17 minute read

Keeping Cool with Hydraulic Case Drains High fluid temperatures diminish a system’s performance

The cooler mounts behind an existing TEFC motor, using the electric-motor fan airflow. Cooling flow is obtained from the case drain of the hydraulic machine and is then guided to the integrated electrical machine. Pressure losses in the electrical machine can be seen as negligible. The outgoing flow moves by gravity as long as the outlet and inlet ports are of adequate dimensions.

To select the best air oil cooler, provide as much information about the application as possible, including oil heat load in Btu/h or hp, oil flow rate in gpm, maximum inlet oil, and maximum ambient air temperatures during operation.

If the required heat dissipation is unknown, it can be estimated that 20% to 30% of the installed horsepower will be converted into heat load. Heat exchangers can be used to remove the excess heat in a hydraulic system. The implementation of a heat exchanger has many variables that need to be taken into account.

The heat exchanger and reservoir should be sized when a system is initially designed to remove the generated heat. The reservoir allows some of the heat to dissipate through the walls to the atmosphere. The heat exchangers should be sized to remove the balance of the heat. The heat exchanger needs to be maintained to ensure excess heat is removed. If an air-type heat exchanger is used, the cooler fins should be cleaned regularly. A degreaser may be necessary to clean the fins.

To ensure profitable and efficient success in a manufacturing operation, maintaining a proper oil temperature in all hydraulic systems is essential. High hydraulic-fluid temperatures can damage system components and significantly alter the way a hydraulic system performs, resulting in costly repairs and downtime.

SIMPLE CIRCUIT WITH FLUID MOTORS: 31%

HYDROSTATIC TRANSMISSIONS: 35%-40%

SIMPLE CIRCUIT WITH MINIMAL VALVES: 25%

SERVO-BASED SYSTEMS: 60%-75%

SIMPLE CIRCUIT WITH CYLINDERS: 28%

TYPICAL CASE-DRAIN APPLICATIONS

GEAR BOXES

HYDRAULIC PRESSES

HYDRAULIC TOOLS

HYDRAULIC POWER UNITS

INDUSTRIAL COMPACTORS

ASSEMBLY CONVEYORS

AKG Case-Drain Series

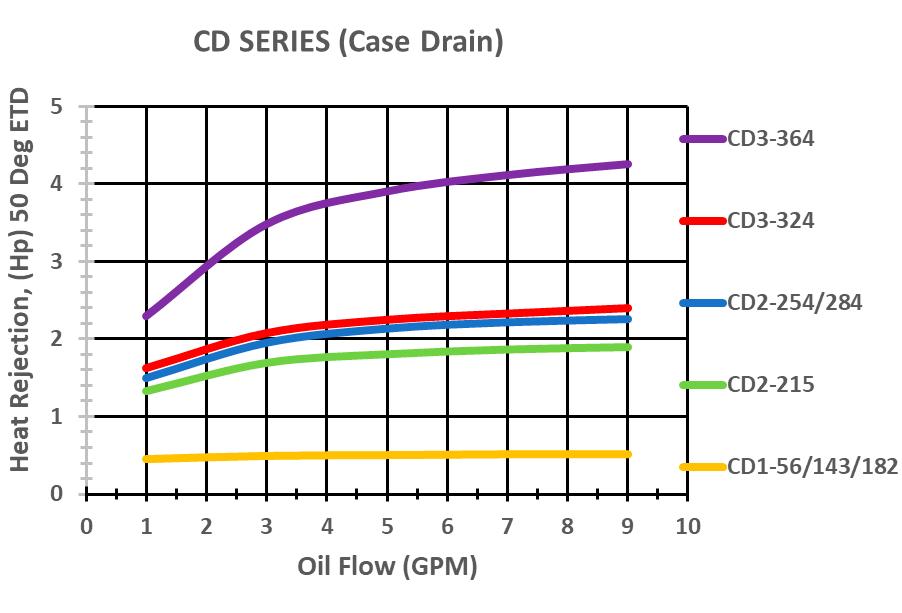

The AKG Thermal Systems CD Series is designed to fit in tight spaces and conveniently mounts onto a power unit with limited envelope space. The narrow profile conditions and cools for a wide array of applications. The AKG tube fin design offers more significant cooling and does not require a protective guard. This cooling setup is compact, low cost, and low flow with minimal heat removal.

