12 minute read

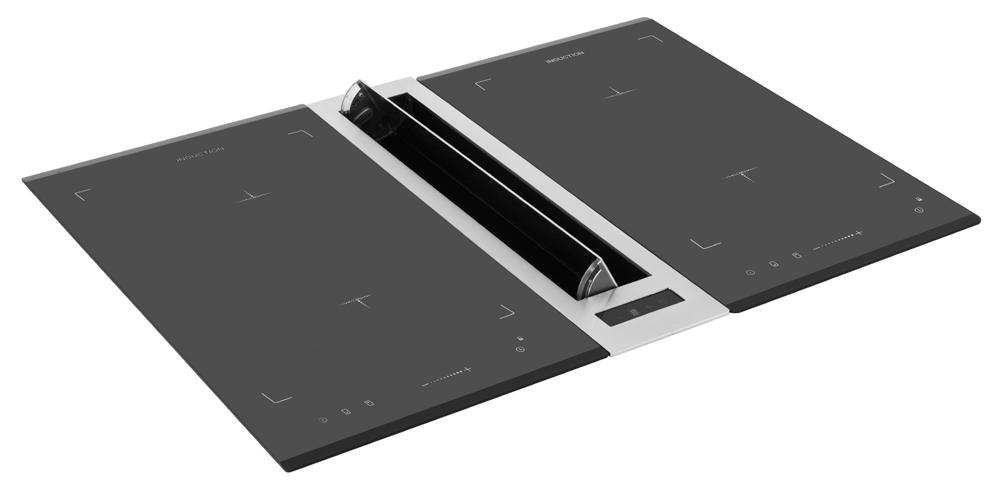

Flow In: Induction hob & extraction hood

by ikonnz

“We love working with the Flow-In because it gives us the freedom to design kitchens to the new open plan living requirements of modern homes but also works well for small kitchens. With the advantage of the downdraft, the cooking can easily be done on the island facing towards the living room, where the family meets, and friends are entertained. This is what makes the kitchen the heart of a home.”

Annett Todt, Living Design

Advertisement

Air extraction that can be directed by 80 degrees to the left and right

Easy cleaning thanks to the detachable inner body

Integrated extraction – Hi -performance extraction system quickly removes the fumes from your cooking surface

• Cooking odours are suctioned directly downwards from the hob into the extractor hood • Not only for conventional kitchens, but also island units, where it may not be possible to install a traditional extractor hood. • Can be flush mounted into your worktop. • The hood is easy to remove and provides direct access to the stainless steel filter which means easy cleaning.

FREE FLOW 3416

Inox Extractor

DOUBLE FLOW 3417

Black & Inox Extractor

BOTH THESE EXTRACTORS CAN ALSO BE ORDERED AS EXTRACTOR AND ONE HOB

300

Carbon & recirculation filters (optional) available as accessory

300

FLOW IN 3413

Inox Extractor

ANOTHER INNOVATIVE PRODUCT FROM IKON!

