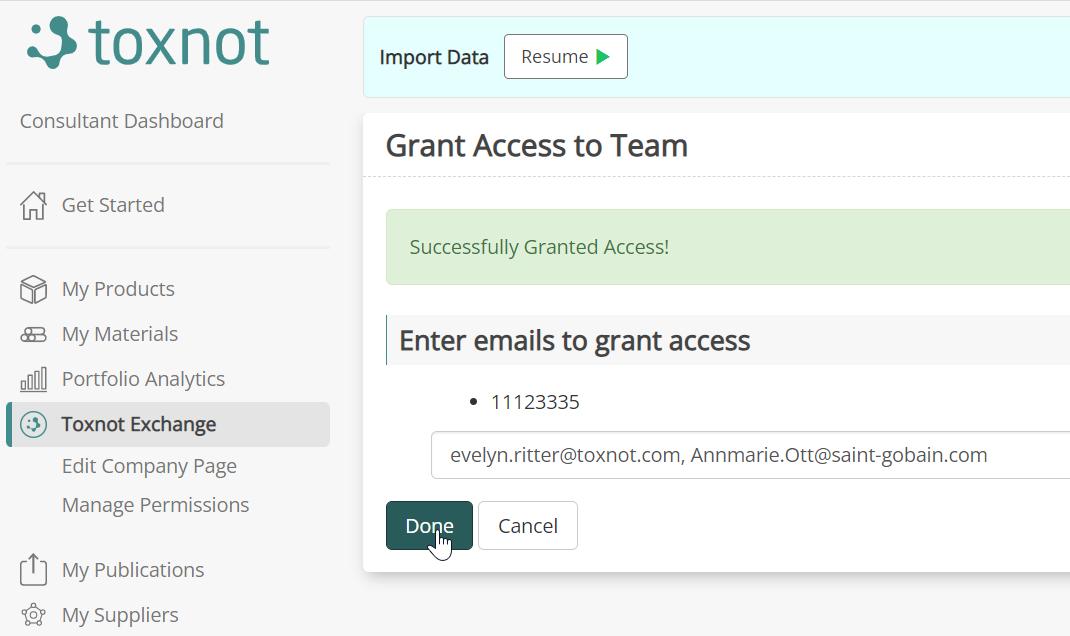

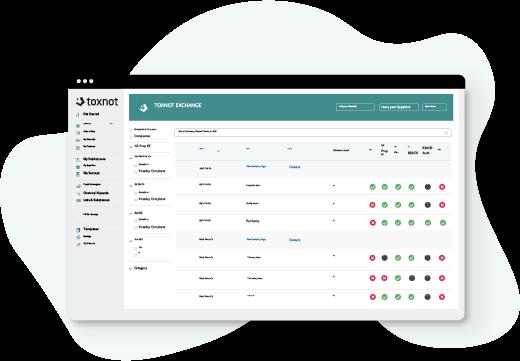

ECOSYSTEM PROGRAMS – TOOLS TO ADVANCE MATERIAL HEALTH Incentivize your Suppliers for HPD data using the Toxnot Exchange Evelyn Ritter, Toxnot

Multiple Business Objectives. One System. Sustainability Reports Screen for Hazards Compliance Reports Optimize Materials Analytics Sustainability Objectives • Declare Labels • Health Product Declaration (HPD) • LEED v4 • Red List Free Letters • Product Circularity Data Sheet • Publish to Mindful Materials • Hazard & Safety Screenings • Carbon Emissions & Water Use Compliance Objectives • CA Prop 65 • EU REACH & SCIP • EU RoHS • Conflict Minerals • 110+ other Regulations & Hazard Lists Make the most of your data collection and drive multiple outcomes with the same data all in the same place.

Toxnot Exchange

Toxnot Exchange

A platform to streamline relationships between suppliers & manufacturers and expedite the exchange of sustainability, transparency & compliance data.

Digital Product Passports Serves as an ExpandableFrameworkDigital Share: • certifications • ingredient disclosure • compliance • circularity details • and more.

should create passports?” “Everyone!” Your product data Your Suppliers Upstream Suppliers

“Who

Supplier

documentation

compliance reports.

property.

customers.

suppliers compliance management | surveys & data collection data exchange | reporting | + more

Benefits Leverage existing

such as an SDS. Create free

Protect intellectual

Reuse completed information for multiple

Free tools for

Free Compliance Reports

Start from Existing Documentation Upload data from: • SDS • IPC 1752A • Excel • CSV

Least Restricted Most Restricted Tailor Material Passport Tailor Material Passport Tailor Material Passport Protect Proprietary Information

Send to additional customers

Getting Started Send a Survey • Create a Toxnot Account • Follow Survey Workflow

Every survey response creates a passport • Upload your collected data into the HPD Builder to create your HPD • Send data to mindfulMATERIALS Publish a Passport • Create a Toxnot Account • Follow Passport Workflow • Share directly to your customer, or as a listing in the exchange for your customers to reference • Create your compliance reports and screen against any upcoming regulations For manufacturers: For suppliers: Toxnot is for everyone!

•

Terry Swack,

ECOSYSTEM PROGRAMS – TOOLS TO ADVANCE MATERIAL HEALTH Sustainable Minds Transparency Report [EPD]™: Integrating EPD and HPD information in one easy-to-understand digital document

Sustainable

Minds

Transparency Report [EPD]™ Integrating EPD and HPD information in one easy-to-understand digital document NEW Transparency Catalog v4.0 Grow your organization's digital specification & Basis of Design product library — in 1 click November 15, 2022 © Sustainable Minds 2022

AGENDA • About Sustainable Minds • Material ingredient disclosure history & the Material Health Overview™ • Demo! • Transparency Report [EPD] w/ Material Health Overview • NEW Transparency Catalog v4.0 • Q & A © Sustainable Minds 2022

provider of environmental product transparency cloud applications & services

in 2007, mission is to operationalize environmental performance and material health in mainstream product development & manufacturing to drive revenue and growth through greener and healthier product innovation. • 2009 first LCA cloud software for product organizations to design greener products; Autodesk investor; used in industry & education, 90+ countries © Sustainable Minds 2022

B2B

Founded

The only end-to-end product transparency solutions provider in the market today. • Program operation – PCR / EPD development • LCA, material ingredient disclosure, carbon accounting services • Innovative cloud transparency assessment & reporting tools, training and education Our solutions are designed to seamlessly integrate product transparency into product marketing to build credibility, preference and value for brands. © Sustainable Minds, 2022

The state of product transparency

From specification requirement to construction requirement

What product transparency is really all about:

Performance

High-performance is how the industry defines successful buildings.