CD SERIES FEATURES: • tube and fin aluminum design, • coolers mount onto the rear of TEFC frame motors, • competitive pricing and assembles from stock, • premium-quality lightweight construction.

For more information, visit www.akgts.com.

Heat Rejection, (hp) 50 Deg ETD

CD SERIES

Oil Flow (gpm)

Performance for AKG CD Series oil coolers. Listed performance curves are based on ISO VG 32 oil @ 50F ETD.

SELECT COMPONENTS FOR PNEUMATIC SYSTEMS SELECT COMPONENTS FOR PNEUMATIC SYSTEMS SELECT COMPONENTS FOR PNEUMATIC SYSTEMS SELECT COMPONENTS FOR PNEUMATIC SYSTEMS

Outcome 3.18: Calculate the kinetic energy required to stop a load Outcome 3.18: Calculate the kinetic energy required to stop a load Outcome 3.18: Calculate the kinetic energy required to stop a load Outcome 3.18: Calculate the kinetic energy required to stop a load SELECT COMPONENTS FOR PNEUMATIC SYSTEMS

with a shock absorber.with a shock absorber.with a shock absorber.with a shock absorber.

It is common practice to position shock absorbers to cushion loads attached to air cylinders, rather than It is common practice to position shock absorbers to cushion loads attached to air cylinders, rather than It is common practice to position shock absorbers to cushion loads attached to air cylinders, rather than It is common practice to position shock absorbers to cushion loads attached to air cylinders, rather than Outcome 3.18: Calculate the kinetic energy required to stop a load to subject the air cylinders to shock loading resulting from end of stoke impact. This practice allows sizing the cylinder to move the load and sizing the shock absorber to stop moving the load within the required distance. to subject the air cylinders to shock loading resulting from end of stoke impact. This practice allows sizing the cylinder to move the load and sizing the shock absorber to stop moving the load within the required distance. to subject the air cylinders to shock loading resulting from end of stoke impact. This practice allows sizing the cylinder to move the load and sizing the shock absorber to stop moving the load within the required distance. to subject the air cylinders to shock loading resulting from end of stoke impact. This practice allows sizing the cylinder to move the load and sizing the shock absorber to stop moving the load within the required distance. with a shock absorber. It is common practice to position shock absorbers to cushion loads attached to air cylinders, rather than CALCULATE THE In motion control, it is desirable that a load be stopped smoothly and without adverse effects such as rebounding or stress upon the machine or part itself. The speed of the object and mass of the object will determine the best method to accomplish this. Previously in other outcomes there has been discussion of deceleration of a cylinder using internal cushions or reducing end of stroke impact by a polymer bumper within the cylinder. When the velocity, mass, and a potential applied force is high, then a shock absorber is the best method to control the deceleration of the object without adverse effects. The kinetic energy that is dissipated is converted into heat energy, so consideration must be given to the cycle rate of the In motion control, it is desirable that a load be stopped smoothly and without adverse effects such as rebounding or stress upon the machine or part itself. The speed of the object and mass of the object will determine the best method to accomplish this. Previously in other outcomes there has been discussion of deceleration of a cylinder using internal cushions or reducing end of stroke impact by a polymer bumper within the cylinder. When the velocity, mass, and a potential applied force is high, then a shock absorber is the best method to control the deceleration of the object without adverse effects. The kinetic energy that is dissipated is converted into heat energy, so consideration must be given to the cycle rate of the In motion control, it is desirable that a load be stopped smoothly and without adverse effects such as rebounding or stress upon the machine or part itself. The speed of the object and mass of the object will determine the best method to accomplish this. Previously in other outcomes there has been discussion of deceleration of a cylinder using internal cushions or reducing end of stroke impact by a polymer bumper within the cylinder. When the velocity, mass, and a potential applied force is high, then a shock absorber is the best method to control