21 minute read

How TSN is revolutionizing industrial automation

Digital transformation is opening up exciting new opportunities for industrial automation and manufacturing. The benefits for manufacturers to embrace the IIoT are manifold, providing deterministic services and integrating the “islands of automation” isolated by the purpose-built protocols of the past.

FROM REDUCING MACHINE DOWNTIME TO adopting entirely new business models, Industry 4.0, as this new wave of digital transformation has also been called, is revolutionizing the global economy in unprecedented ways.

In the past, manufacturers often had to adopt purpose-built protocols and systems, instead of standard Ethernet technologies, for specific industrial control applications. Although early Ethernet networks were only capable of best-effort communications, standard Ethernet has come a long way in recent years.

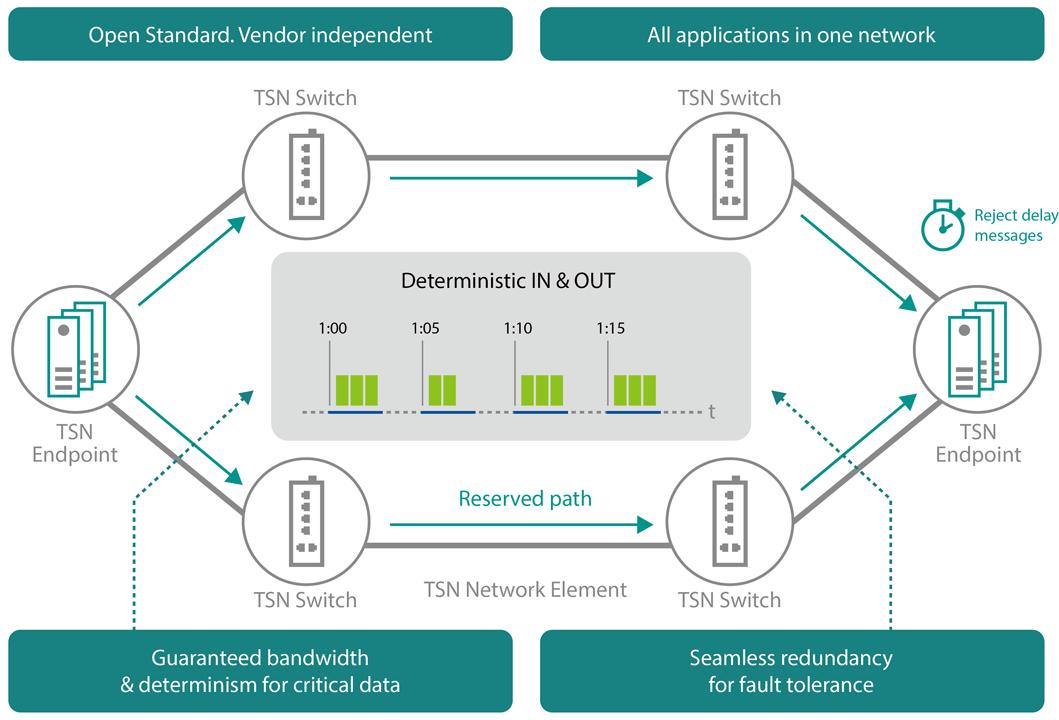

With the advent of Time-Sensitive Networking (TSN), standard Ethernet networks are now able to provide deterministic services and integrate the “islands of automation” that were isolated by the numerous purpose-built protocols of the past.

To define a truly unified network infrastructure for the future of smart manufacturing, international standards organizations and hardware vendors such as Moxa are coming together to develop solutions with Time-Sensitive Networking as the foundation.

With TSN forming a solid base for implementing true IIoT networks, global manufacturers can finally reap the full benefits promised by Industry 4.0.

In this article, you will learn: • How smart manufacturing and the IIoT require deterministic networking and real-time communications for industrial applications over high-bandwidth, low-latency networks • How traditional best-effort Ethernet networks are evolving into TimeSensitive Networks that enable deterministic services on standard Ethernet technologies • How international standards organizations and device vendors such as Moxa are collaborating to make TSN the future foundation of industrial networking

Going beyond the digits

The world today is witnessing a new dawn for digital transformation that will require manufacturers to rethink their existing business models and industrial automation infrastructures. To remain relevant and competitive in the age of “Industry 4.0”, manufacturers need to do more than simply adopt digital technologies and deploy predefined processes in isolated islands of automation as they have done in the past.

