4 minute read

The Shellworks

#InventedAtImperial The Shellworks

This year’s Venture Catalyst Challenge winners, The Shellworks, have created a plastic alternative from seafood waste that breaks down in any natural environment, allowing consumers to throw away their waste worry-free.

Advertisement

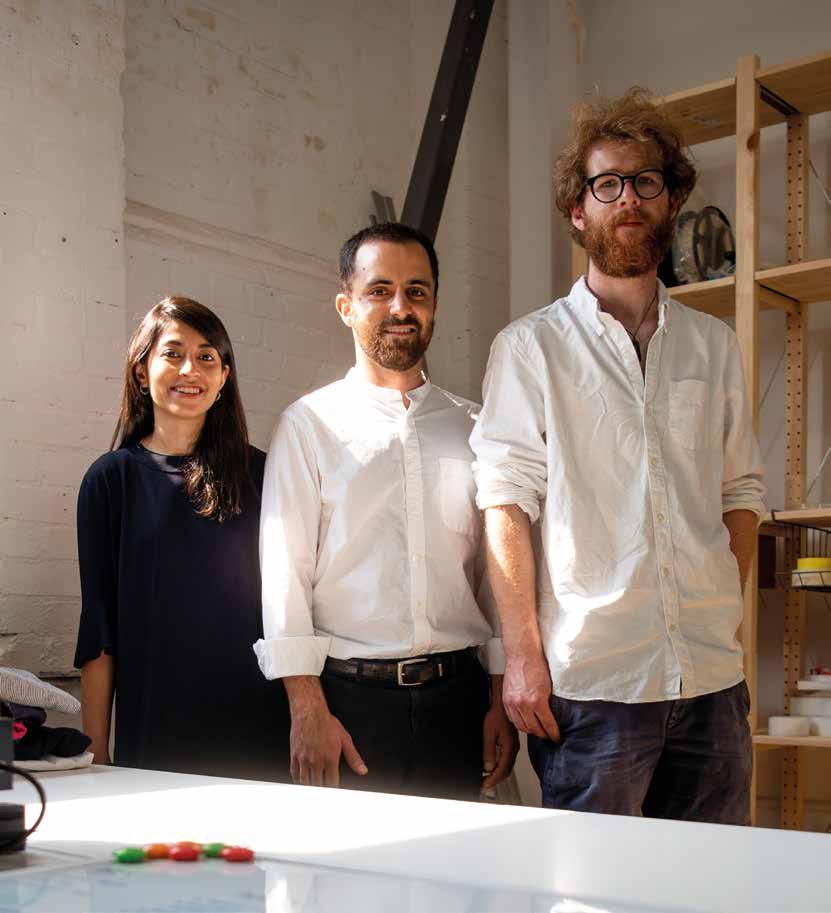

Insiya Jafferjee,

CEO (MSc Innovation Design Engineering 2019)

Amir Afshar, CPO

(MSc Innovation Design Engineering 2019)

Edward Jones, CTO

(MSc Innovation Design Engineering 2019)

The problem

The Shellworks aims to tackle two global crises, plastic pollution and shellfish waste. Plastic pollution is a growing global problem, with eight million tonnes entering our oceans annually, threatening marine life. Recently, plastic pollution has started seeping into our waterways, impacting human health as well as the health of future generations. In addition, dependence on petroleum plastics perpetuates a model built on extracting fossil fuels, which accelerates climate change. While there are some biodegradable solutions, they require specific conditions to degrade, which are often not met or require separate waste management. As a result, they cause just as much harm as traditional plastic if they enter our waste streams. Furthermore, they are derived from plants which start to compete with human food production and land resources.

Finally, up to eight million tonnes of crustacean (crabs, lobsters, crayfish etc.) waste is produced every year by the seafood-processing industries. Crustacean shell is widely cited as solely being a waste stream and must either be landfilled or returned to the ocean.

The solution

The Shellworks creates materials as alternatives to plastic, that break down in any natural environment, allowing consumers to throw away their waste worry-free. We do this by using a biopolymer found in shellfish waste. Our products have three key advantages: they are sustainable, which means they break down in marine and soil environments in a timely manner. They are truly circular, which means our product is actually made from waste and we can use resources that otherwise would end up in landfill or

How Imperial has supported the team 2019 Experts-inResidence

2019 IVMS 2019 Climate-KIC 2020 Venture Catalyst Challenge winners

Get in touch:

Website: www.

theshellworks.com

Instagram:

@theshellworks

The Shellworks creates materials as alternatives to plastic, that break down in any natural environment.

be burned. And they are cost competitive at scale, which stems from using raw materials that are essentially treated as waste resources.

Where did the idea originate?

As a team, we knew we wanted to work on a project that created a social impact. In fact, when we started, we probably investigated every single one of the world’s biggest issues, but we always seemed to gravitate back to ocean plastics. As we dove deeper into the topic, we realised we should use our strengths, which were materials and manufacturing. As a result, we began deep-diving into different material solutions, which is when we discovered Chitosan, a biopolymer that comes from shellfish waste, that can be used to make a replacement for plastics.

How did your team meet?

Our team met through the Innovation Design Engineering course, a joint Master’s between the Royal College of Art and Imperial. We identified each other in our first year as the last people in the studio, often finding ways to work on our projects even after the university was closed. For context, Amir was trying to build a chair out of slime, Ed was working on creating a beehive to help socialise bees and Insiya was working on tiny robots with feelings. It seemed like the perfect fit of people who wanted to make an environmental impact but also genuinely enjoyed making and pushing the boundaries of what was ‘seemingly’ possible.

Do you have any advisers?

We have worked to surround ourselves with mentors and advisers who fill gaps we may have personally, and also meet the startup’s needs at different stages as we evolve. We found two of our favourite mentors through IVMS, a programme provided by the Enterprise Lab, which really helped us get off the ground and build a real company.

Beyond that we’ve had a more targeted approach of looking for people who are often retired ex-CEOs of the companies we aspire to be like, who have a really deep understanding of the industry and the potential pitfalls and opportunities.

What stage is the business at and what are your plans moving forward?

We are just coming out of our first year of the journey, which was filled with a number of pivots to help identify where we should focus. We are now entering the stage of early commercialisation combined with continued R&D. We are refining our material and running early pilots, so that in a year we have a product that we can confidently scale.

What’s been your biggest success so far?

The team. Flexibility is key in a startup, and every day could be a success or failure. I think our biggest success is building a team environment where we enjoy problem solving, so it starts to feel like there aren’t any big failures, just different problems we need to overcome.

What’s been the biggest challenge?

I don’t think there has been one big challenge. I believe the challenge is actually building resilience; the ability to not see things as challenges but more as areas that we could innovate in.

What advice would you give to aspiring entrepreneurs?

Speak to customers and build what people want, not what you think people want.

Support from Imperial

Upon graduating from the Master’s programme, we were accepted into the Climate-KIC Accelerator programme, which was really helpful, not only because we received funding and mentorship, which were crucial for us to keep going, but it also introduced us to a number of other startups in the space that we could learn from.