the deceleration of the object without adverse effects. The kinetic energy that is dissipated is converted into heat energy, so consideration must be given to the cycle rate of the In motion control, it is desirable that a load be stopped smoothly and without adverse effects such as rebounding or stress upon the machine or part itself. The speed of the object and mass of the object will determine the best method to accomplish this. Previously in other outcomes there has been discussion of deceleration of a cylinder using internal cushions or reducing end of stroke impact by a polymer bumper within the cylinder. When the velocity, mass, and a potential applied force is high, then a shock absorber is the best method to control the deceleration of the object without adverse effects. The kinetic energy that is dissipated is converted into heat energy, so consideration must be given to the cycle rate of the to subject the air cylinders to shock loading resulting from end of stoke impact. This practice allows sizing the cylinder to move the load and sizing the shock absorber to stop moving the load within the required distance. In motion control, it is desirable that a load be stopped smoothly and without adverse effects such as rebounding or stress upon the machine or part itself. The speed of the object and mass of the object will KINETIC ENERGY shock absorber to ensure that this heat is taken into account. shock absorber to ensure that this heat is taken into account. shock absorber to ensure that this heat is taken into account. shock absorber to ensure that this heat is taken into account. determine the best method to accomplish this. Previously in other outcomes there has been discussion of deceleration of a cylinder using internal cushions or reducing end of stroke impact by a polymer bumper It is common practice to position shock absorbers to cushion loads attached to air cylinders, rather than to subject the air cylinders to shock loading resulting from end-of-stroke impact. This practice allows sizing the cylinder to move the load and sizing the shock absorber to stop moving the load within the required distance. In motion control, it is desirable that a load be stopped smoothly and without adverse effects such as rebounding or stress upon the machine Shock absorbers fall within two categories – fixed or adjustable. Fixed and adjustable shock absorbers operate on similar principles to a cylinder cushion in that the deceleration is accomplished by forcing internal fluid over a series of restrictions to provide the damping force required. The advantage of the adjustable shock absorber is that the unit can be fine-tuned over a variety of mass and velocity profiles to achieve precise deceleration. Another possible variant is to use a self-adjusting shock absorber which Shock absorbers fall within two categories – fixed or adjustable. Fixed and adjustable shock absorbers operate on similar principles to a cylinder cushion in that the deceleration is accomplished by forcing internal fluid over a series of restrictions to provide the damping force required. The advantage of the adjustable shock absorber is that the unit can be fine-tuned over a variety of mass and velocity profiles to achieve precise deceleration. Another possible variant is to use a self-adjusting shock absorber which Shock absorbers fall within two categories – fixed or adjustable. Fixed and adjustable shock absorbers operate on similar principles to a cylinder cushion in that the deceleration is accomplished by forcing internal fluid over a series of restrictions to provide the damping force required. The advantage of the adjustable shock absorber is that the unit can be fine-tuned over a variety of mass and velocity profiles to achieve precise deceleration. Another possible variant is to use a self-adjusting shock absorber which Shock absorbers fall within two categories – fixed or adjustable. Fixed and adjustable shock absorbers operate on similar principles to a cylinder cushion in that the deceleration is accomplished by forcing internal fluid over a series of restrictions to provide the damping force required. The advantage of the adjustable shock absorber is that the unit can be fine-tuned over a variety of mass and velocity profiles to achieve precise deceleration. Another possible variant is to use a self-adjusting shock absorber which within the cylinder. When the velocity, mass, and a potential applied force is high, then a shock absorber is the best method