• Now includes environmental performance and material health.

• Performance criteria used in both product manufacture and product selection.

Primary intent for doing LCA and material assessments is for a manufacturer to gain insights into the environmental and human health impacts over the life cycle of its products.

• Those who understand what’s causing impacts can make better decisions about how to make higher performing, more innovative products.

Why improving performance is important – now.

• Impacts on natural environment and human health dramatically increasing at a fast pace.

• Buildings are a compilation of products, the sum of its parts. Actual performance matters.

Builds credibly greener brands – but not by just producing disclosures. Value for manufacturers to provide environmental information about their products comes from demonstrating they understand what it means and they know what they’re doing.

© Sustainable Minds 2022

Back in 2015 when product transparency was new...

© Sustainable Minds 2022

SM Transparency Report [EPD]™ Our brand of EPD Leverage your LCA investment to create consistent and understandable marketing tools. Effectively present your greener & healthier brand. © Sustainable Minds 2022

1. Performance dashboard 2. LCA results & interpretation 3. How we make it greener SM Transparency Report™ 3 pages © Sustainable Minds 2022

Back in 2015 when product transparency was new...

© Sustainable Minds, 2015

We wondered…

• Why are there so many different ways to disclose material ingredients?

• Why do different AEC professionals ask for different disclosures?

• How many disclosures should a manufacturer do?

• What questions does each answer?

o What does the manufacturer learn? Help with design? o What do they tell the customer? AND

• If a different kind of assessment and report is required, why not provide all in the same place?...along with the other info people use to make purchase decisions. © Sustainable Minds, 2015

Back in 2015 when product transparency was new...

Material evaluation research findings • Too technical, what does it mean? • Can’t always easily determine what’s in the product and why? • Manufacturer may disclose hazardous ingredients with no explanation • Not comparable • No marketing info How does an architect, builder, contractor use to make a purchase decision? Certifier Certificate # Yes X No Yes X No X Development X Reproductive X X X Endocrine X Respiratory X Yes No Yes No GREENGUARD Certified; GREENGUARD Gold Certifications and Compliance (if the area below is full, refer to the following pages for additional listings) VOC Emissions VOC Content Does the product contain exempt VOCs? N/A Are VOC-free tints available? N/A Neurotoxicity Mammal Skin or Eye Aquatic toxicity Land toxicity Physical hazard Global warming Ozone depletion Multiple Unknown Aluminum, Proprietary Additives, Polyvinyl Chloride, Zinc, Copper, Magnesium, Pigment Ingredient, Pigment Ingredient, Pigment Ingredient, Pigment Ingredient, Pigment Ingredient, Pigment Ingredient, Pigment Ingredient, Organotin or Calcium-Zinc, Silicone, Iron, Chromium, Chrome Antimony Titanate Buff Ruttle (pigment ingredient), Carbon Black (pigment ingredient), Chromium (III) Compound (pigment ingredient), Chromium (III) Compound (pigment ingeredient), Copper Dusts (pigmemt ingredident), Carbon Black (pigment ingredient), Chrome Antimony Titanate Buff Ruttle (pigment ingredient), Carbon Black (pigment ingredient), Chromium (III) Compounds (pigment ingredient), Manganese, Berylium (aluminum residual), Berylium (aluminum residual), Lead (aluminum residual), Lead (aluminum residual), Lead (aluminum residual), Cadmium (aluminum residual), Cadmium (aluminum residual), Cadmium (aluminum residual), Nickel (aluminum residual), Antimony Trioxide (vinyl residual), Arsenic Compounds, Inorganic (vinyl residual), Vinyl Chloride Contents in Descending Order of Quantity (if the area below is full, refer to the following pages for additional listings) Predicted by process chemistry As per MSDS (1,000 & 10,000 ppm) The content of this product was assessed for health hazard warnings as required using pharos Full Disclosure of Intentional Ingredients Full Disclosure of Known Hazards Disclosure Notes Contents and disclosures have been determined by using supplier's Material Safety Data Sheets (MSDS). N/A Second Party Third Party 10 26 00 InPro Corporation Amanda Goetsch Environmental Sustainability Manager 262-679-9010 agoetsch@inprocorp.com Classification Contact Name Title Phone Email Muskego, WI 53150 S80 W18766 Apollo Drive Measured 100 ppm (ideal) Highest concern GreenScreen score Benchmark Name Product ID Website The 130 Corner Guard series (134, 138, 139, 1312) is used for corner wall protection. The corner guard is comprised of an extruded aluminum retainer and extruded vniyl cover. Accessories include molded top and bottom caps. Self-declared 130 Surface Mount Corner Guard 1312 http://www.inprocorp.com Health Product Declaration v1.0 (15 Dec 2012) Summary hpdcollaborative.org Page of 19 SILVER Material Health Carpet XYZ ISSUED TO: Carpet Company Name ASSESSED BY: Assessor PRODUCT OPTIMIZATION SUMMARY Cradle to Cradle Certified™ Banned List compliant Material Health optimization strategy developed No exposure from carcinogens, mutagens, or reproductive toxicants Meets VOC emissions testing requirements Product is fully optimized does not contain any GREY or x-assessed chemicals Process chemicals have been identified and none are GREY or x-assessed PERCENTAGE OF MATERIALS ASSESSED BY WEIGHT ASSESSMENT RATING BY WEIGHT PRODUCT OPTIMIZATION 99-100% 61 Materials CERT NO. MHC2315 EXPIRES: January X, 2017 STANDARD: v3.0 PRODUCTS COVERED: Carpet A. Carpet B, Carpet C C: 60-67.3% X: 13-17.3% GREY 0-.1% ASSESSED SCENARIOS: Manufacture, Installation, Use as insulation, Collection, Recycling or B: 15.3-25% or B C GREY Inventory threshold for chemicals in each material = 100 ppm Copyright 2015 GreenScreen and GreenCircle Certified Sample Manufacturer’s Inventory Report FOR IMMEDIATE RELEASE GreenScreen/Clean Production Action and GreenCircle Announce Partnership on Material Ingredient Reporting November 20 2014 Royersford, PA – When the USGBC released LEED the fall 2013, there were updates to the widely adopted green building rating system. Specifically, the Materials and Resources section saw many changes including, the first time, the inclusion material health considerations With these alterations there has been steep learning curve for both manufacturers and LEED practitioners that are scrambling keep current with the new system. As the market works adapt, industry leaders are partnering and combining their expertise make compliance easier. this respect, he recent partnership between GreenScreen/Clean Production Action and GreenCircle Certified, LLC aims to assist compliance various Material Ingredient credit options the current LEED v4 Rating System ways for manufacturers comply with the Material Ingredient credit options Options for earning the Reporting credit vary from Manufacturer nventories that include material contents and hazards; Health Product Declarations (HPDs); or obtaining Cradle to Cradle certification Options for earning the Optimization credit include providing proof that products not contain - obtaining higher levels Cradle Cradle certification; demonstrating REACH Optimization (for international projects) To aid manufacturers, GreenCircle and GreenScreen/Clean Production Action have partnered to facilitate the development anufacturer’s Inventories and cert that products do not contain chemicals. Together implify and streamline this very confusing credit for LEED project teams architects and designers alike The partnership brings together Clean Production Action GreenScreen® for Safer Chemicals methodology and GreenCircle’s third-party certification expertise. eveloped method for identifying chemicals high concern and safer alternatives integral part the Material Ingredient credit Specifically GreenScreen used LEED compliant Manufacturer’s nventories which require disclosure all -proprietary ingredients and their CAS numbers along with GreenScreen assessment proprietary ingredients. This ethod designed to protect proprietary product formulas while preserving precision and transparency. © Sustainable Minds, 2015 Back in 2015 when product transparency was new...

