5 minute read

Ultimate perfection TOS Varnsdorf

ULTIMATE PERFECTION

A combination of high performance, progressive design and reliability is the hallmark of TOS Varnsdorf, the producer of machine tools supplied to global markets. Unshaken by the pandemic, the company is expecting demand to return.

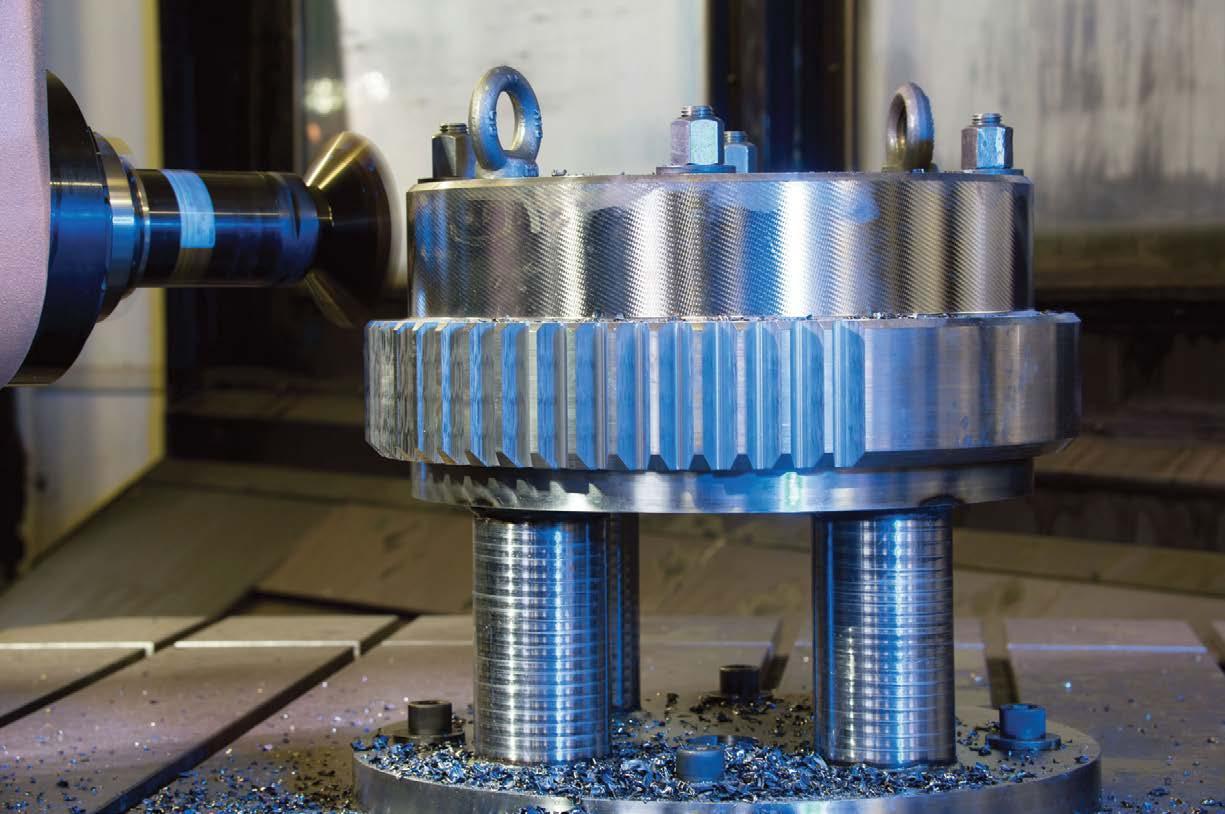

TOS Varnsdorf, located on the German border in the western part of the Czech Republic, is a world leading manufacturer of machine tools, specialising in the production of medium-class horizontal milling and boring machines and machining centres.

Founded in 1903, the company boasts an impressive manufacturing tradition. Its top-quality products reflect the know-how and experience of generations of technicians and skilled workers as well as the innovative focus of today’s companies. They are used for machining of components for the transport, mining, construction, and energy industries, as well as for general mechanical engineering.