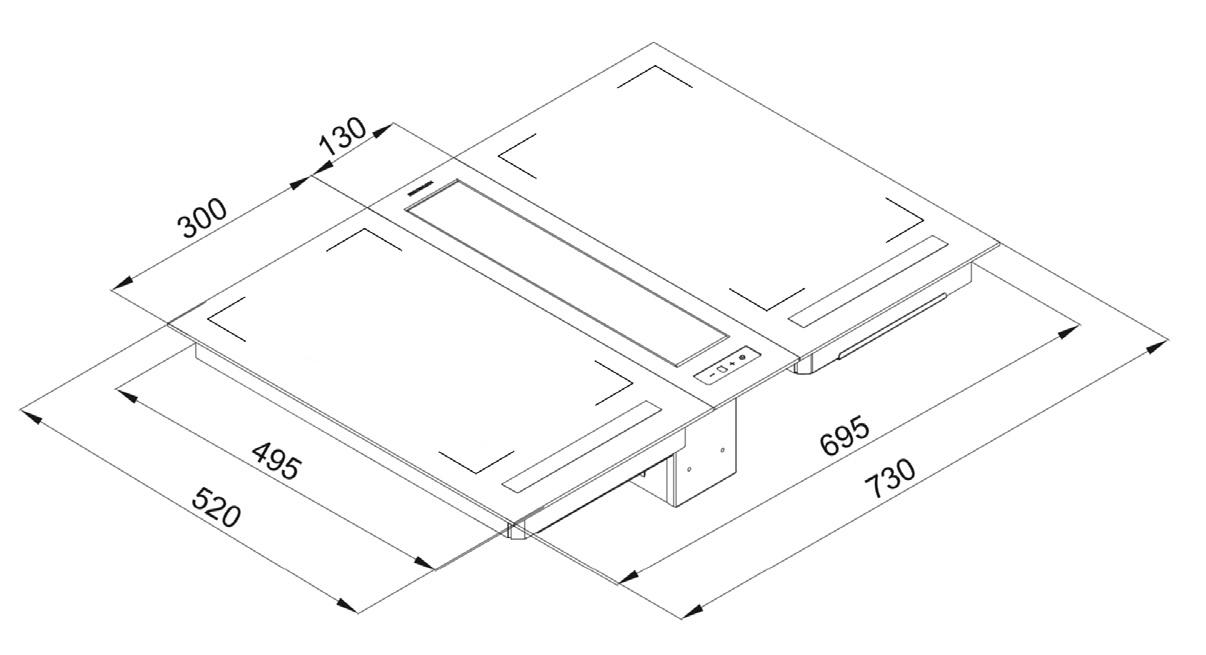

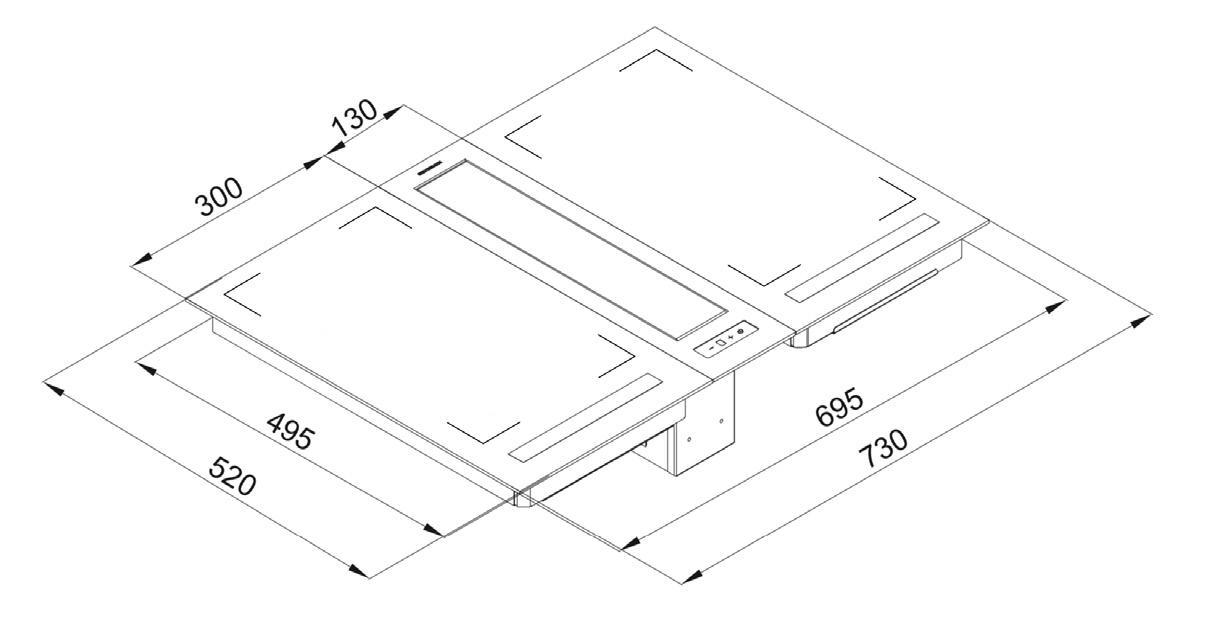

USE THIS ENTIRE SIDE AS ONE LARGE COOKING ZONE OR SEPARATELY FOR MULTIPLE POTS! FLOW-TECHNIQUE Planning and MountingFLOW-TECHNIQUE Planning and MountingFLOW-TECHNIQUE Planning and Mounting CENTRE EXTRACTION PIECE COMES IN EITHER STAINLESS OR BLACK* Cutting size of the countertop: 750 x 490 mm Diagrams of the sides Cutting size of the countertop: 750 x 490 mm Diagrams of the sides Diagrams of the sidesFLOW-TECHNIQUE Planning and Mounting

Black tempered glass cooktop Four speed Four zones Surface induction Touchscreen Timer function for all elements Cleaning indicator Stainless steel filters Can be recirculated* Integrated flow-in extraction Can be flush mounted

