9 minute read

Induction Lamps Light Lambeau

Historic Lambeau Field, home of the Green Bay Packers, is getting an energy-effi cient upgrade using induction-lamp technology.

Advertisement

New induction high-bays illuminate the concourses under the stadium’s end-zone seats.

One of the National Football League’s most revered stadiums, Lambeau Field in Green Bay, WI, home of the Green Bay Packers, features the only true retro look in the entire league. Recently the structure has been transformed from a football stadium that fans used only 10 days during the season to a Packers cultural center that can be enjoyed throughout the year. Lambeau Field managers also implemented a major lighting overhaul. Powrtek Engineering Inc., an electrical-engineering fi rm based in Waukesha, WI, searched for a solution that would meet building codes and decrease maintenance costs. The fi nal choice: 200-W induction high-bay fi xtures from EverLast Lighting, Jackson, MI. Designed to improve safety and visibility and meet emergency regulations, the induction high-bays offer 100,000 hours of lamp life and an effi cacy of 85 lumens/W, making the technology very energy effi cient and cost effective. The concourses under the south end zone received 71 induction high bays to supplement existing lighting. Several hundred additional induction fi xtures will

High-bay fi xtures with induction lamps are saving energy and providing the desired color temperature at the home of the Green Bay Packers.

be installed throughout the stadium this winter.

“The manufacturer provided a color temperature that we needed as a custom blend at 3,000 K,” said Greg Sadowski, president of Powrtek Engineering. “Additionally, there were strict emergency-lighting specifications that we had to meet. The fixture had to be able to turn on within 10 seconds in the event of an outage. The induction fixtures are doing double duty: They possess the required color rendition in addition to the instant-on feature.

“HID [high-intensity-discharge lamps] cannot provide the specifi cations required,” Sandowski added. “Furthermore, with induction’s 100,000-hour lifetime on their fi xtures, it was an easy decision. We would’ve been lucky to get 20,000 hours out of any other fi xtures. Once we took the warranty and the lower maintenance costs into consideration, we knew that we wanted to go with induction.”

A 100-year-old overnight sensation

Induction technology is an electrode-less lamp that has been around for more than 100 years. Due to recent advancements, it has become an effective lighting option for roadways, parking structures, municipalities, warehouses, and largescale facilities. With no electrodes, the lamp relies on the fundamental principles of gas discharge and electromagnetic induction to produce light.

Based on these principles, light is generated using gas discharged through magnetism. Rings with magnetic coils create an electromagnetic fi eld

using a high frequency generated by an electronic ballast. This fi eld goes around a gas-fi lled glass tube. The discharge path induced by the coils forms a closed loop, accelerating free electrons that collide with mercury atoms and excite the electrons. As the electrons begin to reach a lower, more stable level, they give off energy in the form of invisible ultraviolet light, which converts to visible light when it passes through a phosphor coating on the surface of the tube. The lamp’s unique shape maximizes the fi elds generated during this process.

The system blends technology that was fi rst discovered more than 30 years ago with new features that were not commercially practical until now. Induction has overcome the barriers of high cost and technological setbacks such as electromagnetic interference, lumen depreciation, and inability to dim. ”The induction high-bay fi xture has been sought out especially in large facilities where lower maintenance costs have been deciding factors as a result of the long life span of the fi xture and the 10-year warranty,” said Jim Fink, who covers the state of Wisconsin for Alternative Sales and Marketing, Forest Lake, MN, and worked with Powrtek on the project. “Once we began evaluating the new construction, it was obvious that was the direction that we would go.”

“The success of the induction fi xtures in the upper Midwest region has been phenomenal for reasons such as engineering support, providing lighting layouts, custom modifi cations when needed, product stock, and a U.S.- manufactured product,” said Fink. “The key successes in this market are the operation of the induction lighting in exceptionally cold weather.”

EverLast Lighting engineered its 200-W Huron aluminum high-bay unit to match the existing lighting temperature and protect the visual integrity of the historic stadium. Virtually maintenance-free for as long as 15 years, the fi xtures are 50% to 70% more energy-effi cient than metal halides. The fi xtures provide a more natural, higher color-rendition light than traditional metal-halide fi xtures.

In addition, induction lighting fi xtures are available with a bi-level dimming option triggered by photosensors, providing even more energy savings when areas are vacant. Building codes often require large sports stadiums to have lights on all day or all night, regardless of the lighting need. Bi-level fi xture controls present an opportunity to save energy by dimming light levels in unoccupied areas. They also can turn off perimeter lights in areas that receive suffi cient daylight to meet lighting needs.