Material evaluation research findings What do you want to… Learn? Do with results? Certifier Certificate # Yes X No Yes X No X Development X Reproductive X X X Endocrine X Respiratory X Yes No Yes No GREENGUARD Certified; GREENGUARD Gold Certifications and Compliance (if the area below is full, refer to the following pages for additional listings) VOC Emissions VOC Content Does the product contain exempt VOCs? N/A Are VOC-free tints available? N/A Neurotoxicity Mammal Skin or Eye Aquatic toxicity Land toxicity Physical hazard Global warming Ozone depletion Multiple Unknown Aluminum, Proprietary Additives, Polyvinyl Chloride, Zinc, Copper, Magnesium, Pigment Ingredient, Pigment Ingredient, Pigment Ingredient, Pigment Ingredient, Pigment Ingredient, Pigment Ingredient, Pigment Ingredient, Organotin or Calcium-Zinc, Silicone, Iron, Chromium, Chrome Antimony Titanate Buff Ruttle (pigment ingredient), Carbon Black (pigment ingredient), Chromium (III) Compound (pigment ingredient), Chromium (III) Compound (pigment ingeredient), Copper Dusts (pigmemt ingredident), Carbon Black (pigment ingredient), Chrome Antimony Titanate Buff Ruttle (pigment ingredient), Carbon Black (pigment ingredient), Chromium (III) Compounds (pigment ingredient), Manganese, Berylium (aluminum residual), Berylium (aluminum residual), Lead (aluminum residual), Lead (aluminum residual), Lead (aluminum residual), Cadmium (aluminum residual), Cadmium (aluminum residual), Cadmium (aluminum residual), Nickel (aluminum residual), Antimony Trioxide (vinyl residual), Arsenic Compounds, Inorganic (vinyl residual), Vinyl Chloride Contents in Descending Order of Quantity (if the area below is full, refer to the following pages for additional listings) Predicted by process chemistry As per MSDS (1,000 & 10,000 ppm) The content of this product was assessed for health hazard warnings as required using pharos Full Disclosure of Intentional Ingredients Full Disclosure of Known Hazards Disclosure Notes Contents and disclosures have been determined by using supplier's Material Safety Data Sheets (MSDS). N/A Second Party Third Party 10 26 00 InPro Corporation Amanda Goetsch Environmental Sustainability Manager 262-679-9010 agoetsch@inprocorp.com Classification Contact Name Title Phone Email Muskego, WI 53150 S80 W18766 Apollo Drive Measured 100 ppm (ideal) Highest concern GreenScreen score Benchmark Name Product ID Website The 130 Corner Guard series (134, 138, 139, 1312) is used for corner wall protection. The corner guard is comprised of an extruded aluminum retainer and extruded vniyl cover. Accessories include molded top and bottom caps. Self-declared 130 Surface Mount Corner Guard 1312 http://www.inprocorp.com Health Product Declaration v1.0 (15 Dec 2012) Summary hpdcollaborative.org Page of 19 SILVER Material Health Carpet XYZ ISSUED TO: Carpet Company Name ASSESSED BY: Assessor PRODUCT OPTIMIZATION SUMMARY Cradle to Cradle Certified™ Banned List compliant Material Health optimization strategy developed No exposure from carcinogens, mutagens, or reproductive toxicants Meets VOC emissions testing requirements Product is fully optimized does not contain any GREY or x-assessed chemicals Process chemicals have been identified and none are GREY or x-assessed PERCENTAGE OF MATERIALS ASSESSED BY WEIGHT ASSESSMENT RATING BY WEIGHT PRODUCT OPTIMIZATION 99-100% 61 Materials CERT NO. MHC2315 EXPIRES: January X, 2017 STANDARD: v3.0 PRODUCTS COVERED: Carpet A. Carpet B, Carpet C C: 60-67.3% X: 13-17.3% GREY 0-.1% ASSESSED SCENARIOS: Manufacture, Installation, Use as insulation, Collection, Recycling or B: 15.3-25% or B C GREY Inventory threshold for chemicals in each material = 100 ppm Copyright 2015 GreenScreen and GreenCircle Certified Sample Manufacturer’s Inventory Report FOR IMMEDIATE RELEASE GreenScreen/Clean Production Action and GreenCircle Announce Partnership on Material Ingredient Reporting November 20 2014 Royersford, PA – When the USGBC released LEED the fall 2013, there were updates to the widely adopted green building rating system. Specifically, the Materials and Resources section saw many changes including, the first time, the inclusion material health considerations With these alterations there has been steep learning curve for both manufacturers and LEED practitioners that are scrambling keep current with the new system. As the market works adapt, industry leaders are partnering and combining their expertise make compliance easier. this respect, he recent partnership between GreenScreen/Clean Production Action and GreenCircle Certified, LLC aims to assist compliance various Material Ingredient credit options the current LEED v4 Rating System ways for manufacturers comply with the Material Ingredient credit options Options for earning the Reporting credit vary from Manufacturer nventories that include material contents and hazards; Health Product Declarations (HPDs); or obtaining Cradle to Cradle certification Options for earning the Optimization credit include providing proof that products not contain - obtaining higher levels Cradle Cradle certification; demonstrating REACH Optimization (for international projects) To aid manufacturers, GreenCircle and GreenScreen/Clean Production Action have partnered to facilitate the development anufacturer’s Inventories and cert that products do not contain chemicals. Together implify and streamline this very confusing credit for LEED project teams architects and designers alike The partnership brings together Clean Production Action GreenScreen® for Safer Chemicals methodology and GreenCircle’s third-party certification expertise. eveloped method for identifying chemicals high concern and safer alternatives integral part the Material Ingredient credit Specifically GreenScreen used LEED compliant Manufacturer’s nventories which require disclosure all -proprietary ingredients and their CAS numbers along with GreenScreen assessment proprietary ingredients. This ethod designed to protect proprietary product formulas while preserving precision and transparency. © Sustainable Minds, 2015 Back in 2015 when product transparency was new...

