4 minute read

Precise in the actions Tornos

PRECISE IN THE ACTIONS

With a new subsidiary in Brazil and strengthened operations at its other bases, Tornos is looking to build its business in Europe and to achieve strong growth in the BRIC countries. This, according to vice-president and head of sales and marketing Willi Nef, will come through the continued development of innovative machinery.

“There is always a big demand in new markets for our machinery and with our new equipment, particularly the MultiSwiss, we are seeing a lot of interest,” he says.

Innovative new products

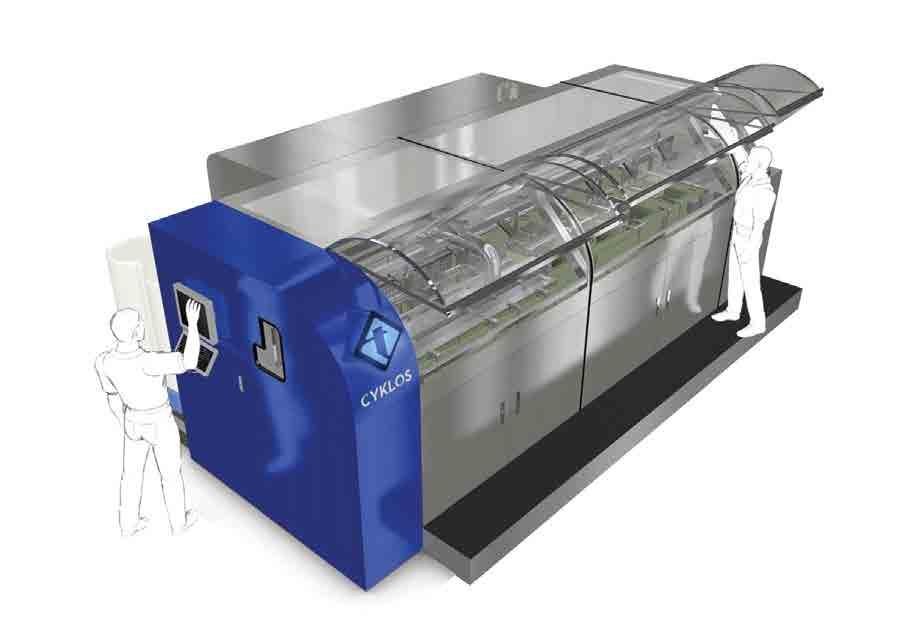

Tornos specialises in the manufacture of machines designed to produce parts requiring extreme precision and quality. The company has a worldwide sales and services network. It primarily manufactures CNC Swiss type single-spindle turning machines for parts less than 38mm in diameter, multispindle machines with numerical or cam control for parts up to 34mm in diameter and machining centres for complex parts of 1 dm3 in volume, requiring high precision. And a completely new field covered by Tornos is the surface treatment machine called Cyklos.

At the Hanover Fair in September 2011, Tornos launched a range of new products. The Moutier-based company chose it as the arena to unveil no fewer than five world premieres, along with two new completely revolutionary product ranges – the MultiSwiss 6x14 and the Cyklos lines.

“The MultiSwiss is a very compact, high production machine for small parts,” explains Mr Nef. “There has been a very, very high level of interest in these unique machines and so we expect strong demand.”

The MultiSwiss 6x14 machine provides a link between multi-spindle turning machines and swiss type single spindle machines. Based on the ‘fully integrated’ concept and featuring innovative front access, this new machine is designed with three types of customer in mind: users of numerical multi-spindle turning machines; users of cam-operated machines and users of single-spindle turning machines.

User-friendly

The numerically-controlled machine features new technologies and contains all the peripherals required for optimal operation, at a lower price than any other CNC multi-spindle machine. It takes its name from the maximum bar passage diameter (14mm) multiplied by the number of spindles.

The user-friendly MultiSwiss has been designed to offer maximum user comfort and is the first frontal machine available on the market in this size. It is also the first machine not to use Hirth gearing to lock the barrel. This classic system, well-known to Tornos, has been successfully replaced with a torque motor.

The quill type spindles are equipped with a hydrostatic bearing to guarantee excellent damping. In addition, the MultiSwiss

6x14 is the first multi-spindle turning machine on the market to offer an integrated peripheral concept.

Surface treatment

Cyklos will be the first of a new kind of surface treatment machine. It is the first surface treatment machine that can be installed in a standard machine shop avoiding transport cost and logistic difficulties. No waste nor vapour will be outside the machine – all is collected for maximum environmental friendliness.

Unlike a traditional process, which works using vertical immersion, the Cyklos works by rotating, thus guaranteeing superior quality.

It was presented alongside the MultiSigma 8x28 Chucker machine. This machining solution allows Tornos to establish itself as a supplier of genuine solutions. The new concept allows its customers to make serious steps forward in how they organise the treatment of their large-volume parts. With Cyklos and MultiSigma, Tornos offers a real lean manufacturing solution.

Extensive range

Tornos showed at EMO 2011 the first time the Delta 38/5 machine – its passport to the world of large diameters. This turning machine offers great rigidity and high power as well as specific G900-type programming help macros. Now Tornos has the most extensive range of products in the world when it comes to swiss type automatic turning machines.

Also presented was the Almac CU1007 machining centre. With its de-greasing and cleaning cell, this enables parts to be fully machined, which means front and rear faces are machined on a single machine. The robot at the centre of the assembly enables the part to be loaded and transferred between machines, and also manages the palletisation and cleaning of the part. The machining centre will be used to produce a brand new medical part.

“All these machines are about improving efficiency and production levels for our customers,” says Mr Nef. “The MultiSwiss in particular is ideal for many companies as it is easy to access for set-up and because of its modularity allows quick changeover.” n