The future of industry rests on understanding the factors driving this new wave of digitization, the limitations of the current model of industrial automation to achieving digital transformation, and how to overcome these limitations to realize the full benefits of Industry 4.0.

Today's Purdue Model.

Tomorrow's Purdue Model.

Driving digital transformation

The foundation of the current trend of automation and data exchange in manufacturing technologies, also called “Industry 4.0” or the “Industrial Internet of Things” (IIoT), is essentially digitization. By converting analog signals, sounds, images, texts, and other information into a computerreadable format, digitization has been transforming the very nature of industries for decades.

Not only have traditional industries been able to improve efficiency and productivity, but previously unimaginable opportunities

SOURCE: MOXA

Fully Centralized Time-Sensitive Networking (TSN) Model.

have also opened up and revolutionized the way we do business all over the world. For the foreseeable future, these trends are going to keep pushing growth at a very strong rate and there is expected to be significant benefits to not just the industrial sector, but the global economy.

Yet digital transformation in industry involves more than the process of converting analog information into a series of 1s and 0s. For manufacturers to make sense of all these bits of information, the data must be transported from countless sensors and equipment on the factory floor and processed for humans or other machines to make informed decisions in real time. Necessarily, digital transformation for smart manufacturing encompasses the various networking technologies and protocols that enable seamless communication and greater visibility among all walks of digitized equipment from sensors to sophisticated robots with artificial intelligence.

Indeed, the ability of digitization to enable the integration of data from connected devices and the ability to collect and act upon performance-enhancing feedback is driving many manufacturers to adopt IIoT technologies. Companies have clear motivations to adopt smart manufacturing in order to improve operational efficiency and business practices. Whether they seek to reduce machine downtime, improve performance to open new opportunities for business innovation, or adopt entirely new business models, such as offering productsas-a- service—manufacturers are embracing digital transformation.

Limits of industrial automation

Ever since the industrial revolution, manufacturers have been looking for ways to increase productivity. Following the mechanization of production, manufacturers have embraced device connectivity as a means to improving efficiency and profits.

Beginning in the 1980s, manufacturers began adopting digital devices, which led to the emergence of industrial automation as we know it today. A helpful way to visualize the current architecture of industrial automation is the often-referenced Purdue model.

In the current Purdue model, industrial automation forms a pyramid where isolated purpose- built protocols occupy distinct layers.

However, this model also gives rise to a number of infrastructure challenges for industrial networks today. Although independent purpose-built protocols may be very good at automating the original tasks for which they were developed, they are essentially speaking different “languages” which results in real-time communication difficulties.

Traditional industrial networks in this model are also tuned for latency and control, unable to “share the wire”, and are often limited to 100 Mb/s (or lower) transmission speeds that ultimately hinder scalability.

Furthermore, using proprietary hardware and software for multiple applications obstruct interoperability and increases maintenance and operation costs. Consequently, systemic integration and visibility across layers becomes difficult to achieve, which negatively affects the overall value chain.

Evidently, manufacturing strategies also need to evolve for companies to remain globally competitive. Today, customer demands are becoming increasingly diversified and companies are looking for ways to satisfy these new and future needs while also increasing operational efficiency. Businesses strive to remain competitive globally by becoming as nimble, efficient, and responsive as possible.

Gone are the days when manufacturers could scale their production based on sales forecasts alone. Instead, manufacturers may need to leverage relevant insights from big data analytics to help fulfill customer demands in real time and optimize production at lower costs. This is just one example of how manufacturers can deploy the latest technology to move towards “Industry 4.0” and come out ahead.

Equipment, devices, and people in complex and global operations are more connected than ever due to the fact that industries are continuing to digitize, automate, and innovate.

Ultimately, industrial networks need to catch up with market and industry developments to ensure that businesses can turn the efficiency, flexibility, and availability made possible by a more reliable and scalable network into better performance, higher employee and customer satisfaction, as well as more growth.

The future of industrial automation

The traditional Purdue model, as represented by the “automation pyramid”, outlines different layers of network communication that remain fragmentary and potentially unreliable and difficult to maintain, particularly in the long term.