Artifi cial sunshine

In addition to the savings from bi-level controls, replacing existing light fi xtures with high-performance fi xtures, such as induction, can produce signifi - cant energy and lifecycle cost savings. Fixture replacements and bi-level controls can create peak demand reductions (kW) and hourly energy-use reductions (kWh). Typical energy savings for parking lots and garages retrofi tted with bi-level lighting are 20% to 70%, depending on the previous and newly installed equipment.

“Proprietary to the manufacturer, our bilevel option includes an advanced internal heatmanagement system designed for separation and airfl ow between the ballast and lamp. By isolating specifi c areas, the technology is able to ensure electronic components have a longer life cycle,” explained Justin Baldwin, EverLast vice president. “When developing the technology, we took into consideration fi xture maintenance and ease of installation.” The result is a lamp with a life span roughly equivalent to 100 incandescent, fi ve HID, fi ve typical fl uorescent, or two LED lamp changes.

Because lighting technologies vary, the lighting specifi ers considered visibility lumens for the Lambeau Field application. Metered footcandle readings—the intensity of illumination without regard for the contribution of the eye’s rods in color recognition and how the human eye works—only tell half the story. The more artifi cial light varies from natural sunlight, the less effective it is for visual acuity.

Induction is the closest light to the natural, full-color spectrum of sunlight. Visually effective lumens (VEL) are the measure of lumens factored to account for visual acuity. VEL refl ects a combination of the color-rendering index (CRI) of a light source as well as the Kelvin temperature (K). Induction lighting combines very high CRI with 5,000 K, and the natural, full-color spectrum of sunlight. The result is excellent acuity.

However, management at Lambeau Field wanted to maintain the feel of their stadium, which is why they decided to pursue the custom 3,000 K blend, which emits a warm light that matches the history and character of the stadium. “Projects like Lambeau Field get us excited because we are lighting-solution providers, not just fi xture manufacturers,” explained Brandon Marken, vice president of sales at EverLast. “When customers and/or our representatives come to us with a specifi c set of criteria and needs, we feel confi dent that we can deliver a customized solution that will exceed their expectations.”

Induction vs. LED

Although LED technology has become a major force in the lighting industry, several factors drove Lambeau managers’ decision not to pursue LEDs as a stadium lighting solution:

• Induction offers considerably lower luminaire prices, and the fi xtures’ lamp life is twice as long as LEDs. • Induction luminaires can be easily re-lamped, unlike many LED fi xtures. • Induction technology has much better lumen maintenance over the lifetime of the fi xture. • Induction prevents the harsh glare of directional LED light sources because of its spherical light source and visually comfortable color rendering, typically ranging between 2,700 K to 6,000 K. White-light LEDs are in a higher range, emitting too much blue light.

Federal, state, and local tax incentives are currently available to offset the cost of implementing energy-effi cient lighting. “The federal tax incentive for installing induction lights is 60 cents/square foot,” explained Bryan Schultz, west coast regional sales manager for EverLast. “A number of utility companies are also offering incentives, such as credits and rebates, for energy-effi ciency upgrades.”

The 200-W Huron high bays installed in Lambeau Field present several options besides bi-level technology to increase fi xture effi ciency. The manufacturer offers a patented septum to maximize lamp geometry, which improves spacing ratios throughout the facility and increases the effi ciency of the fi xture. The septum also increases down light, minimizes trapped light, and decreases up light.

The Huron high bay offers a unique fi xture lens and optional white coating inside the fi xture housing. The lens incorporated into each high bay, made with U.S. raw material, produces a lower haze to allow more transparent light distribution. Although the standard spun-aluminum material increases refl ectivity, the white coating also increases refl ectivity and increases down light by more than 5%.

Induction high-bay fi xtures boast the lowest total cost of ownership, compared with T8, LED, HPS, and HID lighting solutions. Many U.S. facilities have begun to take advantage of the technology and its rebate incentives. Induction high bays also offer 68% more delivered lumens than conventional technologies and 50% less glare than LED high bays.

With traditional architecture and a history of great football plays and players, venerable Lambeau Field will see its 55th season of football this year. Thanks to the new induction lighting, Packer fans, players, and coaches will see each

game—and each Lambeau Leap—more clearly

for free information, CIRCLE 18

and visit our digital magazine at www.cbpmagazine.com/digital/julaug2013 and click on the icon.

