3 minute read

IN THIS ISSUE

August 2023

VOLUME 30 • ISSUE 8

Features

6 Cover Story

Using Multimedia Monitoring to Optimize Energy Consumption

Real-time monitoring of utilities such as compressed air can help reduce energy consumption and improve process efficiency in food and beverage operations.

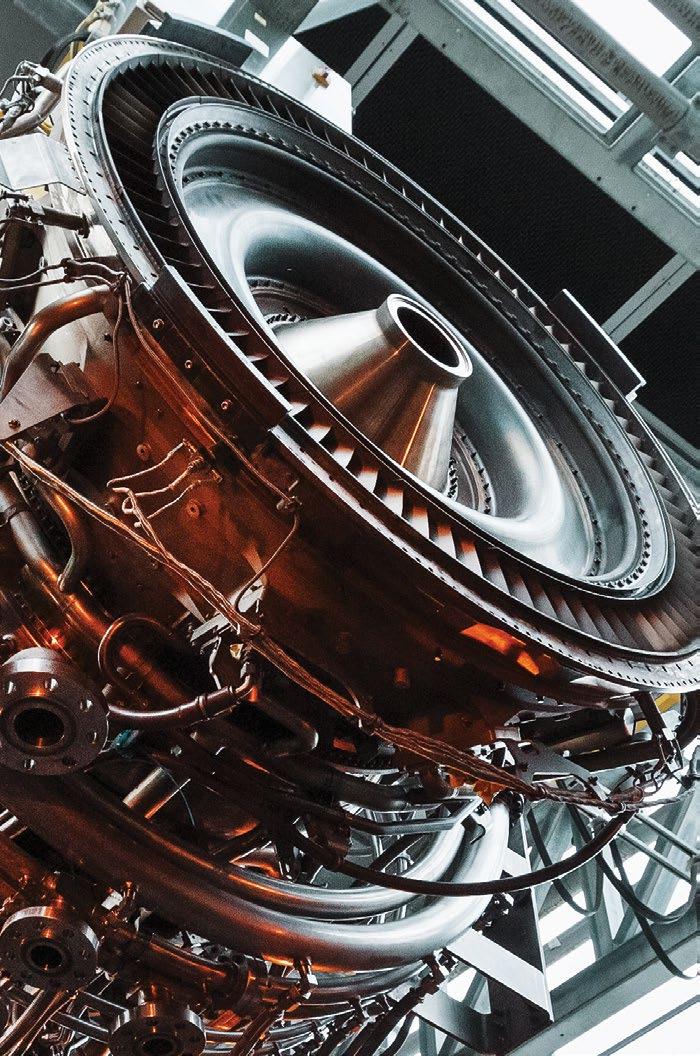

8 Duplex Filter Solutions for Power Generating Turbines

The best way to achieve optimal oil filtration for power generating turbines.

18 The Next Step in Predictive Maintenance for Mobile Equipment

Failure in machinery or equipment can have catastrophic impacts, and so breakdowns need to be proactively prevented.

23 Test Your Skills

The “STAMPED” Method Designing & Specifying Tube Assembly Components

26 The Impact of Smart Manufacturing on Maintenance Practices

Smart manufacturing integrates advanced technologies for companies seeking leverage in efficiency

Publisher’s Note: The information provided in this publication is for informational purposes only. While all efforts have been taken to ensure the technical accuracy of the material enclosed, Fluid Power Journal is not responsible for the availability, accuracy, currency, or reliability of any information, statement, opinion, or advice contained in a third party’s material. Fluid Power Journal will not be liable for any loss or damage caused by reliance on information obtained in this publication.

Contamination Control

Routine and scheduled maintenance of hydraulic systems are vital to getting the most out of your Hitachi Mining Excavator. While maintenance plays the largest role in the prevention of unnecessary machine downtime, it can also expose the hydraulic system to high levels of contamination rapidly decreasing component longevity. The importance of contamination control is sometimes overlooked when performing maintenance due to incorrect practices being used.

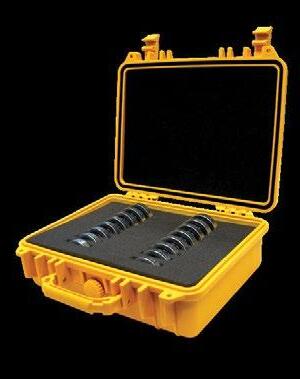

THE FLANGELOCK™ TOOL AND CIRCUIT BLANKING CAPS

The FlangeLock™ tool and caps are the ultimate contamination control tools for protecting your hydraulic system. The FlangeLock™ allows for the simple sealing of open hydraulic flanges without tools while the caps can be bolted in place of a flange connection. Easy on, easy off, they offer a leak-proof solution to hydraulic systems and environmental cleanliness. FlangeLock tools and caps stop the mess.

Hitachi Making Contamination Control Easy

Hitachi have packaged FlangeLock™ tool and caps specifically for Hitachi mining excavators. The Hitachi customised kits make sure no matter which component routine maintenance is being performed on, you will always have the exact number of FlangeLocks™* and caps to help reduce contamination.

*Note: FlangeLocks are not to be used under pressure

The FlangeLock™ Tool is the ultimate contamination control tool for protecting your hydraulic systems. It allows for the simple sealing of open SAE code 61, 62 & CAT-Style hydraulic flanges without tools. Constructed from lightweight aluminum. Easy on, easy off. Offers a leakproof solution to hydraulic system and environmental cleanliness. FlangeLock™ Tools stop the mess!

• No tools required

• No expensive hardware needed

• No more rags stuffed into hoses

• No more messy plastic caps

• The ultimate contamination control tool

ERGONOMICS PLAYS AN important role in optimizing the design of industrial filtration systems by making them easier to maintain and safer for the user. Operators who change out consumable filter bags will benefit from systems that minimize physical strain, the time it takes to complete their tasks, and potential exposure to dangerous conditions and substances.

Per the U.S. Bureau of Labor Statistics, most nonfatal occupational injuries resulting in missed work are caused by musculoskeletal disorders (MSDs) including sprains/strains, pinched nerves, bruises, and lacerations due to lifting/pushing/pulling heavy items, bending down, reaching overhead and/or working in awkward body positions. OSHA further estimates that U.S. employers pay almost $1 billion per week for direct workers' compensation costs alone—a reminder that implementing improved safety measures is always good business. Here is how functional design can make a big difference in the overall efficacy of industrial filtration systems and how ergonomics can have the added benefit of positively impacting your profits:

Bigger is not always better

Large-sized filters (where housings will tend to have a high access point) are popular for the efficiencies they create. However, it may be more practical to design a smaller filter unit having a lower access point, where filter bags are also smaller/shorter, thus enabling personnel to easily remove them while standing on the ground. This eliminates the need for special lift equipment or scaffolding that is labor-intensive, disruptive to operations, and can pose a safety risk. In certain cases, a high-capacity filtration solution in a shorter size can even outperform a larger, standard-capacity model while offering better height accessibility.