Calls within the industry have been made to move towards an “autonomous pyramid” that is capable of responding to market and business conditions in real-time. In this newly envisioned architecture, isolated islands of automation and network data flows are able to communicate with each other through common semantics and a unified infrastructure.

This new “autonomous pyramid” envisions the future of industrial automation as a seamlessly connected system where: • Small-scale, static, and isolated control loops evolve into larger-scale, dynamic, and open control loop communications, also known as cyber-physical systems” (CPS) that deeply intertwine software and physical components. • Formerly closed loop data can openly communicate across a common foundation, enabling new bilateral data communication flows that can intelligently interact with each other. • All business assets, from equipment to materials to personnel, are intelligently connected in a unified infrastructure that enables the fulfillment of diverse customer needs through end-to-end

“autonomous” communications, collaboration, reaction, adaptation, and optimization, all at the “right times”.

By using a unified network infrastructure for a multitude of disparate applications— including automation, maintenance, analytics, and more—manufacturers can achieve the following benefits.

As different end devices are able to talk to each other in real time, configuring the system, devices, and applications to enable a real-time feedback loop becomes significantly easier.

A unified, context-driven network structure also allows machine learning to take place, so in the long term, it is possible to leverage big data analytics and respond accordingly, further increasing made-to-order flexibility and efficiency.

Improved access to data allows for production monitoring to be conducted in real time, so higher quality, more detail-oriented KPIs can be established under different scenarios.

A more robust network infrastructure can support more applications for equipment on the shop floor, such as counting, sorting, quality control, and video surveillance. Machines no longer work in isolation but act in tandem with other machines to improve productivity, thanks to all the real-time data fed into the system. Combined with developing technologies in robotics and machine sensing, such as motion guidance, augmented reality, machine vision, and haptics, factory assets can deliver optimized performance at lower costs.

Standardized technologies and a scalable structure, such as those based on Ethernet standards, afford much greater flexibility. Through standardization of infrastructure technologies and protocols, topological differences—which used to present significant challenges for network configuration—can be managed in similar ways as other modular units or extensions. Building, maintaining, and removing layers are more cost-effective and less time-consuming.

Indeed, a unified infrastructure that breaks down the barriers separating the islands of automation in today’s Purdue model will create a system of connected, physical industrial objects and allow them to exchange and analyze data with the purpose of generating value- added information. In doing so, the Industrial Internet of Things enables the right decisions to be made at the right time and place, thereby transforming formerly predefined processes into truly dynamic processes.

Ultimately, the future of industrial automation and control systems is about the integration of information and Internet technologies that continue to satisfy requirements for high availability and real-time communications, and also supports the development of new products and innovative solutions based on the optimal balancing of costs and benefits. More precisely, the unified network infrastructure of the future also requires deterministic communication capabilities that can ensure performance and QoS as well as, or better than, the purposebuilt protocols that isolate our current islands of automation today.

Thankfully, standards organizations and independent vendors have recognized the potential benefits of Industry 4.0 and are working together to develop a new, unified foundation for industrial networks: TimeSensitive Networking.

Fully Centralized Time-Sensitive Networking (TSN) Model.

Setting the standards: TSN

Heeding the call for a unified yet deterministic infrastructure, TSN is a collection of standards that enables deterministic messaging over standard Ethernet networks. As defined by the Institute of Electrical and Electronics Engineers (IEEE), TSN involves a form of network traffic management to ensure non-negotiable time frames for end-to-end transmission latencies.

Consequently, all TSN devices must synchronize their clocks with each other and use a common time reference to support real-time communications for industrial control applications. Although TSN standards were initially developed by the IEEE, it is important to recognize that TSN goes beyond the main IEEE standards and includes the hard work and collaborative efforts of many international organizations and companies.

Early standard Ethernet networks were incapable of guaranteeing data delivery and subject to high latency. As a result, industries that required high network reliability and availability developed their own specialized, proprietary networking solutions (e.g., modified Ethernet networks, fieldbuses) for industrial control systems and automation.