to control the deceleration of the object without adverse effects. The kinetic energy that is dissipated is converted into heat energy, so consideration must be given to the cycle rate of the shock absorber to ensure that this heat is taken into account. or part itself. The speed of the object and mass of the object will determine the best method to accomplish this. When the velocity, mass, and a is now offered by several manufacturers. These typically have a range of self-adjustment, so it is still is now offered by several manufacturers. These typically have a range of self-adjustment, so it is still is now offered by several manufacturers. These typically have a range of self-adjustment, so it is still is now offered by several manufacturers. These typically have a range of self-adjustment, so it is still potential applied force is high, then a shock absorber is the best method to control the deceleration of the object without adverse effects. The important and necessary to calculate the amount of kinetic energy to be absorbed. important and necessary to calculate the amount of kinetic energy to be absorbed. important and necessary to calculate the amount of kinetic energy to be absorbed. important and necessary to calculate the amount of kinetic energy to be absorbed. Shock absorbers fall within two categories – fixed or adjustable. Fixed and adjustable shock absorbers kinetic energy that is dissipated is converted into heat energy, so consideration must be given to the cycle rate of the shock absorber to ensure that this heat is taken into account. Shock absorbers fall within two categories – fixed or adjustable. Fixed and adjustable shock absorbers operate on similar principles to a cylinder cushion in that the deceleration is accomplished by forcing internal fluid over a series of restrictions to provide the damping force required. The advantage of the adjustable shock absorber is that the unit can be fine-tuned over a variety of mass and velocity profiles to achieve precise deceleration. Another possible variant is to use a self-adjusting shock absorber, now offered by several manufacturers. These typically have a range of Safety tip: Energy that is input to the shock absorber should be accurately calculated if possible or conservatively estimated for worst case. A shock absorber that “bottoms-out” in service because of insufficient energy capacity will cause the mounting structure of the shock to absorb the remaining energy. This may result in damage to the mounting structure, the shock, or both. Safety tip: Energy that is input to the shock absorber should be accurately calculated if possible or conservatively estimated for worst case. A shock absorber that “bottoms-out” in service because of insufficient energy capacity will cause the mounting structure of the shock to absorb the remaining energy. This may result in damage to the mounting structure, the shock, or both. Safety tip: Energy that is input to the shock absorber should be accurately calculated if possible or conservatively estimated for worst case. A shock absorber that “bottoms-out” in service because of insufficient energy capacity will cause the mounting structure of the shock to absorb the remaining energy. This may result in damage to the mounting structure, the shock, or both. Safety tip: Energy that is input to the shock absorber should be accurately calculated if possible or conservatively estimated for worst case. A shock absorber that “bottoms-out” in service because of insufficient energy capacity will cause the mounting structure of the shock to absorb the remaining energy. This may result in damage to the mounting structure, the shock, or both. operate on similar principles to a cylinder cushion in that the deceleration is accomplished by forcing internal fluid over a series of restrictions to provide the damping force required. The advantage of the adjustable shock absorber is that the unit can be fine-tuned over a variety of mass and velocity profiles to achieve precise deceleration. Another possible variant is to use a self-adjusting shock absorber which is now offered by several manufacturers. These typically have a range of self-adjustment, so it is still important and necessary to calculate the amount of kinetic energy to be absorbed. self-adjustment, so it is still important and necessary to calculate the amount of kinetic energy to be absorbed. Safety tip: Energy that is input to the shock absorber should be accurately calculated if possible or