Material health evaluation and disclosure programs

Report Health Product Declaration®

A format for reporting product contents and their relationship to particular potential human and environmental health impacts.

Manufacturer Inventory

An inventory of the materials used in the manufacture of a product

Cradle to Cradle Certified™ label

Multi-attribute eco-label that assesses a product’s safety to humans and the environment; and evaluates design for future life cycles

List screening & evaluation method/program

HPD Priority Hazard Lists

Priority lists are primarily selected based upon criteria developed for the GreenScreen for Safer Chemicals method. Additional lists not currently included in GS have been added to address several issues on ozone depletion and global warming i.e.

GreenScreen List Translator v1.2

An abbreviated form of the full GreenScreen method that includes only those hazard lists specified in the full method guidance. It specifies thirty six list categories of authoritative and screening hazard lists.

GreenScreen for Safer Chemicals is a method for comparative chemical hazard assessment used for assessing the inherent hazards of chemicals and their potential effect on human health and the environment

C2C v3 Banned List of Chemicals

Ingredients and substances are included due to their hazardous characteristics and tendency to accumulate in the biosphere leading to irreversible negative human health effects.

C2C Certified is a 5-level standard covering 5 assessment categories. In the material health category, a product must comply with Banned List of Chemicals.

Coming: C2C Material Health Certificate

© Sustainable Minds, 2015

Administered by Health Product Declaration Collaborative (HPDC) Clean Production Action Cradle to Cradle Products Innovation Institute

Standard Health Product Declaration Open Standard Guidance for using GreenScreen for Safer Chemicals in LEEDv4

Cradle to Cradle Certified Product Standard

in

when product transparency was new...

Back

2015

Back in 2015 when product transparency was new...

Programs in consideration for LEEDv4

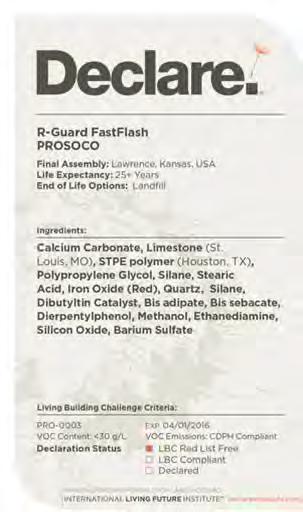

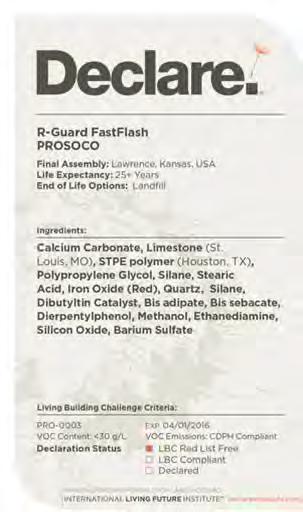

Report Declare label

A nutrition label' based on product ingredient inventory, sourcing and end of life options.

level®

A comprehensive, multi-attribute, thirdparty certification with a wide range of credits in four main categories: materials; energy and atmosphere; human and ecosystem health; and social responsibility.

Standard Manufacturers Guide to Declare ANSI/BIFMA e3 Furniture Sustainability Standard

List screening & evaluation method/program

Living Building Challenge Red List

Represents the ‘worst in class’ materials, chemicals, and elements known to pose serious risks to human health and the greater ecosystem.

Declare supports selection of products for the Living Building Challenge™ (LBC) projects. The LBC is an international sustainable building certification program that calls for the creation of building projects at all scales that operate as cleanly, beautifully and efficiently as nature's architecture.