Solid Range

The company manufacturing programme includes four groups of products: table-type machine tools for universal purposes and highperformance parts machining, large WRD-series floor-type machine tools for demanding technological operations performed on the largest workpieces, machining centres with the most progressive modern tools, and gantry-type machining centres for general highperformance, high-precision machining of steel and cast-iron parts. The company has a strong service team to carry out all warranty requirements and customer servicing.

“Our flagship continues to be the WHN (Q) 13 CNC machine - a universal horizontal milling and boring machine designed for precise milling, line-coordinate drilling, boring and thread cutting of box- and board-type workpieces as well as complicated workpieces from cast iron, steel cast iron and steel with a weight of up to 25,000 kg. The first model of the machine was produced in 1968 and so far, nearly 2,700 units have been sold to global markets. Last year the WHN (Q) 13 CNC machine accounted for 40% of all production,” says the company’s Sales Director Mr Miloš Holakovský.

He explained that TOS Varnsdorf has been gradually introducing the new dual-type WHT 110/130 onto the market – a milling and boring machine, a powerful, efficient representative of the company’s advanced generation, which responds to the needs of modern progressive technology.

“We have great ambitions for these machines and would like to see their sales gradually reach the level of the WHN (Q) 13 CNC. With this combination, we can offer our customers a classic powerful horizontal machine and a modern, fast, and highly productive machining centre. We believe that with today’s trend for using higher cutting speeds and feed rates, customers will be looking for these specific machines.”

The pandemic challenge

TOS Varnsdorf operates a network of subsidiaries in China, Russia, and the USA - the company’s key markets - that provide spare parts, warranty, and post-warranty service. “Service and spare parts availability tend to be the decisive factors for customers when choosing a new machine. The immediate availability of spare parts and the professional approach of our staff help to open doors to

RETOS VARNSDORF s.r.o

RETOS VARNSDORF s.r.o. is a traditional Czech company. We are located at the premises, where in 1915 under the name „Arno Plauert, Maschinenfabrik“ the first horizontal boring mills were produced. In 1993, RETOS VARNSDORF was founded as a remanufacturer for TOS VARNSDORF machines. Our products benefit from the experience, know-how and the network in the region. Today, we also produce and sell world-wide horizontal boring mills of our own design. We have specialised in specific boring mills including table type, floor type and T-type machines in CNC or conventional versions, among them the famous solid conventional W100A.

new customers as well as satisfy the needs of existing customers,” claims Holakovský.

“The company manufactures over a hundred machines per year and 85% of total production is exported. “Depending on its size, it takes four to eight months to manufacture a machine. This is then partially dismantled and sent to the customer, where it is subsequently installed over a period of three to eight weeks,” Holakovský adds, describing a standard contract.

“The coronavirus crisis has impacted this process significantly - due to travel restrictions, we could not visit clients, they could not come to the factory for machine handover and our fitters could not travel to site to assemble the machines.”

“And then there are the thousands of machines manufactured and supplied over the past years, which naturally require servicing from time to time. For us, the travel restrictions have presented the biggest pandemic challenge,” he admits.

The new normal

The pandemic has further accelerated the trend of digitisation, and TOS Varnsdorf is venturing into new ways of communicating with customers, devising new ways of inspecting all machines virtually, of all sizes, equipment levels and technological accessories.

The customer can thus move around a virtual manufacturing hall and see a machine from all sides and use POI (Point of Interest) buttons to get all the technical and technological information. Using mobile equipment, the machine can be positioned in the selected configuration virtually in the customer’s manufacturing hall. “We believe this will be the trend of the future – hard copy catalogues will soon be a thing of the past,” says Holakovský.

Given its proven expertise and track record, the company has weathered the impacts of the unprecedented crisis of 2020 with flying colours. Now it is to be seen what the future brings. “The market has cooled down of course, and investment has virtually ground to a halt. Last year, while demand continued, contracts were being delayed. We are hoping for a market revival in mid-2021,” he concluded. n