Keep up to date on all the news from Husqvarna Construction. Our monthly newsletter will provide the latest information on new products, features and insights, giving you the latest information.

Keep up to date on all the news from Husqvarna Construction. Our monthly newsletter will provide the latest information on new products, features and insights, giving you the latest information.

Any building structure that is meant to last for a long time needs to be built on solid ground. Similarly, business needs to be built on a solid foundation to last and Husqvarna is the partner you and your customers can trust to help build it. We provide the tools and solutions that help customers deliver. Our compaction concept builds on three basic principles:

1/ High-performing and well-designed quality equipment,

2/ Clear focus on efficiency,

3/ Service and support network to back you up in any event. That is how we support you and your customers – with a better way of working.

Husqvarna’s compaction equipment is developed for maximum productivity, performance and durability. Every little detail in our machines – from the ergonomic, vibration-damped handles to the hard, wear-resistant steel surface beating the soil – is designed to get the job done with maximum uptime and minimum service requirement.

LF 75 LAT with a 500m plate width and 15,000 centrifugal force is a fast-operating forward plate compactor, designed for efficient compaction of asphalt and soil.

Ideal for repair jobs and maintenance work, such as driveways and parking lots. The large water tank features an oversized cap to enable less frequent and fast refills.

It is easy to clean and the specialised asphalt plate provides a smooth finish while using whatever water is available onsite.

LF 75 LAT with a 500m plate width and 15,000 centrifugal force is a fast-operating forward plate compactor, designed for efficient compaction of asphalt and soil. Ideal for repair jobs and maintenance work, such as driveways and parking lots. The large water tank features an oversized cap to enable less frequent and fast refills. It is easy to clean and the specialised asphalt plate provides a smooth finish while using whatever water is available onsite.

The efficient, patented low-vibration handle lowers the vibration levels below 2 m/s2 allowing the operator to work for hrs without becoming fatigued or exceeding regulatory thresholds. Watering system prevents the bottom plate from sticking to the hot asphalt using only a minimum of water thanks to the easily adjustable water flow.

The efficient, patented low-vibration handle lowers the vibration levels below 2 m/s2 allowing the operator to work for hrs without becoming fatigued or exceeding regulatory thresholds. Watering system prevents the bottom plate from sticking to the hot asphalt using only a minimum of water thanks to the easily adjustable water flow

The handle completely folds to save space making transport and storage easy and the bottom plate is specially designed for asphalt work ensuring it will not get stuck on hot asphalt or leave turning marks. Learn more

The handle completely folds to save space making transport and storage easy and the bottom plate is specially designed for asphalt work ensuring it will not get stuck on hot asphalt or leave turning marks. Learn more

LT 6005 with a plate width of 280mm and weighing in at 69kg, is a well-balanced and powerful rammer, developed for efficient compaction of granular and cohesive soils such as clay and silt. Ideal for compaction in trenches or other narrow spaces, for example around pillars and pipes. Equipped with the latest Honda GXR120 engine, which is especially designed for rammers. The rammer offers superb control, low noise and low emissions.

powerful rammer, developed for efficient compaction of granular and cohesive soils such as clay and silt. Ideal for compaction in trenches or other narrow spaces, for example around pillars and pipes. Equipped with the latest Honda GXR120 engine, which is especially designed for rammers. The rammer offers superb control, low noise and low emissions.

LT 6005 with a plate width of 280mm and weighing in at 69kg, is a well-balanced and powerful rammer, developed for efficient compaction of granular and cohesive soils such as clay and silt. Ideal for compaction in trenches or other narrow spaces, for example around pillars and pipes. Equipped with the latest Honda GXR120 engine, which is especially designed for rammers. The rammer offers superb control, low noise and low emissions.

LT 6005 with a plate width of 280mm and weighing in at 69kg, is a well-balanced and powerful rammer, developed for efficient compaction of granular and cohesive soils such as clay and silt. Ideal for compaction in trenches or other narrow spaces, for example around pillars and pipes. Equipped with the latest Honda GXR120 engine, which is especially designed for rammers. The rammer offers superb control, low noise and low emissions.

Thanks to its powerful Honda GXR engine mounted in a compact durable chassis, the LT6005 delivers high speed and high impact force. It’s 3 position throttle control makes it easy to manoeuvre and provides excellent traction. Easy access to all service points, air filter cleaning/replacing and equipped with an hour meter, air filter and oil warning indicator.

Thanks to its powerful Honda GXR engine mounted in a compact durable chassis, the LT6005 delivers high speed and high impact force. It’s 3 position throttle control makes it easy to manoeuvre and provides excellent traction. Easy access to all service points, air filter cleaning/replacing and equipped with an hour meter, air filter and oil warning indicator.

Thanks to its powerful Honda GXR engine mounted in a compact durable chassis, the LT6005 delivers high speed and high impact force. It’s 3 position throttle control makes it easy to manoeuvre and provides excellent traction. Easy access to all service points, air filter cleaning/replacing and equipped with an hour meter, air filter and oil warning indicator.