ANSI/BIFMA Chemicals of Concern List

Created for level® program to deliver the most open and transparent means of evaluating and communicating the environmental and social impacts of furniture products in the built environment.

level® program credits cover management and policy, measurement and reporting, and specific requirements for the product, manufacturing process, and facility. Each credit provides one or more points toward certification. After six prerequisites, products must achieve specific numbers of points to be certified at level 1, 2, or 3.

Cradle to Cradle Products Innovation Institute

C2C Material Health Certificate

A contextual assessment based on chemical hazard identification and qualitative exposure considerations during a product’s final manufacture, use, and endof-use.

Material

Health Certificate Standard

C2C v3 Banned List of Chemicals

Ingredients and substances are included due to their hazardous characteristics and tendency to accumulate in the biosphere leading to irreversible negative human health effects

The Material Health Certificate provide manufacturers with a trusted way to communicate their work towards chemically optimized products.

© Sustainable Minds, 2015

Administered by International Living Future Institute Business and Institutional Furniture Manufacturers Association (BIFMA)

Material health evaluation and disclosure programs

© Sustainable Minds, 2015

Report Standard List screening & evaluation method/program Disclosure programs Rating system programs Back in 2015 when product transparency was new...

Administered by

Back in 2015 when product transparency was new...

How to select program that fits your needs?

Transparency. Concerned about proprietary ingredients or hazards?

• Proprietary ingredients – Not required by Manufacturer Inventory, C2C and HPD

• Hazard disclosure

o Required for Manufacturer Inventory and HPD when material ingredients are not fully disclosed

o Not required by C2C and Declare Brand. Do you need a branded eco-label or disclosure ok?

• What material ingredient information do your customers need/want to make a purchase decision?

Ex: depth of screening criteria, type of hazards disclosed

• Are one or several of the eco-labels seen as valuable by your customers?

Third party verification. How important is it?

• It is ‘baked in’ to branded eco-label; one stop shopping

• Manufacturer Inventory and HPD can be self-declared or verified by choice of verifier

Price. Many variables:

• Validity period – HPD: 3 years | MI: 3 years | C2C: 2 years | Declare: 1 year

• Consultants or accredited assessors – Do you need them or can you do it yourself?

• Purchase or create GS Benchmarks – If not available

• Verification – Do your customers want 3rd party verification or is self declared sufficient?

• Number of products – Do you have a few or many?

© Sustainable Minds, 2015

Back in 2015 when product transparency was new...

What questions are answered

What is it made of? X When disclosing intentional ingredients

Are there any hazardous ingredients in this product?

Manufacturer Inventory

Ingredients and/or hazards disclosed

If yes, how bad are they?

GS LTs and BMs indicate hazard level

Are there any exposure concerns?

Ingredients and/or hazards are disclosed

Ingredients or hazards disclosed

Neither disclosed; represented by declaration status

Neither disclosed; represented by rating level

GS LTs and BMs indicate hazard level

LBC Red List indicates hazard level

Certification level may indicate exposure concerns

Where do materials come from; where do they go at the end?

What is the company doing about improving the human health impacts?

Optimization strategy © Sustainable Minds, 2015

X X

X

X

X

X

X

X

X

X

X

X

X

The

an LCA:

© Sustainable Minds 2015

deliverable of

is an LCA report. An EPD: is a report of the LCA report. (Why are they still so long? Because they’re disclosures.)

© Sustainable Minds 2015 LCA:TR : : BACKROUND REPORT EARNS THE LEED CREDIT ISO 14025 TYPE 3 ENVIRONMENTAL DECLARATION SILVER Material Health Carpet XYZ ISSUED TO: Carpet Company Name ASSESSED BY: Assessor PRODUCT OPTIMIZATION SUMMARY Cradle to Cradle Certified™ Banned List compliant Material Health optimization strategy developed No exposure from carcinogens, mutagens, or reproductive toxicants Meets VOC emissions testing requirements Product is fully optimized does not contain any GREY or x-assessed chemicals Process chemicals have been identified and none are GREY or x-assessed PERCENTAGE OF MATERIALS ASSESSED BY WEIGHT ASSESSMENT RATING BY WEIGHT PRODUCT OPTIMIZATION 99-100% 61 Materials CERT NO. MHC2315 EXPIRES: January X, 2017 STANDARD: v3.0 PRODUCTS COVERED: Carpet A. Carpet B, Carpet C C: 60-67.3% X: 13-17.3% GREY 0-.1% ASSESSED APPLICATIONS Manufacture, Installation, Use as insulation, Collection, Recycling. ASSESSED SCENARIOS: Manufacture, Installation, Use as insulation, Collection, Recycling B: 15.3-25% A or GREY Inventory threshold for chemicals in each material = 100 ppm C2C:MHO

© Sustainable Minds 2015 : : SILVER Material Health Carpet XYZ ISSUED TO: Carpet Company Name ASSESSED BY: Assessor PRODUCT OPTIMIZATION SUMMARY Cradle to Cradle Certified™ Banned List compliant Material Health optimization strategy developed No exposure from carcinogens, mutagens, or reproductive toxicants Meets VOC emissions testing requirements Product is fully optimized does not contain any GREY or x-assessed chemicals Process chemicals have been identified and none are GREY or x-assessed PERCENTAGE OF MATERIALS ASSESSED BY WEIGHT ASSESSMENT RATING BY WEIGHT PRODUCT OPTIMIZATION 99-100% 61 Materials CERT NO. MHC2315 EXPIRES: January X, 2017 STANDARD: v3.0 PRODUCTS COVERED: Carpet A. Carpet B, Carpet C C: 60-67.3% X: 13-17.3% GREY 0-.1% ASSESSED APPLICATIONS Manufacture, Installation, Use as insulation, Collection, Recycling. ASSESSED SCENARIOS: Manufacture, Installation, Use as insulation, Collection, Recycling B: 15.3-25% A or GREY Inventory threshold for chemicals in each material = 100 ppm Disclosures Marketing tools

SM Material Health

Questions answered quickly:

1. What is this product made of?

2. Are there any hazardous ingredients?

3. If yes, how bad are they?

4. Are there any exposure concerns?

5. Where do materials come from; where do they go at the end of life?

6. What is the company doing about improving the human health impacts?

© Sustainable Minds 2021

Leverage your material evaluation investment to create credible, consistent marketing tools. Effectively present your healthier brand.