Cutting size of the countertop: 750 x 490 mmDiagrams of the sides

3413.4.742.01

The rotation of the exhaust air box Cutting size of the countertop: 750 x 490 mm helps in guiding the air exhaust connection towards The rotation of the exhaust air the left or the right. box helps in guiding the air The rotation of the exhaust air box exhaust connection towards helps in guiding the air exhaust connection towards the left or the right.The rotation of the exhaust air box the left or the right. helps in guiding the air exhaust connection towards the left or the right. Thanks to the air filter, the purified air is redirected into The rotation of the exhaust air box the kitchen, hence eliminating the risk of moisture in helps in guiding the air exhaust connection towards the cabinet or in the base, or damages and mould.Thanks to the air filter, the purified air is redirected into the left or the right. Optional accessories the kitchen, hence eliminating the risk of moisture in (Only in Air circulation mode • Easy-clean induction cooktop Device for launching air circulation to be mounted at the base (Average height: 10cm), Connection of the flat duct Connection sizes = 222x89mm Base motor (Solely for FLOW-IN Intern Premium): Connection to the motor by way of a round tube, with a diameter With the air filter, purified air is redirected into the kitchen, eliminating the risk of moisture damage and mould in the cabinet and base (Only in Air circulation mode Device for launching air circulation to be mounted at the (Average height: 10cm), Connection of the flat duct Connection sizes = 222x89mm Base motor (Solely for FLOW-IN Intern the cabinet or in the base, or damages and mould. 352 Optional accessories (Only in Air circulation mode Device for launching air circulation to be mounted at the base Thanks to the air filter, the purified air is redirected into the kitchen, hence eliminating the risk of moisture in the cabinet or in the base, or damages and mould. Optional accessories (Only in Air circulation mode Thanks to the air filter, the purified air is redirected into the kitchen, hence eliminating the risk of moisture in the cabinet or in the base, or damages and mould. • • • • • • 22Horizontal touch control, LED display Safety lock 9 power levels Bridge function for left front and rear zones 4 timers simultaneously usable Auto adapt (heating area adapts itself to the pot) of 150mm, exiting the motor with a flat duct of 222x89mm. The rotation of the motor in all directions helps in pushing out the exhaust air. The FLOW-IN cooktop can be mounted flush or laid on a stand. The following diagrams show the dimensions of the countertop: Base motor Connection to the motor by way of a round tube, with a diameter of 150mm; exiting the motor with a flat duct of 222 x 89mm. The rotation of the motor in all directions helps push out the exhaust air Premium): Connection to the motor by way of a round tube, with a diameter of 150mm, exiting the motor with a flat duct of 222x89mm. The rotation of the motor in all directions helps in pushing out the exhaust air. (Average height: 10cm), Connection of the flat duct Connection sizes = 222x89mm Base motor (Solely for FLOW-IN Intern Premium): Connection to the motor by way of a round tube, with a diameter of 150mm, exiting the motor with a flat duct of 222x89mm. The rotation of the motor in all Device for launching air circulation to be mounted at the base (Average height: 10cm), Connection of the flat duct Connection sizes = 222x89mm Base motor (Solely for FLOW-IN Intern Premium): Connection to the motor by way of a round tube, with a diameter of 150mm, exiting the motor with a flat duct of 222x89mm. • Auto-stop (in case of inadvertent start, long absence, over heating) The FLOW-IN cooktop can be mounted flush or laid on a stand. directions helps in pushing out the exhaust air. The rotation of the motor in all directions helps in pushing out the • • • • • back of cabinetA B C 3413.4.742.01 4 Residual heat indicators (2 super boosters) Front left heating zone 210 x 177mm 1400/2000W (booster) Rear left heating zone 210 x 177mm 1400W (booster) Rear right heating zone 210 x 177mm 2300/3000W (booster) Front right heating zone 210 x 177mm 1400W (booster) The following diagrams show the dimensions of the countertop: The FLOW-IN cooktop can be mounted flush or laid on a stand. The following diagrams show the dimensions of the countertop: exhaust air. The FLOW-IN cooktop can be mounted flush or laid on a stand. The following diagrams show the dimensions of the countertop: • 7100W, total power consumption

ACCESSORIES AVAILABLE:

22

Filter (one) YM974.3413.04

27

28

DUCTING CAN C 285mm 140mm CAN BE RECIRCULATED BE MODIFIED TO GET BETTER USE OF YOUR CABINETS USING NABER PRODUCTS Cooktop- accessory mounting Cooktop- accessory mounting 270mm 270mm to back of cabinet when ducted to back vent (no clearance given for duct Cooktop- flush mounting Cooktop- flush mounting WITH SPECIAL CHARCOAL FILTERS*Cooktop- accessory mountingCooktop- accessory mounting vent out back)D Cooktop- flush mounting Cooktop- flush mounting

18

Recirculating vent YM974.3413.03

27

18 *Recirculation kit must be ordered separately. Can also purchase 28 recirculating vent YM974.3413.03 (see above). To change rangehood panel to glass from stainless must also be ordered separately.

