5 years without breakage

Product selected for:

ENGLISH

+30% cooling capacity -30% energy consumption

Results achieved only by dry coolers equipped with “5 years without breakage preventive maintenance programme“

IDROTECH Copyright© Idrobase Group. All rights reserved. Adiabatic cooling for dry coolers with preventive maintenance programme Pump maintenance 750 hours Pump maintenance 1500 hours Machine maintenance 3000 hours Machine maintenance 750 hours

years without breakage

5

FOG Adiabatico 5 Years Without Breakage

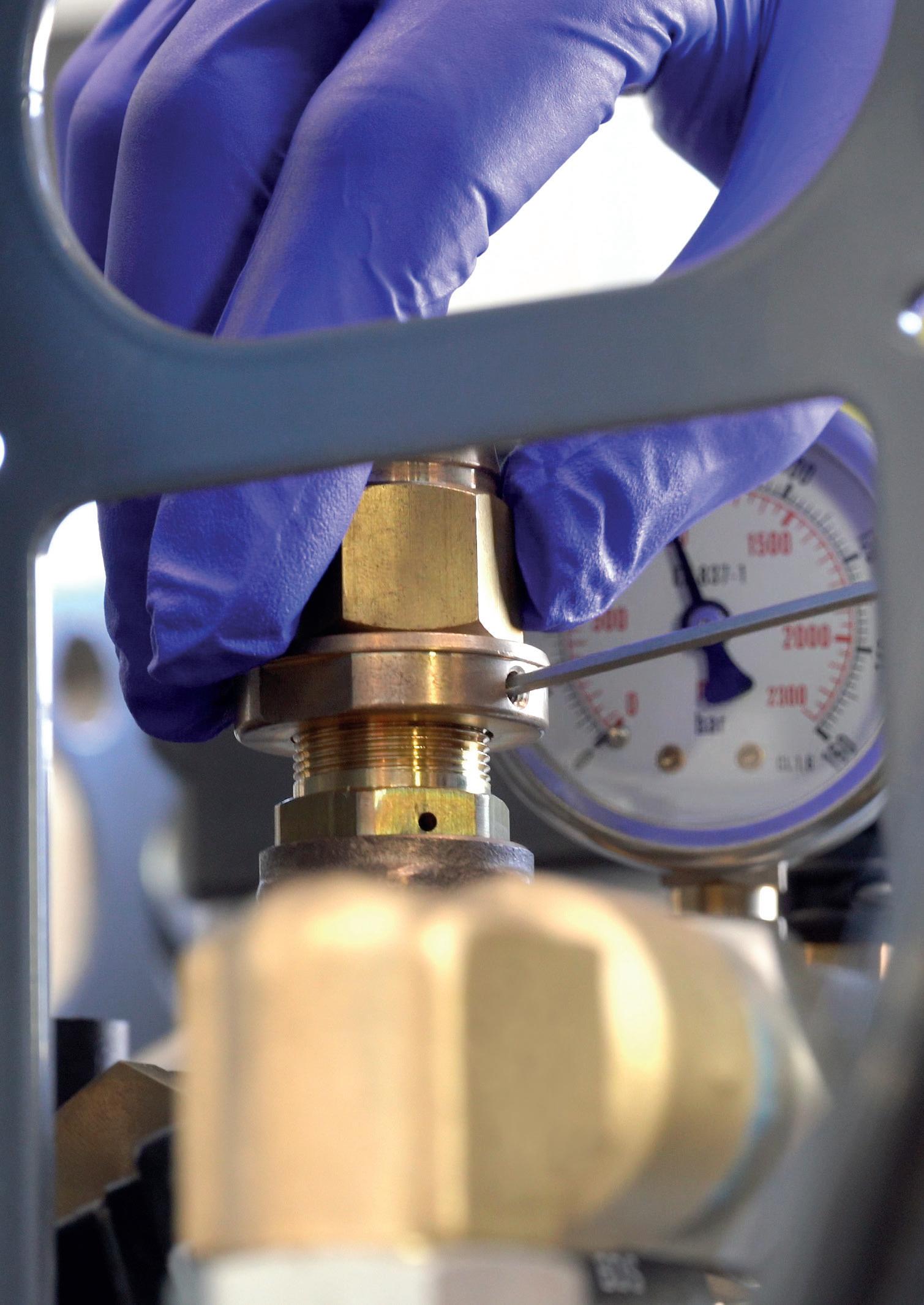