Overview Back in 2015 when product transparency was new...

Report, the first EPD and material health evaluation delivered in one cloud-based report.

Standalone report OR include in an SM Transparency

Health Product Declaration® C2C Material Health Certificate Declare Manufacturer Inventory

product

Back in 2015 when

transparency was new...

SM Transparency Products

1. SM Transparency Report™ = In 3-pages, SM’s brand of EPD includes everything a professional needs to make a purchase decision: Functional and environmental performance information, understandable LCA results, how the manufacturer is making products greener.

2. SM Material Health Overview™ = Informs safer & healthier decisions by distilling disclosure data, providing context & interpretation and describing what the manufacturer is doing to improve; standardizes results presentation from ANY program (HPD, Declare, C2C…).

3. SM Performance Fact Sheet™ = Leverages your existing disclosures and gets data into the cloud. Summarizes the key attributes from EPDs, carbon and water footprints and material evaluations and links to product and marketing info on your site.

1 3 All three reports include Page 1 of the award - winning SM Transparency Report™ – an innovation in Type III environmental declaration (EPD) design and delivery .

2

© Sustainable Minds, 2021

Delivered in your Brand Showroom

© Sustainable Minds 2021 HPD Builder API Application Programming Interface (API) allows software solutions to communicate with each other. Together, committed to delivering easy to use tools Sharing HPDs Finding products w/ HPDs (& HPDs) Creating HPDs Selecting and understanding HPD Builder

© Sustainable Minds 2021 Together, committed to delivering easy to use tools Reporting MFR Analytics Dashboard Owens Corning | Jan 1– Apr 30, 2021 HPDs #3 and #5 most downloaded docs

Same HPD found & downloaded by:

1. Going directly to company listing OR 2. Any combination of search criteria, sometimes including other MFR names – yet still arriving at OC.

© Sustainable Minds 2021

Deeper and more useful integration of partner data

© Sustainable Minds, 2022

Thank you transparencycatalog.com © Sustainable Minds 2022

ECOSYSTEM PROGRAMS – PROGRESS IN RATING & CERTIFICATION PROGRAMS Simplifying Data-Driven Sustainability

Jack Dinning, Brightworks Sustainability

Paul Shahriari, ecomedes

the common materials framework

600+ sustainability certifications are used in the market today for product and building evaluation 3xN-GxN Guide to Sustainable Building Certifications

How does someone make better decisions?

Challenges in Comparing Diversity of Metrics from Dissimilar Rating Systems

What is the Common Materials Framework?

ABOUT BRIGHTWORKS SUSTAINABILITY

––––––––––––

ADVISORY BOARD (CAB) CONTENT WORKING GROUP (CWG) ECOSYSTEM PARTNERS Together Mapping the Materials Landscape

CONTENT

(CMF)

