5 minute read

Creative engagement Stadco

CREATIVE ENGAGEMENT

Stadco is a global tier-one supplier of ‘body-in-white’ pressings and assemblies. The company’s German operation is unique in that it is engaged exclusively by Ford of Europe to provide just-in-time assemblies in sync with Ford’s own production lines. Philip Yorke spoke to the company’s managing director, Reinhard Rupprecht, about its unique relationship with Ford and remarkable new ‘organic-based’ composites that could change the way modern vehicles are manufactured.

Stadco is well known globally as a leading tier-one ‘body-in-white’ (BIW) supplier to the world’s biggest automotive OEMs. The company’s core competences include the design, production and supply of steel and aluminium stampings and the manufacture of body structures of entire BIW assemblies. This is in addition to providing a wide range of products and a broad design service facility. The company is uniquely flexible and is able to offer customers an infinite variety of all-in-one solutions that range from low-volume niche to high volume production requirements.

Today Stadco offers comprehensive solutions that include product development, prototyping, design and development and specific services involving research and design. In addition the company manufactures complex stampings and provides engineering, tool procurement and the construction of complete manufacturing facilities. Stadco’s capabilities do not end with the automotive industry but are also valued by other manufacturing sectors such as the commercial vehicle market and the aerospace industries.

Synchronised success

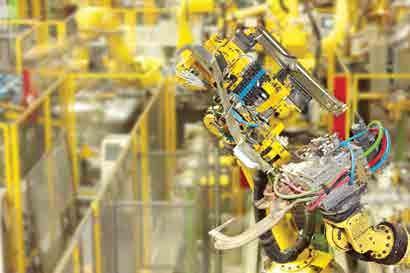

Stadco Saarlouis in Germany is where high-performance engineering and service excellence meet. Thanks to its unique inhouse expertise the company has entered an agreement with Ford of Europe to offer step-by-step productivity, which is dovetailed to fit perfectly with Ford’s own production line activities. With its high-performance capabilities and contribution from 330 fully automatic robotic systems, the result is perfect production harmony between supplier and customer.

As a system supplier of BIW components to Ford of Europe since 1998, Stadco Saarlouis has become an integral part of the Ford Industrial Supplier Park. Super-efficient production processes, state-of-the-art manufacturing facilities and over 300 highly qualified and dedicated staff, ensure that the company’s BIW assemblies are supplied at the right time, in the right quantity and in the right quality. Stadco not only supplies components ‘just-in-time’ (JIT) but also ‘just-insequence’ (JIS) according to the customer’s specific requirements.

Mr Rupprecht said, “Our exclusive manufacturing arrangement with Ford is a unique business model that provides complex body-in-white parts in perfect synchronisation with Ford’s assembly plant, which is located close to our main facility in Germany. However, we are not restricted to supply only Ford of Europe as at another plant nearby we are developing lightweight engineering products that may revolutionise passenger car manufacturing in the future. We will be able to share this revolutionary technology not only with Ford but with other major OEMs such as Jaguar Land Rover in the UK and GM, VW etc in Europe.

Mr Rupprecht added, “This research pushes the boundaries of bionic design engineering, which we started in association with the Alfred Wegener Institute for Marine Research in Germany. The research involves the exploitation of micro-organisms like ‘Diatoms’ or ‘deep-sea sponges’ which have unique properties combining exceptional strength with highly resistant lightweight properties. These structures can be used for strengthening body pillars, for example as glass fibre inlays. In addition, the new composite can be used for modern bumperbeam systems. This innovative concept is typical of our ability to think ‘outside the box’ and we launched the concept recently at the Frankfurt Motor Show, which generated much interest.

“As a company we are committed to lowering costs and to offering optimal efficiency to our clients. This means having the capability to provide manufacturing facilities that are not only more innovative and flexible, but that can also offer significant savings compared to the in-house production facilities of the same items. This commitment to product excellence and cost-effectiveness keeps us at the forefront of our industry”.

Fast-change flexibility

Stadco has developed its own quick-change production cells which enable the manufacture of components for different car types in cycle times that are tuned to the second. This exceptional efficiency requires a wide variety of special handling devices and equipment, as well as tools, weld guns and grippers which are individually designed, installed and operated for each special application.

Advanced industrial robots with load capacities ranging from 20 to 400kg are utilised for handling and welding operations. The fine-tuned coordinated interaction of all the facilities involved, and the close proximity to customers, means that a maximum level of process reliability, equipment availability and productivity is achieved.

Increasing global presence

Whilst Stadco Saarlouis continues to set the best example for optimal client cooperation and fulfilment, it is also leading the field in the development of innovative, sustainable lightweight materials. This not only enhances its position globally but also provides a unique product pipeline as the company continues to extend its global reach. Stadco has a major presence in the UK and it also established a technical centre in India in 2008 in order to support both its international OEMs as well as the domestic Indian automotive manufacturers.

Today the company’s Indian presence is extensive and offers a wide variety of technical services as well as BIW prototype facilities. Furthermore, it provides Asian OEMs with the possibility of complete body structures and assemblies for both passenger car and commercial vehicles. In order to stay close to its global customers, Stadco continues to establish press shops and BIW assembly facilities around the world for its leading OEMs, which include Ford, GM and Jaguar Land Rover. n

For further details of Stadco’s innovative products and services visit: www.stadco.de