5 minute read

European leader in lathe machinery FAT

EUROPEAN LEADER IN LATHE MACHINERY

Fabryka Automatów Tokarskich SA (FAT) is part of the Belgian HACO Group. FAT HACO, operating from Wrocław in Poland, is Europe’s leading manufacturer of conventional and CNC lathe machinery. The powerful FAT lathes are used throughout the world, particularly amongst clients in western Europe, North America, as well as South Africa, the Far East, Australia and Oceania. With over 60 years of experience in lathe construction, FAT delivers top performance lathes at competitive prices. Piotr Sadowski writes for ‘Industry Europe’.

When FAT HACO last featured in an article published in this magazine a few years ago the company had a number of major projects to complete, involving the production of very heavy lathes, with high turning diameters and turning torques. “We have successfully completed these projects,” says Ireneusz Ostrowski at FAT HACO. “The TUR 4MN machines are now in operation at ThyssenKrupp in Germany and are generating contracts for new machines of this type.

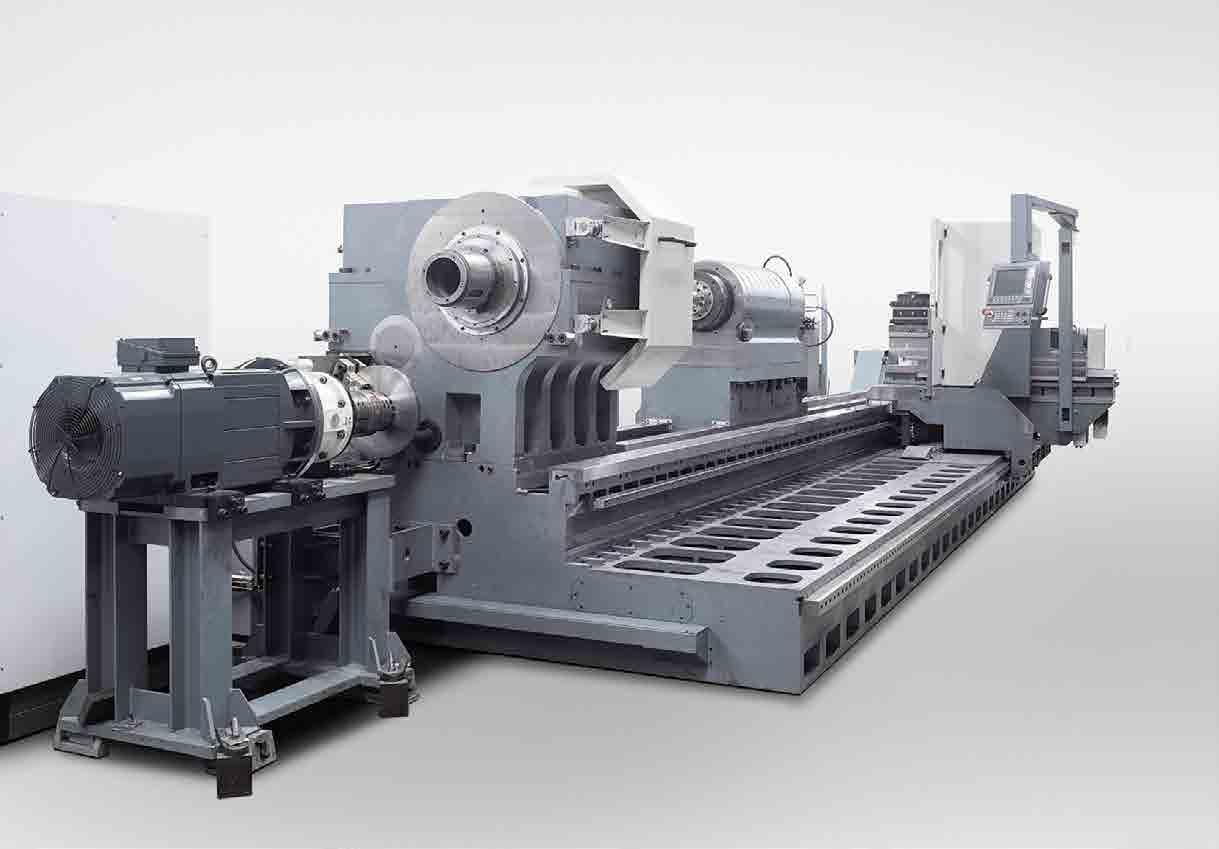

Moreover, we held Open Days in 2013 during which we exhibited our largest ever machine, the TUR lathe compound with two independent machine beds, turning diameter of three metres and a 22-metre distance between centres. The machine was produced for our American customer Ellwood City Forge. It is currently being assembled by our specialist team of engineers.”