18 We recommend Naber ducting to reduce noise and increase flow

A18 B C D

3413, 3416 & 3417 DUCTING OPTIONS

Depending on cabinet and benchtop size, you CAN have cooking appliances or drawers underneath your flow in. Contact your joiner to find out how. CAN BE DUCTED LEFT OR RIGHT

Recirculated option

steam rises at one meter per second, flow-ins extract at four meters per second

Flawless integration of the induction hob and hood

CHOOSE THE RIGHT VENTILATION

The layout of your kitchen will determine whether your rangehood can be mounted on a wall, incorporated into your cabinets, suspended from the ceiling or installed into your bench top.

By that we mean that windows, ceilings, cooking on island unit or wall unit, and the position of your kitchen in relation to your home all contribute to what rangehood options you have available to you. This is where a kitchen designer’s experience is invaluable and will help with your options prior to design.

One of the main considerations is what option is more effective and less noisy. In our experience remote motor options are always the quietest because the motor is positioned somewhere other than where it is extracting, so reduces the noise of the motor. Traditionally canopy hoods have always been the noisiest because the motor is positioned at head level so will be louder. We find that a rangehood with only three speeds is generally speaking nosier as the extraction goes up in larger increments meaning it is all or nothing.

If you intend to go with a traditional canopy or island rangehood then look for something with more speed levels to combat the motor being at head height level or opt for the ones that offer remote motor options.

DUCTING

Another important consideration is the ducting of your rangehood which is unfortunately often an afterthought. Builders tend to put in flexible ducting which has a significant impact on the flow and noise of a rangehood, especially if it is more of a technical design.

We are now seeing the kitchen industry taking particular care when planning kitchens making sure to discuss ducting with the homeowner at the design stage. Not many people know that you can achieve an extra 10-15% increase in flow and decrease in noise by using the right ducting for your rangehood. There are companies out there who specialise in just the installation of rangehoods and install rigid ducting to achieve this.

EXTRACTION RATE

We have also seen consumers get smarter at interpreting what is marketing spin and specifications.

Years ago everyone just looked at extraction rates of rangehoods and compared extraction rates only. Now people are asking whether these are gross figures or net extraction figures.

Gross means what the motor is capable of extracting but not necessary what the rangehood extracts once it is installed. Whereby others market it as net rate, meaning what the rangehood can extract with the motor in it.

AIRFLOW POWER

The airflow power required normally depends on the size of kitchen and type of cooking. The correct airflow for your specific kitchen can be easily worked out. Simply multiply the volume of the kitchen by ten and you will obtain the ideal airflow for that room.

For example, for a kitchen of 3m x 4m with a height of 2.7m: (3 x 4 x 2.7) x 10 = 324. In this case, any Ikon cooker hood with airflow equal to our superior to 324 m3/h will therefore guarantee the complete and efficient ventilation of the room. For a large family, for those who love cooking as an art, or where a group of friends are gathered together in a spacious kitchen to experiment with some exotic recipes, the hood capacity should be over 500 m3/h.

Effective capture of cooking fumes also depends on the correct use of the product, where the product is mounted, what you are cooking and how and how the rangehood is ducted.

TYPES OF DUCTING – DUCTED VS. RECIRCULATED

Ducting a rangehood can be either ducted through the eaves, wall or roof. The ducted version will carry the steam, vapours and oils to the outside vent and remove them from the kitchen, whereas the recirculated version captures the air, purifies it through charcoal filters and sends it back into the kitchen environment.

Where possible we always recommend a rangehood is ducted as opposed to recirculated, however sometimes this is not possible. To duct a rangehood is always more expensive to begin with but nothing is required after the installation. However, with the recirculated versions, you do need to replace filters on a regular basis which becomes an ongoing cost and inconvenience to replace.

The ducted version must be connected to the outside through ducting that carries all the captured air from the house. This requires piping with a sufficiently large diameter at least 125mm (though 150mm is preferred). The piping must also not be too long or tortuous, otherwise the aerodynamic resistance of the passage can cause “power loss”, that is cubic metres of lost airflow.

Piping is not required for the recirculated version, since the captured air is purified through the rangehood’s active carbon filters and then returned to the kitchen environment. In this version it is extremely important to observe correct maintenance of the odour filters, and to replace them when necessary.

REMOTE MOTOR TO MINIMISE NOISE

The only way to reduce the noise on your rangehood is to have a remote motor. Some of the noise of a rangehood comes from the motor located just inside your rangehood. You will always have some noise in a rangehood, which would be the actual air movement through the vents provided to extract, but it is significantly reduced with a remote motor.

The higher the extraction, the noisier your rangehood will be unless you remove the motor from its rangehood body and place it somewhere else in the house. Note, remote motors are brand specific.