To meet the high availability and low latency requirements of industrial applications for manufacturing, traditional best-effort Ethernet technologies have had to evolve to become more deterministic. TSN is essentially the next stage in the evolution of standard Ethernet technologies to satisfy the requirements of our IIoT future.

Besides providing a set of standards for deterministic services over Ethernet, TSN is bringing together many different industry organizations and market leaders under a common goal to realize the full potential of Industry 4.0 and the promise of digitization.

Evolving best-effort networks

Traditional Ethernet networking technologies generally include hubs and switches that employ best-effort packet delivery. Most of the time, data packets are successfully delivered in sequence, but there are no guarantees. Although best-effort networks may perform adequately for web browsing applications, industrial control applications require higher availability, zero packet loss, and lower latency. After all, if there are no guarantees for packet delivery, critical control data might

What's Time-Sensitive Networking?

not be delivered to the right place at the right time.

In the 1980s, when manufacturers started migrating to digital technologies from mechanical or analog technologies, best-effort Ethernet networks were not considered a suitable infrastructure option for industrial control systems that required high precision, availability, and guaranteed real-time transmissions, despite offering higher bandwidths compared to traditional fieldbuses.

Besides the prohibitive costs of Ethernet technologies at the time, Ethernet retransmission algorithms and collision detection could not satisfy the performance requirements for industrial control systems. Consequently, manufacturers had to develop purpose-built systems and protocols to enable digitization through deterministic networking.

Unlike best-effort networking, deterministic networks support the following services: • Time synchronization • Resource reservation • Extremely low packet loss • Guaranteed end-to-end latency and bandwidth

Since those early days of Ethernet and industrial automation, networking technology has evolved considerably. In fact, modern Ethernet technologies can even supply deterministic services that meet the needs of many industrial applications that formerly required proprietary systems and protocols.

Due to the growing trend towards converged networks and the corresponding increase in demand for bandwidth, truly deterministic Ethernet networks could be more cost-effective and future-proof than purpose-built networks.

Determinism and TSN

To enable truly converged networks that can stream real-time controls, as well as audio/ video in industrial facilities, the TSN task group of the IEEE 802.1 working group is defining a set of standards for the deterministic data transmission over Ethernet networks. As a collection of standards, TSN is more like a tool box than an all-in-one solution; you need to understand what “tools” are available and how each tool works in order to determine which tools are suitable for your application.

As the key protocols described in the following table indicate, Time-Sensitive Networking standards focus on the following main areas: • Time synchronization • Latency • Reliability • Resource management

As the name “Time-Sensitive Networking” suggests, TSN requires all network equipment to implement IEEE 802.1AS (IEEE 802.1ASRev in the future), which defines standards for timing and synchronization. After all, a shared concept of time among all end devices and Ethernet switches is one of the key characteristics of deterministic networking. In addition, IEEE 802.1Qbv defines how devices must transmit time-critical frames according to a hard schedule, but also retain best-effort communications for other bulk traffic sharing the same “line”.

Besides the network infrastructure itself, TSN also requires a new approach to handling data streams and corresponding requirements that require more complex computations.

Consequently, IEEE 802.1Qcc defines the management interfaces, mechanisms, and principles for enabling a new approach to network administration.

For illustrative purposes, TSN can be viewed as a railway system where trains are analogous to Ethernet frames of data. In this example, Ethernet switches and end devices are like railway stations. Imagine what would happen if each railway station kept a different local

The Road toward IIoT and Industry 4.0

time without following a strict timetable for the entire system.

If a train departs from Station A, how will passengers know when the train will arrive at Station B if the stations do not share a common reference for time? This problem was precisely why railroads began standardizing time for railway passengers and trains, and also demonstrates why industrial networks require time synchronization.

Managing network traffic

An integral part of TSN is a management model that manages and directs traffic streams on the network and allows the family of IEEE protocols to be configured for successful operation on the same network.

In our railway system analogy, the network management model is akin to a railway signaling system that handles train (data) traffic, so the trains (payloads) arrive at their destinations without colliding with one another. As stated in the IEEE P802.1Qcc protocol, there are three possible management models, which include a fully centralized model, a fully decentralized model, and a partially centralized model.

In the fully centralized model, end devices initiate communication with the centralized management entity regarding their stream requirements. The centralized management entity then uses these requests to work out the necessary schedule of streams on the network to satisfy those requirements and configures the switches and end devices (represented by railway stations in our analogy) accordingly.