Learn more

Learn more

Learn more

Thanks to its powerful Honda GXR engine mounted in a compact durable chassis, the LT6005 delivers high speed and high impact force. It’s 3 position throttle control makes it easy to manoeuvre and provides excellent traction. Easy access to all service points, air filter cleaning/replacing and equipped with an hour meter, air filter and oil warning indicator.

Learn more

New training content being added monthly on the Husqvarna Trade Masters academy.

New training content being added monthly on the Husqvarna Trade Masters academy.

Don't have an account? Sign up via the link below.

New training content being added monthly on the Husqvarna Trade Masters academy.

Don't have an account? Sign up via the link below.

New training content being added monthly on the Husqvarna Trade Masters academy.

Sign up here!

Don't have an account? Sign up via the link below.

Sign up here!

Don't have an account? Sign up via the link below.

We will continue to run training days to support your sales team in understanding how to use our products and applications they are suited for.

With training days already conducted in August, more dates and venues will be added.

Click on the links below to book your spot.

Sydney

Tunnel Syndrome, Vibration White Finger, impaired blood flow in the hands, reduced strength in the arms and fingers and increase sensitivity.

- Hand Arm Vibration Syndrome is the term used to describe medical conditions caused by handheld tools that induce vibration in the user. These medical conditions include Carpal Tunnel Syndrome, Vibration White Finger, impaired blood flow in the hands, reduced strength in the arms and fingers and increase sensitivity

- Early symptoms include finger numbing, pins and needles but can progress to pain in the wrists, arms, elbows and shoulders followed by nerve damage, bone and joint disorders and in extreme situations cause gangrene. The damage caused is cumulative, that continuous daily use of handheld vibrating equipment increases the risk of the user developing symptoms.

- Hand Arm Vibration Syndrome is the term used to describe medical conditions caused by handheld tools that induce vibration in the user. These medical conditions include Carpal Tunnel Syndrome, Vibration White Finger, impaired blood flow in the hands, reduced strength in the arms and fingers and increase sensitivity

- Early symptoms include finger numbing, pins and needles but can progress to pain in the wrists, arms, elbows and shoulders followed by nerve damage, bone and joint disorders and in extreme situations cause gangrene. The damage caused is cumulative, that continuous daily use of handheld vibrating equipment increases the risk of the user developing symptoms.

- Early symptoms include finger numbing, pins and needles but can progress to pain in the wrists, arms, elbows and shoulders followed by nerve damage, bone and joint disorders and in extreme situations cause gangrene. The damage caused is cumulative, that continuous daily use of handheld vibrating equipment increases the risk of the user developing symptoms.

Government Regulation:

- Exposure Action Value is 2.5m/s², above which level employers should introduce technical and work rotation measures to reduce exposure.

Government Regulation:

Government Regulation:

- Exposure Action Value is 2.5m/s², above which level employers should introduce technical and work rotation measures to reduce exposure.

- Exposure Action Value is 2.5m/s², above which level employers should introduce technical and work rotation measures to reduce exposure.

Solution:

- Early symptoms include finger numbing, pins and needles but can progress to pain in the wrists, arms, elbows and shoulders followed by nerve damage, bone and joint disorders and in extreme situations cause gangrene. The damage caused is cumulative, that continuous daily use of handheld vibrating equipment increases the risk of the user developing symptoms.

Solution:

Solution:

Husqvarna Construction Division has developed efficient, patented low-vibration handles on its forward plate compactors which lower the vibration level below 2 m/s² allowing you to work for hours without becoming fatigued or exceeding any regulatory threshold limit values.

Government Regulation:

Husqvarna Construction Division has developed efficient, patented low-vibration handles on its forward plate compactors which lower the vibration level below 2 m/s² allowing you to work for hours without becoming fatigued or exceeding any regulatory threshold limit values.

Husqvarna Construction Division has developed efficient, patented low-vibration handles on its forward plate compactors which lower the vibration level below 2 m/s² allowing you to work for hours without becoming fatigued or exceeding any regulatory threshold limit values.

- Exposure Action Value is 2.5m/s², above which level employers should introduce technical and work rotation measures to reduce exposure.

Below are Husqvarna’s Anti Vibration handle solution on LF – machines (excluding LFV80)

Solution:

Below are Husqvarna’s Anti Vibration handle solution on LF – machines (excluding LFV80)

Below are Husqvarna’s Anti Vibration handle solution on LF – machines (excluding LFV80)

Husqvarna Construction Division has developed efficient, patented low-vibration handles on its forward plate compactors which lower the vibration level below 2 m/s² allowing you to work for hours without becoming fatigued or exceeding any regulatory threshold limit values.

Below are Husqvarna’s Anti Vibration handle solution on LF – machines (excluding LFV80)

symptoms.

Government Regulation:

- Exposure Action Value is 2.5m/s², above which level employers should introduce technical and work rotation measures to reduce exposure.

Solution:

Husqvarna Construction Division has developed efficient, patented low-vibration handles on its forward plate compactors which lower the vibration level below 2 m/s² allowing you to work for hours without becoming fatigued or exceeding any regulatory threshold limit values.