The TUR 4MN machine is a manual/CNC combination high precision, heavy-duty lathe equipped with the latest Siemens SINUMERIK 840 D SL control system and AC drives. It functions as a production unit for manufacturing high precision complicated parts made as one-offs or in small and large batches, and has unlimited applications. To ensure very high torque at low speeds, the machine is equipped with a gearbox which is automatically programmable as standard. To achieve higher productivity, more flexibility and to reduce non-cutting time, the machine can be equipped with special tooling systems.

FAT HACO has also manufactured, as planned and on the basis of previous contracts (as in the case of ThyssenKrupp), new heavy-duty lathes capable of processing workpieces of up to 30 tonnes in weight. The company has also modernised the FCT 700 slant bed lathe into a fast, precise and highly productive turn-mill centre for the machining of complicated large and small parts. The machine has been re-designed and the bed extended up to 4.100mm in length between centres. Several models of this lathe have already been sold. “FCT 700 is a turning centre providing a significant increase in productivity and results in increased profitability,” says Mr Ostrowski. “The 70 degree inclined bed ensures optimum chip removal, easy setting and inspection of the tools, and optimal access to the workpiece for the operator. The lathe is equipped, as standard, with a 12-station bi-directional tool turret for static VDI 50 tooling. It can be optionally equipped with a tool turret for driven tools which, in combination with the continuous C-axis, enables complicated milling, drilling and tapping operations.”

Continuously strengthening market position

FAT HACO does not have any competitors in Poland so its main challengers come from Europe – countries such as Spain, Italy, Germany and the Czech Republic. Nevertheless, the company is able to improve and strengthen its position on the global market with machines manufactured strictly to customers’ needs. FAT HACO produces around 200 machines every year, with an increasing share of large, heavyweight units. “The trend in the market is that customers are looking for solutions which will replace several machines, lower costs and boost productivity,” explains Mr Ostrowski. “We are able to produce such solutions, which become in effect dedicated processing machines of the highest quality and reliability. The key to

flexibility and reliability also lies in the fact that FAT produces almost 80 per cent of all components itself or within the HACO Group and thus has an excellent check on the quality of materials.”

The company regularly exhibits its excellent products at the largest trade fairs both in Poland and abroad, where its dedicated dealers promote the company through their comprehensive knowledge of the applicability and suitability of FAT lathes for potential customers’ various needs. A big focus has also been put on promotion through the Internet with the corporate website becoming much more integrated with the websites of individual dealers across the world. “We manage to attract a wide range of customers, who include owners of small workshops as well as the largest players in power hydraulics, ship and aircraft building, steel and foundry industries,” says Mr Ostrowski. “We also produce machines for clients in the plastics and paper industries, agriculture and increasingly in the oil and gas sector. The company sells 30 per cent of its products in Poland and 70 per cent across export markets: the whole of western Europe, USA, Canada, South Africa, Australia and New Zealand, amongst other countries.”

Excellent prospects for the future

FAT also invests in its own technology and always ensures that it sources the components that it requires only from the most reliable producers. Most of the company’s suppliers are globally-renowned manufacturers with whom it has cooperated for many years. FAT is also one of the most robust and independent companies in the HACO Group, and the only one which produces lathes. “However, in addition to lathes, we also produce other special machines which are, in some way, linked to turning and milling technology,” concludes Mr Ostrowski. “One recent very special device developed for a client in Russia was a complete production line for the grinding of welds on large gas pipe ends. Our latest project is a special, large peeling machine for aluminium shafts. We are currently building this lathe for a customer in China.” n