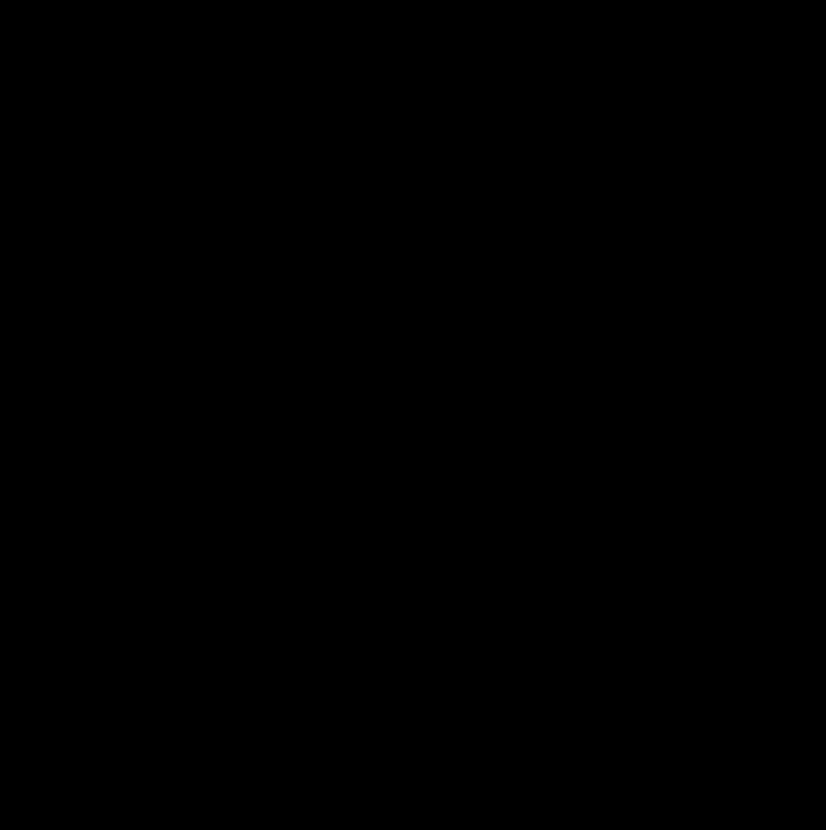

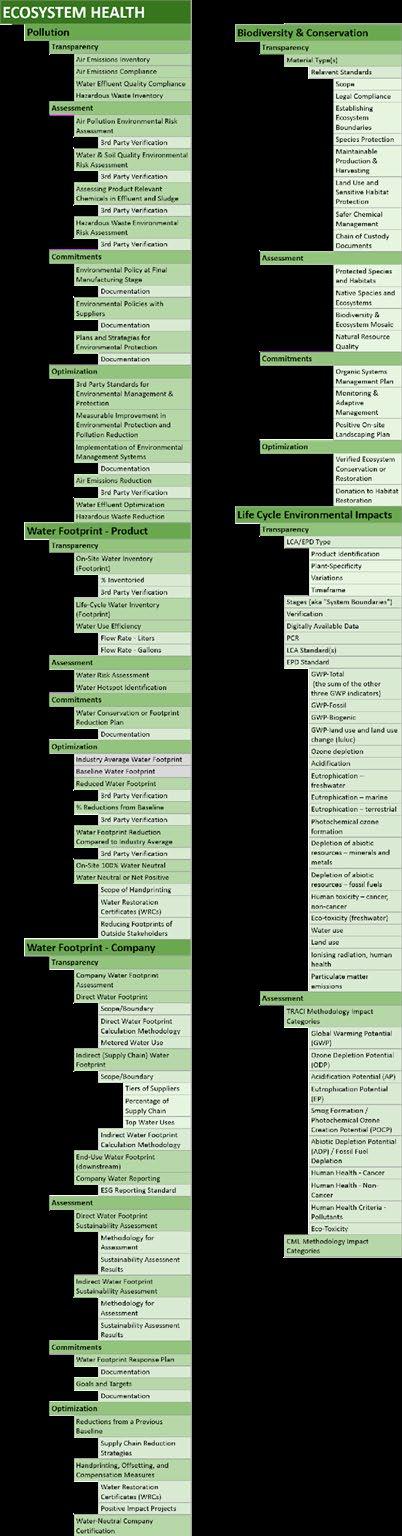

HUMAN HEALTH Substances VOCs Company Human Health Impacts Developing the Common Materials Framework

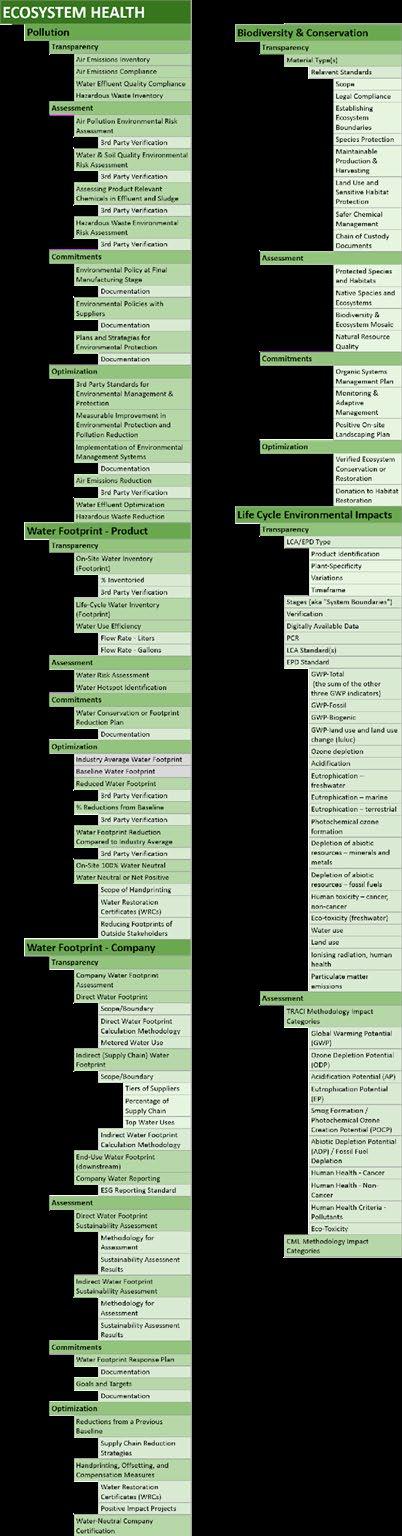

Buckets and Sub-buckets CLIMATE HEALTH Embodied Carbon Company Carbon Ecosystem Health Pollution Product Water Footprint Company Water Footprint Biodiversity & Conservation Life Cycle Env. Impacts Social Health & Equity Company Workplace Supply Chain Community Circular Economy Sourcing End-of-Life Packaging Waste Company Circularity

Common Materials Framework (CMF) Structure

Buckets

The 5 major buckets, as aligned by industry pledges

Sub-Buckets

Each bucket includes subbuckets to further differentiate impact areas

TACO Structure

Each sub-bucket then has 4 sections, Transparency, Assessment, Commitments, and Optimization (TACO)

Factors & Sub-Factors

Within each section are the specific factors and sub-factors that are relevant to the type of evaluation

Across 5 Buckets 600+ Factors from 150+ Standards This is the

language.

common

Certifications & Data are Framed in Common Context

AEC & Owners Can Search with Consistency & Meaning

Beta Portal is now live! portal.mindfulmaterials.com

Standards & Certifications

mM Portal

2050 materials

powered by Owner and A&D Specific Tools

150+

ECOSYSTEM PROGRAMS – PROGRESS IN RATING & CERTIFICATION PROGRAMS Optimizing Material Health and Maximizing LEED Credits Nina Hwang, Green Seal

OPTIMIZING

Nina Hwang Senior Environmental Scientist Green Seal, Certification Department

Nina Hwang Senior Environmental Scientist Green Seal, Certification Department

MATERIAL HEALTH AND MAXIMIZING LEED CREDITS

Global non-profit

Symbol of a high benchmark of health & environmental leadership Standards and certification

Setting Health & Environmental Targets with Impact

Pathway to Material Health Optimization

1. Report 2. Screen 3. Assess 4. Optimize

HPDC and Green Seal Partnership Green Seal is now an approved Health Product Declarations (HPD) preparer and third-party verifier Certified paints and coatings can receive a complimentary HPD Report prepared by Green Seal. Promote public disclosure to increase transparency Green Seal can prepare or verify HPD Reports for other paints and coatings and provide a complimentary eligibility screening for GS-11. Continue to drive material optimization

GS Certification for Paints, Coatings, Stains, and Sealers and LEED LEED v4/4.1 Low Emitting Materials Credit LEED v4/4.1 Ingredient Reporting Credit LEED v4/4.1 Material Ingredients Optimization Credit (pending)

Nina Hwang Senior Environmental Scientist nhwang@greenseal.org www.greenseal.org

ECOSYSTEM PROGRAMS – PROGRESS IN RATING & CERTIFICATION PROGRAMS Mission Possible - Healthier Projects using Materials Modeling Gina Ciganik and Anjanette Green, Healthy Building Network

Mission Possible: Healthier Projects using Materials Modeling

Gina Ciganik, CEO Anjanette Green, Senior Director of Market Transformation

Gina Ciganik, CEO Anjanette Green, Senior Director of Market Transformation

15, 2022

HPDC Material Health Open Innovation Symposium November

Vision

All people and the planet thrive when the environment

is free of toxic chemicals.