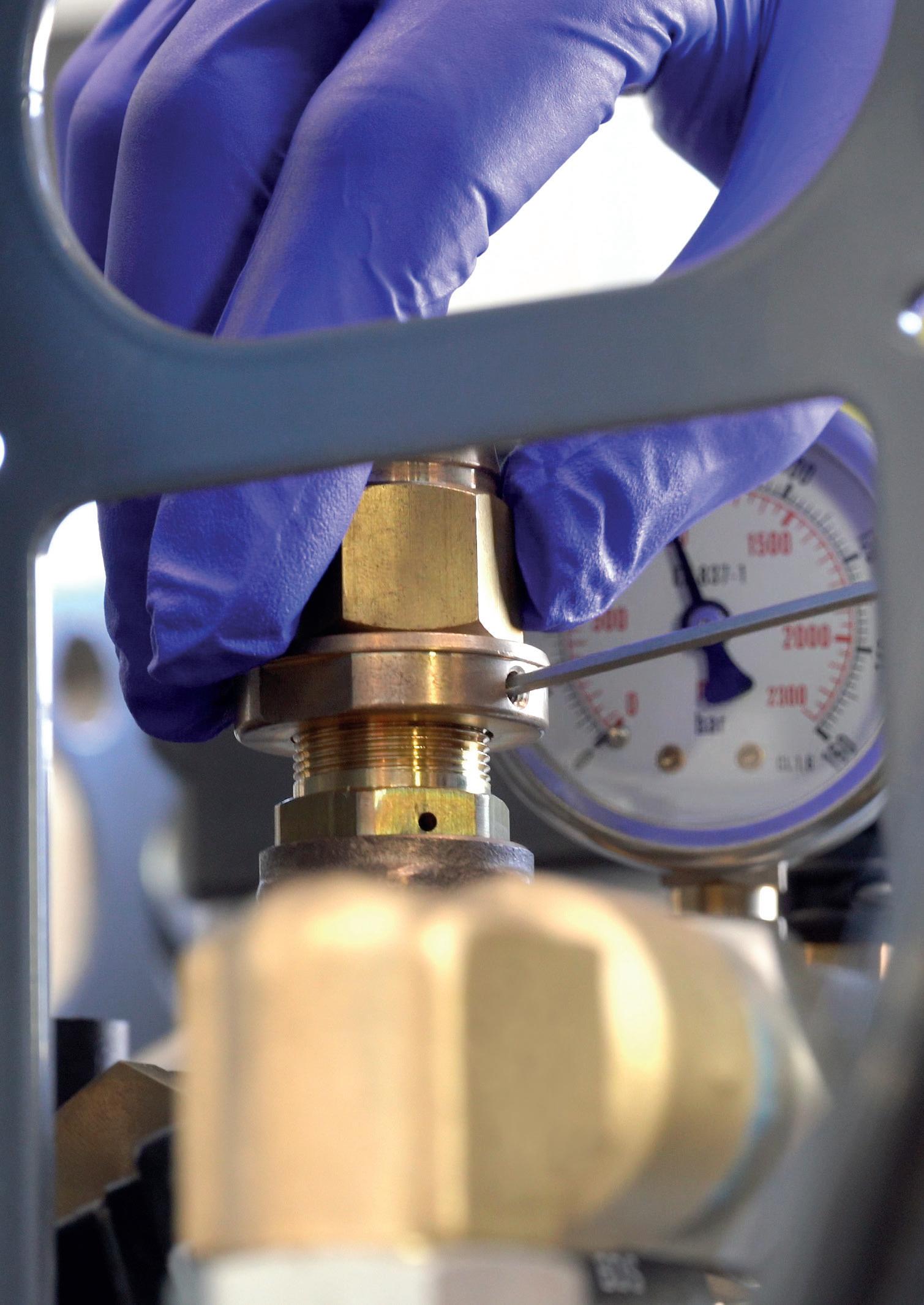

FOG Adiabatico 5 Years Without Breakage is a high-pressure adiabatic system for dry coolers designed, studied and engineered to maintain constant and optimal performance for 5 years, eliminating machine downtime and service requests.

Washing

Key benefits

• Increase cooling capacity up to 30%

• Energy consumption decrease, up to 30%

• Increase the efficiency of HVAC & reduce running cost

• Maintenance is minimized & extend the life of the system

• Lowe investment cost

• Quick installation

Copyright© Idrobase Group. All rights reserved.