In the fully decentralized model, open streams are offered by talkers to listeners (usually end devices) and an application on an end device notifies the network elements along the way to reserve the resources required for a particular stream. No central management entity is necessary in this approach.

Although there is a centralized management entity in the partially centralized model, the data from the end devices are passed to the closest bridge over a standardized protocol before being forwarded to the centralized management entity. In other words, the centralized management entity in the partially centralized model only manages individual network traffic streams and resources without addressing, at a global level, the stream requirements or payload data from every end device.

As defined by the IEEE 802.1CB protocol, “Standard for Local and metropolitan area networks - Frame Replication and Elimination for Reliability”, TSN stream identification offers several different ways to identify streams. These methods include destination MAC address and VLAN identifier, source MAC address and VLAN identifiers, and others. In addition, stream Identification is used to compute the flow of data for a specific stream through the network as well as to handle redundant paths for fault tolerance.

Fully centralized model

Although the fully centralized network management model is not the only approach for handling traffic in Time-Sensitive Networking, the model is the most straightforward of the three methods for illustrative purposes. As previously discussed, the fully centralized network management model has a centralized management entity that performs two critical roles. In the following diagram, these functions are represented by the Centralized User Configuration (CUC) and Centralized Network Configuration (CNC).

The fully centralized TSN model includes the following five components:

End Stations (Talkers and Listeners):

These end devices run applications that require time-critical deterministic communications and function as the sources (talkers) and destinations (listeners) of the Ethernet frames transmitted through the TSN system.

Bridges (Ethernet switches): TSN bridges are Ethernet switches that send and receive the Ethernet frames comprising the timecritical communication streams. The hardware can be developed by any vendor but must be capable of transmitting messages according to a strictly synchronized schedule.

Centralized User Configuration (CUC): The Central User Configuration is a vendor-specific application that communicates with the CNC and the end devices. The CUC represents the control applications and the end stations, requesting deterministic communication with the CNC.

Central Network Configuration (CNC): The Central Network Controller is a vendor-specific application that facilitates deterministic messaging for control applications on the network and defines the schedule according to which all the time-critical information streams are transmitted and then deployed to the TSN-enabled bridges (Ethernet switches).

Time-Critical Information Streams: The information transmitted between talkers and listeners in the TSN model comprise time-critical “streams”. Each time-critical information stream between talkers and listeners in the TSN model is uniquely identified by the end devices and has stringent time requirements that need to be honored for deterministic messaging.

In contrast to the fully distributed or partially centralized models that only handle individual requirements or network capabilities separately, the fully centralized TSN model uses centralized methods to represent both the “user requirements” and the “network capabilities” in order to automatically integrate all components throughout the entire system. Although the fully centralized model offers improved integration, more complex computations are required to ensure better network utilization. In the end, whichever TSN model you choose depends on the particular requirements for your application and fall outside the scope of the IEEE standards developed by the TSN task group.

Coming together for Industry 4.0

TSN technologies offer a scalable, predictable approach to deterministic networking over standard Ethernet. But since TSN is more of a toolbox than a single, comprehensive solution, system integrators must ultimately rely on independent vendors and multiple protocols to satisfy the specific requirements for each industrial application. This predicament is precisely why interoperability is the key to ensuring the success of TSN adoption. Ultimately, a unified infrastructure based on TSN fundamentally requires interoperability on two critical fronts: • A common architecture that is TSN-compliant for Layer 2 networking and messaging • Common semantics for communication across multiple protocols throughout the network

Recognizing the benefits of Industry 4.0 and the future of smart manufacturing, global standards organizations, working groups, and independent vendors are putting their “best effort” into building a common infrastructure and enabling interoperability so that machineto- machine collaboration, data access from cells, and more applications can be realized.

Layer 2 interoperability

As a deterministic Ethernet standard, TSN is essentially a Layer 2 technology within the Open Systems Interconnection (OSI) model of computer networking. Also called the Data Link Layer, Layer 2 encompasses technologies that are programmed to forward Ethernet frames.