SAFETY TIP: Energy that is input to the shock absorber should be accurately calculated if possible or conservatively estimated for worst conservatively estimated for worst case. A shock absorber that “bottoms-out” in service because of case. A shock absorber that “bottoms-out” in service because of insufficient energy capacity will cause the mounting structure of the shock insufficient energy capacity will cause the mounting structure of the shock to absorb the remaining to absorb the remaining energy. This may result in damage to the mounting structure, the shock, or both. energy. This may result in damage to the mounting structure, the shock, or both.

Fig. 3-30 Shock Absorber Applications Fig. 3-30 Shock Absorber ApplicationsFig. 3-30 Shock Absorber ApplicationsFig. 3-30 Shock Absorber Applications

The typical characteristics of stopping a load fit into one of the six scenarios shown in Fig. 3-30: The typical characteristics of stopping a load fit into one of the six scenarios shown in Fig. 3-30: The typical characteristics of stopping a load fit into one of the six scenarios shown in Fig. 3-30: The typical characteristics of stopping a load fit into one of the six scenarios shown in Fig. 3-30: There are four (4) parameters that must be known to accurately size a shock absorber. There are four (4) parameters that must be known to accurately size a shock absorber. There are four (4) parameters that must be known to accurately size a shock absorber. There are four (4) parameters that must be known to accurately size a shock absorber. • • Mass to be decelerated m (kg) or (slugs)• Mass to be decelerated m (kg) or (slugs)• Mass to be decelerated m (kg) or (slugs)Mass to be decelerated m (kg) or (slugs) • • Impact velocity v (m/s) or (ft./sec.)• Impact velocity v (m/s) or (ft./sec.)• Impact velocity v (m/s) or (ft./sec.)Impact velocity v (m/s) or (ft./sec.) • • Propelling or driving force F (N) or (lb.)• Propelling or driving force F (N) or (lb.)• Propelling or driving force F (N) or (lb.)Propelling or driving force F (N) or (lb.) • • Number of impact cycles per hour C (#/hr)• Number of impact cycles per hour C (#/hr)• Number of impact cycles per hour C (#/hr)Number of impact cycles per hour C (#/hr)

The total energy that will need to be absorbed by the shock absorber is the sum of the kinetic energy and any applied force or thrust energy imparted to the object. The first step in these scenarios is to calculate The total energy that will need to be absorbed by the shock absorber is the sum of the kinetic energy and any applied force or thrust energy imparted to the object. The first step in these scenarios is to calculate The total energy that will need to be absorbed by the shock absorber is the sum of the kinetic energy and any applied force or thrust energy imparted to the object. The first step in these scenarios is to calculate The total energy that will need to be absorbed by the shock absorber is the sum of the kinetic energy and any applied force or thrust energy imparted to the object. The first step in these scenarios is to calculate Fig. 3-30 Shock Absorber Applications Figure 1: Shock absorber applications. the kinetic energy of the moving load which is given by the formula: the kinetic energy of the moving load which is given by the formula: the kinetic energy of the moving load which is given by the formula:the kinetic energy of the moving load which is given by the formula: The typical characteristics of stopping a load fit into one of the six scenarios shown in Fig. 3-30: The typical characteristics of stopping a load fit into one of the six scenarios shown in figure 1. There are four parameters that must be known Eq. 3.22 E = 1 2 • mv2 E = Kinetic energy ft.-lb. m = mass slugs v = velocity ft./sec. E = Kinetic energy Joules m = mass kg v = velocity m/sec. Kinetic energy of an object to be dissipated by shock absorber. Eq. 3.22 E = 1 2 • mv2 E = Kinetic energy ft.-lb. m = mass slugs v = velocity ft./sec. E = Kinetic energy Joules m = mass kg v = velocity m/sec. Kinetic energy of an object to be dissipated by shock absorber. Eq. 3.22 E = 1 2 • mv2 E = Kinetic energy ft.-lb. m = mass slugs v = velocity ft./sec. E = Kinetic energy Joules m = mass kg v = velocity m/sec. Kinetic energy of an object to be dissipated by shock absorber. Eq. 3.22 E = 1 2 • mv2 E = Kinetic energy ft.-lb. m = mass slugs v = velocity ft./sec. E = Kinetic energy Joules m = mass kg v = velocity m/sec. Kinetic energy of an object to be dissipated by shock absorber. There are four (4) parameters that must be known to accurately size a shock absorber. • Mass to be decelerated m (kg) or (slugs) • Impact velocity v (m/s) or (ft./sec.) • Propelling or driving force F (N) or (lb.) to accurately size a shock absorber: • Mass to be decelerated m (kg) or (slugs) • Impact velocity v (m/s) or (ft./sec.) • Propelling or driving force F (N) or (lb.) • Number of impact cycles per hour C (#/hr)• Number of impact cycles per hour C (#/hr)

The total energy that will need to be absorbed by the shock absorber is the sum of the kinetic energy and any applied force or thrust energy