5 minute read

mixing masterclass HF Group

MIxING MaSTERCLaSS

The HF Group is a broad industrial conglomerate that provides products and services to the global tyre, technical rubber goods, oil seed processing and food industries. The company’s key business units cover extrusion technology, tyre building machines and curing presses. Philip Yorke reports.

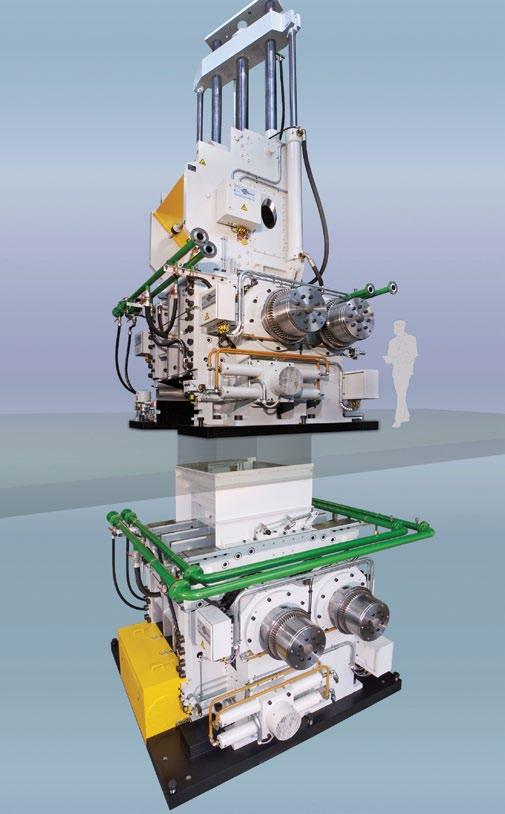

Harburg-Freudenberger Maschinenbau GmbH was founded in Hamburg, Germany in 1855 and has been delivering cutting edge engineering solutions to major manufacturing industries ever since. The HF Group is one of ten divisions belonging to the German-owned holding company L.Possehl & Co. Under the umbrella of the HF Mixing Group, the HF Tyre-Tech Group is focused on providing industrial scale equipment for rubber mixing, which is predominantly internal mixers, single screw and twin screw dump extruders, mixing room control systems and auxiliary equipment such as strip-cutting machines and bale cutters.

The HF Group’s machines also create compounds for a vast number of specialised products for the automotive industry, such as special seals and brake pads and for the building and appliances industries, where it produces items such as rubber seals for windows and washing machines. The mixers are available in a wide range of sizes, from 0.3 litres to 1000 litres capacity.

Innovative biomass technology

The HF Group’s experience in developing innovative recycling techniques for the biomass sector is unrivalled and its subsidiary, HF Press+LipidTech, (HF-PLT) continues to set the standards for the industry. Today it is possible to select the best available technology to process and add value to biomass and animal fat products. This unique HF technology allows companies to produce high quality products for new applications, which in turn can open up new markets and new industries. Animal meal is one of the products used as protein-rich animal feed, nitrogen-rich fertiliser, and as an energy source in power stations and cement kilns.

The second main product is animal fat which also finds its way into animal feed, but also as a fuel, either directly as crude fat or after conversion to biodiesel. Both the meal and the fat are starting points for a large variety of final products and fuels. This demonstrates the importance of state-of-the-art recycling technologies for these raw organic products. For over 40 years, HF has been building on its experience and innovation in rendering and recycling technologies.

Today HP-PLT provides the most modern equipment, process systems and complete turnkey plants, all of which subscribe to the latest and most stringent European hygiene standards. One special key component in the entire process sequence is the HF disc dryer. It is designed for drying sterilised animal waste and can also be used to dry oilseeds, grains, distiller’s grains, and a wide variety of other industrial inorganic or organic sludge and slurries. Apart from the most advanced disc dryers, sterilisers and other process equipment, HF is also known worldwide for its market-leading Krupp-Screw Press products.

Flexible tyre building

Changes in the automotive market are posing new challenges for tyre manufacturers in their production processes. It is recognised that the variety of tyres in the automotive market is growing, especially for the larger size tyres of over 17”. These are steadily gaining an increasing share of the tyre market. The most pressing challenge today is the requirement for tyre manufacturers to enable production for quick code changes and at the same time be able to produce smaller lots cost-effectively. Quality requirements are also constantly being upgraded. These are driven by the automotive industry and not only as a result of the latest tyre labelling legislation, which has been mandatory in the EU and South Korea since 2012, but also due to the requirement to sign OE Tyre sizes visually on the sidewall. These pre-requisites will be implemented in other markets such as the US, China, Brazil and Japan in the near future.

Interestingly, HF has developed an entirely new tyre-building machine that meets these requirements by means of a flexible drum concept, which ensures the diversified production of highly complex and innova-

tive tyre designs. The company’s PL2-SD-Flex is the answer to tackling the range of challenges posed by today’s tyre market. By means of a mere tool change it is possible to build all tyre constructions currently available on the market, in either flat or high crown building processes in just one basic machine.

Tyre constructions, especially in the layer area, can be built ranging from C-envelope to ply-down tyres, thus offering decisive advantages in the sidewall area, which is the most critical part in relation to the tyre’s performance. Tyre sizes that previously required the so-called two-stage process can now be produced directly in a single stage on HF’s new PLT2-SD-Flex machine.

New energy-saving technologies

The automotive sector’s demand for more energy-saving tyres is having a significant impact on the tyre machinery sector. This trend is linked to current developments among the world’s car manufacturers, for whom energy-saving technologies are now a major focus. This takes the form of reducing the energy consumed during curing and increasing process efficiency by raising the throughput of the presses, which can often create a bottleneck in the tyre manufacturing process.

At the HF Group, one of the latest energy saving products is a quick mould change device, which significantly reduces the mould changeover times and the energy consumed. There are also other uses of HF’s technology on the horizon to increase still further the intelligence and efficiency of its curing presses.

In terms of energy saving, the company has developed many new technologies including the introduction of advanced process control systems which offer high speed open-and-close facilities in order to trap the heat. In addition, improved insulation and heat recovery options help to improve energy saving still further. n

For more details of the HF Group’s latest innovative energy saving technologies and services visit: www.hfgroup.com