5 minute read

Transforming perceptions of power generation in Europe Electroputere

TRANSFORMING

PERCEPTIONS OF POWER GENERATION IN EUROPE

Today Electroputere is one of Europe’s foremost engineering companies and is focused on the design and manufacture of transformers and electric motors. Philip Yorke talked to Anders Lundgren, the company’s CEO about its recent restructuring programme and dynamic growth outside its traditional markets.

Electroputere was founded in 1949 in Craiova, Romania, and today it is one of the largest industrial companies in the region. When it was run as a state-owned company, the company’s huge facility covered 50 hectares and produced diesel and electric locomotives, as well as urban vehicles and railway rolling stock. Since it was privatised in 2007 Electroputere has gone through a series of major structural changes and the company’s workforce has been reduced from 2500 to around 700 people today. A Saudi investment company now owns 80 per cent of the shares and the balance is traded on the Romanian stock exchange.

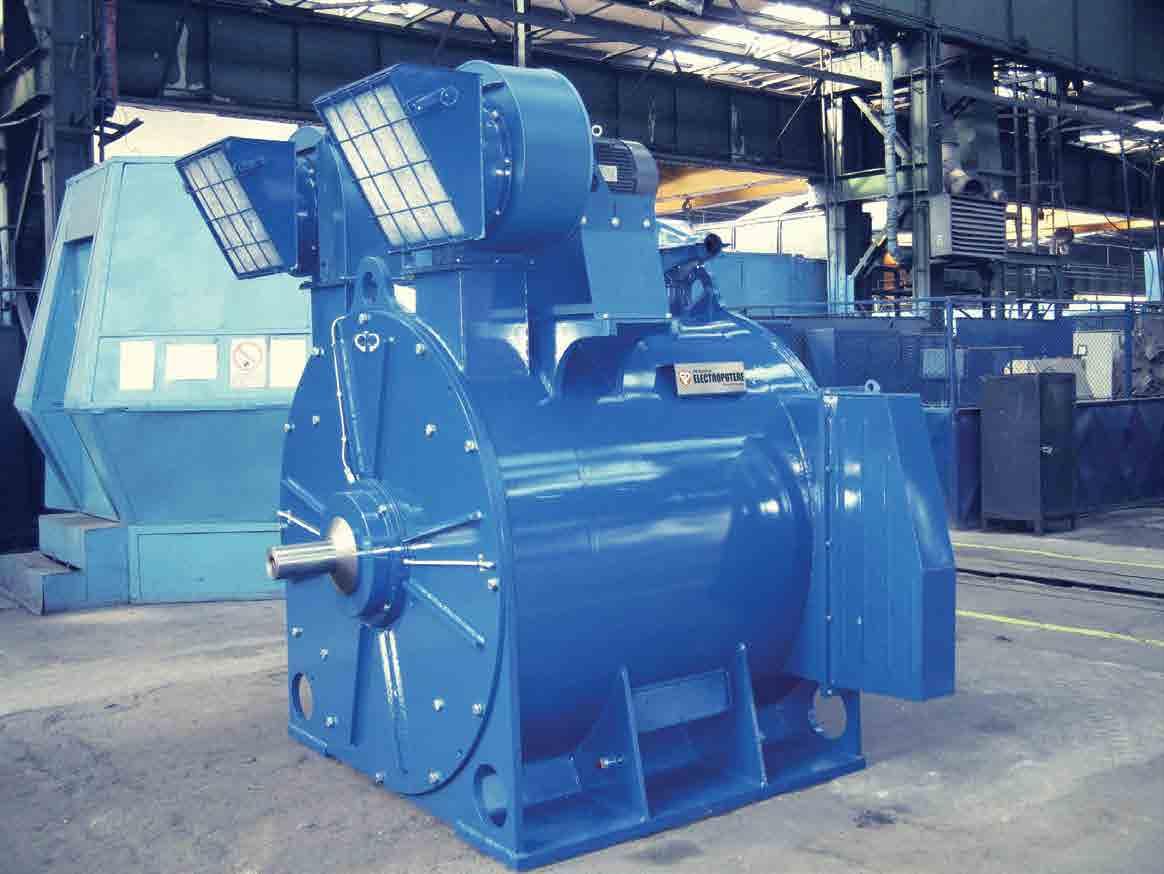

Since privatisation, the much leaner and state-of-the-art equipped company has specialised in the design and manufacture of tailor-made power transformers and electric motors. In addition, the company’s traditional markets have now been supplemented by overseas markets such as the UAE, the Middle East countries and North Africa.