In order to fulfill the Industry 4.0 requirements of real-time communication over low-latency networks, robustness despite high network loads, and converged data transport for both information technology (IT) and operation technology (OT), many Ethernet switch manufacturers and industry organizations are adopting the open TSN standards developed by the IEEE.

In collaboration with other leading Ethernet switch providers, Moxa contributes directly to the development of Layer 2 technologies by implementing deterministic Ethernet communications on future-ready solutions that conform to IEEE 802.1 TSN standards. With TSN-ready Ethernet switches from manufacturers like Moxa, system integrators can fulfill the high-bandwidth real-time requirements of Industry 4.0 without changing their existing application programs.

Furthermore, they can do this and add “plugand-produce” devices to converged networks by simply using standard IEEE Ethernet switches. Indeed, TSN-ready Ethernet switches enable highly deterministic networks for IIoT and Industry 4.0 applications that perform as well—if not better than—traditional proprietary systems. In addition to delivering scalability, flexibility, high bandwidth, and high availability, TSN Ethernet switches are cost effective to deploy and maintain.

Besides providing the standard Ethernet hardware used to construct a unified infrastructure that conforms to TSN standards, Moxa has been actively participating in cross-vendor TSN plugfests (events where the designers of electronic equipment test the interoperability of their products for a technical standard with products of other manufacturers) and testbeds around the world.

Interoperability beyond Layer 2

Even though devices within the “autonomous pyramid” of the future can be developed by independent vendors, each piece of equipment must be able to communicate with every other component in the system—not just Layer 2 devices—in order to realize the full benefits of the Industrial Internet of Things. Besides removing the barriers that isolate traditional islands of automation at the Layer 2 level, a successful TSN implementation requires protocol interoperability across layers to enable more flexible topologies and open up new opportunities for industrial applications.

OPC UA companion specifications

The OPC UA companion specs allow companies with existing machines communicating via different protocols to map to the OPC Unified Architecture enabling the IIoT communications. In fact, EtherCAT, MTConnect, PROFINET, Sercos, Powerlink, and others has accomplished their mapping into OPC UA companion specification.

The OPC UA companion specs provide a way to represent different industrial protocols where the information usually structured in different format into a shared universal language (OPC UA). In this way, machines from different vendors can enable interoperability without immediately abandoning their existing systems and protocols.

A universal language: OPC UA

Although the OPC UA companion specs provide an intermediary solution for machine interoperability, a new initiative is to leverage OPC UA as a common platform for all levels of applications from field to cloud no matter horizontally or vertically. Since OPC UA can be used to completely describe complex systems and semantics, it is possible for industrial automation applications to leverage OPC UA for “native” protocol interoperability combining with the support of TSN technologies. For instance, if everyone in the world spoke the same language, nobody would require a dictionary to communicate with anyone else.

Indeed, the benefits of seamless interoperability without the need to translate between different protocols are clearly driving industry organizations and independent vendors to support a common language (OPC UA) for the future of industrial automation.

By adopting one unified network infrastructure, it is possible to enable bilateral IIoT data communications from sensors, actuators, machines, and controllers on the factory floor to the cloud without sacrificing performance on the industrial control/ automation. However, greater integration and interconnection also exposes industrial systems to cybersecurity risks. But just because there are risks involved does not mean manufacturers should avoid adopting IIoT technologies and forgo the benefits of TimeSensitive Networking over standard Ethernet.

Thankfully, IEC is also developing global standards for industrial network and system security, such as IEC 62443. Consequently, choosing these advanced technologies can shore up the unified architecture of future IIoT networks and mitigate the risks of tapping into the opportunities afforded by Industry 4.0 and digital transformation.

Unified foundation for success

Today, the arrival of Time-Sensitive Networking means that standard Ethernet technologies are able to provide deterministic services, evolving beyond the traditional limitations of best- effort communications. With TSN, manufacturers no longer need to confine their applications to isolated islands of automation with purpose-built protocols and control systems.

Instead, industrial applications can look forward to an integrated future with new bilateral communication flows that transcend the horizontal and vertical compartments of the traditional Purdue model.

Indeed, as international standards organizations and device vendors like Moxa continue to coalesce around TSN, standard Ethernet technologies are well positioned to become the future foundation of industrial networking in the IIoT era.

Jack Lin, Product Manager, Moxa.