Planetary Boundaries

Climate Change

Novel Entities (aka Chemical Pollution)

(Credit: Designed by Azote for Stockholm Resilience Centre, based on analysis in Persson et al 2022 and Steffen et al 2015)

(Credit: Designed by Azote for Stockholm Resilience Centre, based on analysis in Persson et al 2022 and Steffen et al 2015)

● climate change ● chemical pollution ● loss of biodiversity

Chemical pollution plays a huge role in affecting the others and needs to be dealt with in order to save the planet.”

“The world is facing a triple planetary crisis of highly interlinked issues

-

ChemSec

Informed™

2060

2.5 Trillion Square Feet by

Transparency: Celebrate Progress & Manufacturer Leadership ~10,500 HPDs Certifications: ~1,000 Declare ~400 Cradle2Cradle

How do you make an informed decision when the product you want is not yet disclosed?

Undisclosed Building Product Market

Informed

TM

HBN's preemptive modeling tool that reveals material health ranking.

Informed™

Informed™

Installation

Manufacturing

Use End of Life

Informed™ Approachable Guidance: Informs users at the broad product level. Color Ranking System: Let’s users know what to avoid and what to prefer.

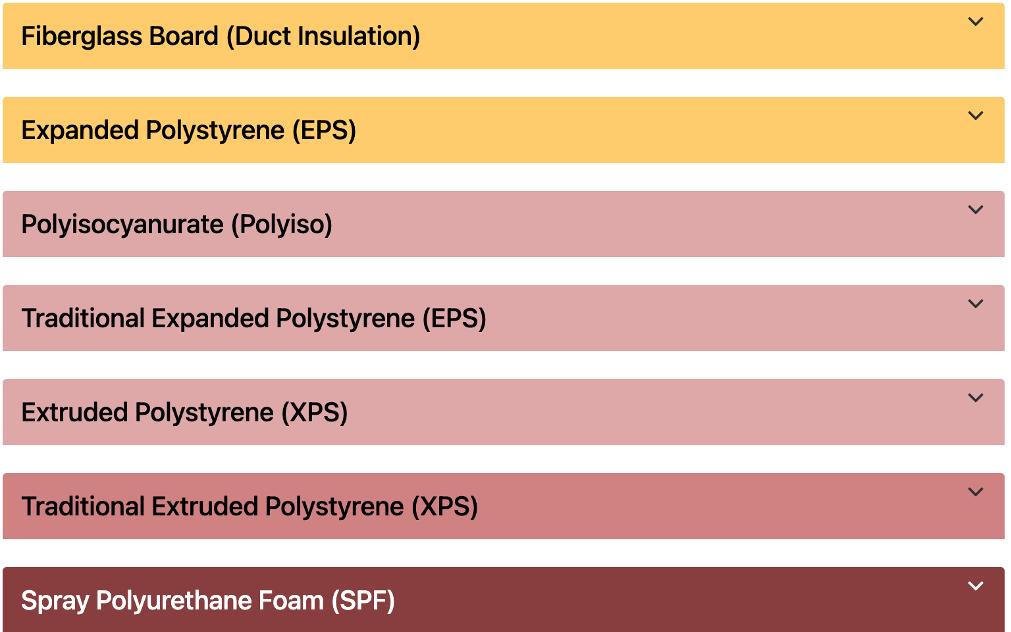

Informed™ 07 21 00 Thermal Insulation Avoid, Eliminate, Innovate Prefer, Prioritize, Specify

Informed™ InformedTM Pre-emptive Assessment ECO Labels 1 Refine & Compare 2 Complementary, Two-Step Approach: Materials Modeling Sets Teams Up for Success

Informed™

Informed™

Informed™

Informed™

Informed™

Supporting Transparency

Informed™

Informed™ InformedTM

Compare

Pre-emptive Assessment 1 Refine &

2

Assessments Illustrate Project Findings & Stories of Impact

Preliminary INFORMED Assessment

Impacts

Overall Rankings

By choosing paint in the green: Avoided hundreds to thousands of pounds of endocrine disrupting chemicals.

By choosing flooring in the green: Avoided toxic chemical use and release in fenceline communities (mercury, PFAS, asbestos).

We can address chemical pollution and plastics

Urgently At Scale Justly STOP Using products in the Red-Zone

All

people and the planet thrive when the environment is free of toxic chemicals.

Mission Possible: Healthier Projects using Materials Modeling

Thank you!

Gina Ciganik, CEO

November 15, 2022

Anjanette Green, Senior Director of Market Transformation HPDC Material Health Open Innovation Symposium

Toxnot Exchange

Toxnot Exchange

Nina Hwang Senior Environmental Scientist Green Seal, Certification Department

Nina Hwang Senior Environmental Scientist Green Seal, Certification Department

Gina Ciganik, CEO Anjanette Green, Senior Director of Market Transformation

Gina Ciganik, CEO Anjanette Green, Senior Director of Market Transformation

(Credit: Designed by Azote for Stockholm Resilience Centre, based on analysis in Persson et al 2022 and Steffen et al 2015)

(Credit: Designed by Azote for Stockholm Resilience Centre, based on analysis in Persson et al 2022 and Steffen et al 2015)