Investment and restructuring

The company’s remarkable turnaround since privatisation in 2007, has propelled it from being perceived as a middle-of-the-road multifaceted engineering company to one that not only competes favourably with the best in Europe but has a highly focused product portfolio. In addition, with its low labour costs and its investment in new technology and manufacturing plant, Electroputere is also able to provide some of the most competitive rates in the business.

Mr Lundgren said, “Since our latest restructuring programme and investment in new technology, we are able to move forward in two key areas of activity. The first is power transformers where we have many decades of expertise, and the second is customer-designed electric motors. All other products have been deleted from our portfolio, the most recent being the rolling-stock business unit which was sold just two months ago. Although we still own a considerable amount of land at the original site, we are slowly selling this off and today our production is focussed on a facility extending to over 40,000m2 for our transformer business and more than 30,000m2 for our electric motor manufacturing.

“Traditionally our main markets have been Romania and Greece, however, since privatisation we have been able to expand our market reach to countries such as Saudi Arabia, Iraq, and more recently to Algeria. We have employed a local sales specialist in Saudi and another to cover North Africa. We are also focusing our marketing efforts on the Gulf countries and in particular the UAE. In northern Europe we also see opportunities for growth in countries such as Germany and the Netherlands where we have been successful with our initial contacts with wholesalers there.”

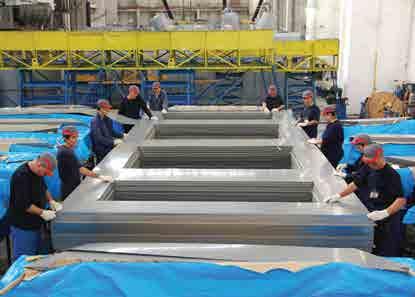

Mr Lundgren added, “If you look at the transformer market for products up to 100MVA then we are able to respond to this market very quickly; however to go beyond this you need to have products running for a year or more in advance. As the transformer manufacturing process is very labour intensive – in fact you could say that it is almost a hand-built product – the most important element is the winding process. From this you can understand that in tandem with our ongoing investments in technology, we are in a very strong position to offer the most competitive prices.

“Transformers currently represent over 70 per cent of our turnover and our average contract in Saudi Arabia is around €500,000 per item, which equates to approximately

€1.5 million per order. This contrasts with our motor contracts, which average somewhere in the region of €300,000 each. This year we produced over 3000MVA and next year project to generate more than 6,000MVA.

“When it comes to motors we are offering a diverse range of products. For example, currently we are producing motors for offshore dredgers and special application motors for items such as conveyer belts and explosionproof motors of up to 7.2MW. We are also looking at other special applications including micro-hydroelectric motors for power plants and smaller generators for other specialised niche markets. We see some big growth opportunities in this area and consider our main USPs as being our low labour costs and highly skilled workforce, short delivery times and a flexible approach to business. In addition we are able to offer short lead times and have the capacity and technology to ensure highquality, reliability and on-time delivery.

“Of course, as with all our competitors, it is not possible to deliver such very large units in a fully assembled state for logistical reasons. However, we are able to dismantle and then transport them, reassemble the units and then fully install them prior to commissioning.

“Some of our customers are the biggest names in the business and so are many of our top suppliers, which include ABB Components and Nynas AB of Sweden, Alstom Grid SpA and Copper Field of Italy, Laromet Metal SA and Erdemir Srl of Romania and Maschinenfabrik Reinhausen GmbH of Germany. High-quality suppliers further enhance our commitment to both quality, reliability and customer service and I am pleased to say that we have a very positive outlook for our order books in the years ahead.”

Quality assured

At Electroputere, quality control is executed at every stage of production and all routine tests are performed in the company’s own laboratories. Type tests and special tests are performed in the ICMET laboratory which is an independent facility and certified by DATECH of Germany and RENAR of Romania. The company can also offer a wide range of transportation services via rail, road and sea, or any combination of all three. The company’s logistics systems can provide all appropriate means of transportation as well as tailor-made packaging for the goods that are to be delivered.

Electroputere also uses the latest technologies and solutions for its transformer windings, depending upon the nominal voltage and current. The design of the transformer windings is dependent on their ability to withstand electrodynamic stress, as well as on an efficient circulation of cooling liquid.

By using specialised software, the company is able to check, as early as at the design stage, the stress produced by the electrodynamic forces and the distribution of the impulse waves along the winding. In order to optimise the winding space, the winding principles and conductor types are carefully selected for each and every individual requirement. n

For further details of Electroputere transformers and motor products visit: www.electroputere.ro