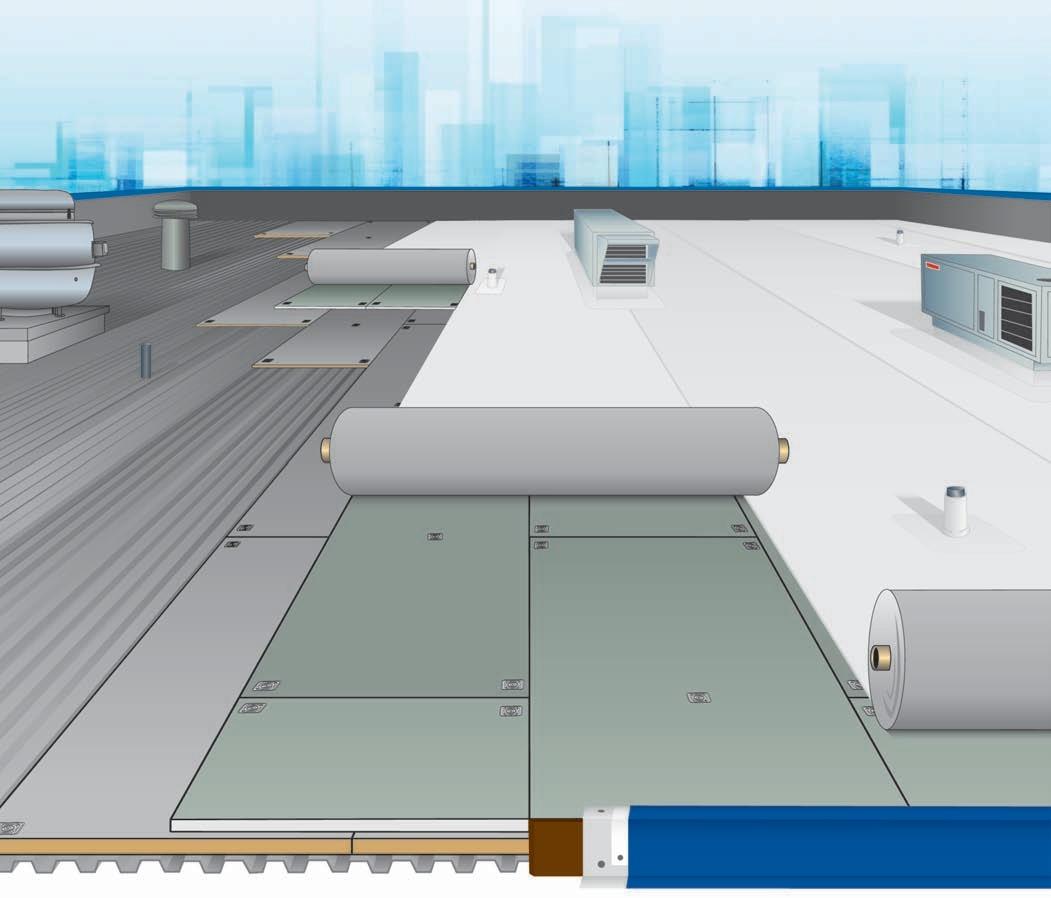

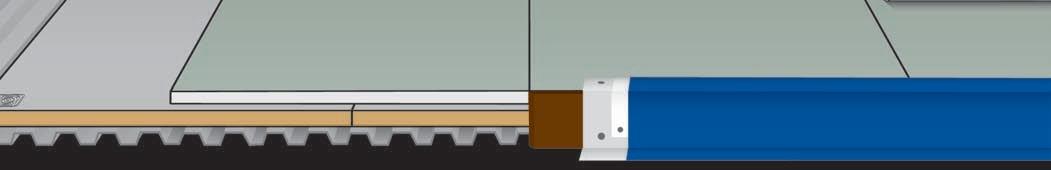

Edge-to-Edge & Deck-to-Sky ™

than ever.

Best PVC Membranes Custom Prefabricated Flashings

Duro-Guard ® Insulation EXCEPTIONAL ® Metals Edge Details & Accessories The Industry’s Best Warranties

Duro-Last ® is your single-source for complete roofing systems, engin eered to provide long-term Edge-to-Edge & Deck-to-Sky ™ protection. Installed by authorized contractors, and warranty issued by the industry’s largest and best-trained quality assurance team.

800-248-0280 www.duro-last.com / Twitter: @durolast CONTACT DURO-LAST, INC. FOR THE “WORLD’S BEST ROOF” ® Duro-Last, Duro-Guard, EXCEPTIONAL, and the “World’s Best Roof” are registered marks owned by Duro-Last Roofing, Inc. EXCEPTIONAL Metals is a division of Duro-Last Roofing, Inc.