Below are Husqvarna’ ibration handle solution on LF – machines (excluding LFV80)

Turbo jointed segments combine high cutting speed with a high quality finishing cut, even in the hardest stone and concrete. Fast cutting of a large variety of materials, best for occasional to medium users. Available in 300, 350 and 400mm diameter.

Turbo jointed segments combine high cutting speed with a high quality finishing cut, even in the hardest stone and concrete. Fast cutting of a large variety of materials, best for occasional to medium users. Available in 300, 350 and 400mm diameter.

Learn more

Turbo jointed segments combine high cutting speed with a high quality finishing cut, even in the hardest stone and concrete. Fast cutting of a large variety of materials, best for occasional to medium users. Available in 300, 350 and 400mm diameter.

Learn more

Learn more

Turbo jointed segments combine high cutting speed with a high quality finishing cut, even in the hardest stone and concrete. Fast cutting of a large variety of materials, best for occasional to medium users. Available in 300, 350 and 400mm diameter

access to the latest product-related

The following marketing activities will be active during the month and will be promoted rade Masters Facebook and Instagram sites:

With our new website, you have easy access to the latest product-related information for Husqvarna Construction equipment, accessories and diamond tools. Find the latest technical specifications for your favorite Husqvarna machines, tools and accessories.

Check it out

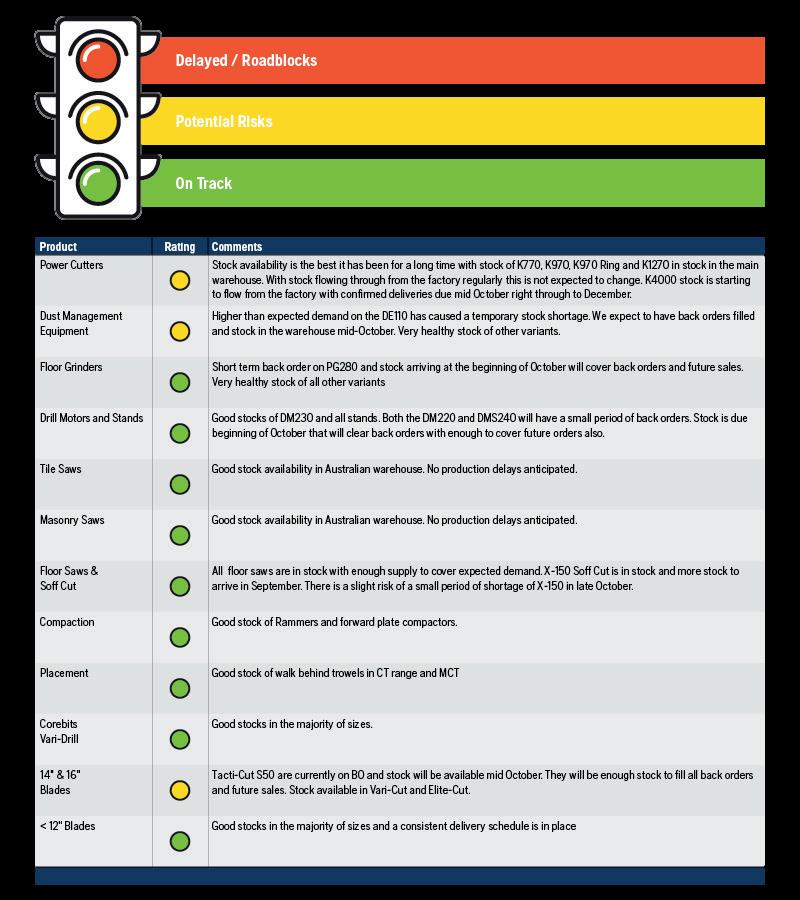

component supply issues and an improvement in sea and airfreight. Freight availability is continuing to improve with an increase in passenger planes and less port restrictions. There is still a risk of freight issues over the next 3-6 months but it does appear the worst is behind us.

The stock levels are continuing to increase due to better supply from the factory, reduced component supply issues and an improvement in sea and airfreight. Freight availability is continuing to improve with an increase in passenger planes and less port restrictions. There is still a risk of freight issues over the next 3-6 months but it does appear the worst is behind us.

The stock levels are continuing to increase due to better supply from the factory, reduced component supply issues and an improvement in sea and airfreight. Freight availability is continuing to improve with an increase in passenger planes and less port restrictions. There is still a risk of freight issues over the next 3-6 months but it does appear the worst is behind us.

Follow us on socials

behind us.

Copyright 2022 Husqvarna AB (publ) all rights reserved. This is a newsletter from Husqvarna Construction. Visit our website www.husqvarnacp.com/au | Unsubscribe

Copyright 2022 Husqvarna AB (publ) all rights reserved. This is a newsletter from Husqvarna Construction. Visit our website www.husqvarnacp.com/au | Unsubscribe

Copyright 2022 Husqvarna AB (publ) all rights reserved. This is a newsletter from Husqvarna Construction. Visit our website www.husqvarnaconstruction.com/au | Unsubscribe