Adiabatic System Kit Description ZX.FAD-0401 1 dry cooler FOG 70, 70bar misting module, 4l/min 1,5kW (3x100V) • Polyamide pipe for high pressures ø9,6mm (in metres) 1 AISI 303 stainless steel pipe ø9,6mm 52 Slip lock smart Slip Lock ø9,6mm, made of AISI 303 stainless steel 50 Tube cutter for polyamide pipe ø2-12mm 1 “Tee” pipe connection quick fitting, “tee”, ø9,6mm 4 Line end cap in AISI 316 stainless steel, ø9,6mm 4 Maintenance Kit Description ZX.75IBG10 - Preventive maintenance B, 750 hours, pump 4L ZX.150IBG10 - Preventive maintenance D, 1500 hrs, pump 4L ZX.75F70-C - Preventive maintenance E, 750 hours, Fog 70 Extra ZX.300F70-B - Preventive maintenance F, 3000 hours, Fog 70 Extra Optional Description

kit complete

CdR 80

outlet

NPT-F 900mm, 10m

with ECO1 spray gun,

lance, moulded handle, with bend -

1/4”

hose

5 years without breakage

Copyright© Idrobase Group. All rights reserved. IDROTECH

A Set A

Pump manintenance at: 500 hours, 1.500 hours, 2.500 hours, ecc

B Set B

Pump manintenance at: 750 hours, 2.250 hours, 3.750 hours, ecc

C Set C Pump manintenance at: 1.000 hours, 2.000 hours, 3.000 hours, ecc

D Set D

Pump manintenance at: 1.500 hours, 3.000 hours, 4.500 hours, ecc

Set E

E

F

Pump manintenance at: 750 hours, 1.500 hours, 2.250 hours, 3.750 ore, ecc

Set F Pump manintenance at: 3.000 hours, 6.000 hours, 9.000 hours, ecc

• • • • • • • • • • • • • • • • • • • • • Copyright© Idrobase Group. All rights reserved. MAINTENANCE SET

AND MACHINE

PUMP AND MACHINE MAINTENANCE 500 hours 750 hours 1.000 hours 1.500 hours 2.000 hours 2.250 hours 2.500 hours 3.000 hours 3.500 hours 3.750 hours 4.000 hours 4.500 hours → ∞

PUMP

MAINTENANCE

EXAMPLE

FOG 70 EXTRA (ZX.F70X21) MACHINE MAINTENANCE

Set E - machine maintenance

750 hours consisting of:

750hrs - HP industrial fog module maintenance

By-pass valve service kit

Hollow perforated screw with washer

String-wound cartridge, 1micron

String-wound cartridge, 5microns

10ml Threadlocker medium 25ml Technical grease

Set F - machine maintenance

3000 hours consisting of:

3000hrs - HP industrial fog module maintenance

Solenoid valve brass, NC, 3/8” FF, 230V, (1)

Solenoid valve brass, NC, 1/4” FF, 230V, (3)

Pressure switch (3)

By-pass valve (4)

String-wound cartridge, 1micron (5)

String-wound cartridge, 5microns (6)

Thermal switches Transparent hose 10ml Threadlocker medium 25ml Technical grease

(1) (3) (5) (2) (4) (6)

Idrobase Group. All rights reserved.

Copyright©

ENGLISH

Copyrights© to this catalogue belong to IDROBASE GROUP® Srl. Reading, reference and dissemination in paper or electronic formats for personal use are permitted. Use for commercial purposes is not permitted, nor is any type of alteration except with the written consent of IDROBASE GROUP® Srl.

This catalogue cancels and supersedes the earlier version.

This catalogue provides general information on the products supplied by IDROBASE GROUP® Srl.

It is intended for retailers, system engineers, designers and more generally, all those who are already adequately familiar with said products, the materials from which they are made, their characteristics, efficiency and operation; it is therefore not intended for consumers who, in order to handle, install or perform any operation with the goods described here, must necessarily contact qualified and skilled personnel.

Also, with regard to skilled personnel, this catalogue should be considered a mere commercial tool, not containing the necessary technical specifications - which may be obtained free of charge from Idrobase, and as such, not suitable for use as a single go-to reference tool for the design, construction or installation of any kind of system.

The illustrations, technical characteristics, functions and other information given here about individual products, systems, installations and the like are based on the current state of the art: however, only the most immediately applicable information can be reproduced here, without any consideration for the global data necessary to design, implement and install any system, which must therefore be carefully assessed by designers, system engineers and installers.

Therefore, for specific indications on all products in the catalogue, please contact our main office, where competent staff are always on hand to answer any additional queries.

All the illustrations reproduced here may be slightly different from actual products and therefore, they should simply be intended as closely representing real items.

We reserve the right to introduce changes in all the products. For this reason, too, it is advisable to directly contact our main office.

In case of doubts regarding interpretation, the original Italian text will prevail.

When a new reprint is published, the present edition will no longer be valid.

Idrobase Group Srl

Via dell’Industria, N. 25 35010 Borgoricco (PD) Italia

T: +39 049 9335903 r.a.

www.idrobasegroup.com info@idrobasegroup.com

Recognition of maximum commercial reliability